ARO Extrusion - Finishing Consultants

ARO Extrusion - Finishing Consultants

ARO Extrusion - Finishing Consultants

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

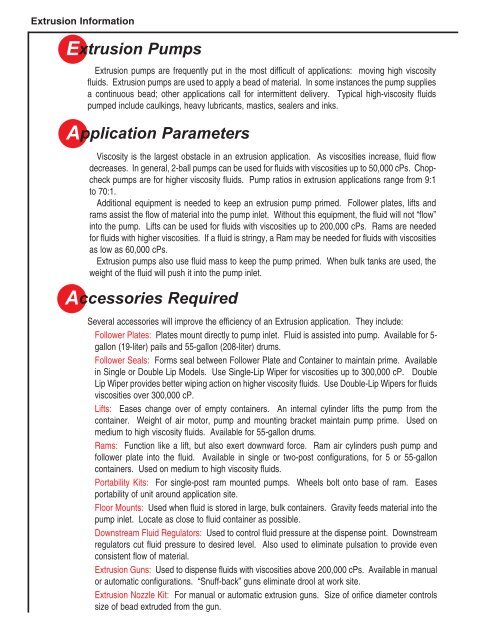

<strong>Extrusion</strong> Information<strong>Extrusion</strong> Pumps<strong>Extrusion</strong> pumps are frequently put in the most difficult of applications: moving high viscosityfluids. <strong>Extrusion</strong> pumps are used to apply a bead of material. In some instances the pump suppliesa continuous bead; other applications call for intermittent delivery. Typical high-viscosity fluidspumped include caulkings, heavy lubricants, mastics, sealers and inks.Application ParametersViscosity is the largest obstacle in an extrusion application. As viscosities increase, fluid flowdecreases. In general, 2-ball pumps can be used for fluids with viscosities up to 50,000 cPs. Chopcheckpumps are for higher viscosity fluids. Pump ratios in extrusion applications range from 9:1to 70:1.Additional equipment is needed to keep an extrusion pump primed. Follower plates, lifts andrams assist the flow of material into the pump inlet. Without this equipment, the fluid will not “flow”into the pump. Lifts can be used for fluids with viscosities up to 200,000 cPs. Rams are neededfor fluids with higher viscosities. If a fluid is stringy, a Ram may be needed for fluids with viscositiesas low as 60,000 cPs.<strong>Extrusion</strong> pumps also use fluid mass to keep the pump primed. When bulk tanks are used, theweight of the fluid will push it into the pump inlet.Accessories RequiredSeveral accessories will improve the efficiency of an <strong>Extrusion</strong> application. They include:Follower Plates: Plates mount directly to pump inlet. Fluid is assisted into pump. Available for 5-gallon (19-liter) pails and 55-gallon (208-liter) drums.Follower Seals: Forms seal between Follower Plate and Container to maintain prime. Availablein Single or Double Lip Models. Use Single-Lip Wiper for viscosities up to 300,000 cP. DoubleLip Wiper provides better wiping action on higher viscosity fluids. Use Double-Lip Wipers for fluidsviscosities over 300,000 cP.Lifts: Eases change over of empty containers. An internal cylinder lifts the pump from thecontainer. Weight of air motor, pump and mounting bracket maintain pump prime. Used onmedium to high viscosity fluids. Available for 55-gallon drums.Rams: Function like a lift, but also exert downward force. Ram air cylinders push pump andfollower plate into the fluid. Available in single or two-post configurations, for 5 or 55-galloncontainers. Used on medium to high viscosity fluids.Portability Kits: For single-post ram mounted pumps. Wheels bolt onto base of ram. Easesportability of unit around application site.Floor Mounts: Used when fluid is stored in large, bulk containers. Gravity feeds material into thepump inlet. Locate as close to fluid container as possible.Downstream Fluid Regulators: Used to control fluid pressure at the dispense point. Downstreamregulators cut fluid pressure to desired level. Also used to eliminate pulsation to provide evenconsistent flow of material.<strong>Extrusion</strong> Guns: Used to dispense fluids with viscosities above 200,000 cPs. Available in manualor automatic configurations. “Snuff-back” guns eliminate drool at work site.<strong>Extrusion</strong> Nozzle Kit: For manual or automatic extrusion guns. Size of orifice diameter controlssize of bead extruded from the gun.