FAST TRAX® - KPI-JCI

FAST TRAX® - KPI-JCI

FAST TRAX® - KPI-JCI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

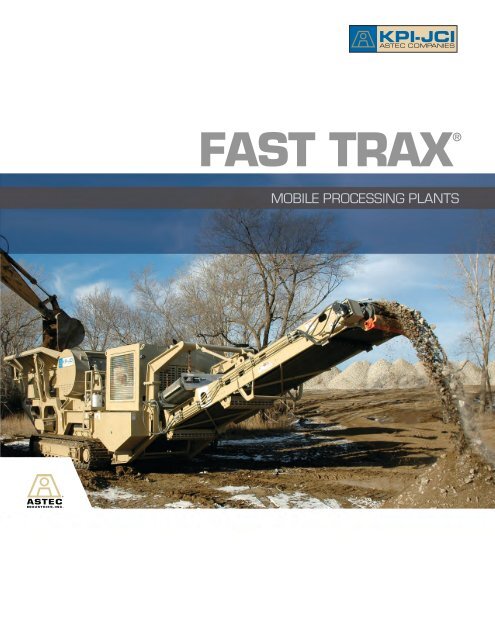

<strong>FAST</strong> TRAX®MOBILE PROCESSING PLANTS

MAKING TRAXTABLE OF CONTENTS▼ ▼ ▼ ▼JAW PLANTS . . . . . . . . . . . . . . . . . . . . . . . . . . 3IMPACT PLANTS . . . . . . . . . . . . . . . . . . . . . . . 5CONE PLANTS . . . . . . . . . . . . . . . . . . . . . . . . . 7SCREEN PLANTS . . . . . . . . . . . . . . . . . . . . . . . 9▼SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111.▼SUPPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MOBILE AND VERSATILEThe Fast Trax ® Series MobileProcessing Plants from <strong>KPI</strong>-<strong>JCI</strong> offerthe ultimate in productivity, mobility,versatility and adaptability. Withnumerous value-added standardfeatures, a hopper full ofperformance-enhancing options, andthe versatility of unit-to-unitcompatibility, you get maximumcapability with minimum effort.Representing the only line oftrack-mounted plants designed,manufactured and supported in theU.S.A., backed by authorized dealersworldwide, the <strong>KPI</strong>-<strong>JCI</strong> Fast Trax ® Plantsare truly Your One Source for bothaggregate and recycling applications.Get ready to discover how you canMake Trax on your competition withmaximum capability from the <strong>KPI</strong>-<strong>JCI</strong>Fast Trax ® Series.2.

MAXIMUM MOBILITYADJUSTABLE UNDERCRUSHER CONVEYORHIGH PRODUCTIONVANGUARD JAWCAPABILITIES▼▼▼▼LARGE FEEDER HOPPER SUPPORTSCONTINUOUS OPERATIONFINES ARE REJECTED BEFORE ENTERINGCRUSHERVANGUARD JAWS OFFER REDUCTION RATESOF 6:1 TO 8:1HEAVY DUTY TRACK DRIVE PROVIDES EXTREMEDURABILITY AND MOBILITY3.

PRODUCTION CAPACITIES UP TO 400 TPHSELF-CLEANINGMAGNET ASSEMBLYHIGH CAPACITYCONVEYORThe FT2640 and FT2650 are YourOne Source for maximum jaw crushingmobility. Featuring Vanguard SeriesJaw Crushers, the FT2650 provides afeed opening of 26” X 50”, and theFT2640 provides a 26” X 40” crusherfeed opening. Equally effective inaggregate or recycle, both plants allowstationary and portable producers tobenefit from the on-site mobility theseplants deliver. Don’t settle foroff-the-shelf configurations! Multiplefeeder sizes, hydraulic-hopperextensions, cross-belt magnetsystems and dust-suppressionsystems are just a few of the optionsavailable to customize your plant toexacting specifications. Ready to MakeTrax on the competition? Do it with<strong>KPI</strong>-<strong>JCI</strong> maximum jaw crushing mobility.FT2640FT2650Crusher (in/mm) 26 x 40 / 660 x 1012 26 x 50 / 660 x 1270Vanguard JawVanguard JawFeeder (in x ft) 40 x 14 50 x 15(mm x m) 1016 x 4267 127 x 4572Grizzly (ft/mm) 4 / 123 Straight 5 / 152 Step DeckProductionCapacity (tph/mtph) Up to 325 / 295 Up to 400 / 363Max Feed Size (in/mm) 21/ 533 21 / 533Plant Weight (lbs/kg) 89,000 / 40,370 100,760 / 45,704Engine (hp/kw) 225 / 168 260 / 1944.

MAXIMUM VERSATILITYHD VIBRATINGGRIZZLY FEEDEREASILY ACCESSIBLECRUSHING CHAMBER▼▼▼CAPABILITIESFINES ARE REJECTED BEFORE ENTERINGCRUSHERBOLT-ON LINERS AND APRON TIPSAS STANDARDANDREAS HSI PRODUCES 12:1 TO 18:1REDUCTION RATIO5.▼OVERLOAD PROTECTION SYSTEM (OPS)ENSURES EASY OPERATION AND OPTIMALPERFORMANCE

PRODUCTION CAPACITIES UP TO 400 TPHSELF-CLEANINGMAGNET ASSEMBLYSCALPING/SIZINGSCREENThe FT4240 and FT4250 are Your OneSource for maximum impact crushingversatility. Featuring Andreas SeriesImpact Crushers, the FT4250 providesa feed opening of 42” X 50”, and theFT4240 offers a 42” X 40” crusher feedopening. Both plants are equipped withour standard Overload ProtectionSystem (OPS). Delivering dramaticallysuperior performance with an easilyadjustable interface, aggregateproducers and recyclers alike will alsobenefit from the availability of an open orclosed circuit configuration, completewith a screen and recirculating conveyor.Optional under-feeder conveyor systems,cross-belt magnet systems, hydraulichopper-wall extensions, hydrostaticdrives and rotor variations allow you tocustomize your plant to exactingspecifications. Ready to Make Trax onthe competition? Do it with <strong>KPI</strong>-<strong>JCI</strong>maximum impact crushing versatility.FT4240FT4250Crusher (in/mm) 42 x 40 / 1067 x 1016 42 x 50 / 1067 x 1270AndreasAndreasFeeder (in x ft) 40 x 14 50 x 15(mm x m) 1016 x 4267 127 x 4572Grizzly (ft/m) 4 / 122 Straight 5 /152 Step DeckProductionCapacity (tph/mtph) Up to 325 / 295 Up to 400 / 363Screen (ft/m)4 x 12 / 122 x 366 2-deck 5 x 12 / 152 X 366 1-deck(mm x m) 1219 x 3658 1524 x 3658Plant OC 80,000 / 36,287 OC 102,500 / 46,493Weight (lbs/kg) CC 92,500 / 41,957 CC 117,500 / 53,297Engine HP (hp/kw) 340 / 253 400 / 2986.

MAXIMUM PRODUCTIVITYOPTIONAL BAGHOUSE SYSTEMHANDHELDREMOTE CONTROLSCAPABILITIES▼▼▼▼KODIAK ® CONES OFFER HIGH REDUCTION RATESAND MATERIAL CUBICITYMEETS COARSE AND FINE CRUSHINGAPPLICATION NEEDSPROVIDES MORE FIRST PASS SPEC MATERIAL,REDUCING RECIRCULATING LOADSDESIGNED TO RUN IN MULTIPLE OPEN ANDCLOSE CIRCUIT CONFIGURATIONS7.

PRODUCTION CAPACITIES UP TO 460 TPHEASILYADJUSTABLE CSSADJUSTABLE HEAVY-DUTY BELT FEEDERThe FT200 and FT300 are Your OneSource for maximum cone crushingproductivity. The FT200 featuresa Kodiak ® 200 Cone Crusher whichproduces up to 400 TPH. The largerFT300 employs a Kodiak ® 300 andproduces up to 460 TPH. However,each plant delivers efficient materialsizing, making them perfect for bothmobile and stationary producers whoneed quick, effortless on-sitemovement. Don’t settle foroff-the-shelf configurations! Optionslike dust-suppression systems andvarious cone liners allow you tocustomize your plant to exactingspecifications. Ready to Make Trax onthe competition? Do it with <strong>KPI</strong>-<strong>JCI</strong>maximum cone crushing productivity.FT200FT300Crusher Kodiak 200 Cone Kodiak 300 ConeBelt Feeder (in x ft) 42 x 23 42 x 23(mm x m) 1067 x 7010 1067 x 7010ProductionCapacity (tph/mtph) Up to 400 / 363 Up to 460 / 417Max Feed Size (in/mm) 9 / 2286 11/ 2794Plant Weight (lbs/kg) 83,000 / 37,648 96,000 / 43,548Engine (hp/kw) 325 / 242 425 / 3178.

MAXIMUM ADAPTABILITYOPTIONAL BOGEYTRANSPORT SYSTEMHANDHELDREMOTE CONTROLS▼▼CAPABILITIESFINE SCREENING TO HEAVY SCALPINGCAPABILITIESHIGHER PROBABILITY OF SEPARATION▼REDUCES SCREEN BLINDING AND PLUGGING▼CAPABILITIES OF MAKING UP TO FOURDIFFERENT PRODUCTS9.

PRODUCTION CAPACITIES UP TO 800 TPHOPTIONAL GRIZZLYFEEDERHEAVY DUTYBELT FEEDERThe FT5162, FT6203 andFT6203CC are Your One Source formaximum screening adaptability andperformance. Featuring triple shaft,oval motion screens, these plants offerbetter bearing life, more aggressivescreening action for reduced pluggingand blinding, and a consistent materialtravel speed that does not acceleratethrough gravity for a higher probabilityof separation. As such, these highlyefficient plants are perfect for bothportable and stationary producerswho need quick, effortless on-sitemovement. Options like medium orheavy-duty scalping screens, apron andgrizzly feeders, auxiliary hydraulic powerfor off-plant equipment, dischargechutes, impact idler beds and variousother conveyor choices allow you tocustomize your plant to exactingspecifications. Ready to Make Trax onthe competition? Do it with <strong>KPI</strong>-<strong>JCI</strong>maximum screening adaptability.FT5162FT6203Screen (ft) 5 x 16 6 x 20(mm x m) 1524 x 4877 1829 x 60962-Deck3-DeckBeltFeeder (in/ft) 42 x 18 48 x 18(mm x m) 1067 x 5486 1219 x 5486ProductionCapacity (tph/mtph) Up to 500 / 454 Up to 800 / 726Plant Weight (lbs/kg) OC 56,470 / 25,470 OC 83,000 / 37,648CC 72,000 / 32,659Engine (hp/kw) 173 / 129 173 / 12910.

MAXIMUM COMPATIBILITY11.▼▼CAPABILITIESSINGLE STAGE REDUCTION SYSTEMSJAW + SCREENHSI + SCREENMULTIPLE STAGE REDUCTION SYSTEMSJAW + IMPACTOR + SCREENJAW + CONE + SCREENIMPACTOR + CONE + SCREENJAW + IMPACTOR + CONE + SCREEN(S)JAW + CONE + CONE + SCREEN(S)IMPACTORS + CONES + SCREEN(S)

HIGHLY PRODUCTIVE AND COMPATIBLEThe Fast Trax ® System is Your OneSource for the ultimate in productivity,mobility, versatility and adaptability.Leading us to the most important thing:maximum capability. Every plant isdesigned to function in variousmulti-stage processing systems.Additionally, every plant is designed tofunction seamlessly with <strong>KPI</strong>-<strong>JCI</strong> StackingConveyors, multiplying our capabilities inboth mobile and stationary aggregateand recycling applications. Beginproduction within minutes of arrival andeasily process material on the move. Runany plant as an individual performer or tiethem together for one workhorse of aproduction system. The options—andbenefits, are all yours. Ready to MakeTrax on the competition?Put your entire business on the Fast Traxwith <strong>KPI</strong>-<strong>JCI</strong> maximum performancesystem capability.12.

MAKING TRAX▼CAPABILITIESLOCAL SERVICE SUPPORT 24/7▼LOCAL APPLICATION SUPPORT 24/7▼LOCAL OFF-THE-SHELF PARTS SUPPORT 24/713.▼LOCAL EQUIPMENT INVENTORIES FORRENT AND PURCHASE

LOCAL, AVAILABLE, KNOWLEDGEABLEThe Fast Trax ® series is supportedby Your local One Source <strong>KPI</strong>-<strong>JCI</strong> FastTrax ® Dealer. Equipped withfactory-trained technicians,aggregate specialists andoff-the-shelf parts support, your localdealer is prepared to help youmaximize your capability. Make Trax onincreased uptime and decreasedcosts—contact your local<strong>KPI</strong>-<strong>JCI</strong> dealer today, or visit:www.kpijci.com to find the dealernearest you!14.

NOTE: SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE Rev. 2 12/6/07Because KOLBERG-PIONEER, INC., and <strong>JCI</strong> may use in its catalog & literature, field photographs of its products which may have been modified by the owners, products furnished byKOLBERG-PIONEER, INC., and <strong>JCI</strong> may not necessarily be as illustrated therein. Also continuous design progress makes it necessary that specifications be subject to change withoutnotice. All sales of the products of KOLBERG-PIONEER, INC., and <strong>JCI</strong> are subject to the provisions of its standard warranty. KOLBERG-PIONEER, INC., and <strong>JCI</strong> does not warrant orrepresent that its products meet any federal, state, or local statutes, codes, ordinances, rules, standards or other regulations, including OSHA and MSHA, covering safety pollution,electrical, wiring, etc. Compliance with these statutes and regulations is the responsibility of the user and will be dependent upon the area and the use to which the product is put bythe user. In some photographs, guards may have been removed for illustrative purposes only. This equipment should not be operated without all guards attached in their normal position.Placement of guards and other safety equipment is often dependent upon the area and the use to which the product is put. A safety study should be made by the user of the application,and, if required, additional guards, warning signs and other safety devices should be installed by the user, wherever appropriate before operating the products.