Milling wheat – quality criteria and tests - HGCA

Milling wheat – quality criteria and tests - HGCA

Milling wheat – quality criteria and tests - HGCA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

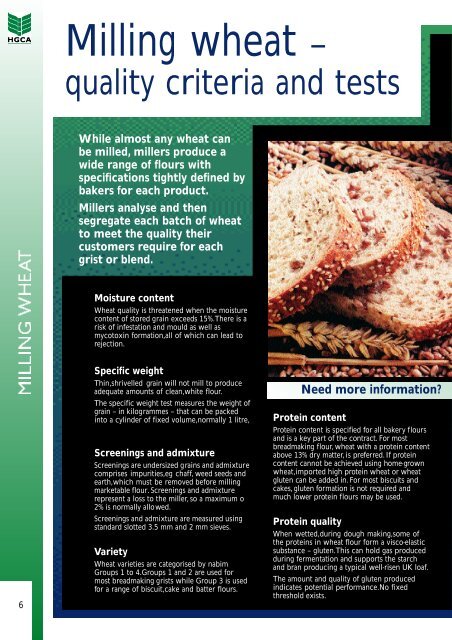

<strong>Milling</strong> <strong>wheat</strong> <strong>–</strong><strong>quality</strong> <strong>criteria</strong> <strong>and</strong> <strong>tests</strong>While almost any <strong>wheat</strong> canbe milled, millers produce awide range of flours withspecifications tightly defined bybakers for each product.Millers analyse <strong>and</strong> thensegregate each batch of <strong>wheat</strong>to meet the <strong>quality</strong> theircustomers require for eachgrist or blend.Moisture contentWheat <strong>quality</strong> is threatened when the moisturecontent of stored g r ain exceeds 15%.There is ar isk of infestation <strong>and</strong> mould as well asmycotoxin formation,all of which can lead torejection.6Specific weightThin,shrivelled grain will not mill to produceadequate amounts of clean,white flour.The specific weight test measures the weight ofgrain <strong>–</strong> in kilog rammes <strong>–</strong> that can be packedinto a cylinder of fixed volume,normally 1 litre,<strong>and</strong> indicates g rain filling.Screenings <strong>and</strong> admixtureScreenings are undersized g rains <strong>and</strong> admixtur ecomprises impurities,eg chaf f, weed seeds <strong>and</strong>earth,which must be removed before millingmarketable flour. Screenings <strong>and</strong> admixtur erepresent a loss to the miller, so a maximum of2% is normally allo wed.Screenings <strong>and</strong> admixture are measured usingst<strong>and</strong>ard slotted 3.5 mm <strong>and</strong> 2 mm sieves.VarietyWheat varieties are categorised by nabimGroups 1 to 4.Groups 1 <strong>and</strong> 2 are used formost breadmaking g rists while Group 3 is usedfor a range of biscuit,cake <strong>and</strong> batter flours.Need more information?Protein contentP rotein content is specified for all bake r y f l o u r s<strong>and</strong> is a key par t of t he contra c t . For mo stb re admaking f l o u r, <strong>wheat</strong> wi th a prot ein c ont en tab ove 13% dr y matter, i s pre fe r re d . I f pro t e i nc ont ent cannot be ach i e ved using home- grow nw h e a t ,i m p o rted high protein whea t or whea tglute n can be a dded in. For most bis cuits an dc a ke s , gluten fo r mation is not re q u i red <strong>and</strong>mu ch lower protein f l o u rs may be used .Protein <strong>quality</strong>When wetted,during dough making,some ofthe proteins in <strong>wheat</strong> flour form a visco-elasticsubstance <strong>–</strong> gluten.This can hold gas producedduring fermentation <strong>and</strong> supports the starch<strong>and</strong> bran producing a typical well-risen UK loaf.The amount <strong>and</strong> <strong>quality</strong> of gluten producedindicates potential performance.No fixedthreshold exists.

Important parametersCharacteristic Farmer test Intake test Buyer responseMoisture content yes yes price deduction or rejectionSpecific weight yes yes price deduction or rejectionScreenings <strong>and</strong> admixture yes yes price deductionVariety no yes price deduction or rejectionProtein <strong>quality</strong> no yes price deduction or rejectionProtein content sometimes yes rejectionHagberg Falling Number sometimes yes price deduction or rejectionfor breadmakingMoulds, damaged grain no yes price deduction or rejection<strong>and</strong> odoursGrain hardness sometimes yes price deduction or rejectionVisit the nabim website at www.nabim.org.ukHagberg Falling NumberLow Hagberg indicates high enzyme activity<strong>and</strong> onset of sprouting. A threshold of 250seconds is used for breadmaking <strong>wheat</strong> <strong>and</strong>samples with low Hagberg are rejected.LowHagberg <strong>wheat</strong> produces bread with a darkcrust colour <strong>and</strong> a weak,sticky crumb thatcannot be sliced.The Hagberg test is used worldwide.Itmeasures the time,in seconds,a plunger takesto descend through aheated mixture of gr oundgrain <strong>and</strong> water. The testprovides an indirectestimate of alphaamylaseactivity.Moulds, damaged grain<strong>and</strong> odoursVisual examination assesses g rain for moulds,Fusarium (pink g rains) <strong>and</strong> particularly er got.Checks are made for live insects <strong>and</strong> graindamaged by insects.Experienced staff also assess grain for unusualodours.“Mustiness”or “chemical”odour sindicate stora ge problems.Individual companies set their own <strong>criteria</strong> forthese assessments.Grain hardnessGrain hardness is a k e y variety trait for milling.Hard <strong>and</strong> soft <strong>wheat</strong>s have dif ferent processingrequirements <strong>and</strong> end-uses.The hard <strong>wheat</strong>sused for breadmaking must absorb suf ficientwater during dough making.Soft <strong>wheat</strong>s arepreferred for biscuits as much added liquid isbaked out to produce a crisp product.By crushing individual g rains within a SingleKernel Characterisation System (SKCS)instrument,the miller can check grain hardness<strong>and</strong> identify mixtures of hard <strong>and</strong> soft varieties.Near infrared calibrations,based on SKCS,canrapidly separate hard <strong>and</strong> soft <strong>wheat</strong> samples.7