burndy unitap - Womack Electric Supply Company

burndy unitap - Womack Electric Supply Company

burndy unitap - Womack Electric Supply Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

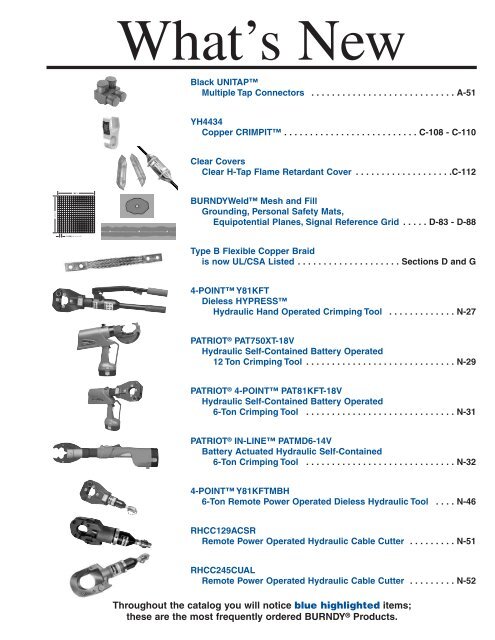

What’s NewBlack UNITAPMultiple Tap Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-51YH4434Copper CRIMPIT . . . . . . . . . . . . . . . . . . . . . . . . . . C-108 - C-110Clear CoversClear H-Tap Flame Retardant Cover . . . . . . . . . . . . . . . . . . .C-112BURNDYWeld Mesh and FillGrounding, Personal Safety Mats,Equipotential Planes, Signal Reference Grid . . . . . D-83 - D-88Type B Flexible Copper Braidis now UL/CSA Listed . . . . . . . . . . . . . . . . . . . . Sections D and G4-POINT Y81KFTDieless HYPRESSHydraulic Hand Operated Crimping Tool . . . . . . . . . . . . . N-27PATRIOT ® PAT750XT-18VHydraulic Self-Contained Battery Operated12 Ton Crimping Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N-29PATRIOT ® 4-POINT PAT81KFT-18VHydraulic Self-Contained Battery Operated6-Ton Crimping Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N-31PATRIOT ® IN-LINE PATMD6-14VBattery Actuated Hydraulic Self-Contained6-Ton Crimping Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N-324-POINT Y81KFTMBH6-Ton Remote Power Operated Dieless Hydraulic Tool . . . . N-46RHCC129ACSRRemote Power Operated Hydraulic Cable Cutter . . . . . . . . . N-51RHCC245CUALRemote Power Operated Hydraulic Cable Cutter . . . . . . . . . N-52Throughout the catalog you will notice blue highlighted items;these are the most frequently ordered BURNDY ® Products.

MASTER INDEXABCDEFGHIJKLMNOMECHANICALConnectors secured by nuts, bolts or allen head devicesSMALL COMPRESSIONConnectors secured by indent or circumferential crimpsMEDIUM AND LARGE COMPRESSIONConnectors secured by indent or circumferential crimpsGROUNDINGIrreversable Compression Grounding System and Mechanical GroundingOVERHEADPower distribution connectors both Mechanical and Compression used on pole applicationsWEJTAPPower actuated connection systemsSUBSTATIONPower distribution connectors for tube cable and bus applicationsALUMINUM WELDMENTSExtra High Voltage devicesNETWORK UNDERGROUNDPower distribution connectors for underground applicationsURD UNDERGROUNDPower distribution connectors for underground applicationsCABLE TIESUNIRAP cable tiesHARDWARENuts, Bolts and Washers of various metalsACCESSORIESOxide Inhibitors Markers and Terminal BlocksTOOLINGHand-Held, Mechanical Hydraulic and PneumaticREFERENCESDies, Connectors Charts and General Information....... ............ .................... ....................................... ......... ................................ ............. ...... ... .................................................. .................................................. ................................... ............................................................. .................. .................................................................... ............ ...................................................

MASTER INDEX............................................... ........................................... ......................... ....................................................................................................................... ....... ............. ........................ .......... .... ................. ............................................................................................................................................................................................................................................................................. ............................................................................................................................................................................................................................................................................. .............................................................................. ...................................................... ...................... ..............................................................................................................ABCDEFGHIJKLMNO

BURNDY ® ProductsMechanicalTABLE OF CONTENTSTypes KS, KS-3 & SC. . . A-4Types VA, VVA . . . . . . . A-21Type BIPC . . . . . . . . . . A-36A-1Type KSU . . . . . . . . . . . . A-5Type HFB-P1 . . . . . . . . A-22SPEC-BLOK . . . . A-37, A-38Type KSA . . . . . . . . . . . . A-6Types KVS, KVSU . . . . . A-7Types KVSW, KVS-A . . . A-8Type QPX. . . . . . . . . . . . A-9Type QPX-Y . . . . . . . . . A-10Type KPA . . . . . . . . . . . A-11Type KPA-UP . . . . . . . . A-12Type KLU . . . . . . . . . . . A-13Type HFB-N . . . . . . . . . A-23Types KA-U, KKA-U . . . A-24Type K2A-U . . . . . . . . . A-25Types K3A-U, KK3A-U. . . . . . . . . . . . . . A-26, A-27Types K4A-U, KK4A,K11A-U, K21A, K22A . A-28Type KAU-KIT . . . . . . . A-29Type AMS. . . . . . . . . . . A-30SPEC-BLOKPLATFORMS . . . . . . . A-39Types BDA, BDB,BDC . . . . . . . . . A-41, A-42,A-43, A-44, A-45Types BIT, BISR . . . . . . A-46Type BIBS . . . . . . . . . . A-47Type BIBD . . . . . . . . . . A-48Types BIBS-MT,BIBD-MT . . . . . . . . . . A-49Types KA, EA . . . . . . . . A-14Type AGSKIT . . . . . . . . A-31Type BISR-DB . . . . . . . A-50Types BGBL, CL50-1 . . A-15Type UGSKIT . . . . . . . . A-31Type 1PL . . . . . . . . . . . A-51Types QA, QQA . . . . . . A-16Type UGSKIT8 . . . . . . . A-32Types Q2A, Q3A. . . . . . A-17Type UGS350ULDB . . . A-32Complies with NFPA 78-86 Ordinary Structures.Complies with NFPA 78-86 Heavy Duty Stacks(order: LD for Lead Plating for Heavy Duty Stacksapplications).Types QB, Q2B . . . . . . A-18Type QGFL. . . . . . . . . . A-33Types QDA & QR . . . . . A-19Type FCB . . . . . . . . . . . A-34Types VT, E-C-G. . . . . . A-20Types KPU-AC,UCU-AC . . . . . . . . . . . A-35

BURNDY ® ProductsMechanicalLIGHTNING PROTECTION INFO.A-2Basic rules for selection are:1 Must be like material to the conductor(Flexitap out due to steel bolts!).2. Two bolts to ground rod — minimum.3 Cable to cable connections can beanything — one bolt, two bolt, compression,etc.4 Cable to steel structure must have 8square inch contact with steel.5. Heavy duty stacks — mechanical only.6. On all connectors with heavy duty stackrating, we must offer 1/16" thick lead platingas an option. Reason is closest 25 ft.to stack opening must use lead coatedproduct.Complies with NFPA 78-86 OrdinaryStructures.Complies with NFPA 78-86 HeavyDuty Stacks(order: LD for Lead Plating for HeavyDuty Stack applications)SPECIAL FEATURESOther features are also available for productslisted in price book such as undrilled orspecial drilling, 45° or 90° pad angles, bellingfor extra flexible cable, smooth or specialthreaded studs, special labeling or packaging,extra long braid, and nuclear certification.REFER TO FACTORY.ALL OTHERSREFER TO FACTORY1-800-346-4175

BURNDY ® ProductsMechanicalREVOLUTIONARYBURNDY DESIGNMEETS STRICT UL486B STANDARDSA-3. . . and puts the bite onaluminum connectionsforever!For use on all combinations• Aluminum to aluminum• Aluminum to copper• Copper to copperUnique ‘‘bite and grip’’ TRITAPSERVIT ® contact delivers safe,long-term reliability—evenwithout scratch brushing . . .without oxide inhibitingcompounds.†PatentedAvailable in sizes from #10 through 500 kcmil.Spacer provides built-inseparation to retardgalvanic corrosion.Triangular edges biteinto cable to breakthrough surface oxides...provide low contact resistance....produces gas tight seal.Tin-plated contactsurface inhibits oxideformation.Special heat-treated hard,aluminum alloy.Anti-galling, high efficiencythreaded components result in highcontact force. Easily installed usingstandard, everyday wrenches.†When used in NEC applications of insulated cables only.

BURNDY ® ProductsMechanicalTYPES KS & KS-3A-4SERVIT ®For Copper, CopperweldCompact, high strength, high copper alloySERVIT ® split-bolt has free-running threadsand easy to grip wrench flats. Highly resistantto season cracking and corrosion, theSERVIT ® provides maximum pressure andassures a secure connection on all combinationsof run and tap conductors. Type KS-3accommodates 3 maximum size conductors.CONDUCTORCOPPER COPPERWELD ▲MIN.TAPRECOMMENDEDCATALOG CROSS RANGE FOR EQUAL WITH MAXIMUM RUN AND TAP TIGHTENINGNUMBER FLATS L W RUN AND TAP MAX. RUN SOL. STR. TYPE A TYPE D TORQUE in-lbKS90 .50 .85 .38 12 STR. - 10 STR. 16 STR. #10 — — —**KS15 .50 .85 .38 10 STR. - 8 STR. 14 STR. #8 — — —80**KS17 .63 1.14 .45 8 STR. - 6 SOL. 14 STR. #6 3 #12 8A 9-1/2D* KS17-3 8 STR. - 6 SOL. 16 STR. #6 3 #12 8A 9-1/2D**KS20 .69 1.20 .51 8 STR. - 4 SOL. 14 STR. #4 3 #10 6A 8D165* KS20-3 8 STR. - 4 SOL. 14 STR. #4 3 #10 6A 8D**KS22 .75 1.50 .60 6 STR. - 2 SOL. 14 STR. #2 3 #8 4A 6D* KS22-3 6 STR. - 2 SOL. 14 STR. #2 3 #8 4A 6D 275**KS23 .82 1.54 .62 6 STR. - 2 STR. 14 STR. #1 3 #7 3A 5D**KS25 .94 1.77 .73 4 STR. - 1/0 STR. 14 STR. 2/0 3 #5 2A 4D**KS26 1.05 1.94 .82 2 STR. - 2/0 STR. 14 STR. 3/0 7 #7 — —385**KS27 1.36 1.86 1.17 1 STR. - 3/0 STR. 8 SOL. — — — — 500**KS29 1.36 2.07 1.17 1 STR. - 250 8 STR. 4/0 7 #5 — —**KS31 1.70 2.51 1.41 1/0 STR. - 350 1/0 STR. — 19 #8 — —650**KS34 1.82 2.79 1.48 2/0 STR. - 500 2/0 STR. — 19 #6 — — 825KS39 2.31 3.29 1.94 4/0 STR. - 750 4/0 STR. — 19 #5 — — 1000KS44 2.56 3.73 2.19 300 - 1000 4/0 STR. — — — — 1100▲ Listed torque values are for maximum conductor combinationsaccommodated. Consult UL486 Tables 7-4, 7-5,7-6 for smaller conductor combinations.See note page A-2* Not UL or CSA Listed** UL Rated for direct burial.TYPE SCSERVIT ® COVERHUG-A-BUGUsed indoors or outdoors, this compact, onepieceplastic SERVIT ® cover saves time andmaterial, eliminates costly taping of splitbolts.Positive latch snaps easily and quicklyover connector, ideal for tight quarters. Selfpositioningplastic fingers wrap around wiresfully insulating joint. UL Listed for 600 voltindoor application with type KS. Three Coversaccommodate a range of 6 SERVIT ® sizesthrough 2/0 Str.SERVIT ® and cover combinationcan be ordered as follows:CKS4 KS20 with coverCKS2/0 KS26 with coverFor other combinations, pleasecontact factory.CATALOGNUMBERSC4SC2SC2/0FOR USE WITHKS17, KS17-3, KS20KSU17, KSU20KS22, KS20-3, KS23,KS22-3, KSA6, KSA4,KSU22, KSU23KS25, KS26, KSA2, KSA 1/0KSU25, KSU26

BURNDY ® ProductsMechanicalTYPE KSUUNIVERSAL SERVIT ®For All Combinations ofCopper, Alum.,ACSR, AAAC, 5005, and SteelA-5Tin-plated, high strength copper alloySERVIT ® with spacer. Spacer separates dissimilarconductors and provides long contactlength that prevents high pressure pointcontacts between run and tap conductors.Use of PENETROX joint compound recommendedwith Aluminum and ACSR.486ACopper OnlyCONDUCTORMAXIMUMCONDUCTORRUN TAP STEEL RECOMMENDEDCATALOG CROSS COPPER & ACSR AAAC COPPER & ACSR † AAAC SOL. 3 STR. NOM TIGHTENINGNUMBER FIG. FLAT L W ALUMINUM 5005 ALUMINUM 5005 BWG BWG DIA. TORQUE in-lb.KSU17 2 .62 .92 .42 12 SOL. - 6 SOL. 8 (6-1) 12 SOL. - 6 SOL. 8 (6-1) 8 — 5/32KSU20 2 .69 1.05 .48 10 SOL. - 4 SOL. 6 (6-1) 10 SOL. - 4 SOL. 6 (6-1) 6 8 7/32165KSU22 2 .74 1.25 .57 10 SOL. - 2 SOL. 6 (6-1) - 4 (7-1) 10 SOL. - 2 SOL. 6 (6-1) - 4 (7-1) 4 6 1/4 275KSU23 2 .81 1.48 .59 8 STR. - 2 STR. 3 (6-1) - 2 (6-1) 8 SOL. - 2 STR. 6 (6-1) - 2 (6-1) — 4 5/16 275KSU25 2 .93 1.77 .70 2 STR. - 1/0 STR. 3 (6-1) - 1 (6-1) 10 STR. - 1/0 STR. 6 (6-1) - 1 (6-1) — — 3/8 385KSU26 2 1.04 1.93 .79 1/0 STR. - 2/0 STR. 1 (6-1) - 1/0 (6-1) 8 STR. - 2/0 STR. 6 (6-1) - 1/0 (6-1) — — 7/16 385KSU27 1 1.38 2.34 1.12 1 STR. - 3/0 STR. 1 (6-1) - 2/0 (6-1) 8 SOL. - 3/0 STR. 8 (6-1) - 2/0 (6-1) — — 1/2 500KSU29 1 1.38 2.50 1.14 1 STR. - 250 2/0 (6-1) - 4/0 (6-1) 8 STR. - 250 6 (6-1) - 4/0 (6-1) — — 1/2 650KSU31 1 1.69 2.88 1.36 4/0 STR. - 350 3/0 (6-1) - 4/0 (6-1) 4 STR. - 350 4 (6-1) - 4/0 (6-1) — — 5/8 650KSU34 1 2.00 3.12 1.47 400 - 500336 (30-7) - 477(18-1)2 STR. - 500 2 (6-1) - 477 (18-1) — — — 825Accommodates compressed conductors within conductorranges.See note page A-2

BURNDY ® ProductsMechanicalTYPE KSAA-6TRITAP SERVIT ®For All Combinations ofAluminum to Aluminum,Aluminum to Copper andCopper to Copper, AluminumAlloy Tin PlatedPATENTED TRIANGULARPENETRATION TECHNOLOGYCONTACTFeatures and Benefits• No scratch brushing required.• No oxide inhibitor required.• Orients the conductor.• Provides maximum pressure and assuresa secure connection of run and tapconductors.• Facilitates piercing the aluminumconductor surface oxides.• UL 486B listed, 90°C rated.• Provides a low contact resistance.• Provides equal coefficient of expansion• Inhibits the reformation of oxides byproducing a gas-tight seal.• Provides improved retention of minimumto maximum conductor combinations.RECOMMENDEDCATALOG CROSS ALUM.TO ALUM., ALUM.TO COPPER, COPPER TO COPPER CONDUCTORS ▲ TIGHTENINGNUMBER FLATS L W MAX. RUN TO MAX.TAP MIN. RUN TO MIN.TAP MAX. RUN TO MIN.TAP TORQUE in-lbKSA6 .75 1.28 .56 #6 STR. (.184) #6 STR. (.184) #10 SOL. (.102) #10 SOL. (.102) #6 STR. (.184) #10 SOL. (.102) 165KSA4 .81 1.38 .62 #4 STR. (.232) #4 STR. (.232) #8 SOL. (.129) #10 SOL. (.102) #4 STR. (.232) #10 SOL. (.102) 165KSA2 .94 1.58 .69 #2 STR. (.292) #2 STR. (.292) #6 SOL. (.169) #8 STR. (.146) #2 STR. (.292) #8 SOL. (.146) 275KSA 1/0 1.00 1.92 .75 #1/0 STR. (.373) #1/0 STR. (.373)#2 STR. COMPACT(.268)#8 SOL. (.129) #1/0 STR. (.373) #8 SOL. (.129) 385KSA 2/0 1.12 1.92 .88 #2/0 STR. (.418) #2/0 STR. (.418)#2 STR. COMPACT(.268)#8 STR. (.146) #2/0 STR. (.418) #8 STR. (.146) 385KSA 4/0 1.49 2.54 1.13 #4/0 STR. (.528) #4/0 STR. (.528)#2 STR. COMPACT(.268)#6 STR. (.184) #4/0 STR. (.528) #6 STR. (.184) 500*KSA 350 1.69 3.24 1.50 350 KCMIL (.681) 350 KCMIL (.681)#1/0 STR. COMPACT(.336)#4 STR. (.232) #350 KCMIL (.681) #4 STR. (.232) 650*KSA 500 2.00 3.62 1.73 500 KCMIL (.813) 500 KCMIL (.813)400 KCMIL #2 STR. COMPACT #2 STR. COMPACT#500 KCMIL (.813)COMPACT (.659) (.268)(.268)825▲Listed torque values are for maximum conductorcombinations accommodated. Consult UL486 Tables 7-4,7-5, 7-6 for smaller conductor combinations.* Not CSA listed.** No scratch brushing or oxide inhibiting compoundsrequired for insulated 90° C max. rated conductor forN.E.C. applications.

BURNDY ® ProductsMechanicalTYPE KVSOKLIPMechanical ConnectorFor Copper & CopperweldA-7Compact, two-piece, high strength, highcopper alloy BURNDY ® OKLIP recommendedfor heavy duty connections. Neoprenerings hold DURIUM bolts in place duringinstallation. Installed with ordinary wrench.CONDUCTORCOPPER COPPERWELD RECOMMENDED ▲CATALOG MAX. RUN AND TAP TIGHTENINGNUMBER RUN TAP SOL. STR. TYPE V TORQUE in-lbKVS26 2 STR. - 2/0 STR. 6 SOL. - 2/0 STR. 3/0 7 #8 — 180KVS28 1/0 STR. - 4/0 STR. 10 STR. - 4/0 STR. 4/0 7 #6 V3/0 250KVS31 250 - 350 10 STR. - 350 — 19 #8 V250 325KVS34 400 - 500 10 STR. - 500 — 19 #6 V350 375KVS40 400 - 800 3/0 STR - 800 — 19 #5 — 500KVS44 500 - 1000 3/0 STR. - 1000 — — — 500▲ Listed torque values are for maximum conductor combinationsaccommodated. Consult UL486 Tables 7-4, 7-5,7-6 for smaller conductor combinations.See note page A-2TYPE KVSUUNIVERSAL OKLIPMechanical ConnectorFor All Combinationsof Copper, Aluminum,ACSR, AAAC & 5005Compact, high strength, tin plated copperalloy two-piece connector with spacer and tinplatedsilicon bronze DURIUM hardware.Recommended for heavy duty connections.Spacer separates dissimilar conductors andprovides long contact length. Neoprene ringprevents loss of shorter bolt during installation.Longer peened bolt permits swivel actionfor easier installation.Use of PENETROX joint compound recommendedwith aluminum and ACSR.CONDUCTORRUN TAP RUN TAPCOPPERCOPPERACSR, ACSR, SOL., SOL., RECOMMENDEDCATALOG AAAC, AAAC, COPPERWELD STEEL COPPERWELD STEEL TIGHTENINGNUMBER COPPER & ALUM. & 5005 COPPER & ALUM. & 5005 SOL., NOM. DIA. SOL., NOM. DIA. H J L W TORQUE in-lbKVSU26 2 STR. - 2/0 STR. 3 - 2/0 6 STR. - 2/0 STR. 6 - 2/0 1 - 3/0 5/16 - 7/16 #6 - 3/0 3/16 - 7/16 2 5/16 1 1-1/2 180KVSU28 1/0 STR. - 4/0 STR. 1/0 - 4/0 6 STR. - 4/0 STR. 6 - 4/0 2/0 - 4/0 3/8 - 1/2 #6 - 4/0 5/32 - 1/2 2-3/8 3/8 1-1/8 1-3/4 250KVSU31 250 - 350 4/0 - 300 6 - 350 6 - 300 — 9/16 - 5/8 #6 - 4/0 3/16 - 5/8 2-5/8 1/2 1-3/8 2-1/8 325KVSU34 400 - 500 336.4 - 397.5 4 - 500 5 - 397.5 — 3/4 - 3/4 #4 - 4/0 7/32 - 3/4 3 1/2 1-1/2 2-1/4 375KVSU40 400 - 800 4/0 - 800 4/0 - 800 3/0 - 715.5 — 3/4 - 1 — 1/2 - 1 3-1/2 1/2 1-5/8 2-1/2KVSU44 500 - 1000 4/0 - 1000 4/0 - 1000 4/0 - 900 — 7/8 - 1-1/8 — 1/2 - 1-1/8 4 3/8 2 3500Accomodations compressed conductors within diameterrange.See note page A-2

BURNDY ® ProductsMechanicalTYPE KVSWA-8OKLIPMechanical ConnectorFor Copper and Copperweld.Similiar to OKLIP Type KVS except for ahigh copper alloy spacer that separates runand tap conductors. Provides high contactpressure, confines conductor strands, andassures vibration-proof connection. Longerpeened bolt, permits swivel action for easierinstallation. Silicon bronze DURIUM hardware.RECOMMENDEDCATALOG CONDUCTOR TIGHTENINGNUMBER RUN TAP TORQUE in-lbKVSW26 2 STR. - 2/0 STR. 6 SOL. - 2/0 STR. 180KVSW28 1/0 STR. - 4/0 STR. 6 SOL. - 4/0 STR. 250KVSW31 250 - 350 4 SOL. - 350 325KVSW34 400 - 500 4 STR. - 500 375KVSW40 400 - 800 4/0 - 800 500KVSW44 500 - 1000 250 - 1000 500See note page A-2TYPE KVS-AALUMINUM OKLIPMechanical ConnectorFor All Combinations ofCopper, Aluminum†, ACSR†,AAAC and 5005Three-piece, high-conductivity, non-copperbearing aluminum alloy connector with thickspacer and aluminum hardware. Hardware inKVS26A and KVS28A is stainless steel.Recommended for heavy duty dissimilarmetal applications. Spacer separates conductorsand provides long contact length. Belledentrances prevent chafing, permit easierassembly of conductors. Longer peened boltpermits swivel action for easier installation.Neoprene ring prevents loss of shorter bolt.PENETROX joint compound recommendedwith aluminum and ACSR.CONDUCTORRUN TAP RECOMMENDEDCATALOG COPPER, ACSR†, COPPER, ACSR†, TIGHTENINGNUMBER & ALUM.† AAAC, & 5005 & ALUM.† AAAC & 5005 TORQUE in-lbKVS26A 2 STR. - 2/0 STR. 4 - 2/0 10 STR. - 2/0 STR. 6 - 2/0 180KVS28A 1/0 STR. - 4/0 STR. 1/0 - 4/0 10 STR. - 4/0 STR. 6 - 4/0 240KVS31A 250 - 350 4/0 - 336.4 6 STR. - 350 6 - 336.4 300KVS34A 400 - 500 336.4 - 397.5 4 STR. - 500 5 - 397.5 300KVS40A 400 - 800 336.4 - 715.5 3/0 STR. - 800 3/0 - 715.5 300KVS44A 500 - 1000 397.5 - 900 3/0 STR. - 1000 3/0 - 900 480† Accommodates compressed conductors within diameterrange.See note page A-2THESE CONNECTORSCAN ACCOMMODATEACSR CONDUCTORSOVER ARMOR ROD WITHINTHE DIAMETER RANGEINDICATED.APPLICATION OVERARMOR RODCONDUCTOR RANGE BY DIAMETERCATALOGMAX. RUN &NUMBER MIN. RUN DIA. MIN.TAP DIA. TAP DIA. H J L WKVS26A .281 .116 .447 2-1/4 5/16 1-1/4 1-5/8KVS28A .360 .116 .564 3 3/8 1-5/8 2-1/16KVS31A .565 .184 .681 3-1/16 1/2 1-15/16 2-7/16KVS34A .728 .216 .814 3-9/16 1/2 2-5/16 2-5/8KVS40A .728 .470 1.036 4-1/16 1/2 2-7/16 2-7/8KVS44A .806 .470 1.162 4-7/8 5/8 2-1/2 3-1/8

BURNDY ® ProductsMechanicalTYPE QPXVERSITAPParallel Clamp For Copper,Copperweld, Copperweld-CopperA-9The VERSITAP Type QPX is recommendedfor Tee, Cross, Parallel, Butt and Tap connections.Range-taking, only 10 connectorsrequired to accommodate conductor sizesfrom #6 Str. to 1000 kcmil. Edges are roundedfor easy taping. Made of high strength,high-conductivity copper alloy and siliconbronze DURIUM hardware.* For various configurations, see pageA-10.Fig. 1 Fig. 2RECOMMENDEDCATALOG COPPER CONDUCTOR TIGHTENINGNUMBER RUN TAP FIG. NO. H J L W TORQUE in-lb ▲QPX2C2C 6 STR. - 2 STR. 6 STR. - 2 STR. 1-1/2 1-3/8 1505/16 1-5/16QPX282C 6 STR. - 2 STR. 2-1/161-9/161 STR. - 4/0 STR.250QPX28281 STR. - 4/0 STR. 1 3/8 1-13/16 1-13/162-3/8QPX342C6 STR. - 2 STR.5/16 1-3/8 1-7/8QPX3428 250 - 500 1 STR. - 4/0 STR. 2-3/4 1-3/4 2-1/16 3753/8QPX3434 250 - 500 2 32-1/16 2-3/16QPX442C 6 STR. - 2 STR. 2-11/16 5/16 1-3/8 2-1/41QPX44281 STR. - 4/0 STR.2-7/8 1-13/16500 - 10002-7/16QPX4434250 - 500 3-1/16 3/8 2-1/162QPX4444 500 - 10003-7/16 2-5/8 2-9/16500▲ Listed torque values are for maximum conductor combinationsaccommodated. Consult UL486 Tables 7-4, 7-5, 7-6for smaller conductor combinations.See note page A-2.CONDUCTORRUNTAPCATALOG COPPERWELD COPPERWELDNUMBER COPPERWELD – COPPER COPPERWELD – COPPERQPX2C2C 5 SOL. - 3 #7 8A - 4A 5 SOL. - 3 #7 8A - 4AQPX282C 7 #9 - 7 #5 3A - 3/0 V 5 SOL. - 3 #7 8A - 4AQPX2828 7 #9 - 7 #5 3A - 3/0 V 7 #9 - 7 #5 3A - 3/0 VQPX342C 5 SOL. - 3 #7 8A - 4AQPX3428 19 #9 - 19 #6 4/0 EK 7 #9 - 7 #5 3A - 3/0 VQPX3434 19 #9 - 19 #6 4/0 EKQPX442C 5 SOL. - 3 #7 8A - 4AQPX4428 7 #9 - 7 #5 3A - 3/0 V19 #6 —QPX443419 #9 - 19 #6 4/0 EKQPX4444 19 #6

BURNDY ® ProductsMechanicalTYPE QPX-YA-10UNIVERSAL VERSITAPUniversal Parallel ClampFor Copper and AluminumHigh copper alloy cast connector, tin-plated foruse with copper or aluminum cable. Makesparallel, tap, tee, cross or end-to-end connections.Edges rounded for easy taping.PENETROX joint compound recommended.▲ Listed torque values are for maximum conductorcombinations accommodated. Consult UL486Tables 7 4, 7-5 7-6 for smaller conductorcombinations.See note page A-2.Fig. 1 Fig. 2CONDUCTORRECOMMENDEDCATALOG ALUMINUM OR COPPER TIGHTENINGNUMBER RUN TAP FIG. NO. H J L W TORQUE in-lb ▲QPX2C2C-Y 6 STR. - 2 STR. 6 STR. - 2 STR. 1-5/8 1-5/815/16 1-1/2QPX282C-Y 1/0 STR. - 4/0 STR. 6 STR. - 2 STR.1-7/81-7/8150QPX2828-Y 1/0 STR. - 4/0 STR. 1/0 STR. - 4/0 STR. 2 3/8 2 2-1/8 250QPX342C-Y 6 STR. - 2 STR. 1 2-1/4 5/16 1-1/2 2-1/8QPX3428-Y 250 - 500 1/0 STR. - 4/0 STR. 2-1/2 2 2-1/2 3753/8QPX3434-Y 200 - 500 2 2-7/82-1/2 2-5/8QPX4444-Y 750 - 1000 750 - 1000 2 3-7/8 1/2 3-1/2 3-1/2 500APPLICATIONVARIATIONSPARALLEL TAP CROSSSPLICETEE

BURNDY ® ProductsMechanicalTYPE KPASCRULUGFor Copper CableA-11High copper alloy tin-plated terminal for joininga wide range of cable to equipment padsor terminal blocks. Especially good in lightindustrial applications. The tongue and bodyare a one-piece design. The pressure barequalizes pressure over the conductor andprevents the screw from cutting into the cable.Fig. 1 Fig. 2STUDRECOMMENDEDCATALOG FIG. HOLE TIGHTENINGNUMBER WIRE RANGE NO. C D H K SIZE L N T TORQUE in-lbKPA8C 8 STR. - 14 SOL. 1 .38 .47 .72 .21 .10 .95 .22 .06 12KPA4C 14 SOL. - 4 STR. 1 .50 .59 .94 .27 1/4 1.20 .30 .06 45KPA25 4 STR. - 1/0 STR. 2 .75 .81 1.25 .33 5/16 1.70 .41 .10 180KPA28 1/0 STR. - 4/0 STR. 2 .97 1.12 1.66 .40 3/8 2.29 .53 .13 250KPA34 4/0 STR. - 500 kcmil 2 1.38 1.38 2.44 .54 1/2 3.14 .75 .20 375NOTE: For unplated version add “UNPL” suffix.

BURNDY ® ProductsMechanicalTYPE KPA-UPA-12SCRULUGFOR COPPER CABLEHigh copper alloy terminal for joining a widerange of cable to equipment pads or terminalblocks. Plain copper finish.Features and Benefits• One piece design. Superior torque and pullout performance.• Convenient range taking design. Reduces catalog numbers.One catalog number accommodatesseveral conductor sizes.• High conductivity copper alloy. Long lasting, reliable contact.• Compact design. Easy to use.• Slot Robertson screw, hex head,hex socket bolt. No special installation tools required.Eliminates over-torquing/potentialconductor damage.NOTE: For tin plating drop “-UP” suffix and add “-TP” suffix(example: KPA4CTP).For use in grounding applications with a green screw - contactfactory. Listed for grounding per UL467.Fig. 1 Fig. 2 Fig. 3STUDRECOMMENDEDCATALOG WIRE FIG. HOLE TIGHTENINGNUMBER RANGE NO. C D H K SIZE L N T HARDWARE TORQUE in-lb14 SOL. 1/4 Dia. SlotKPA8CUP0.38 0.51 0.81 0.20 #10 1.01 0.24 0.07356 STR.Robertson114 SOL.5/16 Dia. SlotKPA4CUP0.50 0.71 1.00 0.28 1/4 1.28 0.33 0.07454 STR.Robertson

BURNDY ® ProductsMechanicalTYPE KLUSCRULUGFOR COPPER CABLE -OFFSET TONGUE -NON-PLATEDA-13High copper alloy terminal with offset tonguefor joining a wide range of cable to equipmentpads or bar. Easy to install with screwdriver orwrench. Connector is reusable. Plain copperfinish.Features and Benefits• Convenient range-taking design. Reduces catalog numbers.One conductor accommodatesseveral conductor sizes.• High conductivity copper alloy. Long lasting reliable contact.• Compact design. Easy to use. Reduces labor time.• Slot Robertson screw, hex head/hexsocket bolt. No special installation tools required.Eliminates over-torquing/potentialconductor damage.Fig. 1 Fig. 2 Fig. 3➀ RECOMMENDED STUD STRIPCATALOG FIG. B C K L N T TIGHTENING HOLE QUANTITY/ LENGTHNUMBER CONDUCTOR NO. (MM/IN) (MM/IN) (MM/IN) (MM/IN) (MM/IN) (MM/IN) TORQUE IN LBS. HARDWARE SIZE PACKAGE (IN.)KLU25 14 Sol. 1.63 (0.64) Dia. to 6.4 8.0 3.6 26.0 6.3 1.9 No. 8 - 32 Slotted Round320KLU25TP 10 Sol. 2.60 (1.02) Dia. CU.26 .31 .14 1.02 .21 .07Machine Screw#6 100 7/16KLU35 14 Sol. 1.63 (.0641) Dia. to 8.4 10.0 6.0 31.6 5.6 1.8 1/4 UNF Slotted Set45KLU35TP 6 Str. 4.67 (.184) Dia. CU .33 .39 .20 1.24 .22 .07Screw#10 100 5/8KLU70 8 Sol. 3.28 (.129) Dia. to 11.8 12.0 6.7 39.6 6.4 2.1 5/16 UNF Slotted Set250KLU70TP 2 Str. 7.42 (.292) Dia. CU.46 .47 .26 1.56 .25 .08Screw1/4 100 3/4KLU125 2 Str. 7.42 (.292) Dia. to 16.9 16.9 6.5 50.5 10.8 2.7 3/8 UNF Slotted Set50KLU125TP 1/0 Str. 9.44 (.372) Dia. CU .63 .63 .26 1.99 .43 .11Screw1/4 25 15/16KLU175 4 Str. 5.89 (.232) Dia. to 18.0 19.0 10.0 66.0 11.0 4.0 3/8 UNF Socket Set1243/8 12 1KLU175TP 3/0 Str. 11.94 (.470) Dia. CU .71 .75 .39 2.20 .43 .16Screw1KLU225 2 Str. 7.42 (.292) Dia. to19.6 26.2 8.5 65.0 13.0 3.1 7/16 UNF Socket Set2045/16 12 1-5/16KLU225TP 4/0 Str. 13.4 (.528) Dia. CU .77 .99 .33 2.56 .51 .12ScrewKLU300 1/0 Str. 9.44 (.372) Dia. to 25.2 26.2 10.0 72.0 13.1 3.1 5/8 UNF Slotted Set3253/8 6 1-5/8KLU300TP 350 MCM 17.30 (.681) Dia. CU 1.0 .99 .39 2.83 .52 .12Screw2KLU400 1/0 Str. 9.44 (.372) Dia. to29.6 38.0 10.0 104.0 23.0 4.5 5/8 UNF Slotted Set3753/8 3 1-5/32KLU400TP 500 MCM 207 (.813) Dia CU 1.16 1.60 .39 4.09 .91 .18ScrewNOTES:➀ Suffix “-TP” on catalog number denotes tin plate (example:KLU400TP).2 Material: Copper alloy.

BURNDY ® ProductsMechanicalTYPE KAA-14KA-LUGFor Copper CableCompact, economical, high copper alloyterminal for joining a wide range of cable toequipment pads or terminal blocks.Fig. 1 Fig. 2Fig. 3STUDRECOMMENDEDCATALOG FIG. HOLE TIGHTENINGNUMBER CONDUCTOR NO. C H J K SIZE L N T TORQUE in-lbKA8C 14 SOL. - 8 STR. 3/8 5/8 #12 7/32 #10 13/16 3/16 3/32 251KA4C 14 SOL. - 4 STR.9/16 3/4 5/16 9/32 1/4 1-1/8 1/4 7/64 45KA25 4 STR. - 1/0 STR. 2 3/4 15/16 1/2 27/64 3/8 1-11/16 3/8 1/8 200KA25-2TC 38 4 STR. - 1/0 STR. 3 3/4 15/16 1/2 27/64 3/8 2-13/16 3/8 1/8 200KA28 1 STR. - 4/0 STR. 15/16 1-1/4 5/8 27/64 3/8 1-15/16 7/16 3/16 2752KA34 4/0 STR. - 5001-3/8 2-3/32 13/16 9/16 1/2 2-9/16 9/16 9/32 375▲ Listed torque values are for maximum conductor sizesaccommodated.Consult UL486 Tables 7-4, 7-5, 7-6 for smaller conductorsizes.TYPE EAVERSILUGFor Copper CableCompact, high copper alloy terminal for joininga wide range of cable to equipment padsor bar. Clamping element adjustable toseveral angles. One-wrench installation.NO. OF STUD RECOMMENDEDCATALOG HOLES HOLE TIGHTENINGNUMBER CONDUCTOR IN PAD C D E H K SIZE L N T TORQUE in-lbEA2C 8 SOL. - 2 STR. 1 13/16 1-1/16 — 1-3/8 3/8 2-1/2 13/32 1501/4EA25 2 STR. - 1/0 STR. 1 7/8 1-1/8 — 1-7/16 7/16 3/8 2-11/16 7/16180EA28 1 1-3/8 — 3/8 3-3/16 17/321/0 STR. - 4/0 STR.EA28-2N2 NEMA 1-1/16 1-3/43-5/8 1-3/41/2 5-1/8 5/85/16 250EA34 1 1-5/8 — 9/16 1/2 4 13/16250 - 5001-3/82-1/4EA34-2N2 NEMA3-5/8 1-3/41/2 5-5/8 5/83/8 375* “N” indicates NEMA standard stud holes.▲ Listed torque values are for maximum conductorsizes accommodated.Consult UL486 Tables 7-4, 7-5, 7-6 for smallerconductor sizes.

BURNDY ® ProductsMechanicalTYPE BGBLLAY-IN QIKLUG*UL LISTED 90° C, 600 VA-15The Lay-In QIKLUG, Type BGBL is manufacturedfrom high strength 6061-T6aluminum, and is ideally suited for groundingand bonding applications accommodatingboth copper and aluminum conductor sizes#14 AWG to 250 kcmil. Features and Benefits• * UL 486B listed, AL9CU rated. For copper and aluminum conductorcombinations up to 90° C, 600 Voltapplications.• UL Recognized for grounding and bonding. Ensures reliability.• Electro-tin plated. Provides low contact resistance.• Lay-in feature. Eases installation.Fig. 1Fig. 2DIMENSIONSCATALOG FIG CONDUCTOR H K HEXNUMBER NO. RANGE C D E REF J DIA. L N T SIZE*BGBL-4 1 4 - 14 AWG.39 .62 .48 .79 .22 1.10 .20 .131/4 - 28[10] [16] [12] [20][6] [28] [5] [3]SLOTBGBL-1/0 1 1/0 - 14 AWG.63 .80 .83 1.16 .28 1.63 .44 .193/8 - 24[16] [20] [21] [29][7] [41] [11] [5]SLOTBGBL-250 2 250 kcmil - 6.88 1.18 1.00 1.72 .28 2.18 .45 .257/16 - 18[22] [30] [30] [44][7] [55] [11] [6]7/32NOTE: PEN-A PENETROX ® inhibitor is recommended for allaluminum terminations.TYPE CL50-1COPPER LAY-IN QIKLUGFOR COPPERThe Lay-In QIKLUG is manufactured fromhigh strength pure electrolytic copper toensure maximum strength and conductivity.UL467 Listed for direct burial in earth or concrete.The open-faced design allows for fastlay-in of the conductor without the need forcutting or breaking.CATALOG WIRE RANGENUMBER COPPER STUD HOLECL50-1 #14 - #4 CU #10

BURNDY ® ProductsMechanicalTYPES QA, QQAA-16QIKLUGFor Copper CableType QA heavy duty, compact, high copperalloy terminal for joining a wide range of cableto equipment pads or bar. Fast one-wrenchinstallation. Type QQA heavy duty, highcopper alloy terminal for joining cable toequipment pads or bar. Twin clampingelements secure joint vibration and flexing.One-wrench installation.Type QAType QQANO. OF STUD RECOMMENDEDCATALOG NUMBER* CONDUCTOR HOLES HOLE TIGHTENINGTYPE QA TYPE QQA COMMERCIAL NAVY IN PAD C D E & F H K SIZE L LL N T TORQUE in-lbQA8C-B QQA8C 1 9/16 — 1-3/8 2-5/16 9/3214 SOL. - 8 STR. 4 - 149/1611/16#10QA8C-2B QQA8C-221-1/4 5/87/322 3 5/165/32 75QA4C-B QQA4C 1 5/8 — 1-7/16 2-3/88 STR. - 4 STR. 23 - 403/45/16 3/16 110QA4C-2B QQA4C-22 1-3/16 5/89/32 1/4 2 2-15/165/8QA1C-B QQA1C 13/4 — 1-3/4 2-13/164 STR. - 1 STR. 50 - 75111/32 150QA1C-2B QQA1C-22 1-9/16 7/811/32 5/16 2-9/16 3-5/87/32QA26-B QQA26 1 1 — 2 3-3/161/0 STR - 2/0 STR. 100 - 12513/16 1-3/167/16 180QA26-2B QQA26-221-15/16 1 3 4-3/1613/32 3/8QA28-B QQA28 1 1-1/16 —2-1/4 3-9/16 17/32QA28-2B 3/0 STR. - 4/0 STR. 150 - 200 2 1 2 1 1-5/16 3-9/16 — 7/16 1/4 250QA28-2N* QQA28-2N* 2 NEMA 3-1/8 1-3/4 9/16 4-5/16 5-5/8 5/81/2QA31-B QQA31 1 1-3/8 — 17/322-11/36 4-1/8 11/16QA31-2B 250 - 350 250 - 350 2 1-3/16 1-31/32 1 1-11/16 7/16 3/8 3-3/8 — 7/16 5/16 325QA31-2N* QQA31-2N* 2 NEMA 3 1-3/4 9/16 4-7/16 5-7/8 5/81/2QA34-B QQA34 1 1-5/8 — 17/323-3/16 4-7/8 13/161-3/8QA34-2B 22 13/32 3-9/16 — 7/16400 - 500 400 - 5001 23/85/16 375QA34-4B4 1-7/8 1-15/167/163-1/2 — 7/16QA34-2N* QQA34-2N* 2 NEMA 1-3/8 3-3/32 1-3/4 9/16 1/2 4-11/16 6-9/32 5/8QA40-B 1 1-7/8 — 11/16 5/8 3-11/16 — 27/32QA40-2N* QQA40-2N* 600 - 800 650 - 800 2 NEMA 1-5/8 2-7/16 4-14/163 1-3/4 9/16 1/27-3/32 5/8QQA40-4N 4 NEMA 3—3/8QA44-B 1 2 — 11/16 5/8 3-15/16 — 1QA44-2N* QQA44-2N 850 - 1000 1000 2 NEMA 1-7/8 3 2-3/41-3/4 9/16 1/2 5 7-1/8 5/8QA44-4N* QQA44-4N* 4 NEMA 3 3-1/161/2500QA46-B 1 2-1/8 — 13/16 3/4 4-3/8 — 1-1/161100 - 1500 1300QA46-2N*2 NEMA 2-1/8 3-1/83 1-3/49/16 1/2 5-1/4 — 5/89/16 600* ‘‘N’’ indicates NEMA standard stud holes.All 4N items See note page A-2

BURNDY ® ProductsMechanicalTYPE Q2AQIKLUGFor Copper CableA-17Compact, high copper alloy terminal for joiningtwo cables to equipment pads or bars.Each element accommodates a wide rangeof cable. One-wrench installation.NO. OF STUD RECOMMENDEDCATALOG HOLES IN HOLE TIGHTENINGNUMBER* CONDUCTOR PAD C D E & F H K SIZE L N T W TORQUE in-lb ▲Q2A1C-2 4 STR. - 1 STR. 2 1-1/2 1-7/8 1 1-1/16 7/16 3/8 2-7/8 7/16 7/32 1-13/16 150Q2A26-2N 1/0 STR. - 2/0 STR. 2 NEMA 1-5/8 3/4 1-3/16 4-3/16 7/32 1-15/16 180Q2A28-2N 2 NEMA 1-7/8 4-3/8 1-15/16Q2A28-4N 3/0 STR. - 4/0 STR. 1-3/8 1/44 NEMA 32-1/8250Q2A31-2N 2 NEMA 2-3/8 4-1/2 2-1/8250 - 3501-11/16 5/16Q2A31-4N4 NEMA 3 3-1/83325Q2A34-2N 2 NEMA 2-1/2 1-3/4 9/16 1/2 5/8 3400 - 5002 4-11/16 3/8Q2A34-4N4 NEMA 33-3/4375Q2A40-2N 2 NEMA 3-3/4600 - 800 3 2-7/16 5 7/16Q2A40-4N4-11/32 5004 NEMAQ2A44-4N 850 - 10003-1/4 2-3/4 5-1/4 1/2 4-11/323-1/4Q2A46-4N 1100 - 1500 4 NEMA 3-1/23-1/8 5-1/2 11/16 5 600* ‘‘N’’ indicates NEMA standard stud holes.All 4N items See note page A-2TYPE Q3AQIKLUGFor Copper CableCompact, high copper alloy terminal for joiningthree cables to equipment pads or bar.Each element accommodates a wide rangeof cable. One-wrench installation.NO. OF STUD RECOMMENDEDCATALOG HOLES IN HOLE TIGHTENINGNUMBER* CONDUCTOR PAD C D E & F H K SIZE L N T W TORQUE in-lbQ3A28-2N 2 NEMA 1-7/8 4-5/16Q3A28-4N 3/0 STR. - 4/0 STR. 1-3/84 NEMA 34-3/81/4 3-3/16 250Q3A31-2N 2 NEMA 2-3/8250 - 350Q3A31-4N4 NEMA 3 3-1/81-11/16 4-7/16 5/16 4-1/16 325Q3A34-2N 2 NEMA 2-1/2 1-3/4 9/16 1/2 5/8400 - 5001-15/16 4-3/4 3/8 4-9/16 375Q3A34-4N4 NEMA3Q3A40-4N 600 - 8002-7/16 5 7/16 5-13/164 NEMA500Q3A44-4N 850 - 10003-1/4 2-3/4 5-1/4 1/2 6-5/83-1/4Q3A46-4N 1100 - 1500 4 NEMA 3-1/23-1/8 5-1/2 11/16 7-7/8 600* ‘‘N’’ indicates NEMA standard stud holes.

BURNDY ® ProductsMechanicalTYPE QBA-18QIKLUGFor Copper CableCompact, high copper alloy side entranceterminal for joining a range of cable at rightangles to terminal blocks. One-wrenchinstallation.NO. OF STUD RECOMMENDEDCATALOG HOLES HOLE TIGHTENINGNUMBER* CONDUCTOR IN PAD C D E H K SIZE L N T TORQUE in-lb ▲QB8C 14 SOL. - 8 STR. 1 9/16 9/16 — 7/8 7/32 #10 1-1/8 9/32 5/32 75QB4C 8 STR. - 4 STR. 1 27/32 — 13/16 1-3/8 1/4 11011/169/32 1/411/32QB1C 4 STR. - 1 STR. 113/16 — 11-1/21507/32QB26 1/0 STR. - 2/0 STR. 1 13/16 1 — 1-1/32 1-13/16 7/1618013/32 3/8QB28 3/0 STR. - 4/0 STR. 1 1 1-1/16 — 1-5/162-1/16 17/32 1/4 250QB31-2N 250 - 350 2 NEMA 13/16 3-1/4 1-3/4 1-11/16 9/16 1/2 4-1/2 5/8 5/16 325“N” indicates NEMA standard stud holes.TYPE Q2BQIKLUGFor Copper CableCompact, high copper alloy terminal for joiningtwo cables at right angles to a singleterminal block. Each element accommodatesa range of cable. One-wrench installation.NO. OF STUD RECOMMENDEDCATALOG HOLES HOLE TIGHTENINGNUMBER* CONDUCTOR IN PAD C D E & F H K SIZE L N T TORQUE in-lbQ2B28-2N 3/0 STR. - 4/0 STR. 2 NEMA 1-7/8 3-1/8 1-3/4 1-3/8 3/8 5-3/16 1/4 250Q2B31-2N 250 - 350 2 NEMA 2-3/8 3-3/16 1-11/16 1-3/8 9/16 1/2 5-7/8 5/8 5/16 325Q2B40-4N 600 - 800 4 NEMA 3 3-1/16 1-3/8 2-5/16 1 6-11/16 7/16 500“N” indicates NEMA standard stud holes.All 4N items See note page A-2

BURNDY ® ProductsMechanicalTYPE QDAQIKLUGFor Copper CableA-19Compact, high copper alloy terminal for joininga wide range of cable to equipment studs.Provides low contact resistance whengripped between two contact nuts. Onewrenchinstallation.STUDRECOMMENDEDCATALOG CONDUCTOR HOLE TIGHTENINGNUMBER COMMERCIAL NAVY C H K SIZE L T TORQUE in-lbQDA8C 14 SOL. - 8 STR. 3 - 14 11/16 3/16 751-7/8QDA4C 8 STR. - 4 STR. 23 - 40 1 3/4 7/16 3/87/32 110QDA1C 4 STR. - 1 STR. 50 - 75 1 2-3/16 9/32 150QDA26 1/0 STR. - 2/0 STR. 100 - 125 1-3/16 2-1/2 1801-1/49/16 1/2QDA28 3/0 STR. - 4/0 STR. 150 - 2001-5/162-5/8 2505/16QDA31 250 - 350 250 - 350 1-1/2 1-11/16 11/16 5/8 3325QDA34 400 - 500 400 - 500 1-7/8 2 13/16 3/4 3-5/8 375QDA40 600 - 800 650 - 800 2-1/8 2-5/16 1-1/16 1 4-3/16 3/8 500TYPE QR QIKLINK ®SPLICE OR REDUCERFor Copper Cable to CableHigh copper alloy splicer/reducer for joining arange of cable end to end. Neat, compacteasy to tape installation. One-wrenchinstallation.RECOMMENDEDCATALOG CONDUCTOR TIGHTENINGNUMBER EITHER SIZE H L W TORQUE in-lbQR4C 8 STR. - 4 STR. 3/4 1-11/16 5/8 110QR1C 4 STR. - 1 STR. 1-1/16 1-15/16 11/16 150QR26 1/0 STR. - 2/0 STR. 1-3/16 2-1/8 13/16 180QR28 3/0 STR. - 4/0 STR. 1-3/8 2-3/8 1 250QR31 250 - 350 1-11/16 2-5/8 1-1/4 325QR34 400 - 500 1-15/16 3-1/16 1-7/16 375QR40 600 - 800 2-7/16 3-5/8 1-7/8 500See note page A-2.

BURNDY ® ProductsMechanicalTYPE VTA-20VARITAP T-CONNECTORFor Copper Cable to CableHigh copper alloy T-connector for cable run,cable tap. V-bolt clamping elements accommodatelarge range of cable and areparticularly suited for extra flexible cable.One-wrench installation.RECOMMENDEDCATALOG CONDUCTOR TIGHTENING TORQUE in-lbNUMBER RUN TAP H L W RUN TAPVT2C2C 8 SOL. - 2 STR. 8 SOL. - 2 STR. 1-5/16 2-5/16 1-5/16 275 275VT2525 6 SOL. - 1/0 STR. 6 SOL. - 1/0 STR. 2-5/8 1-7/16 385 385VT2825 6 SOL. - 1/0 STR. 1-5/8 3-1/8 1-1/4 250 3851/0 STR. - 4/0 STR.VT28281/0 STR. - 4/0 STR. 3-1/16 1-11/16 250 250VT3025 6 SOL. - 1/0 STR. 3-3/8 1-3/8 325 3851/0 STR. - 3001-7/8VT30301/0 STR. - 3003-5/16 1-15/16 325 325VT3425 6 SOL. - 1/0 STR. 3-11/16 1-1/2 375 385VT3428 1/0 STR. - 4/0 STR. 3-1/2 1-11/16 375 250300 - 5002-5/16VT34301/0 STR. - 3003-5/8 1-15/16 375 325VT3434 300 - 500 3-3/4 2-1/4 375 375VT4040 500 - 800 500 - 800 2-9/16 4-1/2 2-5/8 500 500VT4425 6 SOL. - 1/0 STR. 4-5/16 2 500 385750 - 10002-7/8VT44281/0 STR. - 4/0 STR.4-1/8 2 500 250VT4834 300 - 500 5-1/4 5 600 375VT4844 1500 - 2000 750 - 1000 4-1/4 5-3/4 5 600 500VT4848 1500 - 2000 6-1/4 5 600 600See note page A-2TYPE E-C-GTRANSFORMERTAP ADAPTERFor CopperMulti-tap, range-taking cast copper alloy connectordesigned to take 2, 3 or 4 conductorsfrom a single secondary transformer outlet.RECOMMENDEDCATALOG NO. OF CONDUCTOR A TIGHTENINGNUMBER CONDUCTORS SIZE DIA. D H J L W TORQUE in-lbE2C34G1 2 3-1/2E3C34G1 3 1/0 SOL. - 500 .78 3-3/4 2-7/8 1/2-13 6-1/4 5-1/4 480E4C34G1 4 6-7/8

BURNDY ® ProductsMechanicalTYPE VA, VVAVARILUGFor Copper CableA-21High copper alloy terminal for joining a widerange of cable to equipment pads or bar.Particularly suitable for use on extra flexiblecable. One-wrench installation. Type VVA,twin elements secure joint against vibrationand flexing. Particularly recommended foruse on extra flexible cables. One-wrenchinstallation.Type VAType VVANO. OF STUD RECOMMENDEDCATALOG NUMBER* HOLES HOLE TIGHTENINGTYPE VA TYPE VVA CONDUCTOR IN PAD C D E & F H K SIZE L LL N T TORQUE in-lbVA2C VVA2 8 SOL. - 2 STR. 13/16 1-1/4 — 1-1/2 2-3/4 4-1/16 13/32 27517/161/4VA25 VVA25 6 SOL. - 1/0 STR.7/8 1-5/16 — 1-7/83/8 2-7/8 4-5/16 7/16385VA28 VVA28 1 1-1/2 — 7/16 2-7/8 4-1/8 17/321/0 STR. - 4/0 STR.VA28-2N VVA28-2N2 NEMA 1-1/16 2-1/42503-1/2 1-3/49/16 1/2 4-15/16 6-3/6 5/85/16VA30 VVA30 1 1-5/8 — 7/16 3/8 3-1/4 4-5/8 5/81/0 STR. - 3001-1/82-3/16325VA30-2N VVA30-2N2 NEMA 3-9/16 1-3/45-3/16 6-9/16 5/8VA34 VVA34 1 2 — 3-13/16 5-5/16 13/161-3/89/16 1/2VA34-2N VVA34-2N 300 - 500 2 NEMA 3-5/8 1-3/4 3-11/325-3/8 6-7/8 5/8 375VA34-4N VVA34-4N 4 NEMA 3 3-5/8 1-3/4 5-3/8 6-7/8 5/83/8VA40 VVA40 1 2-5/16 — 11/16 5/8 4-1/2 6-3/8 15/161-5/8VA40-2N VVA40-2N 500 - 800 2 NEMA 3-5/8 1-3/4 2-7/8 9/16 5-13/16 7-11/16 5/8 5001/2VA40-4N VVA40-4N 4 NEMA 3 2-5/8 1-3/4 9/16 5-13/16 7-11/16 5/8“N” indicates NEMA standard stud holes.All 4N items See note page A-2

BURNDY ® ProductsMechanicalTYPE HFB-P1A-22BAR CLAMP ASSEMBLYCOMPONENTSFor Copper BarTo build your own high strength clamp assemblyfor multiple flat bar using type HFB-P1 barclamps and clamping hardware, the followingtables have been provided. The clampassembly eliminates the need for drilling theflat bar and is used in indoor and outdoorapplications.ONE CLAMP HALFBAR CLAMP BAR “J” RECOMMENDEDCATALOG RUN TAP BOLT TIGHTENINGNUMBER ‘A’ ‘AA’ DIA. L W Z TORQUE in-lbHFB22P1 2.00 2.00 3/8 4.38 4.38 * 240HFB33P1 3.00 3.00 3/8 4.38 4.38 * 240HFB42P1 4.00 2.00 3/8 5.75 5.75 * 240HFB44P1 4.00 4.00 1/2 5.75 5.75 * 480HFB63P1 6.00 3.00 1/2 7.75 4.75 * 480HFB66P1 6.00 6.00 5/8 8.12 8.12 * 660HFB88P1 8.00 8.00 3/4 10.50 10.50 * 1990*Z=Space between the bar clamp contact surfacesBAR CLAMP ASSEMBLY COMPONENTS †COPPERSILICON BRONZE CLAMPING HARDWAREBUS BARSPLIT LOCKWIDTH (INCHES) BAR CLAMP BOLTS NUTS WASHERSRUN-A TAP-AA QTY. CAT. NO. QTY. CAT. NO. QTY. CAT. NO. QTY. CAT. NO.2 2 2 HFB22P1 4 38 X (*) HEB 4 38CHEN 4 38SW3 3 2 HFB33P1 4 38 X (*) HEB 4 38CHEN 4 38SW4 2 2 HFB42P1 4 38 X (*) HEB 4 38CHEN 4 38SW4 4 2 HFB44P1 4 50 X (*) HEB 4 50CHEN 4 50SW6 3 2 HFB63P1 4 50 X (*) HEB 4 50CHEN 4 50SW6 6 2 HFB66P1 4 62 X (*) HEB 4 62CHEN 4 62SW8 8 2 HFB88P1 4 75 X (*) HEB 4 75CHEN 4 75SW† Ordered separately from BURNDY®.* See table below when ordering assembly clampingbolts to specify correct bolt length in Cat. #.BOLT LENGTHCLAMP “J” WHEN WHEN WHEN WHEN WHEN WHEN WHEN WHENNUMBER BOLT DIA. Z = 1.25 Z = 1.50 Z = 1.75 Z = 2.00 Z = 2.25 Z = 2.50 Z = 2.75 Z = 3.00HFB22P1 3/8 (-16) 3.00 3.25 3.50 4.00 4.00 4.50 4.50 5.00HFB33P1 3/8 (-16) 3.00 3.25 3.50 4.00 4.00 4.50 4.50 5.00HFB42P1 3/8 (-16) 3.00 3.25 3.50 4.00 4.00 4.50 4.50 5.00HFB44P1 1/2 (-13) 3.25 3.50 3.75 4.00 4.50 4.50 5.00 5.00HFB63P1 1/2 (-13) 3.25 3.50 3.75 4.00 4.50 4.50 5.00 5.00HFB66P1 5/8 (-11) 3.50 4.00 4.00 4.50 4.50 5.00 5.00 5.50HFB88P1 3/4 (-10) 3.75 4.00 4.50 4.50 5.00 5.00 5.50 5.50NOTE: When ordering assembly bolts specifycorrect bolt length in catalog number asindicated in table.

BURNDY ® ProductsMechanicalTYPE HFB-NBAR CLAMP TAPPAD ADAPTERFor Copper BarA-23High conductivity copper, tap pad adapterprovides a NEMA drilled contact pad whenassembled to the HFB-P1 clamps. Tapconnections can be made from copper busbar(s) without drilling, by bolting standardmechanical or compression terminal padsdirectly to the pre-drilled tap padFig. 1Fig. 2CATALOG FIG. USE WITH ‘H’ CLAMPNUMBER NO. A-C E & F L N CATALOG NUMBER 1HFB33-4N 1 3.00 1.75 7.00 .62 HFB33P1HFB44-4N 1 4.00 1.75 9.12 1.12 HFB44P1HFB66-6N 2 6.00 1.75 11.31 1.12 HFB66P11 ‘H’ Clamp (two required per assembly) and hardware (asshown) not included with bar clamp tap pad, orderseparately.

BURNDY ® ProductsMechanicalTYPES KA-U, KKA-UA-24UNIVERSAL TERMINAL(One Conductor) For Aluminumand Copper ConductorsThese dual-rated one-conductor lugs areconstructed from high strength aluminumalloy and electro tin-plated to provide lowcontact resistance.Fig. 1 Fig. 2AL9CUFig. 3 Fig. 4WIRE RANGE STUD DIMENSIONS RECOMMENDEDCATALOG FIG. ALUMINUM OR HOLE ** ** TIGHTENING ▲NUMBER* NO. COPPER SIZE D L N W E T H TORQUE in-lbKA6U 1 14 STR. - 6 STR. .63 1.06 .25 .50 — .09 .50 45KA2U 1 14 STR. - 2 STR. .63 1.16 .31 .50 — .10 .55 501/4KA25U 1 14 STR. - 1/0 STR..81 1.50 .44 .63 — .19 .80 50KA26U 2 6 STR. - 2/0 STR. .81 1.47 .47 .63 — .19 .80 120KA29U 2 6 STR. - 250 .94 2.00 .50 1.00 — .25 1.13 2755/16KA30U 2 6 STR. - 300.94 2.00 .50 1.00 — .25 1.12 275KA31U 2 6 STR. - 350 1.03 2.25 .88 1.13 — .25 1.25 375KA34U 2 4 STR. - 500 3/8 1.50 2.81 .88 1.51 — .31 1.58 500KA36U 2 2 STR. - 600 1.72 3.19 .78 1.50 — .44 1.56 500KA40U 2 300 - 800 1.69 3.38 .88 1.75 — .50 1.94 5001/2KA44U 2 500 - 10001.69 3.38 .88 1.75 — .50 1.94 600KKA31U-2N 3 6 STR. - 350 3.16 5.50 .63 1.25 1.75 .38 1.50 375KA36U-2N 4 2 STR. - 600 3.22 4.69 .63 1.50 1.75 .44 1.57 5001/2KA40U-2N 4 300 - 8003.03 4.75 .63 1.75 1.75 .50 1.94 500KA44U-2N 4 500 - 1000 3.03 4.75 .63 1.75 1.75 .50 1.94 600* "N" indicates NEMA standard stud holes.▲ Listed torque values are for maximum conductor sizesaccommodated. Consult UL486 Tables 7-4, 7-5, 7-6 forsmaller conductor sizes.** Maximum dimension.

BURNDY ® ProductsMechanicalTYPE K2A-UUNIVERSAL TERMINAL(Two Conductor)For Aluminum andCopper ConductorsA-25These dual-rated two-conductor lugs are constructedfrom high strength aluminum alloyand electro tin-plated to provide low contactresistance.Fig. 1 Fig. 2Fig. 3WIRE RANGE STUD DIMENSIONS RECOMMENDEDCATALOG FIG. ALUMINUM OR HOLE ** ** TIGHTENING ▲NUMBER* NO. COPPER SIZE D L N W E T H TORQUE in-lbK2A25U 1 Two: 14 STR. - 1/0 STR. .81 1.47 .44 1.13 — .19 .79 501/4K2A26U 2 Two: 14 STR. - 2/0 STR..81 1.47 .44 1.25 — .19 .79 50K2A29U 2 Two: 6 STR. - 250 3/8 1.50 2.56 .50 1.66 — .25 1.20 275K2A31U 2 Two: 4 STR. - 350 1.69 2.88 .88 1.94 — .25 1.25 2751/2K2A36U 2 Two: 2 STR. - 6001.75 3.20 .63 2.41 — .44 1.58 375K2A40U 2 Two: 300 - 800 1.66 3.38 .88 3.19 — .50 1.94 3755/8K2A44U 2 Two: 500 - 10001.66 3.50 .88 3.52 — .50 1.94 375K2A31U-2N 3 Two: 6 STR. - 350 3.00 4.50 .63 2.31 1.75 .31 1.38 275K2A36U-2N 3 Two: 2 STR. - 600 3.22 4.69 .63 2.41 1.75 .44 1.56 3751/2K2A40U-2N 3 Two: 300 - 8003.03 4.75 .63 3.19 1.75 .50 1.94 375K2A44U-2N 3 Two: 500 - 1000 3.03 4.75 .63 3.19 1.75 .50 1.94 375* "N" indicates NEMA standard stud holes.▲ Listed torque values are for maximum conductor sizesaccommodated. Consult UL486 Tables 7-4, 7-5, 7-6 forsmaller conductor sizes.** Maximum dimension.

BURNDY ® ProductsMechanicalTYPES K3A-U, KK3A-UA-26UNIVERSAL TERMINAL(Three Conductor)For Aluminum andCopper ConductorsDual-rated three-conductor lugs are constructedfrom high strength aluminum alloyand electro tin-plated to provide low contactresistance.Fig. 1 Fig. 2AL9CUFig. 3WIRE RANGE STUD RECOMMENDEDCATALOG FIG. ALUMINUM OR HOLE DIMENSIONS TIGHTENING ▲NUMBER* NO. COPPER K SIZE D L N W E T H TORQUE in-lbK3A2U-2* 1 Three: 14 STR. - 2 STR. 11/32 5/16 1.63 2.19 .34 1.59 .88 .19 .62K3A25U-2* 1 Three: 14 STR. - 1/0 STR. 7/16 3/8 2.09 2.91 .34 1.94 1.00 .25 .88 50K3A26U-2N 3 Three: 14 STR. - 2/0 STR. 3.06 3.75 .63 1.95 .19 1.79K3A27U-2N 3 Three: 6 STR. - 3/0 STR. 3.00 3.88 .63 2.81 .31 1.12K3A29U-2N 3 Three: 6 STR. - 250 3.00 4.00 .63 2.81 .31 1.19 275K3A31U-2N 3 Three: 6 STR. - 350 3.00 4.31 .63 3.00 .31 1.389/16 1/21.75K3A36U-2N 3 Three: 2 STR. - 6003.22 4.69 .63 3.63.44 1.56KK3A36U-2N 2 Three: 2 STR. - 600 3.00 5.63 .56 4.22 .44 1.69KK3A40U-2N 2 Three: 300 - 800 3.03 5.69 .63 4.81 .50 1.94375KK3A44U-2N 2 Three: 500 - 1000 3.34 6.19 .63 4.75 .56 1.88* Slotted screw.** ‘‘N” indicates NEMA standard stud holes.▲ Listed torque values are for maximum conductor sizesaccommodated.Consult UL486 Tables 7-4, 7-5, 7-6 for smaller conductorsizes. All 4N items See note page A-2

BURNDY ® ProductsMechanicalTYPES K3A-U, KK3A-U(Continued)A-27AL9CUFig. 1 Fig. 2Fig. 3 Fig. 4WIRE RANGE STUD RECOMMENDEDCATALOG FIG. ALUMINUM OR HOLE DIMENSIONS TIGHTENING ▲NUMBER** NO. COPPER K SIZE D L N W E T H TORQUE in-lbK3A2U-4* 3 Three: 14 STR. - 2 STR. 11/32 5/16 1.63 2.19 .34 1.59 .88 .19 .62K3A25U-4* 3 Three: 14 STR. - 1/0 STR. 7/16 3/8 2.09 2.91 .34 1.94 1.00 .25 .8850K3A27U-4N 3 Three: 6 STR. - 3/0 STR. 3.00 3.88 2.81 .31 1.12K3A29U-4N 3 Three: 6 STR. - 250 3.00 4.00 2.81 .31 1.19 275K3A31U-4N 3 Three: 6 STR. - 350 3.00 4.31 3.00 .31 1.38K3A36U-4N 3 Three: 2 STR. - 600 3.22 4.69 3.63 .44 1.569/16 1/2.631.75K3A40U-4N 3 Three: 300 - 8003.03 4.754.81.50 1.94 375KK3A36U-4N 4 Three: 2 STR. - 600 3.00 5.63 4.22 .44 1.69KK3A40U-4N 4 Three: 350 - 800 3.34 6.19 5.34 .56 1.88 275KK3A44U-4N 4 Three: 500 - 1000 3.34 6.19 4.75 .56 1.88 375* Slotted screw** ‘‘N” indicates NEMA standard stud holes.▲ Listed torque values are for maximum conductor sizesaccommodated. Consult UL486 Tables 7-4, 7-5, 7-6 forsmaller conductor sizes.All 4N items See note page A-2

BURNDY ® ProductsMechanicalTYPES K4A-U, KK4A-UA-28UNIVERSAL TERMINAL(Four Conductor)For Aluminum andCopper ConductorsThese dual-rated four conductor lugs areconstructed from high strength aluminumalloy and electro tin-plated to provide lowcontact resistance.Fig. 1 Fig. 2AL9CUWIRE RANGE STUD RECOMMENDEDCATALOG FIG. ALUMINUM OR HOLE DIMENSIONS TIGHTENING ▲NUMBER* NO. COPPER SIZE D L N W E T H TORQUE in-lbK4A29U-4N 1 Four: 6 STR. - 250 3 4 3.69 .31 1.19275K4A31U-4N 1 Four: 6 STR. - 350 3 4.31 5.04 .31 1.381/2.631.75KK4A36U-4N 2 Four: 2 STR. - 6003.34 5.635.44 1.69375KK4A40U-4N 2 Four: 300 - 800 3 6.19 6 .56 1.88* ”N” indicates NEMA standard stud holes.All 4N items See note page A-2TYPES K11A-U,K21A-U, K22A-UUNIVERSAL TERMINALFor Aluminum andCopper ConductorsDual-rated panelboard lugs are constructedfrom high strength extruded aluminum alloyand electro tin-plated to provide low contactresistance.Fig. 1Fig. 2Fig. 3Fig. 4 Fig. 5AL9CUWIRE RANGE STUD RECOMMENDEDCATALOG FIG. ALUMINUM OR HOLE DIMENSIONS TIGHTENING ▲NUMBER* NO. COPPER SIZE D L N W E T H TORQUE in-lbK11A30U* 1 Two: 6 STR. - 300 5/16 .94 3.00 .47 1.00 — .31 2.00 275K11A34U-2 2 Two: 4/0 STR. - 500 1/4 2.91 .25 1.44 .69 .63 2.38K11A36U-2 3 Two: 2 STR. - 600 1.50K21A36U-2 4 Three: 2 STR. - 600 2.502.31K22A36U-2 5 Four: 2 STR. - 600 3/84.91 .38 2.50 1.38 .75 3.00375K11A39U-2 3 Two: 1/0 STR. - 750 1.69K22A39U-2 5 Four: 1/0 STR. - 750 3.06* Not CSA Listed.▲Listed torque values are for maximum conductor sizesaccommodated. Consult UL486 Tables 7-4, 7-5, 7-6 forsmaller conductor sizes.

BURNDY ® ProductsMechanicalTYPE KAU-KITTRANSFORMER LUG KITThese dual-rated lugs are constructed fromhigh strength aluminum alloy and electro tinplatedto provide low contact resistance.Lugs and mounting hardware packagedtogether in these kits.A-29Features and Benefits• UL listed AL9CU dual rated set screwterminals and CSA certified. Ensure the transformer feeders andtaps are terminated properly.• Plated steel cap screws and hex nutswith captive conical washers or individualBelleville washers. Terminal to bus connections are madeusing proper hardware resulting in truetorque to pressure performance.Compensates for dissimilar metalexpansion and contraction.• Hardware packed in plastic bag. No lost hardware prior to installation.• Larger 800 kcmil lugs in KIT3 and KIT4. Accommodates common 750 kcmil tapconductors in larger transformers.TERMINALS WIRE RANGECATALOG TRANSFORMER CATALOG ALUMINUM HARDWARENUMBER KVA RATING QTY. NUMBER OR COPPER QTY. BOLT SIZE QTY. NUT QTY. WASHERKAU-KIT115 - 37.5 1Ø 8 KA2U #14 - 215 - 45 3Ø 4 KA29U #6 - 2508 1/4-20 3/4 HH 8 1/4 20 HN — Captive to NutKAU-KIT250 - 75 1Ø 8 1/4-20 3/4 HH12 KA29U #6 - 25075 - 112.5 3Ø8 1/4-20 2 HH16 1/4 20 HN — Captive to NutKAU-KIT3100 - 167 1Ø 6 K2A31U #6 - 350 5 1/2-13 3 HH 22 1/2 FW11 1/2-13 HN150 - 300 3Ø 7 K2A40U 300 - 800 6 1/2-13 2-1/2 HH11 1/2 BellevilleKAU-KIT4 400 - 500 3Ø 15 K2A40U 300 - 8007 1/2-13 2 22 1/2 FW11 1/2-13 HN4 1/2-13 2-1/211 1/2 Belleville

BURNDY ® ProductsMechanicalTYPE AMSA-30DUAL RATEDSPLICER/REDUCERFor Copper andAluminum CableAll splicer/reducers are dual rated for use withaluminum and copper conductors and areconstructed from high strength, tin platedaluminum. PENTROX oxide inhibiting jointcompounds are recommended for allaluminum applications.Features and Benefits• All connectors are tin-plated. Provide low contact resistance andprevents galvanic corrosion.• Connectors feature rounded bottoms. Facilitates taping.• Solid center barrier. Prevents contact of dissimilar metals.• Large screw diameters. Ensures greater surface contact withwires for maximum pullout force.• Large cable ranges. Each splice is also an effectivereducing connector.CATALOG WIRE RANGE NO. OF SCREW HEXNUMBER MAX. MIN. L W H1 H2 MAX. SCREWS DIA. SIZEAMS-2* 2 14 1-19/32 9/16 9/16 .79 2 3/8 SAMS-0* 1/0 14 1-29/32 3/4 3/4 .86 2 7/16 SAMS-4/0 4/0 6 2-5/16 1 1-3/32 1.28 2 9/16 5/16AMS-250 250 6 4-3/32 1 1-3/32 1.29 4 5/8 5/16AMS-350 350 6 4-11/32 1 1-3/32 1.30 4 11/16 5/16AMS-500 500 3/0 4-25/32 1-1/4 1-3/8 1.48 4 13/16 3/8AMS-750 750 250 6-1/16 1-7/16 1-5/8 1.98 4 15/16 1/2AMS-1000 1000 500 8-11/16 1-21/32 1-7/8 2.34 6 1-1/8 9/16* Slotted Screws. H2 measured with maximum conductors,reference only.Complies with NFPA 78-86.

BURNDY ® ProductsMechanicalTYPE AGSKITABOVE GRADE SPLICE KITSFor all Aluminum orCopper/AluminumCombinationsA-31Type AGS Above Grade Splice Kit consists ofa standard AMS splice/reducer and a heavywall heat-shrink sleeve. The AMS Splice isdual rated for use with aluminum and copperconductors and are constructed from highstrength, tin plated aluminum that provideslow contact resistance and reduces theeffects of galvanic corrosion. Connector isinstalled with common installation tools. Theheavy wall heat shrink sleeve is lined withadhesive material, providing a positive sealagainst moisture egress. Heat shrink sleeveis installed with standard propane torch, orelectric heat gun.Fig. 1 Fig. 2Catalog Figure Wire RangeNumber Number Maximum MinimumAGSKIT2 1 2 8AGSKIT250 2 250 1TYPE UGSKITWATERTIGHT/UNDERGROUNDSPLICE KITSFor all Aluminum orCopper/AluminumCombinationsType UGS Watertight Underground Splice Kitconsists of a standard AMS splice/reducerand two heavy wall heat-shrink sleeves. TheAMS Splice is dual rated for use withaluminum and copper conductors and areconstructed from high strength, tin platedaluminum that provides low contact resistanceand reduces the effects of galvaniccorrosion. Connector installed with commoninstallation tools. Both heavy wall heat shrinksleeves are lined with adhesive material,providing a watertight splice that can withstandabrasions that may occur during directburial applications. Heat shrink sleeveinstalled with standard propane torch, or electricheat gun.Fig. 1 Fig. 2Catalog Figure Wire RangeNumber Number Maximum MinimumUGSKIT2* 1 2 8UGSKIT250* 2 250 1*UL486D Listed for Direct Burial

BURNDY ® ProductsMechanicalTYPE UGSKIT8A-32UF DIRECT BURIALSPLICE KITType UGS UF Splice Kit consists of a UFsplice connector and a heavy wall heat-shrinksleeve. The UF splice connector can accommodateup to four UF conductors and isinstalled with common installation tools. Theheavy wall heat shrink sleeve is lined with anadhesive material, providing a watertightsplice that can withstand abrasions that mayoccur during direct burial applications. Heatshrink sleeve installed with standard propanetorch, or electric heat gun.CatalogNumberUGSKIT8**UL486D Listed for Direct BurialWire RangeCopper8 AWG –14 AWGTYPE UGS350ULDBIN-LINE SPLICE/REDUCERFor Direct BurialFeatures and Benefits• EPDM rubber covered 6061-T6 aluminumconnector.• Dual rated AL9CU for copper or aluminumconductor.• UL Listed and CSA Certified for DirectBurial.• Broad range taking capability.• Low installation cost.CATALOG LENGTH HEIGHT TORQUENUMBER WIRE RANGE In. [mm] In. [mm] HEX SIZE (In. Lbs.)UGS350ULDB12 AWG - 350 kcmil8.50 2.81[216] [71.4]5/16 350Dimensions in brackets [ ] are in millimeters.

BURNDY ® ProductsMechanicalTYPE QGFLBARTAPFor Copper Cable To FlatA-33High copper alloy BARTAP for joining arange of cable to bar or pad. One-wrenchinstallation.CATALOG COPPER TNUMBER CONDUCTOR B H J (MAX.) WQGFL1CB1 1-7/8 1/410 SOL. - 1 STR. 1-1/81QGFL1CB1T62-3/8 3/43/8QGFL26B1 2-1/81/4QGFL26B1T6 1-1/4 2-5/8 3/48 SOL. - 2/0 STR.QGFL26B2*2-1/2 1/41-1/8QGFL26B2T6* 2-1/8 3/41-1/2QGFL29B1*2-5/8 1/46 STR. - 2501-3/8QGFL29B1T6*3-1/8 3/41-5/8QGFL31B1*2-7/8 1/42 SOL. - 3501-5/8QGFL31B1T6*3-1/4 3/41-3/4QGFL34B13-1/8 1/41/0 SOL. - 500QGFL34B1T63-5/8 3/421/21-3/4QGFL39B13-1/41/4350 - 750QGFL39B1T63-5/8 3/4QGFL44B1 3-3/8 1/4750 - 1000QGFL44B1T64-1/8 3/42-1/8QGFL46B1 2-1/4 4 1/41000 - 1500QGFL46B1T64-1/2 3/42-1/2QGFL48B1 5-1/4 1/41500 - 2000QGFL48B1T65-1/4 3/43* Can be installed side by side or in-line on NEMA drilled bar.

BURNDY ® ProductsMechanicalTYPE FCBA-34TRANSFORMERTAP ADAPTERFor Copper and AluminumSilver brazed 101% conductivity coppertransformer tap adapter designed to accommodatefrom 1 to 6 NEMA drilled copper oraluminum terminal taps from a singlesecondary transformer outlet. Tin-plated.Order mounting hardware & tap terminalsseparately.Fig. 1FIG. CATALOG A HNO. NUMBER DIA. REF. L P1 FCB63-4N .50 5.25 3.75 2.252 FCB63-6N .50 5.25 5.50 2.251 FCB64-4N .75 5.75 4.00 2.752 FCB64-6N .75 5.75 5.75 2.751 FCB65-4N 1.00 7.00 4.25 4.002 FCB65-6N 1.00 7.00 6.00 4.00FCB63-2NP300 .50 5.00 3.50 3.004 FCB64-44NP50 .75 9.00 5.00 5.00NOTE: All pads are NEMA drilled.Fig. 2

BURNDY ® ProductsMechanicalTYPE KPU-ACPOLYTAPInsulated Gutter Tap for AllCopper and AluminumCombinationsA-35Wide range-taking tin-plated aluminum parallelclamp and insulating cover assembly forindustrial and multiple story structure applications.Only six connectors cover the entire 14Sol.-750 kcmil range. Covers having flexiblefingers that conform to conductor, fully insulatingthe connection. UL486B listed for 600volts maximum 90° C service. Cover andconnector are packaged together. No tapingrequired.600 Volt Max. 90° CCONDUCTORRECOMMENDEDCATALOG COPPER OR ALUMINUM TIGHTENINGNUMBER RUN TAP W H L TORQUE in-lbKPU29A26AC 1/0 STR. - 250 14 SOL. - 2/0 STR.KPU29A29AC 1/0 STR. - 250 6 STR. - 2504 2-11/16 3-1/8 375KPU34A26AC 4/0 STR. - 500 14 SOL. - 2/0 STR.KPU34A34AC 4/0 STR. - 500 6 STR. - 5004-11/32 1-7/8 3-1/2 450KPU39A26AC 500 - 750 14 SOL. - 2/0 STR.KPU39A39AC 500 - 750 1/0 STR. - 7504-13/16 3-1/4 600▲ Listed torque values are for maximum conductor combinationsaccommodated. Consult UL486 Tables 7-4, 7-5, 7-6for smaller combinations.See note page A-2.TYPE UCU-ACRISER TAPParallel-groove riser tap and insulation coverfor copper and aluminum. Wide range-takingassembly for apartment house and lightindustrial applications. Cover and connectorare packaged together. Covers having insulatingfingers that conform to conductors, fullyinsulating the connection. UL486B Listed for600 volts max. 90° C service.600 VOLT MAX. 90° C MAX.RECOMMENDEDCATALOG CONDUCTOR TIGHTENING ▲NUMBER RUN TAP W H L TORQUE in-lbUCU28AC 2 STR. - 4/0 STR. 10 SOL. - 2 STR. 2-1/4 1-13/16 2-5/8 120▲ Listed torque values are for maximum conductorcombinations accommodated. Consult UL486 Tables 7-4,7-5, 7-6 for smaller combinations.

BURNDY ® ProductsMechanicalTYPE BIPCA-36UL Listed 90° C, *600 VoltThe TYPE BIPC, Burndy Insulation PiercingConnector is ideally suited for splicing andtapping aluminum and copper conductor wiresizes: #10 AWG to 500 kcmil. The BIPC'sunique insulation piercing design allows foruse on hot-line applications, eliminating theneed for taping.Features and Benefits• Insulation piercing capability. Eliminates the need for conductorinsulation stripping.• UL486B listed, AL9CU rated. For copper and aluminum conductorcombinations up to 90° *600 Voltapplications.• Insulation piercing design. For use on hot-line applications.Eliminates the need for taping.• Easy snap-out tabs. Eases installation, protects connectionfrom dirt and debris.• Simple bolt-on connection. Eases installation.Fig. 1 Fig. 2MAX.CATALOG CONDUCTOR RANGE BOLT SOCKET FIG. DIMENSIONS RECOMMENDED VOLTAGENUMBER RUN TAP SIZE SIZE NO. H L W TORQUE (N,m) RATINGBIPC1/0-21/0 - 8 AWG 2 - 8 AWG 2.00 1.53 2.56 180 in. lbs.[50 - 6 mm 2 ] [35 - 6 mm 2 5/16-18 1/2 1][51] [39] [65] [20.3 N.m]600VBIPC4/0-64/0 - 1/0 AWG 1/0 - 6 AWG 2.50 2.12 2.00 250 in. lbs.[95 - 50 mm 2 ] [50 - 16 mm 2 5/16-18 1/2 2][64] [54] [51] [28.3 N.m]300VBIPC4/0-1/04/0 - 1/0 AWG 4/0 - 1/0 AWG 2.50 2.12 2.06 250 in. lbs.[95 - 50 mm 2 ] [95 - 50 mm 2 5/16-18 1/2 2][64] [2.12] [52] [28.3 N.m]300VBIPC350-4/0350 - 4/0 AWG 4/0 - 10 AWG 3.00 1.59 2.50 375 in. lbs.[185 - 95 mm 2 ] [95 - 6 mm 2 3/8-16 9/16 1][76] [40] [64] [42.4 N.m]300VBIPC350-350350 - 4/0 AWG 350 - 4/0 AWG 3.00 2.62 2.75 300 in. lbs.[185 - 95 mm 2 ] [185 - 95 mm 2 3/8-16 9/16 2][76] [67] [70] [33.9 N.m]300VBIPC500-4/0500 - 350 kcmil 4/0 - 4 AWG 3.25 1.59 2.62 400 in. lbs.[240 - 185 mm 2 ] [95 - 25 mm 2 3/8-16 9/16 1][83] [40] [67] [45.2 N.m]600V

BURNDY ® ProductsMechanicalSPEC-BLOKPOWERDISTRIBUTIONCONNECTORSUnique, modular, made-to-order, powerdistributionassemblies accommodate anynumber of supply and load conductors in anynumber of poles. Capacity matches the conductorsaccommodated and SPEC-BLOKassures uniform loading.A-37Adjacent poles are separated by easy-tohandle,wrap-around insulating covers whicheliminate taping and reduce heat build-up byallowing air to flow freely around connectors.SPEC-BLOK is UL Listed for copper oraluminum conductors for 600 volts. (AL9CU)Assemblies are mounted on platforms suitablefor easy installation in wireway orjunction box.Features and Benefits• Accommodate unlimited conductors. Fits wide range of applications.Eliminates need for non-UL-listedimprovisation.• Connector elements tin-plated. Provides high reliability, low-resistanceconnections.• User friendly, space-saving design. Easy to install. Saves labor.• 94-VO rated insulation folds into placeinsulating the components. Saves time and material. Allowseasy installation.• Connector caps removable for easycable lay-in. Saves labor. Makes installation easier.Allows installation or straight-throughconductors. Eases retrofit.• Belleville washers built-in on pressurescrew assemblies, except in assembliesinstalled with a 5/32" Allen wrench. Provides high-integrity connections.• Conductors can be cut or fed straightthrough. Straight through installation ideal forriser applications.Contact Burndy or Technical Services, 1-800-451-4956or Burndy Customer Service, 1-800-346-4175

BURNDY ® ProductsMechanicalA-38SPEC-BLOKFeatures and Benefits• The SPEC-BLOK system includes12 connector elements A wide variety of conductor sizes canbe accommodated• Each element can be bolted togetherin parallel Provides an efficient flow of current fromone element to another• AL9CU rated for Copper or Aluminumconductors Dual-rated system, with UL486B’shighest temperature rating• 2 Wire (series), 4 (parallel), and Multi-Tapversions available Nearly any conductor combination canbe terminated• Tin-plated Aluminum Alloy Construction High-strength, corrosion-resistantconnector elements• All SPEC-BLOKs are custom made fornearly any Power Distribution systemrequirement Time savings — pre-assembled in ourfactory for immediate installation!EW D TSPEC-BLOK CONNECTORSC S B R A Q U PCATALOG DESIGNATION(MAXIMUMCONDUCTOR)4ConductorA2ConductorQNUMBER OFCONDUCTORSACCOMMODATED4Conductor2ConductorAL or CUWIRE RANGE UNDEREACH CAPFirstConductorsMUST BeSecondConductor(ifrequired)May Be1/0-2/0#12-2/ 0(2/0)B R 3/0-250#6-250(250)C S 1 to 4 (0, 11 or 2250-350#6-350or 2(350)per capper cap)D T 400-500#6-500(500)E W 600-7503/0-750(750)Height OnMaxConductorsDIMENSIONSWidthLength Without Insulator4Conductor2ConductorALLENWRENCHSIZE2-9/161-1/2 2-1./8 7 / 8 5/32"3-1/81-11/164-1/4 1-3/ 83-5/161-13/164-5/8 1-1/ 24-1/162 5-5/8 1-3/ 44-7/82-1/4 7-1/4 2-5/ 81/4"3/8"Catalog Designation(Maximum Conductor)P (1/0)U (1/0 & 500)Number of ConductorsAccommodated1 to 8 (0, 1 or 2 undereach screw)LargeGrooveSmallGrooves**Height OnMaximumConductorsWidth__ 6-1/0 3 1/2 22 to 9 (0, 1 or 2 undereach screw plus onelarge conductor) 3/0-500 6-1/0 4 1/8 2LengthWithoutInsulatorAllenWrenchSize1 3/4 5/32"** This range may be expanded to include #8 provided twoconductors are being installed in that particular element.

BURNDY ® ProductsMechanicalSPEC-BLOKMOUNTING PLATFORMSSPEC-BLOK Mounting Platforms are rigidsteel construction with a black finish. Theycan be supplied for junction box mounting orwireway construction allowing trough conductorsto pass underneath the assemblies.(CPB-)(CPT-)A-39CATALOG L L WNUMBER (Nominal) (Overall) (Overall)CPB6 6 7-3/4 2-1/2CPB8 8 9-3/4 2-1/2CPB10 10 11-3/4 2-1/2CPB12 12 13-3/4 3-1/2CPB16-5/8 16-5/8 18-3/8 3-1/2CPB21-1/4 21-1/4 23 3-1/2CATALOGNUMBER L W HCPT6 5-7/8 2-1/2 2-1/4CPT8 7-7/8 3-1/2 3CPT10 9-7/8 3-1/2 3-1/2CPT12 11-7/8 3-1/2 4CPT16 15-7/8 3-1/2 4SPEC-BLOK catalog numbers describe exactly how the distribution block is assembled:5DR-NDST-GQP-12(assembly pictured)5 Total number of poles in thecompleted assemblyDR One 'D' unit and one 'R' unit, boltedin parallel, forming each phase pole(3 phase poles)N Denotes the beginning of the neutralpole (where required)DST One 'D' unit, one 'S' unit, and on 'T'unit, bolted in parallel, forming theneutral poleGQPDenotes the beginning of the groundpole description (where required)One 'Q' unit and on 'P' unit, bolted inparallel, forming the ground pole.12 Size (inches) of the wireway or troughthat is needed to enclose the assembly.If a junction box enclosure is used,no number is used to denote the sizeof the enclosure.SPEC-BLOK IS A SYSTEM THAT CAN SOLVE MOST POWER DISTRIBUTION APPLICATIONS!

BURNDY ® ProductsMechanicalA-40QUESTIONNAIREFOR SPEC-BLOKOR ELECTRO-RAILAPPLICATIONSWhat is the total capacity of the system?_____________ampsHow many poles in the system(3-wire, 4-wire, single phase, etc.)?_____________polesAre neutral conductors (when required) different sizes (AWG/KCMil)than the phase conductors?Are any conductors continuous? ■ Yes ■ NoIf yes, which ones?_______________________________________________________________________________________What kind of enclosure is connection assembly being mounted intoand what are inside space dimensions?_________the same size__________different sizeTrough size _________________________________________Is a ground connection required? ■ Yes ■ NoWhat are the quantities, sizes (AWG/kcmil) and material (Al/Cu)of the incoming line conductors and outgoing load conductors?CONDUCTORTYPEQUANTITY SIZE (Cu/Al)Box, panel, cabinet, other size___________________________When is a quotation required? Date:______________________When is the material required? Date:_____________________Is there a preference for a particularBurndy distributor? ■ Yes ■ NoPERPHASEPERNEUTRALLINELOADLINELOADIf yes, give name, location & telephone Number:Name:______________________________________________Address:______________________________________________________________________________________________Phone #:____________________________________________PERGROUNDLINELOAD

BURNDY ® ProductsMechanicalVERSI-POLEPOWER DISTRIBUTIONBLOCKSA-41VERSI-POLE Power Distribution Blocksare designed to provide modular solutions topower distribution applications. Each connectorelement is made from a high conductivityaluminum alloy which is insulated with a highstrength polymer housing. One, two, andthree pole versions available. "Add" a pole(snap-together) blocks are also available forwire sizes up to 500 kcmil. For use with Cu orAl. 600 V, AL9CU rated.VERSI-POLE SNAP-TOGETHER BLOCKSFeatures and Benefits• "Add" a pole feature available. Provides capability to create as manypoles as required.• Up to 30 tap conductors accommodated. Ideal for current distribution to multiplelocations.• Single or dual run connections. Allows user to minimize the numberof connectors needed to do the job.• Suitable for use with aluminum orcopper conductors. Provides maximum versatility.• 600 V, AL9CU rated.* Meets or exceeds industry standardrequirements.• Dead-front covers available Provides user protection – one coverper pole.* BDB-430-500-1 not UL recognized or CSA certifiedRUN TAP AMPERECATALOG CONNECTOR WIRE RANGE WIRE RANGE RATING PER NUMBER OFNUMBER RUN TAP AL9CU AL9CU POLE POLESBDA-112-350 350 kcmil - 6 4 - 14 350 ADDERBDA-16-350 350 kcmil - 6 2/0 - 14 350 ADDERBDA-16-500 500 kcmil - 4 2/0 - 4 430 ADDERBDA-26-350 350 kcmil - 6 2/0 - 14 700 ADDERBDA-212-500 500 kcmil - 4 4 - 14 860 ADDERBDA-26-500 500 kcmil - 4 2/0 - 14 860 ADDERBDA-24-500 500 kcmil - 4 4/0 - 6 860 ADDERBDA-11-500 500 kcmil - 4 500 kcmil - 4 430 ADDERBDA-22-350 350 kcmil - 6 350 kcmil - 6 700 ADDERBDA-22-500 500 kcmil - 4 500 kcmil - 4 860 ADDERNOTES:1. Order Optional BDB COVER1 per pole if desired.2. Snap-together blocks can also be assembled to 1, 2, 3pole blocks to create multi-pole distribution blocks.

BURNDY ® ProductsMechanicalVERSI-POLEA-42VERSI-POLE 1, 2, 3 POLEDISTRIBUTION BLOCKSRUN TAP AMPERE OPTIONALCATALOG CONNECTOR WIRE RANGE WIRE RANGE RATING PER NUMBER OF COVER ORDERNUMBER RUN TAP AL9CU AL9CU POLE POLES 1 PER POLEBDB-16-2/0-1 1BDB-16-2/0-2 2/0 - 12 4 - 14 195 2 BDBCOVER2BDB-16-2/0-3 3BDB-26-2/0-1 1BDB-26-2/0-2 2/0 - 14 2 - 14 390 2 BDBCOVER2BDB-26-2/0-3 3BDB-112-350-1 1BDB-112-350-2 350 kcmil - 6 4 - 14 350 2 BDBCOVER1BDB-112-350-3 3BDB-16-350-1 1BDB-16-350-2 350 kcmil - 6 2/0 - 14 350 2 BDBCOVER1BDB-16-350-3 3BDB-14-500-1 1BDB-14-500-2 500 kcmil - 4 2/0 - 14 430 2 BDBCOVER2BDB-14-500-3 3BDB-16-500-1 1BDB-16-500-2 500 kcmil - 4 2/0 - 14 430 2 BDBCOVER1BDB-16-500-3 3BDB-162-500-1 1BDB-162-500-2 500 kcmil - 4 2 - 14 430 2 BDBCOVER2BDB-162-500-3 3BDB-26-350-1 1BDB-26-350-2 350 kcmil - 6 2/0 - 14 700 2 BDBCOVER1BDB-26-350-3 3BDB-212-500-1 1BDB-212-500-2 500 kcmil - 4 4 - 14 860 2 BDBCOVER1BDB-212-500-3 3BDB-26-500-1 1BDB-26-500-2 500 kcmil - 4 2/0 - 14 860 2 BDBCOVER1BDB-26-500-3 3BDB-24-500-1 1BDB-24-500-2 500 kcmil - 4 4/0 - 6 860 2 BDBCOVER1BDB-24-500-3 3

BURNDY ® ProductsMechanicalVERSI-POLEVERSI-POLE 1, 2, 3SPLICE/REDUCER BLOCKSA-43RUN TAP AMPERE OPTIONALCATALOG CONNECTOR WIRE RANGE WIRE RANGE RATING PER NUMBER OF COVER ORDERNUMBER RUN TAP AL9CU AL9CU POLE POLES 1 PER POLEBDB-11-2/0-1 1BDB-11-2/0-2 2/0 - 14 2/0 - 14 195 2 BDBCOVER2BDB-11-2/0-3 3BDB-11-350-1 1BDB-11-350-2 350 kcmil - 6 350 kcmil - 6 350 2 BDBCOVER2BDB-11-350-3 3BDB-11-500-1 1BDB-11-500-2 500 kcmil - 6 500 kcmil - 6 430 2 BDBCOVER1BDB-11-500-3 3BDB-22-2/0-1 1BDB-22-2/0-2 2/0 - 14 2/0 - 14 390 2 BDBCOVER2BDB-22-2/0-3 3BDB-22-350-1 1BDB-22-350-2 350 kcmil - 6 350 kcmil - 6 700 2 BDBCOVER1BDB-22-350-3 3BDB-22-500-1 1BDB-22-500-2 500 kcmil - 4 500 kcmil - 4 860 2 BDBCOVER1BDB-22-500-3 3SNAP TOGETHERSPLICER/REDUCERBLOCKSRUN TAP AMPERE OPTIONALCATALOG CONNECTOR WIRE RANGE WIRE RANGE RATING PER NUMBER OF COVER ORDERNUMBER RUN TAP AL9CU AL9CU POLE POLES 1 PER POLEBDC-14-2/0-1 2/0 - 14 4 - 14 195 1 BDBCOVER3BDA-14-2/0-1 2/0 - 14 4 - 14 195 ADDER BDBCOVER3BDC-11-2/0-1 2/0 - 14 2/0 - 14 195 1 BDBCOVER3BDA-11-2/0-1 2/0 - 14 2/0 - 14 195 ADDER BDBCOVER3

BURNDY ® ProductsMechanicalVERSI-POLE(Continued)A-44VERSI-POLE 1, 2, 3SPLICE/REDUCER BLOCKSThese tables and illustrations refer to VERSI-POLE Power Distribution Blocks listed onpages A-48 through A-50.THE FIGURE TO THE LOWER RIGHT IS APPLICABLE TO THE FOLLOWING:Catalog Number Number of Poles Catalog Number Number of PolesBDA-11-500 1 (adder) BDB-16-500-3 3BDA-112-350 1 (adder) BDB-212-500-1 1BDA-16-350 1 (adder) BDB-212-500-2 2BDA-16-500 1 (adder) BDB-212-500-3 3BDA-212-500 1 (adder) BDB-22-350-1 1BDA-22-350 1 (adder) BDB-22-350-2 2BDA-22-500 1 (adder) BDB-22-350-3 3BDA-24-500 1 (adder) BDB-22-500-1 1BDA-26-350 1 (adder) BDB-22-500-2 2BDA-26-500 1 (adder) BDB-22-500-3 3BDB-11-500-1 1 BDB-24-500-1 1BDB-11-500-2 2 BDB-24-500-2 2BDB-11-500-3 3 BDB-24-500-3 3BDB-112-350-1 1 BDB-26-350-1 1BDB-112-350-2 2 BDB-26-350-2 2BDB-112-350-3 3 BDB-26-350-3 3BDB-16-350-1 1 BDB-26-500-1 1BDB-16-350-2 2 BDB-26-500-2 2BDB-16-350-3 3 BDB-26-500-3 3BDB-16-500-1 1 BDB-430-500-1 1BDB-16-500-2 2NO. OF DIMENSIONS APOLESINCHESAdder 2.501 2.812 5.313 7.81N (2.50 X N) + .31Example for 10 poles:A = (2.50 X 10) + .31 = 25

BURNDY ® ProductsMechanicalVERSI-POLE(Continued)VERSI-POLE 1, 2, 3SPLICE/REDUCER BLOCKSA-45These tables and illustrations refer to VERSI-POLE Power Distribution Blocks listed onpages A-48 through A-50.THE FIGURE TO THE RIGHT ISAPPLICABLE TO THE FOLLOWING:Catalog NumberBDB-11-2/0-1 1BDB-11-2/0-2 2BDB-11-2/0-3 3BDB-11-350-1 1BDB-11-350-2 2BDB-11-350-3 3BDB-14-500-1 1BDB-14-500-2 2BDB-14-500-3 3BDB-16-2/0-1 1BDB-16-2/0-2 2BDB-16-2/0-3 3BDB-162-500-1 1BDB-162-500-2 2BDB-162-500-3 3BDB-22-2/0-1 1BDB-22-2/0-2 2BDB-22-2/0-3 3BDB-26-2/0-1 1BDB-26-2/0-2 2BDB-26-2/0-3 3Number of PolesNO. OF DIMENSIONS APOLESINCHESAdder 1.641 1.942 3.573 5.20N (1.64 X N) + .30Example for 10 poles:A = (1.64 X 10) + .30 = 16.20APPLICABLE VERSI-POLE TM ITEMSCatalog Number Number of PolesBDA-14-2/0-11 (adder)BDC-14-2/0-1 1BDA-11-2/0-11 (adder)BDC-11-2/0-1 1NO. OF DIMENSIONS APOLESINCHESAdder .811 1.082 1.893 2.70N (.81 X N) + .27Example for 10 poles:A = (.81 X 10) + .27 = 8.37

BURNDY ® ProductsMechanicalBURNDY UNITAPA-46CLEAR INSULATEDMULTIPLE TAP CONNECTORSTap connections and in-line splice/reductionsare made quickly and easily with theUNITAP line of connectors. UL486B Listed.Dual-rated AL9CU for any stranded copper orstranded aluminum applications. 600 Volt,90° C.Features and Benefits2 PORT 1 or 2 Sided Entry* Not UL Listed• Clear Plastisol covered AL6061-T6aluminum body. Saves time, lowers installation costs,eliminates taping.• Clear Plastisol. Allows visual confirmation thatconductor is properly inserted.Catalog # of Wire Range Fig.Number Ports (AWG/kcmil) L W H Hex Key No.BIT4 2 #14 - #4 1.16 1.16 1.25 1/8 1BITO4 2 #14 - #4 1.16 1.50 1.25 1/8 2BIT2/0 2 #14 - 2/0 1.52 1.40 1.38 3/16 1BITO2/0 2 #14 - 2/0 1.52 1.56 1.38 3/16 2BIT250 2 #10 - 250 2.03 2.07 2.13 5/16 1BITO250 2 #10 - 250 2.03 2.64 2.13 5/16 2BIT350 2 #10 - 350 2.22 2.32 2.50 5/16 1BITO350 2 #10 - 350 2.22 3.00 2.50 5/16 2BIT600 2 #4 - 600 2.72 2.38 2.75 3/8 1BITO600 2 #4 - 600 2.72 3.00 2.75 3/8 2BIT750* 2 #2 - 750 2.87 2.70 3.00 3/8 1BITO750* 2 #2 - 750 2.87 3.38 3.00 3/8 2• Oxide inhibitor pre-installed. Inhibits moisture and contaminantsfrom entering the contact area.• Range-taking. Reduces number of connectors carriedin inventory.Fig. 1Fig. 2IN-LINE SPLICER/REDUCERCatalog Wire RangeNumber (AWG/kcmil) L W H Hex KeyBISR2 #14 - 2 2.38 0.75 1.22 5/32BISR1/0 #14 - 1/0 2.91 0.91 1.38 3/16BISR250 #10 - 250 4.01 1.19 2.10 5/16BISR350 #10 - 350 4.63 1.34 2.35 5/16BISR500 #6 - 500 5.00 1.62 2.62 3/8

BURNDY ® ProductsMechanicalBURNDY UNITAPA-47MULTI-PORTSingle-Sided EntryCatalog # of Wire Range HexNumber Ports (AWG/kcmil) L W H KeyBIBS4-3 3 #14 - 4 1.59 1.25 1.25 1/8BIBS4-4 4 #14 - 4 2.03 1.25 1.25 1/8BIBS4-5 5 #14 - 4 2.47 1.25 1.25 1/8BIBS4-6 6 #14 - 4 2.91 1.25 1.25 1/8BIBS4-8 8 #14 - 4 3.78 1.25 1.25 1/8BIBS2/0-3 3 #14 - 2/0 2.19 1.31 1.38 3/16BIBS2/0-4 4 #14 - 2/0 2.86 1.31 1.38 3/16BIBS2/0-5 5 #14 - 2/0 3.53 1.31 1.38 3/16BIBS2/0-6 6 #14 - 2/0 4.20 1.31 1.38 3/16BIBS2/0-8 8 #14 - 2/0 5.55 1.31 1.38 3/16BIBS2/0-10 10 #14 - 2/0 6.89 1.31 1.38 3/16BIBS2/0-12 12 #14 - 2/0 8.24 1.31 1.38 3/16BIBS2/0-14 14 #14 - 2/0 9.58 1.31 1.38 3/16BIBS250-3 3 #10 - 250 2.97 2.07 2.13 5/16BIBS250-4 4 #10 - 250 3.91 2.07 2.13 5/16BIBS250-5 5 #10 - 250 4.84 2.07 2.13 5/16BIBS250-6 6 #10 - 250 5.78 2..07 2.13 5/16BIBS250-8 8 #10 - 250 7.66 2.07 2.13 5/16BIBS250-10 10 #10 - 250 9.53 2.07 2.13 5/16BIBS250-12 12 #10 - 250 11.41 2.07 2.13 5/16BIBS250-14 14 #10 - 250 13.29 2.07 2.13 5/16BIBS350-3 3 #10 - 350 3.13 2.32 2.50 5/16Catalog # of Wire Range HexNumber Ports (AWG/kcmil) L W H KeyBIBS350-4 4 #10 - 350 4.04 2.32 2.50 5/16BIBS350-5 5 #10 - 350 4.95 2.32 2.50 5/16BIBS350-6 6 #10 - 350 5.86 2.32 2.50 5/16BIBS350-8 8 #10 - 350 7.68 2.32 2.50 5/16BIBS350-10 10 #10 - 350 9.50 2.32 2.50 5/16BIBS350-12 12 #10 - 350 11.32 2.32 2.50 5/16BIBS350-14 14 #10 - 350 13.14 2.32 2.50 5/16BIBS600-3 3 #4 - 600 4.00 2.38 2.75 3/8BIBS600-4 4 #4 - 600 5.28 2.38 2.75 3/8BIBS600-5 5 #4 - 600 6.56 2.38 2.75 3/8BIBS600-6 6 #4 - 600 7.84 2.38 2.75 3/8BIBS600-8 8 #4 - 600 10.41 2.38 2.75 3/8BIBS600-10 10 #4 - 600 12.97 2.38 2.75 3/8BIBS600-12 12 #4 - 600 15.53 2.38 2.75 3/8BIBS600-14 14 #4 - 600 18.09 2.38 2.75 3/8BIBS750-3* 3 #2 - 750 4.25 2.70 3.00 3/8BIBS750-4* 4 #2 - 750 5.63 2.70 3.00 3/8BIBS750-6* 6 #2 - 750 8.37 2.70 3.00 3/8BIBS750-8* 8 #2 - 750 11.13 2.70 3.00 3/8BIBS750-10* 10 #2 - 750 13.87 2.70 3.00 3/8BIBS750-12* 12 #2 - 750 16.63 2.70 3.00 3/8BIBS750-14* 14 #2 - 750 19.37 2.70 3.00 3/8* Not UL Listed

BURNDY ® ProductsMechanicalBURNDY UNITAPA-48MULTI-PORTDouble-Sided EntryCatalog # of Wire Range HexNumber Ports (AWG/kcmil) L W H KeyBIBD4-2 2 #14 - #4 1.16 1.50 1.25 1/8BIBD4-3 3 #14 - #4 1.59 1.50 1.25 1/8BIBD4-4 4 #14 - #4 2.03 1.50 1.25 1/8BIBD4-5 5 #14 - #4 2.47 1.50 1.25 1/8BIBD4-6 6 #14 - #4 2.91 1.50 1.25 1/8BIBD4-8 8 #14 - #4 3.78 1.50 1.25 1/8BIBD2/0-2 2 #14 - 2/0 1.52 1.56 1.25 3/16BIBD2/0-3 3 #14 - 2/0 2.19 1.56 1.25 3/16BIBD2/0-4 4 #14 - 2/0 2.86 1.56 1.25 3/16BIBD2/0-5 5 #14 - 2/0 3.53 1.56 1.25 3/16BIBD2/0-6 6 #14 - 2/0 4.20 1.56 1.25 3/16BIBD2/0-8 8 #14 - 2/0 5.55 1.56 1.25 3/16BIBD2/0-10 10 #14 - 2/0 6.89 1.56 1.25 3/16BIBD2/0-12 12 #14 - 2/0 8.24 1.56 1.25 3/16BIBD2/0-14 14 #14 - 2/0 9.58 1.56 1.25 3/16BIBD250-2 2 #10 - 250 2.03 2.64 2.13 5/16BIBD250-3 3 #10 - 250 2.97 2.64 2.13 5/16BIBD250-4 4 #10 - 250 3.91 2.64 2.13 5/16BIBD250-5 5 #10 - 250 4.84 2.64 2.13 5/16BIBD250-6 6 #10 - 250 5.78 2.64 2.13 5/16BIBD250-8 8 #10 - 250 7.66 2.64 2.13 5/16BIBD250-10 10 #10 - 250 9.53 2.64 2.13 5/16BIBD250-12 12 #10 - 250 11.41 2.64 2.13 5/16BIBD250-14 14 #10 - 250 13.29 2.64 2.13 5/16BIBD350-2 2 #10 - 350 2.22 3.00 2.50 5/16Catalog # of Wire Range HexNumber Ports (AWG/kcmil) L W H KeyBIBD350-3 3 #10 - 350 3.13 3.00 2.50 5/16BIBD350-4 4 #10 - 350 4.04 3.00 2.50 5/16BIBD350-5 5 #10 - 350 4.95 3.00 2.50 5/16BIBD350-6 6 #10 - 350 5.86 3.00 2.50 5/16BIBD350-8 8 #10 - 350 7.68 3.00 2.50 5/16BIBD350-10 10 #10 - 350 9.50 3.00 2.50 5/16BIBD350-12 12 #10 - 350 11.32 3.00 2.50 5/16BIBD350-14 14 #10 - 350 13.14 3.00 2.50 5/16BIBD600-2 2 #4 - 600 2.56 3.00 2.75 3/8BIBD600-3 3 #4 - 600 3.77 3.00 2.75 3/8BIBD600-4 4 #4 - 600 4.97 3.00 2.75 3/8BIBD600-5 5 #4 - 600 6.17 3.00 2.75 3/8BIBD600-6 6 #4 - 600 7.37 3.00 2.75 3/8BIBD600-8 8 #4 - 600 9.78 3.00 2.75 3/8BIBD600-10 10 #4 - 600 12.97 3.00 2.75 3/8BIBD600-12 12 #4 - 600 15.53 3.00 2.75 3/8BIBD600-14 14 #4 - 600 18.09 3.00 2.75 3/8BIBD750-2* 2 #2 - 750 2.87 3.38 3.00 3/8BIBD750-3* 3 #2 - 750 4.25 3.38 3.00 3/8BIBD750-4* 4 #2 - 750 5.63 3.38 3.00 3/8BIBD750-6* 6 #2 - 750 8.37 3.38 3.00 3/8BIBD750-8* 8 #2 - 750 11.13 3.38 3.00 3/8BIBD750-10* 10 #2 - 750 13.87 3.38 3.00 3/8BIBD750-12* 12 #2 - 750 16.63 3.38 3.00 3/8BIBD750-14* 14 #2 - 750 19.37 3.38 3.00 3/8NOTE: Only 1 conductor per port allowed.* Not UL Listed

BURNDY ® ProductsMechanicalBURNDY UNITAPCLEAR INSULATEDMULTIPLE TAP CONNECTORSA-49MOUNTING VERSIONTYPE BIBS-MT, BIBD-MTThe BIBS-MT and BIBD-MT series UNITAPoffer the same multi-port capabilities as thestandard UNITAP connectors except these-MT types are provided with two isolatedmounting holes at both ends of the connectorfor direct mounting to a trough, gutter orwireway. They will accommodate up tostandard 1/4 hardware.Fig. 1 Fig. 2MULTI-PORTSingle-Sided EntryCatalog # of Wire Range HexNumber Fig # Ports (AWG/Kcmil) L W H KeyBIBS2/04MT 1 4 #14-2/0 3.95 1.31 1.38 3/16BIBS2/06MT 1 6 #14-2/0 5.29 1.31 1.38 3/16BIBS2/08MT 1 8 #14-2/0 6.64 1.31 1.38 3/16BIBS2/010MT 1 10 #14-2/0 7.98 1.31 1.38 3/16BIBS2/012MT 1 12 #14-2/0 9.33 1.31 1.38 3/16BIBS2504MT 1 4 #10-250 5.53 2.07 2.13 5/16BIBS2506MT 1 6 #10-250 7.40 2.07 2.13 5/16BIBS2508MT 1 8 #10-250 9.28 2.07 2.13 5/16BIBS25010MT 1 10 #10-250 11.16 2.07 2.13 5/16BIBS25012MT 1 12 #10-250 13.03 2.07 2.13 5/16BIBS3504MT 1 4 #10-350 5.61 2.32 2.50 5/16BIBS3506MT 1 6 #10-350 7.43 2.32 2.50 5/16BIBS3508MT 1 8 #10-350 9.25 2.32 2.50 5/16BIBS35010MT 1 10 #10-350 11.07 2.32 2.50 5/16BIBS35012MT 1 12 #10-350 12.89 2.32 2.50 5/16BIBS6004MT 1 4 #4-600 7.59 2.38 2.75 3/8BIBS6006MT 1 6 #4-600 10.16 2.38 2.75 3/8BIBS6008MT 1 8 #4-600 12.72 2.38 2.75 3/8BIBS60010MT 1 10 #4-600 15.28 2.38 2.75 3/8BIBS60012MT 1 12 #4-600 17.84 2.38 2.75 3/8MULTI-PORTDouble-Sided EntryCatalog # of Wire Range HexNumber Fig # Ports (AWG/Kcmil) L W H KeyBIBD2/04MT 2 4 #14-2/0 3.95 1.56 1.38 3/16BIBD2/06MT 2 6 #14-2/0 5.29 1.56 1.38 3/16BIBD2/08MT 2 8 #14-2/0 6.64 1.56 1.38 3/16BIBD2/010MT 2 10 #14-2/0 7.98 1.56 1.38 3/16BIBD2/012MT 2 12 #14-2/0 9.33 1.56 1.38 3/16BIBD2504MT 2 4 #10-250 5.53 2.64 2.13 5/16BIBD2506MT 2 6 #10-250 7.40 2.64 2.13 5/16BIBD2508MT 2 8 #10-250 9.28 2.64 2.13 5/16BIBD25010MT 2 10 #10-250 11.16 2.64 2.13 5/16BIBD25012MT 2 12 #10-250 13.03 2.64 2.13 5/16BIBD3504MT 2 4 #10-350 5.61 3.00 2.50 5/16BIBD3506MT 2 6 #10-350 7.43 3.00 2.50 5/16BIBD3508MT 2 8 #10-350 9.25 3.00 2.50 5/16BIBD35010MT 2 10 #10-350 11.07 3.00 2.50 5/16BIBD35012MT 2 12 #10-350 12.89 3.00 2.50 5/16BIBD6004MT 2 4 #4-600 7.59 3.00 2.75 3/8BIBD6006MT 2 6 #4-600 10.16 3.00 2.75 3/8BIBD6008MT 2 8 #4-600 12.72 3.00 2.75 3/8BIBD60010MT 2 10 #4-600 15.28 3.00 2.75 3/8BIBD60012MT 2 12 #4-600 17.84 3.00 2.75 3/8

BURNDY ® ProductsMechanicalBURNDY UNITAPTHE MOLEA-50For Direct Burial600V, 90°CDesigned specifically for direct burial applications,the MOLE inline splice/reducer ismade with a specialized plastisol materialthat forms a rugged weathertight connection.Features and Benefits• UL486D Listed for direct burial.• AL9CU Dual-rated for copper andaluminum applications. 600V 90°C.• Plastisol covered AL6061-T6 aluminumbody saves time by eliminating the needfor heat shrink.• Oxide inhibitor pre-installed preventingmoisture and contaminants from enteringcontact area.• Range-taking capability reduces thenumber of connectors carried in inventory.Number Wire Hex Key WireCatalog of Range Dimensions (Inches) (Torque) StripNumber Ports (AWG/kcmil) L W H (In.-lbs.) LengthBISR4-DB 2 #6 - 4 AWG 4.30 0.80 1.281/8(50)7/8BISR1-DB 2 #2 - 1 AWG 6.30 0.93 1.595/32(130)1-3/32BISR3/0-DB 2 1/0 - 3/0 AWG 6.25 0.99 1.843/16(220)1-3/32BISR250-DB 2 4/0 - 250 kcmil 6.70 1.18 2.035/16(360)1-5/16BISR-DB = BURNDY Inline Splice/Reducer Direct Burial