A Study of Hole Drilling on Stainless Steel AISI 431 by EDM Using ...

A Study of Hole Drilling on Stainless Steel AISI 431 by EDM Using ...

A Study of Hole Drilling on Stainless Steel AISI 431 by EDM Using ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

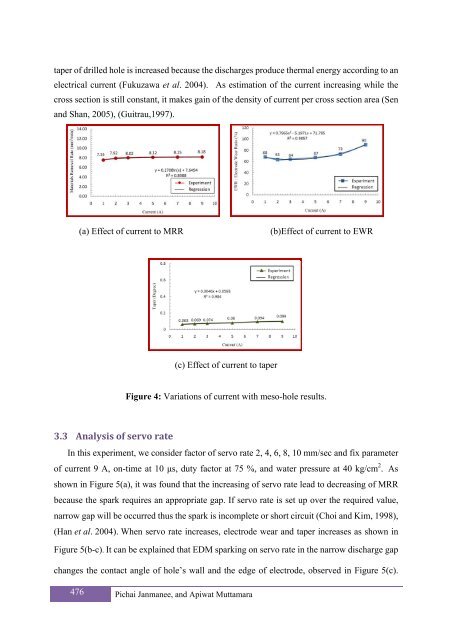

taper <str<strong>on</strong>g>of</str<strong>on</strong>g> drilled hole is increased because the discharges produce thermal energy according to anelectrical current (Fukuzawa et al. 2004). As estimati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the current increasing while thecross secti<strong>on</strong> is still c<strong>on</strong>stant, it makes gain <str<strong>on</strong>g>of</str<strong>on</strong>g> the density <str<strong>on</strong>g>of</str<strong>on</strong>g> current per cross secti<strong>on</strong> area (Senand Shan, 2005), (Guitrau,1997).(a) Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> current to MRR(b)Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> current to EWR(c) Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> current to taperFigure 4: Variati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> current with meso-hole results.3.3 Analysis <str<strong>on</strong>g>of</str<strong>on</strong>g> servo rateIn this experiment, we c<strong>on</strong>sider factor <str<strong>on</strong>g>of</str<strong>on</strong>g> servo rate 2, 4, 6, 8, 10 mm/sec and fix parameter<str<strong>on</strong>g>of</str<strong>on</strong>g> current 9 A, <strong>on</strong>-time at 10 μs, duty factor at 75 %, and water pressure at 40 kg/cm 2 . Asshown in Figure 5(a), it was found that the increasing <str<strong>on</strong>g>of</str<strong>on</strong>g> servo rate lead to decreasing <str<strong>on</strong>g>of</str<strong>on</strong>g> MRRbecause the spark requires an appropriate gap. If servo rate is set up over the required value,narrow gap will be occurred thus the spark is incomplete or short circuit (Choi and Kim, 1998),(Han et al. 2004). When servo rate increases, electrode wear and taper increases as shown inFigure 5(b-c). It can be explained that <strong>EDM</strong> sparking <strong>on</strong> servo rate in the narrow discharge gapchanges the c<strong>on</strong>tact angle <str<strong>on</strong>g>of</str<strong>on</strong>g> hole’s wall and the edge <str<strong>on</strong>g>of</str<strong>on</strong>g> electrode, observed in Figure 5(c).476 Pichai Janmanee, and Apiwat Muttamara