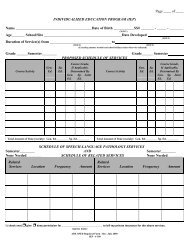

ancmat02.qxd 11/16/06 3:26 PM Page B20B20 • SUPPLEMENT BINTRODUCTION TO OPTIMIZATION(b) The spreadsheet model can be structured in different ways,but it makes sense <strong>to</strong> arrange it in a way that will communicatethe information clearly <strong>to</strong> management. The solvedspreadsheet is shown. The minimum <strong>to</strong>tal cost is $1,010,000.To achieve this, ship 9000 from Kansas City <strong>to</strong> Birmingham,1000 from Kansas City <strong>to</strong> Milwaukee, 2000 from Denver <strong>to</strong>Milwaukee, 6000 from Denver <strong>to</strong> Los Angeles, 3500 fromRaleigh <strong>to</strong> Los Angeles, and 1500 from Raleigh <strong>to</strong> Seattle.The spreadsheet has three sections: unit costs, transportationplan, and transportation costs. The twelve decisionvariables are the twelve cells in the transportation plansection. Based on this plan and the unit costs, the cost foreach plant/distribution center combination is computedand then <strong>to</strong>taled <strong>to</strong> get the objective function. Each row ofthe transportation plan section represents the amountsshipped from each plant, summed in cells F15:F17, andeach column represents the amounts received at each distributioncenter, summed in cells B18:E18. The Solver settingsare as follows for this model:Target CellChanging CellsConstraintsOptionsE30 (minimize)B15:E17F15:F17 F6:F8 (capacity constraints)B18:E18 B9:E9 (demand constraints)Assume Linear ModelAssume Non-Negative1234567891011121314151617181920212223242526272829303132A B C D E F GTowAway Transportation ProblemUnit Transportation Costs and Capacity/Demand EstimatesDistribution CenterPlant Birmingham Milwaukee Los Angeles Seattle CapacityKansas Cty $35 $40 $60 $120 12000Denver $30 $30 $45 $130 8000Raleigh $60 $65 $50 $100 5000Demand 9000 3000 9500 1500Transportation PlanDistribution CenterPlant Birmingham Milwaukee Los Angeles Seattle ShippedKansas Cty 9000 1000 0 0 10000Denver 0 2000 6000 0 8000Raleigh 0 0 3500 1500 5000Received 9000 3000 9500 1500Transportation Costs$B$18: =SUM(B15:B17) (copy right)Distribution CenterPlant Birmingham Milwaukee Los Angeles Seattle OutboundKansas Cty $315,000 $40,000 $0 $0 $355,000Denver $0 $60,000 $270,000 $0 $330,000Raleigh $0 $0 $175,000 $150,000 $325,000Inbound $315,000 $100,000 $445,000 $150,000$B$27: =SUM(B24:B26) (copy right)Total Transportation Costs: $1,010,000$E$30: =SUM(F24:F26)$F$15: =SUM(B15:E15)(copy down)$B$24: =B15*B6(copy right & down)$F$24: =SUM(B24:E24)(copy down)• Problem 2Chris is a student at the local college. Being on the go throughthe day, eating habits and nutrition sometimes do not receive asmuch attention as they should. In an effort <strong>to</strong> improve nutrition,Chris wonders if there is a way <strong>to</strong> eat a reasonably nutritiouslunch and dinner diet at the local fast-food chain. Chrishas collected some nutritional information about the menuitems most often consumed. This isn’t necessarily a diet thatChris will eat every day. However, since Chris often studies for

ancmat02.qxd 11/16/06 3:26 PM Page B21SOLVED PROBLEMS • B21hours at a time at the restaurant, it is likely that both lunch anddinner will sometimes be eaten there. Chris has been advised bya doc<strong>to</strong>r <strong>to</strong> be careful about high sodium intake.Nutritional and cost data are provided in the table. Chrishas decided <strong>to</strong> use linear programming <strong>to</strong> try <strong>to</strong> find a reasonablynutritious diet that minimizes sodium intake. He has determinedthat the nutrition requirements indicate that the dietmust contain 2000–2500 calories, have no more than 85 gramsof fat, and contain at least 100 percent of the “daily value” (DV)of vitamin C, vitamin A, calcium, and iron. Chris has $15 budgetedfor the two meals combined and is willing <strong>to</strong> eat no morethan two of each item from the menu.Large BurgerSmall BurgerChicken StripsChiliCost $2.20 $0.99 $2.30 $0.99 $1.95 $0.99 $1.75 $1.50 $0.79 $1.50Calories 410 270 410 200 410 140 390 400 120 330Total Fat (g) 19 9 18 5 32 8 12 17 4.5 8Vitamin C %DV 10 0 0 4 60 30 60 6 0 0Vitamin A %DV 6 0 0 15 170 140 15 2 10 15Calcium %DV 6 4 0 8 35 8 8 0 25 30Iron %DV 25 20 6 10 20 6 15 8 0 15Sodium (mg) 910 630 1470 870 840 570 160 340 120 150Deluxe SaladSide SaladBaked Pota<strong>to</strong>French FriesMilkShake• Before You BeginThis is similar <strong>to</strong> Solved Problem 1, just a bit more complicated.In this case, the objective function is <strong>to</strong> minimize sodium intakesubject <strong>to</strong> constraints on calories, fat, vitamin A, vitaminC, calcium, iron, and <strong>to</strong>tal cost, while limited <strong>to</strong> a maximum oftwo of any menu item. This is a product mix problem, but nowwe are determining the mix of inputs rather than the mix offinal products. Write out the objective function first, then writeout the constraints. Since we would like an integer solution forthis problem, restrict Solver <strong>to</strong> an integer solution. Solve theproblem using Excel.• SolutionThis problem is actually quite similar <strong>to</strong> the example in thechapter, only larger. As such, the spreadsheet will be arranged ina similar way. A text-based formulation is given. Note the objectivefunction here is not monetary, but rather <strong>to</strong> minimizesodium intake, subject <strong>to</strong> a set of constraints, one of which is abudget constraint.Text-Based Formulation• Decision variables: Number of each menu item <strong>to</strong> purchaseand consume.• Objective function: Minimize sodium intake.• Constraints: Calories, fat, vitamin A, vitamin C, calcium,iron, <strong>to</strong>tal cost, and the maximum of two of each menu item.The other difference in this problem is that we cannot realisticallyorder a fractional quantity of an item. Therefore, we willuse Solver’s capability <strong>to</strong> restrict the decision variables <strong>to</strong> integers.You can consult one of the management science books inthe bibliography for more information about integer variables.A solved spreadsheet is shown. While the spreadsheet issomewhat large, there is only one unique formula written,which is for the objective value (<strong>to</strong>tal sodium) in cell L8. Thisformula is then copied <strong>to</strong> cells L10:L17 <strong>to</strong> compute the LHS valuesof the constraints. The formula in cell L8 is SUMPROD-UCT (B8:K8,B$4:K$4). The SUMPRODUCT function wascovered in Supplement A, but briefly, it multiplies each correspondingpair of entries (e.g., B8*B$4, C8*C$4, etc.) and thenadds up these individual products.Somewhat surprisingly, the optimal solution is <strong>to</strong> eat 1Small Burger, 1 Deluxe Salad, 2 Baked Pota<strong>to</strong>es, and 2 Shakes.The <strong>to</strong>tal Sodium is 2090 mg. Considering the nutritional andcost constraints, we see that they are all satisfied, with Ironbeing the only constraint that is actually binding. The cost ofthis diet is $9.44, significantly less than our budget. The Solversettings are as follows for this model:Target CellChanging CellsConstraintsOptionsL8 (minimize)B4:K4L10 N10 (calorie lower limit)L11:L12 N11:12 (calorie & fat upperlimits)L13:L16 N13:16 (vitamins A & C,calcium, & iron lower limits)L17 N17 (cost upper limit)B4:K4 B5:K5 (item lower limit)B4:K4 B6:K6 (item upper limit)B4:K4 integer (<strong>to</strong> restrict <strong>to</strong> only integervalues)Assume Linear ModelAssume Non-Negative