DS 1 10 21.qxp

DS 1 10 21.qxp

DS 1 10 21.qxp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

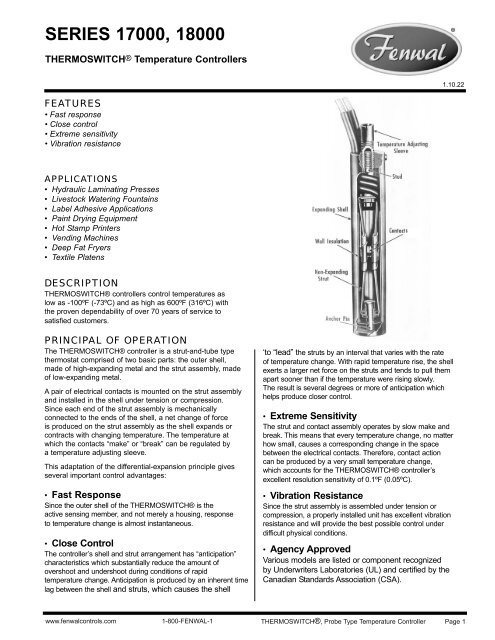

SERIES 17000, 18000THERMOSWITCH® Temperature Controllers1.<strong>10</strong>.22FEATURES• Fast response• Close control• Extreme sensitivity• Vibration resistanceAPPLICATIONS• Hydraulic Laminating Presses• Livestock Watering Fountains• Label Adhesive Applications• Paint Drying Equipment• Hot Stamp Printers• Vending Machines• Deep Fat Fryers• Textile PlatensDESCRIPTIONTHERMOSWITCH® controllers control temperatures aslow as -<strong>10</strong>0ºF (-73ºC) and as high as 600ºF (316ºC) withthe proven dependability of over 70 years of service tosatisfied customers.PRINCIPAL OF OPERATIONThe THERMOSWITCH® controller is a strut-and-tube typethermostat comprised of two basic parts: the outer shell,made of high-expanding metal and the strut assembly, madeof low-expanding metal.A pair of electrical contacts is mounted on the strut assemblyand installed in the shell under tension or compression.Since each end of the strut assembly is mechanicallyconnected to the ends of the shell, a net change of forceis produced on the strut assembly as the shell expands orcontracts with changing temperature. The temperature atwhich the contacts “make” or “break” can be regulated bya temperature adjusting sleeve.This adaptation of the differential-expansion principle givesseveral important control advantages:• Fast ResponseSince the outer shell of the THERMOSWITCH® is theactive sensing member, and not merely a housing, responseto temperature change is almost instantaneous.• Close ControlThe controller’s shell and strut arrangement has “anticipation”characteristics which substantially reduce the amount ofovershoot and undershoot during conditions of rapidtemperature change. Anticipation is produced by an inherent timelag between the shell and struts, which causes the shell‘to “lead” the struts by an interval that varies with the rateof temperature change. With rapid temperature rise, the shellexerts a larger net force on the struts and tends to pull themapart sooner than if the temperature were rising slowly.The result is several degrees or more of anticipation whichhelps produce closer control.• Extreme SensitivityThe strut and contact assembly operates by slow make andbreak. This means that every temperature change, no matterhow small, causes a corresponding change in the spacebetween the electrical contacts. Therefore, contact actioncan be produced by a very small temperature change,which accounts for the THERMOSWITCH® controller’sexcellent resolution sensitivity of 0.1ºF (0.05ºC).• Vibration ResistanceSince the strut assembly is assembled under tension orcompression, a properly installed unit has excellent vibrationresistance and will provide the best possible control underdifficult physical conditions.• Agency ApprovedVarious models are listed or component recognizedby Underwriters Laboratories (UL) and certified by theCanadian Standards Association (CSA).www.fenwalcontrols.com 1-800-FENWAL-1 THERMOSWITCH®, Probe Type Temperature Controller Page 1

THERMOSWITCH® ControllersTHERMOSWITCHUNIT TYPEDIMENSIONSDESCRIPTIONCATALOGNUMBERThe basic element of all THERMOSWITCH®controllers. Has all the desirable featuresof the ideal thermostat - high sensitivity,wide adjustment range, small size, ruggedconstruction, vibration resistance, and lowcost. The unit can be inserted into a .625 in(15.88 mm) reamed hole. Approximateweight is 2.5 ounces (70 grams). 01-017000-000 01-017021-000 01-017002-000 01-017023-000 01-017<strong>10</strong>0-000Has all the features of the Cartridge Typeplus the addition of a pipe thread formounting. Approximate weight is 5 ounces(140 grams). 01-017121-000 01-017<strong>10</strong>2-000 01-017123-000This unit has the same mountingas the Cartridge Type but is designedso modificatons may be included. It alsocan be inserted into a .625 in (15.88 mm)reamed hole. Approximate weight is 3ounces (84 grams). 01-017200-00001-017221-000 01-017202-00001-017223-000 01-017300-000Has all the features of the Block HeadType except a mounting flange has beenprovided. Approximate weight is 4 ounces(112 grams). 01-017321-000 01-017302-00001-017323-000Has electric conduit junction box containingterminal block and temperature adjustingdial and knob. Extended hexagonalsection with pipe thread permits easymounting into tapped hole of boss,immersing shell into fluid medium tobe controlled. 01-017800-000 01-017821-000 01-017802-00001-017823-000The Coupling Head Type has a hexagonalmounting section withpipe threads ateach end. This unit may be directlyattached to electrical conduit. Approximateweight is 5 ounces(140 grams). 01-018000-000 01-018021-000 01-018002-000 01-018023-000inch(mm) = Normally StockedPage 2THERMOSWITCH®, Probe Type Temperature Controller1-800-FENWAL-1www.fenwalcontrols.com

-<strong>10</strong>0 to 600ºF/-73 to 316ºCTEMP.RANGECONTACTOPERATIONON TEMP.RISESHELLANDHEADMATERIALAPPROX.DEGREES CHANGEPER FULL TURN OFADJUSTING SLEEVEEXTREMETEMPERATUREEXPOSURECURRENTRATINGFACTORYTEMP.SETTINGTOLERANCE(MOD. #3)APPLICABLEMODIFIC-ATIONSAPPLICABLESPECIALFEATURES(see Modifications and SpecialFeatures Section)-<strong>10</strong>0 to +400ºF-73 to +204ºC-<strong>10</strong>0 to +600ºF-73 to +316ºCOpensClosesOpensClosesBrass300 SeriesS.S. Shell90ºF/50ºC80ºF/45ºC1<strong>10</strong>ºF/60ºC<strong>10</strong>0ºF/55ºCUnless otherwise specified, all ratingsapply to non-inductive loads such asheaters or resistors. Tungsten filamentlamps have an inrush <strong>10</strong> to 15 timesthe steady state current. Do notexceed ratings.123414313435-<strong>10</strong>0 to +400ºF-73 to +204ºC-<strong>10</strong>0 to+600ºF-73 to +316ºC-<strong>10</strong>0 to +400ºF-73 to +204ºC-<strong>10</strong>0 to +600ºF-73 to +316ºC-<strong>10</strong>0 to +400ºF-73 to +204ºC-<strong>10</strong>0 to +600ºF-73 to +316ºC-<strong>10</strong>0 to +400ºF-73 to +204ºC-<strong>10</strong>0 to +600ºF-73 to +316ºC-<strong>10</strong>0 to +400ºF-73 to +204ºC-<strong>10</strong>0 to +600ºF-73 to +316ºCOpensClosesOpensClosesOpensClosesOpensClosesOpensClosesOpensClosesOpensClosesOpensClosesOpensClosesOpensClosesBrass300 SeriesS.S. ShellBrass HeadBrass300 SeriesS.S. ShellBrass HeadBrass300 SeriesS.S. ShellBrass HeadBrass300 SeriesS.S. ShellBrass HeadBrass300 SeriesS.S. ShellBrass Head80ºF/45ºC75ºF/40ºC<strong>10</strong>0ºF/55ºC90ºF/50ºC80ºF/45ºC70ºF/40ºC<strong>10</strong>0ºF/55ºC90ºF/50ºC80ºF/45ºC70ºF/40ºC<strong>10</strong>0ºF/55ºC90ºF/50ºC125ºF/70ºC75ºF/40ºC160ºF/90ºC90ºF/50ºC80ºF/45ºC75ºF/40ºC<strong>10</strong>0ºF/55ºC90ºF/50ºCUNITS THATOPEN ONTEMPERATURERISE:-<strong>10</strong>0ºF/-73ºCindefinitely and<strong>10</strong>0ºF/55ºC aboveset point for onehour maximumUNITS THATCLOSE ONTEMPERATURERISE:-<strong>10</strong>0º to +400ºF/-73º to +204ºC-<strong>10</strong>0ºF/-73ºCindefinitely and500ºF /260ºCfor one hourmaximum-<strong>10</strong>0º to +600ºF/-73º to +316ºC-<strong>10</strong>0ºF/-73ºCindefinitelyand700ºF /370ºCfor one hourmaximum*AC<strong>10</strong> amps120 volts5 amps240 volts(noninductive)DCratingsconsultFenwalUNITS THATOPEN ONTEMPERATURERISE+ 5ºF from+32º to +<strong>10</strong>0ºF+3ºF or 2%of Setting Value(whichever isgreater)From <strong>10</strong>0º to600ºFUNITS THATCLOSE ONTEMPERATURERISE+ 5ºF or 3%of Setting Value(whichever isgreater)TEMPERATURE OFFSET VALUESDUE TO PRESSURE (APPROX. ONLY)Pressure PSI Set Point Offset<strong>10</strong>0 + 3ºF / 2ºC200 + 6ºF / 3ºC300 + 9ºF / 5ºC400 + 12ºF / 7ºC500 + 15ºF / 8ºCCollapsing pressure (brass shell) 1400 psi at room temperatureCollapsing pressure (S.S. shell) 3,500 psi at room temperature1 thru141 thru141 thru1413123414313435313431343134313435Recognized under the Components Program of Underwriters Laboratories, Inc. (XAPX2)Underwriters Laboratories Listed (XAPX)Certified by Canadian Standards Association (Class 4813 02) CSA File No. LR7378UL and CSA units rated for AC operation only.*www.fenwalcontrols.com 1-800-FENWAL-1 THERMOSWITCH®, Probe Type Temperature Controller Page 3

CORROSION RESISTANT ControllerThis model has a hexagonal mountingsection with male pipe threads at eachend. This unit may be directly attachedto electrical conduits or explosion prooffittings. It is ideally suited for photoprocessing, laboratory and experimentaltest work, food processing, bleaching& dyeing and many other similarapplications. Approximate weight is5 ounces (140 grams).01-180020-029 01-018002-021 01-018023-007 = Normally StockedAPPLICATION HINTS - Contact ProtectionCapacitors are not needed under average conditions.For smoother control of small loads (below 1/<strong>10</strong>th thecontroller rating or to prevent contact bounce due tovibration use capacitance in μF) of 0.28 divided byline voltage.NOTE: Capacitors should be rated a minimum of 600 volts for120 volt circuits and a minimum of <strong>10</strong>00 volts for 240 volt circuit.VOLTAGE SERVICE CAPACITANCE (μF)120 VAC Resistance None Required240 VAC Resistance 0.1120 or 240 VAC Relays 0.001 to 0.0115 to 25 VAC Relays 0.02120 or 240 VAC Motors Use RelayNOTE: Capacitors should be wired in parallel withthermostat leads. For exceptional vibration, increaseabove values 5 to <strong>10</strong> times.Page 4THERMOSWITCH®, Probe Type Temperature Controller1-800-FENWAL-1www.fenwalcontrols.com

-<strong>10</strong>0 to 600ºF/-93 to 316ºC-<strong>10</strong>0 to +500ºF/-73 to 260ºC-<strong>10</strong>0 to +600ºF-73 to +316ºCOpensClosesAll Type316 S.S.<strong>10</strong>0ºF/55ºC-<strong>10</strong>0ºF/-73ºCindefinitely and<strong>10</strong>0ºF/55ºC aboveset point for1 hour maximum-<strong>10</strong>0ºF/-73ºCindefinitely and700ºF/370ºC for1 hour maximumAC <strong>10</strong>amps120 volts5 amps240 voltsDCratingsconsultFenwal+ 5ºF from-<strong>10</strong>0 to <strong>10</strong>0ºF+ 3ºF or 2% ofsetting value(whichever isgreater) from<strong>10</strong>0 to 600ºF+ 5ºF or 3% ofsetting value(whichever isgreater)123414SPECIALFEATURE31RATINGSUnless otherwise specified, all rating applyto non-inductive loads, such as heaters orresistors. Tungsten filament lamps havean inrush of <strong>10</strong> to 15 times the steady statecurrent. Do not exceed switch rating atany time.www.fenwalcontrols.com 1-800-FENWAL-1 THERMOSWITCH®, Probe Type Temperature Controller Page 5

PROTECTIVE WELLSFor use with 170XX 5/8” Diameter Cartridge THERMOSWITCH ControllersCatalog No. 34-011201-000Hex Head Well(321 Stainless Steel Well & Head)Applicable Modifications1 Special MarkingApplicable Special Features31A Extended ShellApproximate weight is 4 ounces (112 grams)Pressure Ratings: <strong>10</strong>0 psi at -<strong>10</strong>0ºF to +250ºF60psi at 600ºFCatalog No. 34-011204-000Coupling Head Well(321 Stainless Steel Well & Head)Applicable Modifications1 Special MarkingApplicable Special Features31A Extended ShellApproximate weight is 5 ounces (140 grams)Pressure Ratings: <strong>10</strong>0 psi at -<strong>10</strong>0ºF to +250ºF60 psi at 600ºFCatalog No. 34-011<strong>10</strong>0-002Aluminum Surface Mounting WellApproximate weight is 4 ounces (112 grams)Pressure Ratings: <strong>10</strong>0 psi at -<strong>10</strong>0ºF to +250ºF60 psi at 600ºFFor use with 172XX and 173XX THERMOSWITCH® ControllersCatalog No. 34-011208-000Low Pressure Hex Head Well(321 Stainless Steel Well & Head)Applicable ModificationsSpecial MarkingApplicable Special Features31A Extended ShellApproximate weight is 4 ounces (112 grams)Pressure Ratings: <strong>10</strong>0 psi at -<strong>10</strong>0ºF to +250ºF60 psi at 600ºFIn many applications involving liquids and gases, the use of awell is recommended. When the removal of a hex or couplinghead THERMOSWITCH® controller would require draining ofthe container in which it is inserted, the use of a well assemblypermits removal of the controller at any time without otherdisturbances.When surrounding ambients are subject to extreme changes thusaffecting THERMOSWITCH® control, the well makes itpossible to insert the THERMOSWITCH® controller completelyinto the medium being controlled thereby eliminating theseambient temperature effects or “head effect”.A well offers protection in applications where fluids have acorrosive effect on the brass shell of the THERMOSWITCH®controller.NOTE: Certain gases or liquids (including water at elevatedtemperatures) could be corrosive and/or cause electrolyticaction, which could severely shorten the life of the controller.Where corrosion or electrolysis is suspect, the use ofstainless steel heliarc welded thermowells or variousplatings or coatings may increase controller life. The rateof corrosion or electrolysis is influenced by a great manysystem parameters such as chemical makeup andtemperature of the solution, stray electric currents, etc.Consult the supplier of your chemicals or Fenwal forsuggestions.In addition, use a well to protect the THERMOSWITCH®controller from external forces or blows which could affectits operation.Page 6THERMOSWITCH®, Probe Type Temperature Controller1-800-FENWAL-1www.fenwalcontrols.com

MODIFICATIONS(1) Special Marking01-9900<strong>10</strong>-XXXSpecial marking may be rubber stampedin indelible ink at points A, B, or C. Amountof marking is limited to the space available.Specify text and location of marking.Modiifications which cannot be combined.(3) Factory Temperature Setting01-990030-00XThe controller may be preset at Fenwal to any temperature within its listed rangeto a minimum of 32ºF (0ºC). Unless this modification is specified, units are presetat approximately 75ºF (25ºC). Modification 4 is recommended when ordering afactory set unit to preclude a possible shift in set point due to mishandling.(6A)(6B)(2) Extended Lead Wires01-9902X-XXXLead wires may be extended to any length.Wire lengths are specified at that portionof lead wire outside of the THERMOSWITCH®controller, indicated by dimension “L”. Speciallead wire stripping may also be obtained byspecifying length shown as dimension “X”.(4) TemperatureRestraining Device01-990040-000A restraining device may be added tosecure the temperature adjustmentsleeve after calibration. This modificationdeters tampering with the setting. It alsominimizes the possibility of a shift incalibration due to vibration.(5) Tamper-proof Cap01-990050-000A tamper-proof cap can be furnished to preventtampering with a THERMOSWITCH controllerequipped with Modification 4 above.(6) Dial and Knob01-990061-0XXA large dial and knob may be added to certainTHERMOSWITCH controllers. Graduationsare marked from “1” to “7” for adjustment tohigher or lower temperature. Controllers maybe ordered unset or factory preset. Dial willbe set on NO. 4 position unless otherwisespecified.01-990062-0XXSame as 6A above except small dial and knob.(<strong>10</strong>) Moisture ResistantTamper-proof Cap01-99011X-XXXTo seal a controller against moisture andtampering, a moisture resistant, tamper-proofcap may be mounted over the adjustingsleeve. It may be used with unset or factorypreset units.(13) Packing Gland on Lead Wires01-990130-00XIn installations where moisture may enterTHERMOSWITCH® controller around leadwires, a packing gland is recommended.Modification 8 should be used with thismodification.(14) Extended TemperatureAdjusting Sleeve01-990140-XXXAdjustment sleeve extensions are availableonly in multiples of one inch. When ordering,the length specified is the “extended by”length “L”. For example, if the standardadjusting sleeve length for the controllerordered is 3 /8 to 5 /8 inch, and a 4 inchextension is ordered, the overall length willbe 4 3 /8 to 4 5 /8 inches. Minimum orderingquantities apply.(8A)(8B)(8) Moisture Resistant Seal01-990080-001Under certain conditions where there isexcessive moisture or vapor, a moistureresistant seal may be added to protect theinterior of the THERMOSWITCH controller.Modification 13 should be ordered withthis modification.01-990080-002A same as 8A above except seal is fourhole type so dial and knob may be used.Modification 13 should be ordered withthis modification.www.fenwalcontrols.com 1-800-FENWAL-1 THERMOSWITCH®, Probe Type Temperature Controller Page 7

SPECIAL FEATURESWhen special features are specified, THERMOSWITCH®controllers are assigned a special catalog number. As aresult, THERMOSWITCH® controllers as received maybear a different catalog number than the one specifiedon the customer order.31 Extended Shell -THERMOSWITCH® ControllersIn applications where a standard THERMOSWITCH®controller is too short to reach the medium to be controlled,the shell length may be extended. Extension must beordered in increments of 1 inch beyond standard length.31A Extended Shell - Protective WellsWells may be extended in increments of one inch.The THERMOSWITCH® controller must also beextended equally in length.34 Plating Of All ExposedBrass PartsTo overcome certain corrosive conditions, all exposedbrass parts may be plated with tin, zinc, or nickel.Specify S.F.34 and plating material.35 Polyvinyl Chloride (PVC)Lead WiresPVC insulated wire can be supplied as a moistureresistantleadwire for those applications where theoperating temperature does not exceed 175ºF (80ºC).Armored CableSF 01-982122-XXXSF 01-982123-XXX5/8 diameter units13/16 diameter unitsArmored Cable provides protection for the leadwires.(Cable is not moisture resistant.) Leadwires will be2 inches longer than cable if cable is over 12 inchesunless otherwise specified. Specify cable length “L”.This feature includes a ground wire provision asrequired by approval agencies.In applications where a standard THERMOSWITCH®controller is too short to reach the medium tobe controlled, the shell length may be extended.Extension must be ordered in increments of 1 inchbeyond standard length.NOTE: Plating restricts the maximum temperatureof the controllers as follows:TinNickelTin300ºF (149ºC)600ºF (316ºC)400ºF (204ºC)HOW TO ORDER1. Select controller and/or protective well detailedon Pages 2 - 7.2. Order using catalog number.3. Select applicable Modifications and/or SpecialFeatures detailed on Page 8 and order using11 digit number shownIn applications where a standard THERMOSWITCH®controller is too short to reach the medium tobe controlled, the shell length may be extended.Extension must be ordered in increments of 1 inchbeyond standard length.!Operation outside specifcations could result infailure of the Fenwal product and other equipmentwith injury to people and property.NOTE: Specifications subject to change without notice400 MAIN STREET, ASHLAND, MA 01721TEL: (508) 881-2000 FAX: (508) 881-7619www.fenwalcontrols.com© 2007 Kidde-Fenwal Printed in U.S.A. TAGThese instructions do not purport to cover all the details or variations in the equipmentdescribed, nor do they provide for every possible contingency to be met in connection withinstallation, operation and maintenance. All specifications are subject to change without notice.Should further information be desired or should particular problems arise which are not coveredsufficiently for the purchaser’s purposes, the matter should be referred to KIDDE-FENWAL,Inc., Ashland, Massachusetts.P/N 1.<strong>10</strong>.22 1/15/07www.fenwalcontrols.com 1-800-FENWAL-1 THERMOSWITCH®, Probe Type Temperature Controller Page 8