Download Magnastart handbook - PDF - Iris Power Engineering

Download Magnastart handbook - PDF - Iris Power Engineering

Download Magnastart handbook - PDF - Iris Power Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

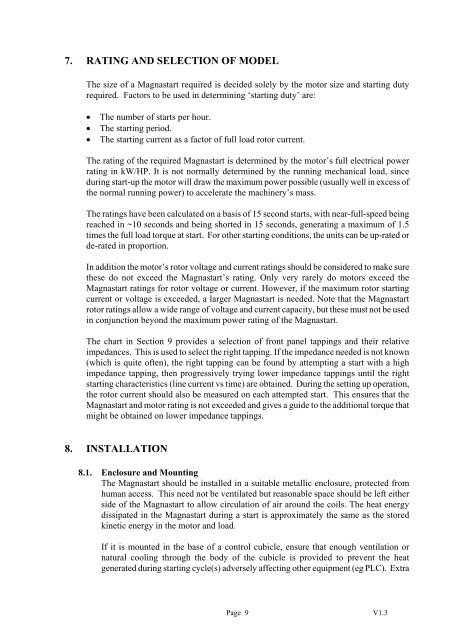

7. RATING AND SELECTION OF MODELThe size of a <strong>Magnastart</strong> required is decided solely by the motor size and starting dutyrequired. Factors to be used in determining ‘starting duty’ are:• The number of starts per hour.• The starting period.• The starting current as a factor of full load rotor current.The rating of the required <strong>Magnastart</strong> is determined by the motor’s full electrical powerrating in kW/HP. It is not normally determined by the running mechanical load, sinceduring start-up the motor will draw the maximum power possible (usually well in excess ofthe normal running power) to accelerate the machinery’s mass.The ratings have been calculated on a basis of 15 second starts, with near-full-speed beingreached in ~10 seconds and being shorted in 15 seconds, generating a maximum of 1.5times the full load torque at start. For other starting conditions, the units can be up-rated orde-rated in proportion.In addition the motor’s rotor voltage and current ratings should be considered to make surethese do not exceed the <strong>Magnastart</strong>’s rating. Only very rarely do motors exceed the<strong>Magnastart</strong> ratings for rotor voltage or current. However, if the maximum rotor startingcurrent or voltage is exceeded, a larger <strong>Magnastart</strong> is needed. Note that the <strong>Magnastart</strong>rotor ratings allow a wide range of voltage and current capacity, but these must not be usedin conjunction beyond the maximum power rating of the <strong>Magnastart</strong>.The chart in Section 9 provides a selection of front panel tappings and their relativeimpedances. This is used to select the right tapping. If the impedance needed is not known(which is quite often), the right tapping can be found by attempting a start with a highimpedance tapping, then progressively trying lower impedance tappings until the rightstarting characteristics (line current vs time) are obtained. During the setting up operation,the rotor current should also be measured on each attempted start. This ensures that the<strong>Magnastart</strong> and motor rating is not exceeded and gives a guide to the additional torque thatmight be obtained on lower impedance tappings.8. INSTALLATION8.1. Enclosure and MountingThe <strong>Magnastart</strong> should be installed in a suitable metallic enclosure, protected fromhuman access. This need not be ventilated but reasonable space should be left eitherside of the <strong>Magnastart</strong> to allow circulation of air around the coils. The heat energydissipated in the <strong>Magnastart</strong> during a start is approximately the same as the storedkinetic energy in the motor and load.If it is mounted in the base of a control cubicle, ensure that enough ventilation ornatural cooling through the body of the cubicle is provided to prevent the heatgenerated during starting cycle(s) adversely affecting other equipment (eg PLC). ExtraPage 9 V1.3