Pumps - PT Hydraulics

Pumps - PT Hydraulics

Pumps - PT Hydraulics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

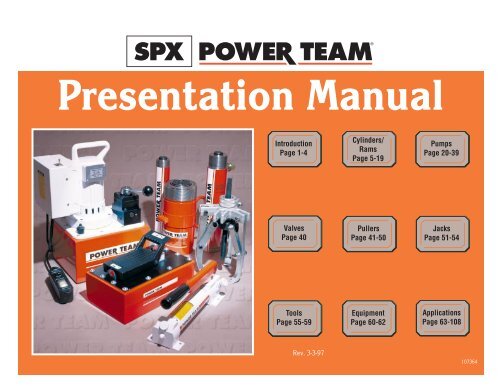

®Presentation ManualIntroductionPage 1-4Cylinders/RamsPage 5-19<strong>Pumps</strong>Page 20-39ValvesPage 40PullersPage 41-50JacksPage 51-54ToolsPage 55-59EquipmentPage 60-62ApplicationsPage 63-108Rev. 3-3-97107364

®Profile1989 - Power Team moves from facility shared with OTC to new 205,000 square foot(19,045 square meters) manufacturing plant in Owatonna1990 - Power Team establishes facilities in:Kerkrade, NetherlandsConsett, UKMelbourne, AustraliaSingapore1991 - Power Team receives Best Plant Award from Industry Week Magazine1992 - Power Team receives Concurrent Engineering Award from Machine Design Magazine1993 - Power Team achieves ISO 9001 registration at USA facility1994 - Power Team achieves ISO 9002 registration at UK facility1995 - Power Team achieves ISO 9002 registration at Netherlands and Singapore facilities22Rev. 1-9-96

®Quality CommitmentThe Total Quality Management philosophy of POWER TEAM is to maintain high quality standards in all phases of design, procurement, manufacturing, sales,and service. POWER TEAM is committed to continuous quality improvement, customer satisfaction, and the reduction of total costs.Design StandardsANSI B30.1 - CylindersANSI B40.1 - GagesIJ100 - HosesNEMA - Power <strong>Pumps</strong>CSA - Power <strong>Pumps</strong>•Federal Specification - GGG-P-00781-D- PullersCE MarkLifetime Marathon Warranty33Rev. 3-21-95

®CE ConformanceCylinders/RamsPower Team cylinders that have an EC Declaration of Incorporation.C series, RA series, RLS series, RSS series, RH series, RP series, RT series, RD series & R series.CE•Requirements:Translated Operating Instructions•Translated Warning Decals•Standards that this product conforms to:Machinery Directive;89/392/EEC, amended by 91/368/EEC, 93/44/EECand 93/68/EEC.•Standards; EN292-1 and EN292-2 Safety of MachineryPictograms follow ISO7000 standardsPower Team's Compliance:•The operating instructions are in the language of theuse. Currently available are French, German, Dutch,Spanish, and English. Other languages are available on•requestWarning decals on the product are in the language ofthe user. Currently we have French, German, Dutch,Spanish, and English•All foreseeable hazards are removed, safeguarded orwarned against in the operating instructions•For consistency and conformity3A3ARev. 3-3-97

®CE ConformanceHand <strong>Pumps</strong>Power Team hand pumps that have an EC Declaration of Incorporation.P12 series, P19 series, P23 series, P300 & P300D series, P157 & P157D series, P159 & P159D series, P460 series, P55 series, and P59 series.CE•Requirements:Translated Operating Instructions•Translated Warning Decals•Standards that this product conforms to:Machinery Directive;89/392/EEC, amended by 91/368/EEC, 93/44/EECand 93/68/EEC. Standards; EN292-1 and EN292-2•Safety of MachineryPictograms follow ISO7000 standardsPower Team's Compliance:•The operating instructions are in the language of theuse. Currently available are French, German, Dutch,Spanish, and English. Other languages are available on•requestWarning decals on the product are in the language ofthe user. Currently we have French, German, Dutch,Spanish, and English•All foreseeable hazards are removed, safeguarded orwarned against in the operating instructions•For consistency and conformity3B3BRev. 3-3-97

®CE ConformanceReciprocating Air <strong>Pumps</strong>Power Team reciprocating air pumps that have an EC Declaration of Incorporation.PA4 series, PA6 series, PA50 series, PA60 and PA64 series.CE•Requirements:Translated Operating Instructions•Translated Warning Decals•Standards that this product conforms to:Machinery Directive;89/392/EEC, amended by 91/368/EEC, 93/44/EECand 93/68/EEC. Standards; EN292-1 and EN292-2•Safety of MachineryPictograms follow ISO7000 standardsPower Team's Compliance:•The operating instructions are in the language of theuse. Currently available are French, German, Dutch,Spanish, and English. Other languages are available on•requestWarning decals on the product are in the language ofthe user. Currently we have French, German, Dutch,Spanish, and English•All foreseeable hazards are removed, safeguarded orwarned against in the operating instructions•For consistency and conformity3C3CRev. 3-3-97

®3DCE ConformancePower Team pumps that have an EC Declaration of Incorporation:PA17 series, PA46 series, PA55 series, PG30 series, PG55 series, PR10 series and PG18 seriesPower Team pumps that have an EC Declaration of Incorporation and a EC Declaration of Conformity:PE17XX-E220 series, PE30XX-E220 series, PE46XX-E220 series, PE55XX-E220 series,PE17XX-UK220 series, PE46XX-UK220 series, PE17XX-UK110 series, PE55XX-UK110 series.CE•Requirements:Translated Operating Instructions•Translated Warning Decals•Standards that this product conforms to:Machinery Directive;89/392/EEC, amended by 91/368/EEC, 93/44/EECand 93/68/EEC. Standards; EN292-1 and EN292-2Safety of MachineryEmissions test:89/336/EEC Electromagnetic compatibility directive.EN55011, EN55014 radio frequency emission std.Immunity test;89/336/EEC Electromagnetic compatibility directive.IEC801-2, IEC801-3, IEC801-4 Electromagnetic compatibility.Low voltage directive;73/23/EEC defines what voltage limits electric equipmentmust be to fall under this directive.Pictograms follow ISO7000 standards•Electric motors are equivalent to IP23IEC or equivalent electrical components are used•The control box meets IP54 standardsPower <strong>Pumps</strong>Power Team's Compliance:•The operating instructions are in the language of theuse. Currently available are French, German, Dutch,Spanish, and English. Other languages are available on•requestWarning decals on the product are in the language ofthe user. Currently we have French, German, Dutch,Spanish, and English•All foreseeable hazards are removed, safeguarded orwarned against in the operating instructions•Compliance means that this product will not interfere orstart other electric or electronic components.•This product will not be affected by outside electricalinterference.•If the voltage is lower than 75VDC or 50 VAC this electricaldirective does not apply.For consistency and conformity•This is a weather resistant standardThis is required by EC directives, for electrical shockprevention by keeping fingers and other objects from•contacting the component contactsThis is a weather resistant standard3DRev. 3-3-97

®CE General Guidelines• All operating instructions must be provided in the original languageand the language that the end user(s) understand completely. Weprovide these with our Declarations of Incorporation upon requesteven though it is not required until the final level machine is completelyassembled.• All Safety Warning Decals must be provided in the language thatthe end user(s) understand completely. We also provide theseupon request for our units having a Declaration of Incorporation.• Electrical machines must comply with the Machinery SafetyDirective 89/392/EEC, the Low Voltage Directive 73/23/EEC andthe EMC Directive 89/336/EEC.• Safety of Machinery-General EN60204-1 compliance is also•required.Emissions Immunity and Low Voltage tests must be conducted bya qualified lab on a representative sample machine which will be•produced with electrical controls and circuits.In production, each individual machine must undergo specific circuittests, like a hipot test for insulation breakdown, as required bythe applicable standards.•All electrical components are to be IEC approved.All hoses are to be ISO approved with a 4 to 1 safety factor, burstto working pressure. These hoses are 1/4" ID and can be providedby us upon request.•Schematics must be drawn to European standards.ALL wires must be marked and must correspond to the schematic•wire numbers.Compliance with the EMC and LVD Directives requires aDeclaration of Conformance and CE mark.•The manufacturer must establish a Technical Construction File.Declarations of Conformance must accompany the OperatingInstructions for the machine and be translated into the same languageas the Operating Instructions.• Safety of Machinery standard EN292-1 asks that ALL FORESEE-ABLE hazards be removed, safeguarded or warned against in the•Operating Instructions.Pictograms and other graphics should follow standards such as•ISO7000 for consistency and conformity.Annex 1 of the MSD specifically requires that Principles of SafetyIntegration 1.1.2, Marking 1.7.3. and Instructions 1.7.4 apply to all•machinery covered by the directive.Noise emissions must be included in the Operating Instructions for•operator areas.Components such as fittings, gauges, fasteners, non-electricalmechanical devices, valves, etc., are NOT REQUIRED to be individuallycertified. CE conformance is assured by the final level assemblydocumentation and testing required by the MSD.• Individually marketed Safety Components must have a Declarationof Conformity, but CANNOT have a CE mark applied.•Lifting machines have stricter requirements.There are 24 other directives being considered for CE approval at•this time.The existing directives are being amended and modified and it isthe responsibility of the manufacturer to remain current with thesechanges. For example, the MSD has 3 amendments: 91/368/EED,93/44/EEC and 93/68/EEC.3E3ERev. 3-3-97

®Innovations4In an on-going effort to differentiate Power Team from Enerpac we continuallyadd new products/services/ideas to achieve that end. The following is a list of items where we were first to the market.In addition, we have added many items to fill the line and now have a breath and depth that equals or exceeds Enerpac.*Aluminum CylindersCribbing Block SetsElectric Powered <strong>Pumps</strong> meeting NEMA 12 Standard•*Cordless <strong>Pumps</strong>Extensive Valve Lines (examples: 9609 pressure comp, flow cont., 9628& 9630 pre-stress valves, 9629 load lowering, 9631 metering valve, etc.)Flame Out Oil*100 Ton Enforcer*Nut Splitters*Flange Spreaders*Inflatable Jacks•*Extensive Puller Line*Extensive Press & Press Accessory LineRoll Bed PressesC Frame PressesExtensive Crane & Lifting Accessory LineSpecial Application Presses & Pullers (railroad axle, etc.)•Hydraulic Tester LineA Commitment to Standards Compliance (CSA, ANSI, IJ100,CE Mark, etc.)•*Lifetime Marathon WarrantyComplete electrical systems on 3 phase power units (includes motorstarter, relays, terminals, etc.)*User safety seminars & video tapes on safety*Add spring return to Pancake and Shorty cylinder seriesProtective BlanketsEnvironmentally Friendly Hydraulic FluidPipe SealantGas <strong>Pumps</strong> with DC Solenoid ValvesHydraulic SpreaderBench Mounting Fixture*Flush Face Couplers*800 number in Order Entry, Technical ServicesSuper Grip-O-Matic PullersEnforcer 55C-Series cylinder accessories rated at full capacity of cylindersTwin cylinder cylindersManual torque wrenches*Power Tech surface treatmentPower BaseSketch PadHydra-Grip-O-Matic Pullers•Post Tension Stressing JacksRebar Benders* = Indicates items later added to Enerpac line4Rev. 4-30-98

®Product Number DefinitionCYLINDER RAMSC51C C = Ram or Cylinder5 = 5 Ton Capacity1 = 1" StrokeC = With Ram Half CouplerRA556 R = Ram or CylinderA = Aluminum Construction55 = 55 Ton Capacity6 = 6" StrokeRA556L L = Locking CollarRLS500S R = Ram or CylinderL = Low ProfileS = Spring Return50 = 50 Ton Capacity0 = Less than 1" StrokeS = With Swivel CapRSS302 R = Ram or CylinderS = ShortyS = Spring Return30 = 30 Ton Capacity2 = 2" StrokeRSS1002D D= Double ActingCYLINDER RAMS (con’t)RD1010 R = Ram or CylinderD = Double Acting10 = 10 Ton Capacity10 = 10" Nominal StrokeRT172 R = Ram or CylinderT = Twin Style17 = 17 Ton Capacity2 = 2" Nominal StrokeRP25 R = Ram or CylinderP = Pull Style2 = 2 Ton Capacity5 = 5" Nominal StrokeRH303 R = Ram or CylinderH = Hollow Style30 = 30 Ton Capacity3 = 3" Nominal StrokeRPS55 R = Ram or CylinderP = PumpS = Set5 = 5 Ton Capacity5 = 5" Nominal StrokeCYLINDER RAMS (con’t)RHA306 R = Ram or CylinderH = Hollow StyleA = Aluminum30 = 30 Ton Capacity6 = 6" Nominal StrokeR1006C R = Ram or Cylinder100 = 100 Ton Capacity6 = 6" Nominal StrokeC = Load Return CylinderR1006L R = Ram or Cylinder100 = 100 Ton Capacity6 = 6" Nominal StrokeL = Locking CollarR1006D R = Ram or Cylinder100 = 100 Ton Capacity6 = 6" Nominal StrokeD = Double Acting4A4ARev. 3-3-97

®PUMPSProduct Number DefinitionPULLERSTOOLS (con’t)P159D P = Hand Pump159 = 159 Nominal ReservoirEP in Cu. In.D = 4 Way ValvePA4R P = PumpA = Air Motor Driven4 = 4 Cu. In. @ 10KR = W/Remote ControlPE552S P = PumpE = Electric55 = 55 Cu. In. @ 10K2 = 2 Way ValveS = Electric SolenoidOperated ValvePE172 P = PumpE = Electric17 = 17 Cu. In. @ 10K2 = 2 Way ValvePG303 P = PumpG = Gas Engine Driven30 = 30 Cu. In. @ 10K3 = 3 Way ValvePH172 P = PullerH = Hydraulic17 = Capacity2 = JawPH173 3 = 3 JawIJ128JACKSIJ = Inflatable Jacks12 = 12 Ton Max. Capacity8 = 8" Stroke Max.TOOLSHS2000 H = HydraulicS = Spreader2000 = 2000 Lb. CapacityHNS150 H = HydraulicN = NutS = Splitter15 = 15 Ton Capacity0 = No Significant MeaningHP35 H = HydraulicP = Punch35 = 35 Ton CapacityHP35SP S = Punch SetP = Electric PumpHT75 H = HydraulicT = Tester75 = 75 Gallon CapacitySPE5513FC6000EQUIPMENTSP = Shop PressE = Electric Pump55 = 55 Ton Capacity13 = 13" StrokeFC = Floor Crane6000 = 6000 Lb. Capacity4B4BRev. 3-3-97

®CustomersCylinders/RamsSales/Customers Power Team got/kept because of cylinder quality/featuresCustomer:• Major U.S. Chemical CompanyMajor U.S. Mining Company•Major Canadian RailroadMajor U.S. Frame Straightening Company• Korea• New Zealand• Many OEM’s; frame straightening, crimping,etc.Cylinders/Rams:• AllAll• AllC Series• RA Series• RLS Series• AllReason:• Better materialsTestingStronger bronze nuts•Higher impact strength materialLonger life•No leakageSurface finishing•Hard coatingPower Tech surface treatment•SwivelsProven reliability over many yearsof service55Rev. 3-21-95

®6RTSERIESRSS SERIESR_____CSERIESRHASERIESRASERIESC SERIESR_____D SERIESCylinders/RamsRDSERIESRH SERIESRLS SERIESR_____L SERIESHighlights:• All cylinders are date-coded and max. rated pressure and capacitymetal stampedManufacture in-housePioneered conformance with ANSI B30.1 standards•All cylinders fully tested to 125% capacity before leaving factoryCylinder bores are roller burnished to harden surface and providesmoother surface to increase seal life by additional 30%•Base mounting holes suitable for use at maximum capacityTypical cylinder burst pressures range from 25,000 psi•(1,750 bar) to 35,000 psi (2,450 bar)Cylinders with gland nuts may be dead ended at 10,000 psi(700 bar)Assembled and tested by certified assemblersAll cylinders covered by Power Team Lifetime Marathon WarrantyEddy Current and/or Mag Particle inspected to detect flaws in steelAll parts/components packaged in special materials to prevent rustBaked epoxy finishPower Tech surface treatment on critical componentsFull coverage decals on “C” Series cylinders/rams•Higher quality product resulting in fewer warranty claimsRemove material from O.D. to ensure flaws are removed. Other usematerials as drawn(rolled) at the mill.•Solid body cylinder – not welded like some competitorsRemovable carry handles standard on most cylinders.6Rev. 3-3-97

®Roller BurnishingCylinders/RamsAll Power Team cylinders are rolled, that means not being ground (honed) but cold rolled to achieve a compressed, work hardened surface.The result of this machining method is a very smooth and wear-resistance surface. The life-time of the cylinder seals is prolonged.7peak-to-valleyheight___________ 15 1510,000 1,000,000 in.Ground Surface:Principally when grinding,a material layer will betaken off in the same wayas by lathe or mill.The ground surface,though showing smallpeak-to-valley-height hassharp edges which willreduce lifetime of theseals.peak-to-valleyheight___________ 15 1510,000 1,000,000 in.Rolled surface:The rolled surface hasthe same peak-to-valleyheightas the groundone; yet the machininggrooves are being rolledand smoothed.7Rev. 7-31-95

®Power-Tech Surface TreatmentCylinders/RamsA Proprietary Power Team process for treating steel surfacesFeatures:•56 Rc minimum surface hardnessPasses ASTM B117-85 100 hour salt spray corrosionresistance testsBenefits:High corrosion resistanceHigh wear resistanceAnti-gallingRetains lubricantsPrevents bronze and other materials from sticking to surfaceIncreases fatigue strengthIncreases impact strengthIncreases surface yield and tensile strength•Improved abrasion and scratch resistanceNo appreciable dimension changeResults:• Significant increase in life expectancy of a treatedproduct• The Power-Tech surface treatment is a standard feature on thegland nut and cylinder body of the following listed Power Teamcylinders: C556CL, C1006CL, C1506CL, RLS50, RLS100,RLS200, RLS300, RLS500S, RLS750S, RLS1000S, RLS1500S,RSS1002, RSS1002D• All RH Series Center-hole cylinders, single- and double-acting,have the standpipe treated with the Power-Tech surfacetreatment.• The Power-Tech surface treatment can be purchasedas an option on any Power Team cylinder of steel construction.Consult our factory for price and availability.88Rev. 3-3-97

®Bronze PlatingCylinders/RamsPower Team has chosen to use bronze plate because it is a sacrificial bearing material with excellent corrosion resistance properties. This is important in lowprofilecylinders where bearing surfaces are short and exposed surfaces are large. We also do chrome plating in our facility.Features:Anti-gallingGood adhesion•High lubricity propertiesHigh corrosion resistanceBenefits:• Protects the more critical seal surfaces in the bore and theshort bearing surface in the retainer nut.Results:• Light scratches may occur in the plating, but the cylinder willcontinue to function without causing damage to internal componentsunlike chrome plate which produces hard, sharp-edged•flakes when the coating deteriorates.When bronze plate wears, it transfers to the mating part and•aids in lubrication.The underlying material in the piston is medium carbon steel,heat treated for strength and hardness. This strength and thegood adhesion of the bronze plating are important in situationswhere high side load may occur and attempt to deform thematerial below the plating.99Rev. 3-21-95

®C SeriesCylinders/RamsForty models to choose from. Capacities range from 5 to 100 tons and strokes up to 16 in. (406 mm).Designed for working pressures up to 10,000 psi (700 bar). Accessories are available to add to these rams’ versatility.Also available with locking collars (C_____CL Series)10Features:•Grooved ram cap (replaceable)•Internal piston rod threads•Aluminum bronze gland nuts (many competitors use lowerstrength bronze)•Urethane or glass filled teflon rod wipers•Tapered gland nut stop area for dead endingCollar threads with thread protector•Solid steel body (not welded like some competitors offer)Chrome plated piston rod (some competitors have unplated•steel)Rod and body made of better material (mediumcarbon/alloy steel)•Hardened steel stroke limiting stop ring•Aluminum Bronze Piston BearingPremium urethane "U" cup seal with seal guideHeavy duty flat wire spring•Simple spring attachmentBase mounting holes (except 75 and 100 ton models)Benefits:•Prevents damage to the end of the piston rod•Keeps load from slidingProvides for attachment of approved accessories on 5 to•25 ton ramsReduces wear on piston rod and provides high strength forfull dead ending•High strength and better wear than 660 bearing bronzeKeeps dirt, water and other contaminants out of the internalbearing and bore surfaces and has high abrasion resistance•Higher burst pressuresUsed to mount ram in a fixture or attachment and whenfully engaged in a mating thread will withstand the fullrated capacity of the ramProtects unused collar thread•Eliminates leakage sourcesBetter wear and corrosion resistance compared with•uncoated steelHigher strength, more uniform than low carbon used byothers•Better wear and higher burst pressuresHigh strength retainer allows full dead ending without damage•High strength and better wear than 660 bearing bronzeProvides high cycle lifeEliminates seal rolling and leakageMore coils and no spring hooks (loops) provide longer life•Saves time in repairSecure mounting10Rev. 7-31-95

®CBT SeriesCylinders/RamsFive models to choose from. Capacities range from 5 to 25 tons and strokes up to 14 1/4 in.Designed for working pressures up to 10,000 psi (700 bar). Accessories are available to add to these rams’ versatility.10ACylinder flat base increasesbase area.Cylinders have threaded basesto accommodate a variety ofadapters.Spreading application withtwo cylinder flat bases, andthreaded connector/orextension rod.Features:•Male (N<strong>PT</strong>) threaded piston rod mounting•Aluminum bronze gland nuts (many competitors use lowerstrength bronze)•Urethane or glass filled teflon rod wipers•Tapered gland nut stop area for dead endingCollar threads with thread protector•Solid steel body (not welded like some competitors offer)Chrome plated piston rod (some competitors have unplated•steel)Rod and body made of better material (mediumcarbon/alloy steel)•Hardened steel stroke limiting stop ring•Aluminum Bronze Piston BearingPremium urethane "U" cup seal with seal guideHeavy duty flat wire spring•Simple spring attachmentInternal base threads(NPSM)Benefits:•Provides for attachment of approved accessories on 5 to•25 ton ramsReduces wear on piston rod and provides high strength forfull dead ending•High strength and better wear than 660 bearing bronzeKeeps dirt, water and other contaminants out of the internalbearing and bore surfaces and has high abrasion resistance•Higher burst pressuresUsed to mount ram in a fixture or attachment and whenfully engaged in a mating thread will withstand the fullrated capacity of the ramProtects unused collar thread•Eliminates leakage sourcesBetter wear and corrosion resistance compared with•uncoated steelHigher strength, more uniform than low carbon used byothers•Better wear and higher burst pressuresHigh strength retainer allows full dead ending without damage•High strength and better wear than 660 bearing bronzeProvides high cycle lifeEliminates seal rolling and leakageMore coils and no spring hooks (loops) provide longer life•Saves time in repairProvides attachment of approved accessories.10ARev. 3-3-97

®C Series AccessoriesCylinders/RamsThe accessories permit additional flexibility in the application of Power Team hydraulic cylinders to perform a wide variety of tasks.Rated for full capacity (10.000 psi) of cylinders, making them more versatile than they already are.Features:•Variety of attachments available.•Rated for full capacity of cylinders.Benefits:•The accessories permit additional flexibility in the applicationof Power Team hydraulic cylinders to perform a•wide variety of tasks safelyNo guessing about safety of accessories in use.Competitors often rate accessories capacity at 50% ofcylinders capacity10B10BRev. 3-3-97

®RA SeriesCylinders/RamsThese rams are rugged enough to handle the tough jobs, yet weigh half as much as steel rams! Pioneered aluminum cylinder design in 1972. Designed forworking pressures up to 10,000 psi (700 bar). Many models to choose from. Also available with locking collars (RA_____L Series).Features:Grooved piston top1/2 weight of comparable steel cylinder•Aluminum material used for body, piston and gland nut60 Rc hard coating on cylinder body, piston rod andgland nut•Standard removable carrying handle (most sizes)Urethane “U” cup sealOptional ram base plate for 55 ton capacity unitsReplaceable steel ram cap•Simple spring attachmentSwivel Cap Accessories for 55 & 100 tonBenefits:Keeps load from sliding on top of the pistonEasier and safer handling•Prevents sparking in explosive environmentsLong wear and corrosion resistance•Ease of handling but removable when requiredProvides higher cycle lifeEliminates leakageAdded stabilityPrevents damage to the end of the piston rod•Saves time in repairReducesoff center loading1111Rev. 3-3-97

®RLS SeriesCylinders/RamsTheir height makes them ideal for “low clearance” jobs. Capacities from 5 to 150 tons! Pioneered spring return in these “pancake” rams.All single-acting models have a heavy-duty return spring for faster ram return.Features:•Very low ram profileDome on rod end (5 through 30 ton) or standard swivelcap with grooves (50 through 150 ton rams)•Power Tech finish standard on the body and gland nutTwo counterbored through mounting holes•5 degree angle on ram couplers•Tapered piston and gland nut contacts when deadendingUnique conical heavy duty spring designHeat treated alloy steel•“O” Ring seal with backupBronze plated pistonBenefits:•Fits in tight quartersMinimize the effect of off center loading•Improved corrosion and wear resistanceSuitable for attaching the ram to another member or•device using socket head cap screwsEasy hook up and higher above surface to prevent•damageHigher burst pressuresInsures rapid retraction and extra bearing lengthDurability and strength•Reduces extrusion, rolling and leakageCorrosion resistant and provides superior bearingproperties1212Rev. 2-1-96

®RSS SeriesCylinders/RamsTheir height makes them ideal for “low clearance” jobs. Capacities from 10 to 250 tons. Pioneered spring return in this series of rams.All single-acting models have a heavy- duty return spring for faster ram return.Features:No spring mounting thru hole on pistonMinimum collapsed height•Grooved piston topBronze plated piston and rod•Steel retaining nutRSS1002 cylinder body has Power Tech surfacetreatment•Accessory swivel caps available for all RSS series rams•except RSS1002D and RSS2503Cribbing block accessories available for 30, 50 & 100•ton ram models (see catalog)Tapered piston and gland nut contact when dead•endingCoupler is angled 5 degrees•Rod and body made of better material (mediumcarbon/alloy steel)•Simple spring attachment“O” Ring seal with backupBenefits:Eliminates leakageGets in places with minimal clearance•Keeps load from sliding on top of the pistonIncrease life (except RSS1002D which is hard chromeplated) and corrosion resistance•Increased strengthCorrosion resistance and reduce wear (All other modelsof “RSS” rams are available with Power Tech as an•extra cost option)Minimize effects of off-center loading•Provides mechanical means to safely support loads for•extended periods of timeHigher burst pressures•Easy hook up and higher above surface to prevent•damageHigher strength, more uniform than low carbon usedby others•Saves time in repairReducesextrusion, rolling and leakage1313Rev. 2-1-96

®RD SeriesRD10THRURD200SERIESCylinders/RamsThere are 20 sizes to choose from, capacities ranging from 10 to 500 tons.Ideally suited for severe applications, high cycles, various mountings. Production fixturing, cabling.Features:Benefits:• Piston rod threads•Withstand full pull tonnage of ramsUrethane or glass filled teflon rod wiperKeep dirt, water and other contaminants out of theinternal bearing and bore surfaces and has high abrasionresistance.• •Urethane “U” cup sealProvides higher cycle lifethreadsto mount ram in a fixture or attachment and when•Collar•Built in safety relief valve on retract side•Aluminum bronze overlay bearings on high strengthsteel in both piston and gland nut•Hard chrome plated heat treated piston rodsT-Seals with energized backups are used on the pistonon most models (superior to o-rings)•Accessory swivel caps are available for some modelsRod, body and gland nut made of higher strength•medium carbon or alloy steelBase mounting holes•Usefully engaged in a mating thread will withstand the full•rated capacity of the ram.Prevents accidental over pressurization if retract port•obstructedLonger wear, corrosion resistance and high strength•Longer wear on both the piston and gland nutReduces extrusion, rolling and leakage•Reduce effects of off-center loadsHigher strength, better wear and higher burst pressure•Secure attachment14RD300,RD400 &RD500SERIES14Rev. 5-10-97

®RT SeriesCylinders/RamsRun cables, screws, etc. through the center of the ram.Single-acting, spring-return, or double-acting, hydraulic return in four different capacities from 17-1/2 to 100 tons.Features:•Quick change insertUnique twin cylinder center hole designCost effective•Easy to repairUrethane cup seals•Double acting ram has trip valve to prevent dead•endingBuilt in safety relief valve on retract side•Time tested modelBenefits:•Switch from a tapped hole to a plain holePermits a cable, rod or pulling screw to pass throughramMore value per ton•Low cost maintenanceLonger life•Eliminates seal rolling and leakagePrevents over pressurization•Prevents accidental over pressurization if retract port•obstructedDesigned for use with Power Team pullers andspecial adaptersDesigned in 1950's and continuously improved formaximum reliability1515Rev. 7-31-95

®RP SeriesCylinders/RamsDesigned for pulling and tensioning applications two models to choose from, 2 and 5 ton capacities.Features:•Piston rod threads•One piece cylinder body design•Chrome plated piston rodThread protector•Collar threads standardRod and body made of better material (medium carbon/alloysteel)•Heavy duty compression spring with spring guideRoller burnishing in bore•Base mounting threadPremium urethane rod wipers•Urethane cup sealsBenefits:•Improved safety (more than 175% stronger than tested•competitors’ units)Burst resistance (200% better than competitor’s unitswith brazed ports)•Better wear and corrosion resistancePrevents damage to threads and protects user fromthread cuts•Can be used at full ram capacityHigher strength, more uniform than low carbon used byothers•Longer cycle life and rapid ram extensionBetter seal wear and longer cycle life (300% better thancompetitors’ units tested)•Attachment of accessories or mounting in a fixtureKeeps dirt, water and other contaminants out of theinternal bearing and bore surfaces and has high abrasionresistance•Longerlife eliminates seal rolling and leakage1616Rev. 2-1-96

®RH SeriesCylinders/RamsSingle and double acting models to choose from. Run cables, screws, etc. through the center of the ram.Single-acting, spring-return, or double-acting, hydraulic return in nine different capacities from 10 to 200 tonsFeatures:•Center hole design•Threaded piston rod for insertsReplaceable head inserts for most rams•Collar threads are standard on many models•Bronze plated or chrome plated piston rodsT-seals with energized backups are used on the piston•on most models (superior to O-rings)Chrome plating or Power Tech surface treatment used•on standpipes of all single acting ramsDouble acting rams have relief valve on retract side•Body made of better material (mediumcarbon/alloy steel)Benefits:•Permits cables or screws to pass through the center ofthe ram (push and pull with rod)•Withstand full pull tonnage (on double acting units)Allows for choice of tapped, plain center hole or solidinserts•Prevents damage to rod end.Use to mount ram in a fixture or attachment and matingthread will withstand the full rated capacity of theram.wear and corrosion resistance•BetterReduces extrusion, rolling and leakage•Improved corrosion resistance and wear•Prevents accidental over pressurization if retract port•obstructedHigher strength, more uniform than low carbon usedby others1717Rev. 3-3-97

®RHA SeriesAluminum Hollow Cylinders/RamsSingle-acting spring return, 30 ton capacity.Features:•Center hole design•Threaded piston rod for attachment of replaceableinserts60 Rc hard coating on cylinder body and piston rodT-seals with energized backups are used on the pistonPower Tech surface treatment used on standpipe•1/2 weight of comparable steel cylinderAluminum material used for body, piston and gland nut•Optional removable carrying handleBenefits:•Permits cables or screws to pass through the center of•the ram (push and pull with rod)Custom inserts can be provided to attach various typesof devicesLong wear and corrosion resistanceReduces extrusion, rolling a nd leakage.Improved corrosion resistance and wear•Easier and safer handlingPrevents sparking in explosive environments and does•not corrode in environments where steel often rustsEase of handling but removable when required17A17ARev. 3-3-97

®C_____CL Series Locking CollarCylinders/RamsPower Team has an extensive line of locking collar rams. These rams are designed to be used in applications where the lifted load will remainsupported on the ram for extended periods of time. This feature affords additional safety and allows the user to lift the load hydraulically then mechanicallysecure the locking collar against the body of the ram. With the locking collar supporting the load, the user can release the hydraulic pressure and rely on amechanical lock to retain the load for an indefinite period of time. The heavy duty Stub Acme type thread used on the piston rods and locking collars is lesssusceptible to nicks and jamming than are other thread forms commonly used on this type of ram. Three models available (spring return for 55 & 100 ton rams,gravity return for 150 ton ram), all features and benefits of the C Series rams plus these.Features:•4 to 1 factor of safety on locking collar and piston rod•threadsRam bodies and gland nuts are treated with Power Techsurface treatment•Piston rods have plated bronze finishHeavy duty stub acme threads on piston rod andlocking collar.Benefits:•This series of rams are designed to survive rugged,•heavy duty applicationsCorrosion and abrasion resistant•Corrosion resistance and superior bearing qualitiesProvides positive mechanical lock to retain lifted loadfor extended periods of timeAllows the pump to be disconnected from ram whileretaining lifted load on locking collar1818Rev. 5-10-97

®RA____L SeriesCylinders/RamsPower Team has an extensive line of locking collar rams. These rams are designed to be used in applications where the lifted load will remainsupported on the ram for extended periods of time. This feature affords additional safety and allows the user to lift the load hydraulically then mechanicallysecure the locking collar against the body of the ram. With the locking collar supporting the load, the user can release the hydraulic pressure and rely on amechanical lock to retain the load for an indefinite period of time. The heavy duty Stub Acme type thread used on the piston rods and locking collars is lesssusceptible to knicks and jamming than are other thread forms commonly used on this type of ram. Two models available no competition! All features andbenefits of the RA Series rams plus these.Features:•2 to 1 factor of safety on locking collar and piston rod•threadsHeavy duty stub acme threads on piston rod andlocking collar•Accessory swivel capsBenefits:•This series of rams is designed to survive rugged,•heavy duty applicationsProvides positive mechanical lock to retain lifted loadfor extended periods of timeAllows the pump to be disconnected from ram while•retaining lifted load on locking collarReduces affects of off center loading18A18ARev. 3-3-97

®R_____C SeriesCylinders/RamsHigh-tonnage, low cycle, economy cylinders with no gland nut.9796MADE IN USA10000 PSI MAXFeatures:•Bronze plated piston rodsAlloy steel heat treated body and piston•Removable handles (most models)Improved overflow port design (weep hole*) stroke•limiterVisual indicator band•Heavy duty Urethane “O” ringOptional grooved swivel caps available for all models of“R” Series ramsBenefits:•Corrosion resistance and superior bearing qualities.Outperforms Teflon coatingReliability and strength• Portability*Insures that the load will not be lost if the seal inadvertentlypasses over this overflow port•**Alerts operator to end of cylinder stroke prior to ventingoil from overflow port•Proven reliabilityReduce effects of off-center load* Note: While we out performed the competition 20:1, inthe event the seal passes over the overflow port, we recommendthat the seal be replaced before the ram is used inanother application.** Note: The majority of “R” Series rams are manufacturedto order with stroke lengths up to 13”(330 mm). The PowerTech surface treatment is recommended on all “R” Seriesrams that will be subjected to corrosion or side loading.1919Rev. 5-10-97

®R_____L Series Locking CollarCylinders/RamsHigh-tonnage, low cycle, economy cylinder with added safety of locking collarto secure cylinder in extended position under load, with no gland nut.Features:•Same as "R_____C" Series plus3 to 1 factor of safety on locking collar and piston rod•threadsHeavy duty stub acme threads on piston rod andlocking collarBenefits:•Same as "R_____C" Series plusFor heavy duty applications•Provides positive mechanical lock to retain lifted loadfor extended periods of timeAllows the pump to be disconnected from ram whileretaining lifted load on locking collar9796MADE IN USA10000 PSI MAX19A19ARev. 3-3-97

®R_____D SeriesCylinders/RamsMany models to choose from. Capacities range from 100 to 565 tons and strokes up to 13 in. (330mm).Designed for working pressures up to 10,000 psi (700 bar).9796MADE IN USA10000 PSI MAXFeatures:•Standard swivel capUrethane or glass filled teflon rod wiper•O-ring seals with backupBuilt in safety relief valve on retract side•Steel piston and gland nutHard chrome plated heat treated piston rods•Rod, body and gland nut made of high strength, alloysteelBenefits:•Reduces affects of off center-loadingKeep dirt, water and other contaminants out of theinternal bearing and bore surfaces and has high abrasionresistance.•Reduces extrusion, rolling and leakagePrevents accidental over pressurization if retract portobstructed•High strength allows full dead ending without damageLonger wear on both the piston and gland nut•Higher strength, better wear and higher burst pressures19B9796MADE IN USA10000 PSI MAX19BRev. 5-10-97

®Customers<strong>Pumps</strong>Sales/Customers Power Team got/kept because of pump quality/featuresCustomers:•<strong>Pumps</strong>:•Reasons:• Major concrete stressing companiesPE55, PE200 & PE400 seriesLow voltage capabilitiesProven pump over the years, some pumpshave been in operation for 20 yearsAll metal constructionHigh durabilityPower Team was first to the marketDisplaced competition because of durability• • •and ease of maintenanceMajor bridge construction and repair companiesReliable long lastingPE17, PE55, PE30 Series & PG 1200-M4DPower Team customer supportRugged construction<strong>Pumps</strong> work well with generators• • • Major railroads PG30, PQ60 & PQ120 SeriesPG30 light weight and durability (use withtrack jack and other rams)PQ series used with railroad bearing pullerand other hydraulic components in shops2020Rev. 3-21-95

®CustomersSales/Customers Power Team got/kept because of pump quality/featuresOEM:•<strong>Pumps</strong>:•Reasons:Major U.S. torquing manufacturesPE55, PA55, PQ60, PQ120, PE200 &PQ400 Series• Major U.S. frame straightening manufactures • PE17 & PE46 Series • Pump reliability• Major U.S. rescue manufactures • PG55, PG120 & PG18 Series • Pump reliability• Major U.S. tensioning & work hardeningmanufactures• PE55, PE17, PA55, PA17, & PA46 Series• • Major hose crimping manufactures PE17, PE46, PE120, PE10, PE17 &PE30 Series21<strong>Pumps</strong>• Torque wrench manufactures have usedthese pump for yearsHave held off all challengers (Titan pump)Have cultivated lasting relationship by makingsome features proprietary to specificcustomersDurability, reliability and integrity are thereasons that we remain strong in thismarketStarting under loadHigh temperatureProprietary modificationsGas engine compatibilityCompact packagesProprietary modifications• ReliabilityAbility to modify to customer requirementsproprietary modifications• DurabilityReliabilityAbility to modify to fit the customersrequirements21Rev. 3-21-95

®<strong>Pumps</strong>• Hand• Reciprocating Air• Hydraulic IntensifierPower <strong>Pumps</strong>• Universal/Permanent Magnet Driven(Including Battery Operated)• Capacitor/Induction Driven• Rotary Air Driven22• Gasoline Driven22Rev. 3-3-97

®Hand/Hydraulic<strong>Pumps</strong>The Power Team hand pump line includes a variety of styles and sizes including single and two-speed models.These pumps are also available in a variety of custom configurations to fill our customers’ specific applications.P19P55Features:•Rugged all metal construction•Heavy-duty, formed sheet metal handleCarry handles on all models (except P12, P19, P23)Fill cap seal acts as safety valve (except P12 & P300)Two-speed models availableA variety of reservoir sizes•Heat treated handle bearing surfaces (only P157/P159D)Max safety relief valveunits 100% tested•AllRelief valve inboard of check valve system•Convenient fill cap•Rugged large round knobBenefits:•Strength and durability•Doesn’t burn thru in welding environmentsLess flex, less operator fatigue than round steel andcomposite handlesEasy to transportPrevents over-pressurizing reservoirReduces handle strokes so you work faster and easierThe right capacity for any applicationLonger service lifeLimits system pressure to 10,000 PSI (700 bar)•Assurance of qualityPrevents loads from drifting down. Does not provide•protection when additional weight is added to system.Allows pumps (except P12 & P460) to be filledhorizontally when mounted. Many models can be•filled vertically.Easeof use23P460SERIES23Rev. 3-3-97

®P12Operation23A23ARev. 7-31-95

®P55Operation23B23BRev. 7-31-95

®2 Stage Hand Pump OperationLow pressurepistonHigh pressurepistonHigh pressureinlet checkReliefvalveUnloadingvalveHigh pressureoutlet checkLow pressureoutlet checkUnloadingspoolLow pressurerelief ball23CInletfilterInlet checkballDirectioncontrolvalve23CRev. 7-31-95

®P460 Series - Model “D”OperationVent toreservoirLow pressure pistonLow pressureinlet checksHigh pressureinlet checkHighpressurepistonLow pressureoutlet checkTo valveHigh pressureoutlet checkLow pressureunloading valvePumpInletReliefvalve23D23DRev. 7-31-95

®Reciprocating/Air Hydraulic<strong>Pumps</strong>For OEM’s as well as maintenance and production people around the world, this is the pump of choice. With more than 25 years of proven performance andcontinual improvement, the PA6 series of air/hydraulic pumps offers dependability, versatility and convenience wherever air is the preferred power source.The most copied air/hydraulic pump in the world (PA6).Features:Air inlet filterFoam mufflerTwo-stage release valveFilter in outlet port•HDPE or metal reservoirsWide variety of models and optionsSee-thru reservoir (HDPE)Standard or large reservoirs availableAll-metal air motor•Serviceable air motor (not a throw away)All units 100% testedBenefits:Protects air motor for reliable performanceQuieter operationGives you complete, metered controlProtects pump from contaminated systems•Suits your application’s requirementsChoose the best, most economical combination foryour requirementsLets you check oil level from any angleSuits your application’s oil requirementsLong dependable service•Economical repairAssuranceof quality2424Rev. 3-21-95

®PA6 SeriesOperationAir Actuator ButtonRelease valve buttonOil return portto reservoirAir inAirpistonAirexhaustOil to ramTwo stagereleaseOutlet checkballAirpistonpoppetHyd. pumpcyl.Inlet checkballReliefValveExhaustvalvestemHydraulicpistonInlet filter24A24ARev. 7-31-95

®Hydraulic Intensifier<strong>Pumps</strong>Uses include utilities, railroads, construction riggers others. Operates off low pressure hydraulic portable pumpsas well as many vehicle on-board hydraulic systems.*Features:•Pressure ratio of 5 to 1•Operates either single-acting or double-acting cylindersand tools such as crimpers, spreaders, cutter etc.be used to operate two separate, single-acting tools•May(with integral valves) independently•Compact, rugged and portable.•Valve options available•Unit uses oil from low pressure pump source3/8 N<strong>PT</strong>F portsPortable low pressurepumps, utilitytrucks, etc.Benefits:•Turns low-pressure portable hydraulic pumps or onboard hydraulic systems into high-pressure power•sources(2000 psi/140 Bar to 10,000 psi/700 Bar).Wide range of options•No need for additional manifold•Great for use inside a utility bucket or storing•in a vehicleAdded versatility•No oil reservoir to maintainCompatible with standard fittings for low & highpressure systemsHydrauliccylinders,crimpers,spreaders,cutters,etc.24B*Note: Input flow must be limited to 10 GPM to prevent overheating. Ideal input is 5-10 GPM at 2000 psi.24BRev. 5-10-97

®Power <strong>Pumps</strong>All power pumps are 100% tested and are super charged thus avoiding sticking pistons with dirty oil and no broken return spring problems.Universal/Permanent Magnet Driven Motors•Lighter than comparable induction motor pumpsIntermittent dutyCapacitor/Induction Driven MotorsLonger life than Universal/Permanent Magnet motor pumps•Continuous runningAvailability of 3 phase motorsRotary•Air Driven MotorsUsed in explosive environmentsGasoline Driven Engines• Doesnot need an external power supplyRev. 7-31-952525

®Universal/Permanent Magnet DrivenPE18SERIESPE30SERIESVANGUARDPE10SERIESHighlights:• Starts and runs at low voltage. Will run downto 60% of nominal voltageStarts under full load•Runs on 50/60 cycle powerCan be run on DC voltage with special•switchesHighest flow per weight ratio of any pump•style (universal motors)Motors are single phase and are rated at intermittentduty as per CSA definition (30 min.•full load)Lighter than comparable Capacitor/Inductionmotor pumpsFlow rates the same whether 50 or 60 cycle•Suitable for use with long extension cordsPioneerin this type of pump - 1958Rev. 3-21-95VANGUARDPE55 SERIES26VANGUARD26

®PE18 Series<strong>Pumps</strong>All these pumps are two-speed with a roller vane type pump providing low pressure, high volume and an axial piston pump providing high pressure.A high noise level ranging from 85 - 90 dBA. Motors are single phase and are CSA rated for intermittent duty.<strong>Pumps</strong> are ideal to use with small hydraulic tools.Features:Lightweight•Integral valvingLow amp drawLarge variety of valve options•Universal motorCSA approvedBenefits:Very portable•Keeps the pump small and compactCan be used with smaller generators and low ampcircuitsAllows pump to be used in a large variety of applications•Low voltage capabilityAssurance that the electrical is built to an identifiablestandardSpecifications:•1/2 hp 115/110 or 220/230 50/60 Hz motor10 amp 115; 5 amp 230Reservoir capacity 104 in. 3 usable or 525 in. 3 usable•All units have a remote controlFlows: 190 in. 3 /min. at 100 psi•18 in. 3 /min. at 10,000 psiWeight 30 lbs.2727Rev. 5-10-97

®PE18 Series3 or 4 Way Valve Operation27A27ARev. 7-31-95

®PE18 SeriesAutomatic Valve Operation27B27BRev. 7-31-95

PE30 Series<strong>Pumps</strong>With these pumps, the low-pressure high-volume (gerotor design) stage provides fast ram piston travel. When high force is needed, the high pressure,low volume (radial piston design) stage takes command. A noise level range between 82 - 87 dBA. Motors are single phase and are CSA rated forintermittent duty. Ideal usage for all around general construction applications where low voltage is a possibility.Features:•True unloading valvePermanent Magnet motor•Choice between a 1 gallon (3.79 liters) and 1.75 gallon•(6.63 liters) reservoirLight weight and integral roll cage carry handle24 volt control circuit on all units with remote controls•Wide range of standard valve optionsCSA approvedSpecifications:•1 hp 110/115 or 220/230 50/60 Hz motor13 amp 115 vac. 6.5 amp 230 vac.•Reservoir capacity 280 in. 3 usable or 380 in. 3 usableFlows: 300 in. 3 /min. at 100 psi•30 in. 3 /min. at 10,000 psiWeight41 lbs. & 49 lbs.®Benefits:•Allows for higher flows at lower amp draw (efficiency)Has the same low voltage capability as the Universal•motor, but has a lower dBA (noise level) ratingThe customer can pick the pump that fits his application•Portable pump, with roll cage protection for the motorand controlsUser/Operator safety•The customer can better fit his applicationAssurance that the electrical is built to an identifiablestandard2828Rev. 5-10-97

®PE55 Series<strong>Pumps</strong>This series of “Universal - gear/axial piston” design of pumps were first developed and introduced in 1958 and has continually been improved.This is a rugged pump that will stand up to years of rough treatment, for example, some of our original pumps are still in service.A high noise level range between 90—95 dBA. Motors are single phase and are CSA rated for intermittent duty. This is a proven pump in many of thetoughest applications. It is and has been the mainstay for the heavy construction industry and the concrete stressing industry world wide and is CE approved.Features:•CSA approved•24 volt control circuit on all building block units with•remote controlsA large variety of valve options available on standard•catalog part numbers. (See catalog for details)True unloading valve•Reservoirs available in sizes up to 10 gallons•"Universal" MotorLight weight/portableBenefits:•Assurance that the electrical is built to an identifiable•standardUser/operator safety•The customer can order the pump he needs for his•application (Also see Building Block and ATO sections)Achieves greater pump efficiency, allowing higher flows•at maximum pressureAllows customer to use larger or multiplecylinders/rams•Starts and runs at reduced voltageBest weight to performance ratio of all Power Teamelectric pumpsSpecifications:PE55•1-1/8 hp 110/115 or 220/230 50/60 Hz motor25 amp 115 vac. 12.5 amp 230 vac.•Reservoir capacity 525 in. 3 usableFlows: 650 in. 3 /min. at 100 psi55 in. 3 /min. at 10,000 psi•Weight 65 lbsPED25•1-1/2 hp 115/230 60 Hz or 110/220 50 Hz motor22 amp 115 or 11 amp 220•Reservoir capacity 1000 in. 3 usableFlows: 300 in. 3 /min. at 100 psi•25 in. 3 /min. at 10,000 psiWeight 170 lbs2929Rev. 5-10-97

PE60 SeriesImproved serviceability of the already most easily maintained pump on the marketFeatures:On/Off/Jog Motor control switch standardOptional fan oil cooler•Pump is 18 lbs. lighter than Enerpac PUM3805D<strong>PT</strong>.Maintained superior first stage oil delivery of 650 cu. in.at 100 psi per min.Heavy duty bearings in high pressure pump•Hardened high pressure pump check blockTool steel shear seals and improved valve rotors arestandard•Improved external pressure regulatorMetal strain relief to retain power cord added•Motor rain deflector skirtAdded bladder & totally sealed hydraulic pumpSpecifications:•1-1/8 hp 110/115 or 220/230 50/60 Hz motor25 amp 115 vac. 12.5 amp 230 vac.•Reservoir capacity 3/4 gallon usableFlows: 650 in. 3 /min. at 100 psi•55 in. 3 /min at 10,000 psiWeight51 lbs®<strong>Pumps</strong>Benefits:More versatilityPrevents pump from overheating•Easier to use and handleFaster than competitionIncreased pump life•Increased pump lifeIncreased pump life•Quieter and easier to adjustReduces possibility of damage to electrical componentswhen cord is pulled•Helps keep dirt and contamination out of motorPrevents airborne dirt from contaminating system oiland preventing external oil leakage.29A29ARev. 5-10-97

®PE60 Series<strong>Pumps</strong>Improved serviceability of the already most easily maintained pump on the marketFeatures:•Screw on canister filterIntegral pressure gauge with integrated guardInsulated carry handle•Improved motor insulation classOptimized fan (80 to 85 dba at 3' distance with 54 dbabackgroundOil level sight gauge•Reduced pump foot printAdded reservoir oil drain port.Benefits:•Reduces pump and valve wearPositions gauge for easy reading while protecting itfrom damageProtect users hand from heat during long duty cycles.•Extends motor lifeReduced noise levelProvides accurate oil level monitoring•Ease of handlingEasyto drain and flush for preventative maintenance29B29BRev. 3-3-97

®PE55 SeriesGear/Axial Piston OperationLow Pressure StageArea where oil is joined at gear pumpIntakeHigh pressure inlet checkCheck valveHigh pressure outlet checkSpool of the unloading valvePressure chamberPistonPistonWobble plateGear pump outletSmall gearGear pump inletLarge gear29C29CRev. 7-31-95

®PE55 SeriesGear/Axial Piston OperationHigh Pressure StageCheck valveSpoolPortSupercharge relieve valveSpring29D29DRev. 7-31-95

30PE10 Series<strong>Pumps</strong>This series of pumps are powered by a 1/4 h.p. Permanent Magnet motor - (gerotor/radial piston design). The portability of a hand operated pump with theease and speed of a power driven pump. A low noise level range between 68 - 72 dBA. Motors are single phase or DC.Best suited for running small portable hydraulic tools.Features:®•Permanent Magnet motor•Bladder type reservoirAvailable in 115, 230 volt AC, and 12 volt DC•Lower pressure higher flow high pressure pistons•availableLightest weight pump•12 volt DC unit•External pressure regulator available as an option on all•pumps24 volt control circuit on all A.C. units with remotecontrols•Two stageValve options•1/4 hp 110/115 or 220/230 50/60 Hz or 12 VDC6 amp 115 vac. 3 amp 230 vac. 25 amp 12 VDC•Reservoir capacity 60 in. 3 usable (bladder)Flows: 120 in. 3 /min at 100 psi10 in. 3 /min at 10,000 psi20 lbsSpecifications:•WeightBenefits:•The same low voltage capability of the Universal motor,but with a lower dBA (noise level) rating•The pump can be used in any directionGives the customer more options to better fit hisapplication•Makes the pump more portable so the customer can use•it in more applicationsCan run on a standard automobile battery or on theportable battery pack available thru Power TeamLonger battery life than competition•Gives the customer more pressure options to better fit his•applications (1,000 PSI/70 bar to 10,000PSI/700 bar)User/Operator safety•Faster cycle times than competitive unitsMoreversatile than competition30Rev. 5-10-97

®Capacitor/Induction DrivenPE46SERIESPQSERIESHighlights:• Longer life than Universal/Permanent Magnet•motorsQuiet running, lower dBA than universal•motorsContinuous running (define per CSA andPower Team definition, PE21 & PE200)•CSA approved (except PE2000 or PE4000)Motors that run at 50 cycles produce 5/6 theflow of those that run at 60 cycles•Induction motors run ± 10% of rated voltageThermal overload projection to preventoverheatingPE20031PE21SERIESPE17SERIES31Rev. 7-31-95

®PE17 & PE84 Series<strong>Pumps</strong>This series of pumps are two-speed with a gerotor design providing low pressure, high volume and a radial piston design pump providing high pressure.A noise level ranging between 67-81 dBA. Motors are single phase and are CSA rated for intermittent duty. These pumps are CE approved and are ideal in awide variety of maintenance and construction applications where low voltage is not a concern.Features:Light weight•12 volt DC available24 volt control circuit on all units with 220 volt motorremote controlsBenefits:Portable and easy to carry•Can be run on a standard automobile batteryUser/Operator safetyNOTE: PE84 Series not available in 50 HZ.Specifications:•1/2 hp 110/115 or 220/230 50/60 Hz motor•10 amp at 115 vac.; 5 amp at 230 vac.Reservoir capacity 295 in. 3 usable (plastic)•375 in. 3 usable (steel)Flows: 190 in. 3 /min. at 100 psi•17 in. 3 /min. at 10,000 psiWeight 45 lbs (plastic)Weight 53 lbs. (steel)3232Rev. 5-10-97

®PE17 SeriesOperationValveValve CheckValveOutletPortPump ReleaseHandleLow PressureGerotor OutputOutputCouplingHigh/LowCheckAutomaticValveCheckBlockGerotorHousingPistonPistonBlockGerotorFilter ScreenLow PressureUnloading Adj.AutomaticValve Piston32A32ARev. 7-31-95

PE46 Series<strong>Pumps</strong>This series of pumps are two speed with a gerotor design providing low pressure, high volume and an axial piston design pump providing high pressure.A noise level ranging between 77-81 dBA. Motors are single phase and are CSA rated for intermittent duty. These pumps are used mostly for under the roofmaintenance and some production applications and are CE approved.Features:•Large selection of valve options•24 volt control circuit on all units with remote controlsSpecifications:•1-1/2 hp 115/230 vac. 60 Hz or 110/220 vac. 50 Hz motor25 amp at 115 vac. 13 amp at 220 vac.•Reservoir capacity 590 in. 3Flows: 450 in. 3 /min. at 100 psi•46 in. 3 /min. at 10,000 psiWeight79 lbs®Benefits:•Lets the customer select the right pump for their•applicationUser/Operatorsafety3333Rev. 5-10-97

®PE46 SeriesOperationLow Pressure StageGerotorInletOutputAnglePlateHighPressurePistonsInlet ChecksLow PressureUnloading AdjustmentOutlet ChecksOutletCheckHigh LowCheckHigh PressureRelief (10,000 PSI)33A33ARev. 7-31-95

®PE46 SeriesOperationHigh Pressure StageGerotorInletOutputAnglePlateHighPressurePistonsInlet ChecksLow PressureUnloading AdjustmentOutlet ChecksOutletCheckHigh LowCheckHigh PressureRelief (10,000 PSI)33B33BRev. 7-31-95

PE21 Series<strong>Pumps</strong>The PE21 series pumps are designed especially for heavy-duty, extended-cycle operations. A gerotor design providing low pressure, high volume and axialpiston design pump providing high pressure. A noise level ranging between 73-78 dBA. Motors are single phase and are CSA rated for intermittent duty.Features:PE21 has a NEMA 12 enclosure•Very low dBA ratingHas electrical shut down in the event of electricalinterruption•24 volt control circuits on units with remote controlsLow speed, high torqueSpecifications:•1 hp 115/230 vac. 60 Hz or 110/220 50 Hz motor15 amp at 115 vac.; 7.5 amp at 220 vac.•Reservoir capacity 590 in. 3 usableFlows: 270 in. 3 /min. at 100 psi•22 in. 3 /min. at 10,000 psiWeight98 lbs®Benefits:NEMA 12 helps keep dirt and moisture out•Meets OSHA noise level requirementsPump shuts off and will not automatically start up untilthe operator presses the pump start button•User/Operator safetyDesignedfor heavy-duty, extended cycle operation3434Rev. 5-10-97

35PQ60 & PQ120 Series<strong>Pumps</strong>A gerotor design providing low pressure, high volume and an axial piston design pump providing high pressure. A low noise level of 70 dBA.Motors are single phase and are CSA rated for intermittent duty. Ideal for press applications.Features:•Metal shroud•Very low dBA ratingHas electrical shut down in the event of electricalinterruption24 volt control circuits on units with remote controls•Low speed, high torque3 phase motor has all the electrical componentsnecessary to operate the pump in the control boxSpecifications:PQ60Benefits:•2 hp 115/230 vac. 60 Hz or 110/220 vac. 50 Hz. motor22 amp at 115 vac.; 11 amp at 220 vac.•Reservoir capacity 1250 in. 3 usableFlows: 730 in. 3 /min. at 100 psi17 in. 3 /min. at 10,000 psi•Weight 169 lbsPQ120•3 hp 230/460 vac. 60 Hz or 220/380 vac. 50 Hz. motor10.5 amp at 230 vac.; 5.3 amp at 460 vac.•Reservoir capacity 1250 in. 3 usableFlows: 730 in. 3 /min. at 100 psi•60 in. 3 /min. at 10,000 psiWeight169 lbs®•Helps keep dirt and moisture out of motor andelectrical•Meets OSHA noise level requirementsPump shuts off and will not automatically start up untilthe operator presses the pump start buttonUser/Operator safety•Designed for heavy-duty, extended cycle operationThe customer has no hidden charges when purchasingthe pump35Rev. 5-10-97

®PQ60 & PQ120 SeriesOperationGerotor PumpPump InletDrainPilot PressurePortPressure RegulatorValveAngle PlatePistonPumpInlet Ball ChecksHigh PressureOutlet Ball ChecksHigh PressureDowel PinUnloading SpoolGerotor PumpUnloading PressureAdjustmentPumpSuper ChargeAdjustmentPump Outletto ValveHigh to Low Pressure CheckBallPump Check ValveSafety Relief Valve35A35ARev. 7-31-95

PE200 & PE400<strong>Pumps</strong>The pumps that can deliver a large quantity of high pressure oil. Use the same design found in some of our other pumps; a gerotor design providing lowpressure, high volume and an axial piston design pump providing high pressure. A low noise level ranging between 73-78 DBA.These pumps are used mostly for heavy construction and heavy maintenance operating large tonnage cylinders.Features:•3 phase motor has all the electrical components necessaryto operate the pump in the control box•Has electrical shut down in the event of electricalinterruptionSpecifications:PE200•7-1/2 hp 230/460 vac. 60 Hz or 220/380 vac. 50 Hz. motor22 amp at 230 vac.; 11 amp at 460 vac.•Reservoir capacity 3927 in. 3 usableFlows: 1200 in. 3 /min. at 200 psi200 in. 3 /min. at 10,000 psi®•Weight 472 lbs•10 hp 230/460 vac. 60 Hz or 220/380 vac. 50 Hz. motor34 amp at 230 vac.; 17 amp at 460 vac.•Reservoir capacity 3927 in. 3 usableFlows: 1200 in. 3 /min. at 200 psi•420 in. 3 /min. at 10,000 psiWeight 492 lbsPE400Benefits:•The customer has no hidden charges when purchasing•the pumpPump shuts off and will not automatically start up untilthe operator presses the pump start button3636Rev. 5-10-97

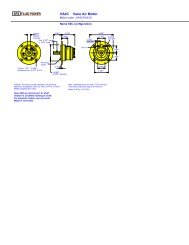

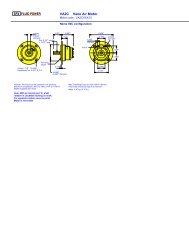

®Rotary Air Driven Hydraulic<strong>Pumps</strong>Air driven pumps work well in environments where gasoline or electric motors can not be used, i.e. mines, petrochemical, and other flammable or explosiveenvironments. Power Team has pumps with a large variety of flows and weights to meet the customers needs.PA17 SeriesGerotor design for the low pressure stage/radial pistondesign for the high pressure stage.Features:•Low weight to output ratioBenefits:•High flows and easy for the customer to carry aroundPA46 SeriesGerotor design for the low pressure stage/axial pistondesign for the high pressure stage.Features:•Variety of valve options standardBenefits:•Gives customer the pump they need for theirapplication37PA55 SeriesGear design for the low pressure stage/axial pistondesign for the high pressure pump.Features:•Same basic pump as our Vanguard SeriesBenefits:•Proven pump in the fieldLong lifeDependability37Rev. 3-21-95

®Gasoline Driven Hydraulic<strong>Pumps</strong>Gasoline driven pumps do not need an external power supply to operate, they can be used in remote applications.Power Team has largest line of gasoline powered pumps in the industry.PG30 SeriesGerotor design for the low pressure stage/radial pistondesign for the high pressure stage. Ideal for the railroad,rescue, and construction industries.Features:•2-cycle engine•Roll cageBenefits:•Lowest weight to horse power ratio of gasoline driven•pumpsProtects pump from damagePG55 SeriesGear design for the low pressure stage/axial pistondesign for the high pressure stage. Ideal for the construction,rescue, and tensioning industries.Features:•Same basic pump as our Vanguard Series•4-cycle engineBenefits:•Proven pump in the field,Long life•DependabilityCleaneroperating, larger horse power, quieter3838Rev. 3-21-95

®Gasoline Driven Hydraulic<strong>Pumps</strong>PG120 SeriesGear design for the low pressure stage/axialpiston design for the high pressure stage. Ideal for thepier setting, bridge listing, and concrete contractingindustries.Features:Roll cageHonda engineA number of specialty pumps•4-cycle engineAvailable with remote control with electrical valveoptionsBenefits:Protects pump from damageMost popular with contractorsAllows customer to pick a pump to fit his application•Cleaner operating, larger horse power, quieterUser/operator safetyPG4004Gerotor design for the low pressure stage/axial pistondesign for the high pressure stage. Ideal for the concretestressing industries.Features:Electric start•Roll cage4-cycle engineBenefits:Convenience•Protects pump from damageCleaneroperating, larger horse power, quieter3939Rev. 3-21-95

®ValvesMETERINGMANUALPILOTOPERATEDSOLENOIDOPERATED4040Rev. 7-31-95

®DirectionalValvesEnvelope: Tells what the valve is doing in this box.Two Position: Two envelopes or positions of a directional valve.Three Position: Three envelopes or positions of a directional valve.40A40ARev. 3-3-97

®DirectionalValvesThis is an envelope showing some of the symbols that would be inside, showing what a valve is doing.AA = Advanced Port: This is where the hydraulic cylinders are attached.P = Pump Port: This is where the hydraulic pump flow goes into the valve to get tothe cylinder.T = Tank Port: This is where the hydraulic fluid goes back to the reservoir.<strong>PT</strong>= Posi-check: This is a feature in Power Team and other directional valves thatprevent the loss of hydraulic pressure when shifting from a pressureport to the center position of a valve.40B40BRev. 5-10-97

®DirectionalValvesPos. 1 Pos. 2Two-Way/Two Position: 9517POS. 1 Oil goes out from the pump to the cylinder. When you shutoff the pump the check ball holds the pressure from the valve to thecylinder.POS. 2 With the pump shut off the oil goes back to tank and thecylinder retracts.Pos. 1 Pos. 2Three-Way/Two Position: 9584, 9610, 9579, 9523POS. 1 Oil goes out from the pump to the cylinder and holds whenthe pump is shut off. Tank line is blocked.POS. 2 All hydraulic oil is open to reservoir through the tank line.CenterPos. 1 Pos. 2Three-Way/Three Position: 9502, 9520, 9605POS. 1 Oil goes out from the pump to the cylinder and holds whenpump is off. Tank line is blocked..POS. 2 All hydraulic oil is open to reservoir through the tank line.CENTER POS. Holds cylinder pressure when the valve is inthis position. The pump can remain running and the oil goes backto tank.40C40CRev. 5-10-97

®DirectionalValvesPos. 1 Pos. 2CenterPos. 1 Pos. 2Four-Way/Two Position: 9504, 9594, 9552POS. 1 Oil goes out to the extend side of the cylinder. The oil fromthe retract side goes back to the tank. Cylinder holds when thepump is shut off.POS. 2 Oil goes out to the retract side of the cylinder. The oil fromthe extend side goes back to tank. Cylinder holds when pump isshut off.Four-Way/Three Position: 9506, 9512POS. 1 Oil goes out to the extend side of the cylinder. The oil fromthe retract side goes back to tank. Cylinder holds when the pump isshut off.POS. 2 Oil goes out to the retract side of the cylinder. The oil fromthe extend side goes back to tank.CENTER POS. Cylinder holds pressure even if pump is running. Oilfrom pump goes through valve back to tank.40D40DRev. 5-10-97

®DirectionalValvesTandem CenterTandem Center - Cylinder ports are blocked (A and B), oil flow fromthe pump goes to tank. Used when the pump stays running. Forexample, gasoline driven pumps.With Double-Acting RamWith Single-Acting Ram40E40ERev. 3-3-97

®DirectionalValvesClosed center for use withmultiple rams and one pumpClosed Center - Cylinder ports A and B are blocked. Pump portand tank port are blocked. Used when running multiple valves inseries from one pump.Closed center set up40F40FRev. 5-10-97

®DirectionalValvesOpen center used when holdingis not a requirementOpen Center - Cylinder ports and oil flow from pump all go totank. Used when running two separate hydraulic tools. Forexample, a cutting tool and crimping tool.Typical application runningtwo single acting tools40G40GRev. 3-3-97

®DirectionalValvesActuators:DetentDetent - Valve stays in that position until it is actuated by theoperator.Manual LeverControlManual Control - Symbol for valve with manual lever.Oil Pilot ControlOil Pilot Control - Symbol for a valve that is moved whenpilot oil from the pump is supplied to it. Air pilot symbol is anopen triangle ▲.Solenoid ControlSolenoid Control - Symbol for a valve that is actuated by an electricsolenoid.Spring ControlSpring Control - Symbol for valve that is actuated by a spring.40H40HRev. 3-3-97

®DirectionalValves9720 & 9721 Counter Balance Valve. The cylinder retracts at the speed of the high pressure flow of the hydraulic pump the customer is usingmax. high pressure pump flow 120 in 3 2000 - 2500 psi min. cracking pressure. For double acting rams only.Gives smooth even lowering of any load. Eliminates bounce and runaway other counter balance valve experience.To CylinderRetractTo DirectionalValve RetractTo DirectionalValve ExtendTo Cylinder Extend40I40IRev. 5-10-97

®Pullers55 TON ENFORCERHYDRAULIC SUPERGRIP-O-MATICMANUALSUPERGRIP-O-MATICMANUALGRIP-O-MATICHYDRAULICPUSH-PULLERSHighlights:•Manual & Hydraulic Grip-O-Matic PullersManual & Hydraulic Super Grip-O-MaticPullersManual & Hydraulic Push-Pullers55 & 100 Ton Hydraulic Enforcers•Manual & Hydraulic Puller SetsAccessories matched to pullers andpush-pullersInternal pulling attachmentsBearing pulling attachmentsSlide hammer pullersBlind hole pullers•Puller accessoriesThe most complete line of Pullers on the•marketOver 70 years of puller design and manufacturing• Forged and heat treated alloy steel jaws on alljaw type pullers•Less than .2% warrantyMostcopied puller in the worldRev. 7-31-9541SPECIAL PULLERS41

®Rolled “V” ThreadsPullersPITCH DIAMETEROF THREADRolled threads start with a material O.D. equalto the pitch diameter of the thread. The rollingprocess moves material from below the pitchdiameter and creates a smoother and strongerthread.CENTERLINEOF SCREWCut threads start with a material O.D. equal tothe thread O.D.. Cutting can cause tears on thethread surface which can make it rough andcan cause minute cracks at root of thread whichcan open up during heat treat and lessen thecapacity of the screw.OUTSIDE DIAMETEROF THREAD4242Rev. 7-31-95

®Manual & Hydraulic Grip-O-Matic and Super Grip-O-MaticPullersFeatures:•Grip-O-Matic feature on all pullers2-way, 3-way and 2/3-way combination pullers1 to 37 ton mechanical pullers5 to 50 ton hydraulic pullers2-1/8”(54 mm) to 27-5/8”(702 mm) reach3-1/4”(83 mm) to 44”(1,118 mm) of spread•Forged alloy steel jawsAlloy steel heads (forged or flame cut)•Rolled “V” threadsSpecial coating on threads•Heat treated alloy steel cross boltsStandard hydraulic rams on Grip-O-Matic series•Adjusting nut on Super Grip-O-Matic seriesMachined puller jaw toesBenefits:•The harder the pulling force, the tighter the jaws gripA wide variety of pullers, select a specific puller for aspecific application or select one or more pullers forgeneral applications•Strongest possible part, the grain of the material followsthe contour of the part.Heat treated and designed for maximum strength•Stronger and smoother than cut threadsResists corrosion, traps lubricationBetter than black oxide•Designed for max. shear strengthRams can be removed from puller and used in otherhydraulic applications•Allows for controlled jaw spread adjustmentLargerand stronger pulling toe than most competitors4343Rev. 2-1-96

®Manual and Hydraulic Push-PullersPullersFeatures:•Push-pull feature on all models10,17-1/2 and 30 ton manual push-pullers17-1/2, 30 and 50 ton hydraulic push-pullers6-1/4”(159 mm) to 30-5/8”(778 mm) of reach2-1/8”(54 mm) to 20-1/2”(521 mm) of spread•Standard hydraulic rams•Forcing screw and leg ends designed to matchaccessoriesBenefits:•Designed to remove and install tight-fitting partsEach unit has a spread range and optional leg lengthsdesigned to match the push-puller capacity•Rams can be removed and used in other hydraulic•applicationsForcing screws can be matched to internal pullingattachments; male to female and female to femalethreaded adapters, step plates and shaft protectorsLeg ends can be matched to bearing pulling attachments;leg end adapters, male to female and female tofemale threaded adapters4444Rev. 2-1-96

®Pulling AttachmentsPullersBearing Pulling AttachmentsFeatures:•Knife-like edges•Wide range of sizes• Adaptable•Forged alloy steel puller blocksBenefits:•Allows attachment to be forced behind parts where•space is limited.Eight attachments to choose from with capacity ranges•from 2 to 50 ton.Can be used with manual or hydraulic 2-jaw pullers,manual or hydraulic push- pullers and on shop press•bed platesStrongest possible part, the grain of the material followsthe contour of the partInternal Pulling AttachmentsFeatures:•Remove oil seals, bearing cups and bushings•Wide range of sizes• AdaptableBenefits:•Choice of jaw positions allows pulling attachments to fit•various diametersReaches from 2-1/8”(54 mm) to 5-7/8”(149 mm) andspreads from 1-1/2”(38 mm) to 9”(229 mm) and•capacities from 10 ton to 30 tonCan be used with manual or hydraulic push-pullers andwith slide hammers4545Rev. 7-31-95

®SpecialPullersPilot Bearing PullersFeatures:•For pulling motor, generator and magneto bearings andflywheel pilot bearingsBenefits:•Choice of ranges, 1/2”(13 mm) to 2-1/8”(54 mm) diameterspreads and 3/4”(19 mm) to 1-3/4”(44 mm) reachSlide Hammer PullersFeatures:Reversible jaws•Two headsOptional jaw lengthsBenefits:Pullers can be used for internal or external pulling•Pullers can be used in 2-jaw or 3-jaw configurationInternal spreads from 3/4”(19 mm) to 6-1/4”(158 mm)external spreads from 3/4”(19 mm) to 7-1/2”(191 mm)reaches from 1-3/16”(29 mm) to 5”(127 mm)Blind Hole PullersFeatures:•Expandable collets•Ten collet sizes•Bridge and slide hammerBenefits:•Allows the pulling of friction fitted parts from blind•holesGives pulling range of 5/16”(8 mm) to 1-3/4”(44 mm)•diametersAchoice of two methods of exerting pulling force4646Rev. 7-31-95

®AccessoriesPullersFeatures:•Male to female threaded adapters•Female to female threaded adapters•Step plate adapters•Shaft protectors•Protective blanketsBenefits:•Adapts push-puller legs to tapped holes in flanges andgearsAdapts push-puller forcing screws to tapped holes inshaft ends•Male ends in inch and metric sizesAdapts push-puller legs to threaded studs in flangesAdapts push-puller forcing screws to threaded shafts•Inch and metric sizes availableFit hollow shafts so forcing screws on pullers and pushpullershave a surface to push against•Protect shaft centers and forcing screw ends from distortionwhen extreme pressures are applied•Used with pullers and push-pullersContains broken or flying parts in most pulling, pressing,pushing or stressing jobs4747Rev. 7-31-95

®SetsPullersFeatures:•Each set is a combination of pullers, push-pullers, specialpullers, attachments and accessories•Manual sets, hydraulic sets and combination sets•Storage optionsBenefits:•Eleven sets to choose from, have the puller you need,•on hand, when you need itThree manual sets, two ten ton sets and one 17-1/2 tonsetThree hydraulic sets, one each 17-1/2 ton, 30 ton and50 tonFive combination manual and hydraulic sets10 ton, 17-1/2 ton, 17-1/2 & 30 ton, 17-1/2 & 50 ton•and 17-1/2, 30 and 50 ton master setSelect from wall boards, wall hanging storage boxes,wood boxes or metal boxes4848Rev. 7-31-95

®55 Ton Enforcer PullersFeatures:•Grip-O-Matic pulling featureOnly cart mounted puller in this capacity on the market•todayCart is equipped with hydraulic lift system•Unique dual pump•Hydraulically actuated jaws•2-or-3 jaw configuration• Self-centeringGuards at pinch pointsSwivel casters and large wheelsLifting eyes•Four ram extensionsChoice of pushing rams and jaw lengths•Remote controlBenefits:•The harder the pulling force the tighter the jaws grip.Puller is easily moved from job to job•Puller height can be precisely adjusted from 12”(305•mm) to 42”(1067 mm)Low pressure pump adjusts jaws and high pressure•pump advances pushing ramRam moves jaws in and out to provide safe & secure•grip on partPermits pulling wheels and other parts with odd or even•number of spokesCenter ram on work, the jaws will automatically grip thework evenlyProtects operatorEasy movement & maneuverabilityPermits use of overhead crane to raise entire unit•Matched to the ram, shorten pushing stroke6-1/4”(159 mm) & 13-1/4”(337 mm) stroke rams andstandard or extra long jaws, match to suit your application•20 ft. (6.1 m.) cord on remote hand control allows operatorto stand away from work-piece.4949Rev. 7-31-95

®100 Ton Enforcer PullersFeatures:•Grip-O-Matic pulling featureAdjustable jaws•Lifting bracket•Adjusting screw•Spring loaded featureTow bar and large wheelsadapters•Pushing•Power pump•Remote controlBenefits:•The harder the pulling force the tighter the jaws gripJaws can be adjusted so that they always pull on a flat•surfacePuller can be lifted if workpiece center line is more than•36”(914 mm) off floorPuller centerline has vertical adjustment of 12”(305 mm) to 36”(914 mm)Puller will align itself•Makes moving puller easySix pushing adapters, 2-1/2”(64 mm) and 4-1/8”(105 mm) diameters. Matched to the ram, shorten•pushing stroke1-1/8 H.P., 115 volt two stage pump also available in•220 volt, 50 HZ25 foot (7.6M) cord on remote hand control allowsoperator to stand away from work-piece.5050Rev. 7-31-95

®JacksBOTTLE JACKSTOE JACKSINFLATABLE JACKS51POWER LIFTTRACK JACKS51Rev. 3-3-97

®Power LiftJacksThe Power Lift is ideal for a wide variety of lifting applications. It is portable and compact, making it the perfect match for railcar maintenance.With lifting capacities ranging from 55 to 150 tons, the Power Lift is clearly the tool of choice for lifting a wide range including even the verylargest off-road equipment in construction and mining maintenance applications.Features:Double-acting system•Jack module is easily removed from the pump moduleAdditional jack modules can be purchased for different•applicationsAir and electric pump options are available with eithermanual or remote controlled valves.Large, urethane-filled tires•Unit has a small footprintRugged steel baseRugged Vanguard pumps and RD Series cylinders•Built in swivel capJack extensions and cribbing blocks availableBenefits:Gives user controlled load lowering•This makes servicing easy and inexpensiveMakes unit versatile and inexpensive•Allows the operator to safely control both raising andlowering without having to stand near the jack.Eliminates flat tire troubles•Fits in very tight quartersDurable and long lasting compared to competitive castunitsMakes this the most reliable jack on the market•Helps prevent off-center loadingAdd versatility and secure a method of mechanicallypreventing the load from lowering51A51A3-3-97

®Bottle JacksJacksBottle jacks are offered in 11 different models with lifting capacities from 2 to 50 ton.Features:•The pressure cylinder, oil reservoir, pump housing and•base are welded together into one part.Fewer working parts, internally machined oil passages,smooth bearing surfaces and close tolerances•Base is hot forged steel rather than cast ironMay be used in the vertical, angle, and horizontalpositionsBenefits:•Oil leakage is greatly reduced•Reliable for higher cycle life•Providing more strengthApplicationversatility5252Rev. 7-31-95

®Toe JacksJacksLift it hydraulically with these rugged, sturdy jacks. Our toe lift jacks need only one inch clearance to get under the loadand the two models - 5.5 and 11 tons - can handle a variety of lifting needs.Features:•Can get under equipment and materials sitting just1”(25.4 mm) off the groundA pressure relief valve•Release valve allows control of lowering speedMay be used in the vertical, angle, and horizontalpositions and has a 360° rotation capabilityBenefits:•Versatile for low clearance jobsPrevents overloading•Sure load controlApplicationversatility5353Rev. 7-31-95