GEA Niro Soavi Panther NS3006L Tech Sheets ENG Rev01 2013

GEA Niro Soavi Panther NS3006L Tech Sheets ENG Rev01 2013

GEA Niro Soavi Panther NS3006L Tech Sheets ENG Rev01 2013

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

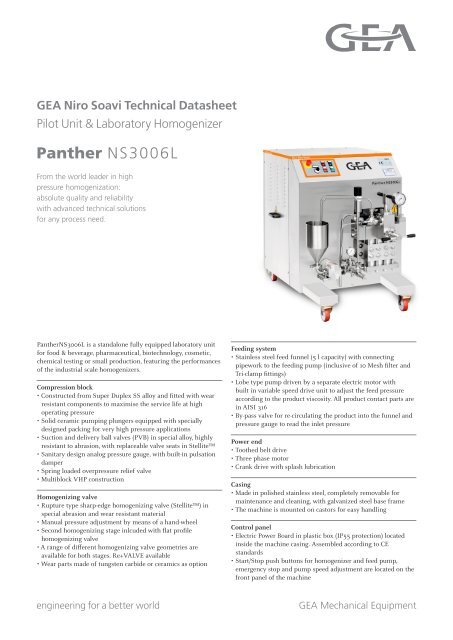

<strong>GEA</strong> <strong>Niro</strong> <strong>Soavi</strong> <strong>Tech</strong>nical DatasheetPilot Unit & Laboratory Homogenizer<strong>Panther</strong> <strong>NS3006L</strong>From the world leader in highpressure homogenization:absolute quality and reliabilitywith advanced technical solutionsfor any process need.<strong>Panther</strong><strong>NS3006L</strong> is a standalone fully equipped laboratory unitfor food & beverage, pharmaceutical, biotechnology, cosmetic,chemical testing or small production, featuring the performancesof the industrial scale homogenizers.Compression block• Constructed from Super Duplex SS alloy and fitted with wearresistant components to maximise the service life at highoperating pressure• Solid ceramic pumping plungers equipped with speciallydesigned packing for very high pressure applications• Suction and delivery ball valves (PVB) in special alloy, highlyresistant to abrasion, with replaceable valve seats in Stellite• Sanitary design analog pressure gauge, with built-in pulsationdamper• Spring loaded overpressure relief valve• Multiblock VHP constructionHomogenizing valve• Rupture type sharp-edge homogenizing valve (Stellite) inspecial abrasion and wear resistant material• Manual pressure adjustment by means of a hand-wheel• Second homogenizing stage inlcuded with flat profilehomogenizing valve• A range of different homogenizing valve geometries areavailable for both stages. Re+VALVE available• Wear parts made of tungsten carbide or ceramics as optionFeeding system• Stainless steel feed funnel (5 l capacity) with connectingpipework to the feeding pump (inclusive of 10 Mesh filter andTri-clamp fittings)• Lobe type pump driven by a separate electric motor withbuilt in variable speed drive unit to adjust the feed pressureaccording to the product viscosity. All product contact parts arein AISI 316• By-pass valve for re-circulating the product into the funnel andpressure gauge to read the inlet pressurePower end• Toothed belt drive• Three phase motor• Crank drive with splash lubricationCasing• Made in polished stainless steel, completely removable formaintenance and cleaning, with galvanized steel base frame• The machine is mounted on castors for easy handlingControl panel• Electric Power Board in plastic box (IP55 protection) locatedinside the machine casing. Assembled according to CEstandards• Start/Stop push buttons for homogenizer and feed pump,emergency stop and pump speed adjustment are located on thefront panel of the machineengineering for a better world<strong>GEA</strong> Mechanical Equipment

<strong>Panther</strong> <strong>NS3006L</strong>Dimensional drawingOverall dimensions (mm)<strong>Tech</strong>nical specifications are not mandatory and subject to change without notice. REV.1_02/2012This pilot high pressure homogenizer unit is designed for continuousoperation up to 1500 bar and for limited productions. The machineachieves the same results as bigger size homogenizers, and its compactdesign allows at the same time easy installation, simple operation andquick maintenance. Suitable also for viscous products, it can be used inmany different sectors, such as food, dairy, chemical, pharmaceutical,cosmetics and biotech.Compression head• Multiblock VHP constructionPump Valves• Ball type (PVB in Stellite)Product line connections• Tri-ClampPower end• Cast iron power frame• Splash lubrication• Polished SS machine casing on galvanized steel frameAvailable options• Suitable for pharma aplications• Electropolished version (Ra 0.5 µm) available as option• 3A execution, FDA approved gaskets, cGMP validation documentationavailable upon request• Suitable for CIP/SIP• Aseptic executionPERFORMANCEPressure (bar) Max Flow Rate (l/h)1000 1201200 1001500 50TECHNICAL DATANumber of plungers 3Stroke40 mmMotor power5.5 kWNet weight560 kgGross weight730 kgLubricating and cooling water60 l/hLubricating oil ISO VG 1503 lFeeding hopper volume4.5 l<strong>GEA</strong> Mechanical Equipment<strong>GEA</strong> <strong>Niro</strong> <strong>Soavi</strong>Via A. M. Da Erba Edoari, 29 - I 43123 Parma (Italy)Phone + 39 0521 965411 Fax +39 0521 242819Info.Gea<strong>Niro</strong><strong>Soavi</strong>@gea.com www.niro-soavi.com