Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

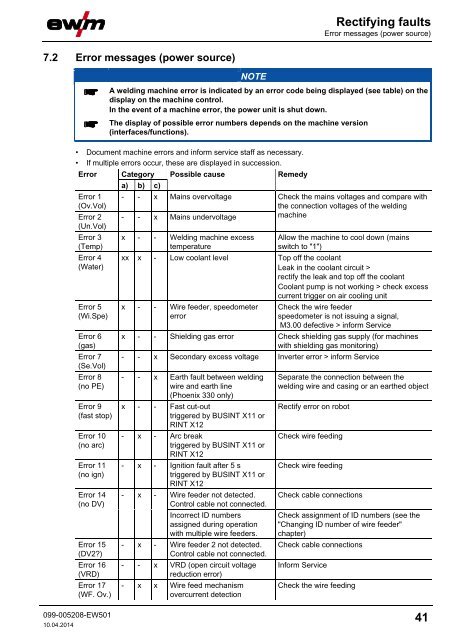

Rectifying faultsError messages (power source)7.2 Error messages (power source)NOTEA welding machine error is indicated by an error code being displayed (see table) on thedisplay on the machine control.In the event of a machine error, the power unit is shut down.The display of possible error numbers depends on the machine version(interfaces/functions).• Document machine errors and inform service staff as necessary.• If multiple errors occur, these are displayed in succession.Error Category Possible cause RemedyError 1(Ov.Vol)Error 2(Un.Vol)Error 3(Temp)Error 4(Water)Error 5(Wi.Spe)Error 6(gas)Error 7(Se.Vol)Error 8(no PE)Error 9(fast stop)Error 10(no arc)Error 11(no ign)Error 14(no DV)Error 15(DV2?)Error 16(VRD)Error 17(WF. Ov.)a) b) c)- - x Mains overvoltage Check the mains voltages and compare withthe connection voltages of the welding- - x Mains undervoltagemachinex - - <strong>Welding</strong> machine excesstemperatureAllow the machine to cool down (mainsswitch to "1")xx x - Low coolant level Top off the coolantLeak in the coolant circuit >rectify the leak and top off the coolantCoolant pump is not working > check excesscurrent trigger on air cooling unitx - - Wire feeder, speedometererrorCheck the wire feederspeedometer is not issuing a signal,M3.00 defective > inform Servicex - - Shielding gas error Check shielding gas supply (for machineswith shielding gas monitoring)- - x Secondary excess voltage Inverter error > inform Service- - x Earth fault between weldingwire and earth line(Phoenix 330 only)x - - Fast cut-outtriggered by BUSINT X11 orRINT X12- x - Arc breaktriggered by BUSINT X11 orRINT X12- x - Ignition fault after 5 striggered by BUSINT X11 orRINT X12- x - Wire feeder not detected.Control cable not connected.Incorrect ID numbersassigned during operationwith multiple wire feeders.- x - Wire feeder 2 not detected.Control cable not connected.- - x VRD (open circuit voltagereduction error)- x x Wire feed mechanismovercurrent detectionSeparate the connection between thewelding wire and casing or an earthed objectRectify error on robotCheck wire feedingCheck wire feedingCheck cable connectionsCheck assignment of ID numbers (see the"Changing ID number of wire feeder"chapter)Check cable connectionsInform ServiceCheck the wire feeding099-005208-EW50110.04.201441