HDGASA V7E1.pdf

HDGASA V7E1.pdf

HDGASA V7E1.pdf

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

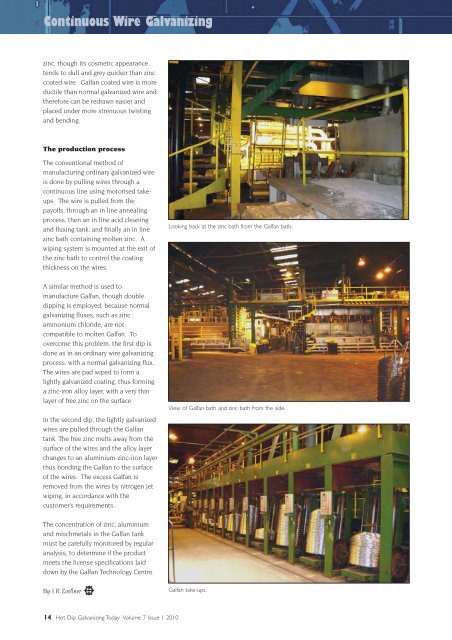

Continuous Wire Galvanizingzinc, though its cosmetic appearancetends to dull and grey quicker than zinccoated wire. Galfan coated wire is moreductile than normal galvanized wire andtherefore can be redrawn easier andplaced under more strenuous twistingand bending.The production processThe conventional method ofmanufacturing ordinary galvanized wireis done by pulling wires through acontinuous line using motorised takeups.The wire is pulled from thepayoffs, through an in line annealingprocess, then an in line acid cleaningand fluxing tank, and finally an in linezinc bath containing molten zinc. Awiping system is mounted at the exit ofthe zinc bath to control the coatingthickness on the wires.Looking back at the zinc bath from the Galfan bath..A similar method is used tomanufacture Galfan, though doubledipping is employed, because normalgalvanizing fluxes, such as zincammonium chloride, are notcompatible to molten Galfan. Toovercome this problem, the first dip isdone as in an ordinary wire galvanizingprocess, with a normal galvanizing flux.The wires are pad wiped to form alightly galvanized coating, thus forminga zinc-iron alloy layer, with a very thinlayer of free zinc on the surface.In the second dip, the lightly galvanizedwires are pulled through the Galfantank. The free zinc melts away from thesurface of the wires and the alloy layerchanges to an aluminium-zinc-iron layerthus bonding the Galfan to the surfaceof the wires. The excess Galfan isremoved from the wires by nitrogen jetwiping, in accordance with thecustomer’s requirements.View of Galfan bath and zinc bath from the side.The concentration of zinc, aluminiumand mischmetals in the Galfan tankmust be carefully monitored by regularanalysis, to determine if the productmeets the license specifications laiddown by the Galfan Technology Centre.By I.R.ZoellnerGalfan take-ups.14 Hot Dip Galvanizing Today Volume 7 Issue 1 2010