You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

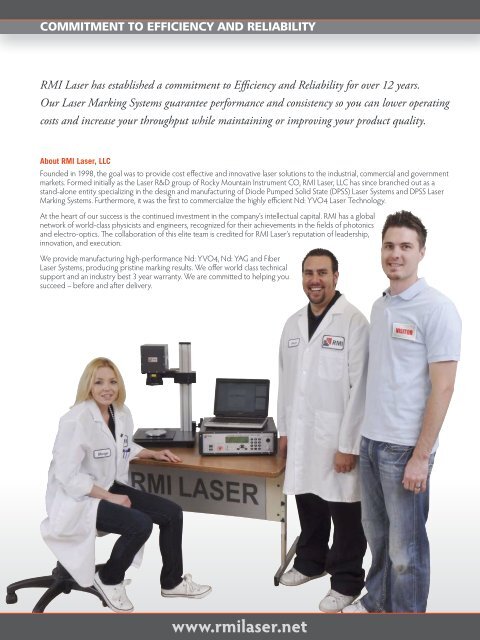

Commitment TO Efficiency and ReliabilityRMI Laser has established a commitment to Efficiency and Reliability for over 12 years.Our Laser Marking Systems guarantee performance and consistency so you can lower operatingcosts and increase your throughput while maintaining or improving your product quality.About RMI Laser, LLCFounded in 1998, the goal was to provide cost effective and innovative laser solutions to the industrial, commercial and governmentmarkets. Formed initially as the Laser R&D group of Rocky Mountain Instrument CO, RMI Laser, LLC has since branched out as astand-alone entity specializing in the design and manufacturing of Diode Pumped Solid State (DPSS) Laser Systems and DPSS LaserMarking Systems. Furthermore, it was the first to commercialize the highly efficient Nd: YVO4 Laser Technology.At the heart of our success is the continued investment in the company’s intellectual capital. RMI has a globalnetwork of world-class physicists and engineers, recognized for their achievements in the fields of photonicsand electro-optics. The collaboration of this elite team is credited for RMI Laser’s reputation of leadership,innovation, and execution.We provide manufacturing high-performance Nd: YVO4, Nd: YAG and FiberLaser Systems, producing pristine marking results. We offer world class technicalsupport and an industry best 3 year warranty. We are committed to helping yousucceed – before and after delivery.www.rmilaser.net

DPSS Laser SeriesApps LabSingle mode (TEM00) beamRMI Laser DPSS Laser Source Series 532 nm & 1064 nmReliable & Efficient Custom SolutionsAt the heart of RMI Laser’s operation is the line of compact DPSS LaserSystems utilizing Nd: YVO4 Technology. RMI Laser’s DPSS Laser Sourcesfeature single mode (TEM00) beam operation and the shortest Q-switchpulse duration in their class. This results in a higher energy density, higherpeak power and better materials processing than with competing lasersystems. The 1064 nm models come in 5, 10, 15, and 20 watts, the 532 nmmodels come in 3 and 6 watt output levels.YVO4 TechnologyRMI DPSS Laser systems are designed with Nd: YVO4 crystals for betterdiode pumping efficiency than other crystal types. A thermoelectric (TE)cooling system enables highly efficient thermal management while eliminatingthe need for external chillers. The result is a smaller footprint, more consistentoutput, and a more efficient operation.Integration and Custom SolutionsRMI DPSS Laser systems are an ideal solution for integration into existingassembly lines as well as a wide range of industrial applications. RMI Laserprovides extensive technical and integration support to create the optimalcustom solution for you.Let us work for you before you make any purchasing decision. We provide acompletely free service to determine which RMI Laser best fits your markingneeds. Our Applications Lab staff will provide full sample Laser Markingevaluation on your parts. With over 11 years of laser marking experience,we are involved in variety of applications and we understand the need forvarious types of Laser Marking Systems.Just send us your materials to be marked and we will mark your parts with ourvarious technologies allowing you to see which laser will best fit your needs.Coupled with the industry’s fastest sample turn-around time, we will provideyou necessary tools to make an informed decision about your company’s lasermarking goals.What you get from RMI Laser’s Applications Lab:• Sample Report – Details marking settings and cycle times with samplenumbers corresponding to the report• Sample Parts – These parts can be used for your environmental testing,process testing, customer approval, and/or executive approval• Proof of Concept – Provides physical evidence of RMI Laser’s capabilities• Sample files to use as templates for your production setupApplications LabSample partsHigher energy densityUsing DPSS technology, you can accomplish a wide range of scribing andprocessing functions on an extremely wide spectrum of materials and products.The highly accurate performance makes it ideal for repeatability and precisionapplications like solar cell scribing, perforation and fine circuit trimming.Sample report and proof of concept303.664.9000 / 888.952.7370 www.rmilaser.net

ApplicationsBearings & ToolsIdentify the manufacturer and specification of the tools by marking logos, model numberspart sizing and serial numbers with RMI Laser Marking Systems. The system marks directlyonto the metal for quick, permanent, and contrasting markings not possible with acidetching or mechanical engraving. RMI Laser Marking Systems are ideal for laser marking onextremely durable metals like titanium or tool steel, and/or on austenitic super alloy suchas Inconel®.Gifts & JewelryCreate one-of-a-kind gifts or jewelry for your customers by personalizing them with a RMILaser Marking System. RMI Laser systems are able to etch or engrave easily on gold, silver,platinum and other highly reflective precious metals. With a Rotary Chuck Engraving System,you can easily mark on rings, bangles, water bottles or any cylindrical surfaces without anydistortion or degradation. Our Laser Markers can also perform high resolution images of upto 1200 DPI making it perfect for true gray scale photos and logos for pendants, pens, USBdrives or any items that you want personalized.Medical InstrumentsMark your medical equipment, surgical instruments and implants without contaminationfrom ink, dye or solvents. When marking with RMI Lasers, there is no physical contact withthe marked object. There is no risk of the part being damaged or deformed. Laser markingis an ideal method for permanent and non-toxic markings that are non-intrusive, free fromcorrosion, and will not be removed by surgical cleaning supplies or chemicals.WafersMeet the challenge of precision scribing and patterning on semi conductor devices andwafers. Machine-readable, miniaturized and clear identification is required for siliconwafers or scribing on solar cells. The Laser Marking Systems and DPSS Laser Sources meetthe strictest requirements when there is no deviation within the specification. With lowmaintenance and reliable operation, our Laser Systems offer a perfect solution for markingor scribing on silicon wafers/solar cells.Automotive & AerospaceReplace traditional molding methods, screen printing or adhesive labels with LaserMarking. With our short pulse width (~8ns),the Heat-Affected Zone (HAZ) is minimal whilemaximizing the contrast on the material being marked. Thus, making RMI Laser System’s wellsuited for heat-sensitive materials while maintaining clean, permanent, and abrasion-proofmarkings without any additional sealing or coating placed on the part.Tracking and TraceabilityImprove the traceability of your components, tools and instruments by permanentlymarking each with serial numbers, part numbers, Barcodes, Data Matrices, and UID Codes.RMI Laser has developed custom software packages, not excluding the UID Wizard (onlyone in the world) for manufacturers providing them with Database Recognition, SerialNumber Duplicate Checking, and the peace of mind to know your etchings will last as longas the life of your part.ElectronicsGain precise control over the material you are marking on. From a spot size as small asfrom 30µm, power control, you can mark with precision accuracy at high speed. RMI LaserMarking Systems are ideal for applications such as phone keypads, computer keyboards,backlit paneling, buttons and switches because controlling the removal of the coating isessential for reliable and consistent marking. RMI Laser Marking Systems are also perfect forIC Chip materials such as resin epoxy or ceramics and PCB Boards because it does not alterthe soldering mask on the circuit boards.OEMExpand product lines and product offerings, or add customization to your existingproducts using RMI Laser OEM systems. RMI Laser will provide full engineering andapplication support as you utilize our Marking Systems on a component level both in thedevelopment of new products or the expansion of your existing products. RMI Laser ishere to fully support you from beginning to end. Let our World Class Laser expertise takeyour business to the next level.Call RMI Laser to find out which laser best fits your need.303.664.9000 / 888.952.7370 www.rmilaser.net

Expand your Capabilities (Accessories)Symbol Writer ProRotary Chuck Engraving SystemMark the inside or outside diameter of rings, water bottles, nuts or any other cylindrical items with RMI Laser’sRotary Chuck. Depending on your part size and weight, RMI Laser has a light-duty rotary chuck and a heavydutyrotary chuck allowing you to mark larger, heavier parts with ease. Symbol Writer Pro is fully interfacedwith the Rotary Chuck System providing full control of the all aspects the Rotary Chuck can offer. Easy toprogram, the only piece of information needed is the diameter of the part that will be marked.Rotary TableNever stop marking with a Rotary Table. Increasing throughput is the goal of every manufacturer. Do not allow your marking needs tobecome a bottleneck. The RMI Laser Rotary Table enables marking in one quadrant while the operator prepares the next quadrantsfor marking. Upon completion of the quadrant’s marking, the table indexes and marks the next quadrant.F-Theta LensesWith wide range of F-Theta Lenses, our Laser’s come with the versatility to change the size of the markingarea. Ranging from 60mm to 420mm in the 1064nm wavelengths and from 100mm to 254mm in 532nmwavelengths, you can mark areas ranging from a 1.5” diameter to a 12” diameter. Whether your applicationis one part at a time, comes down on a conveyor belt, or needs to be done in batches set by fixtures, weprovide the laser and the lens to accommodate your needs.Symbol Writer Pro is a software package developed by RMI Laser, LLC for marking and engraving. Easy to use, thissoftware ensures you can implement the fullest range of possibilities with the laser marking system.Marking in 5 Easy Steps1. Import – Import your file2. Focus – Adjust height ofmarking surface3. Set Parameters – Userfriendly interface for bestquality mark4. Position Preview – Line upobject using red aimingdiode5. Press Start – The systemstarts markingClass One Safety Enclosures100 mm F-Theta Focusing Lens• 60 x 60 mm 2.4 x 2.4” marking area• 85 mm 3.4” Diameter circularmarking area• 30µm spot size163 mm F-Theta Focusing Lens• 100 x 100 mm 4 x 4” marking area• 141 mm 5.6” Diameter circularmarking area• 49µm spot size254 mm F-Theta Focusing Lens• 150 x 150 mm 6X6” marking area• 212 mm 8.3” Diameter circularmarking area• 76µm spot size330 mm F-Theta Focusing Lens• 200 x 200 mm 7.9X7.9” squaremarking area• 283 mm 11” Diameter circularmarking area• 99µm spot size420 mm F-Theta Focusing Lens• 254 x 254 mm 10 x 10” squaremarking area• 358 mm 14” Diameter circularmarking area• 126µm spot sizeUID Wizard• Navigates you through the whole process• Build your UID in a few steps• No need to enter in the ASCII characters• No need to build the proper syntaxBarcodes, Data Matrices, MaxiCodes, QR-Codes, & PDF 417 Codes• Ideal for Part Traceability and Tracking• Place any information into your codebarcodes, uidfonts•••CDRH Certified Class 1 SafetyEnclosures ensure the safe operationof your laser.• Completely encloses Laser’s output• Safety Interlock stops marking if dooris opened during operationLED Light with On/Off switchLaser Safe viewing windowExternal Focusing Diode for easy focusingCustom sizing or design is available upon requestZ-Axis Linear Stand• 15” x 15” base plate• Z Axis adjustment of the Marker Headwith External Focusing Diode• 20” vertical aluminum column(12” travel)• Position guides with lock down handle• 6” or 9” Breadboard Included withpegs for fixturingZ-Axis Lab Jack with Breadboard• Pegs for fixturing• 6”, 9”, or 12” Breadboard includedBarcode Scanners, Readers & UID Verifiers• Scanners for 1D Barcodes• Scanners for 2D Data Matrices• UID Verifiers• Ensures maximum readability of your codingExternal Triggering Devices• Footswitch• Push Button Hand TriggerTrue Type Fonts & Single Stroke Fonts• Supports all fonts from Microsoft Word® & custom fonts• Specifically designed for high-speed and precision markingElliptical Text• Text in an Elliptical Orientation• Utilizes both Single Stroke and True Type FontsGraphics and Imaging• Imports Hi-Resolution Graphics, Photos, and Logos• Imports JPG, BMP, TIF, GIF, PLT, DXF, DWG, SVG• Will work with CorelDraw®, Adobe Illustrator®, and Auto-CAD® FilesSequential Serial Numbering and Custom Auto-Dating• The software automatically updates to the incremented value• Ideal for Part Traceability and Tracking• Customize your format or your information within your Julian DatingElliptical Textserial numbers303.664.9000 / 888.952.7370 www.rmilaser.net