Composite dry sliding bearings â maintenance-free and space-saving

Composite dry sliding bearings â maintenance-free and space-saving

Composite dry sliding bearings â maintenance-free and space-saving

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

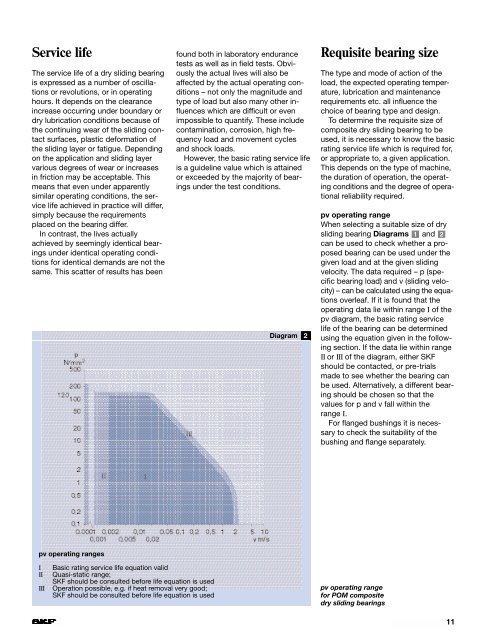

Service lifeThe service life of a <strong>dry</strong> <strong>sliding</strong> bearingis expressed as a number of oscillationsor revolutions, or in operatinghours. It depends on the clearanceincrease occurring under boundary or<strong>dry</strong> lubrication conditions because ofthe continuing wear of the <strong>sliding</strong> contactsurfaces, plastic deformation ofthe <strong>sliding</strong> layer or fatigue. Dependingon the application <strong>and</strong> <strong>sliding</strong> layervarious degrees of wear or increasesin friction may be acceptable. Thismeans that even under apparentlysimilar operating conditions, the servicelife achieved in practice will differ,simply because the requirementsplaced on the bearing differ.In contrast, the lives actuallyachieved by seemingly identical <strong>bearings</strong>under identical operating conditionsfor identical dem<strong>and</strong>s are not thesame. This scatter of results has beenfound both in laboratory endurancetests as well as in field tests. Obviouslythe actual lives will also beaffected by the actual operating conditions– not only the magnitude <strong>and</strong>type of load but also many other influenceswhich are difficult or evenimpossible to quantify. These includecontamination, corrosion, high frequencyload <strong>and</strong> movement cycles<strong>and</strong> shock loads.However, the basic rating service lifeis a guideline value which is attainedor exceeded by the majority of <strong>bearings</strong>under the test conditions.Diagram2Requisite bearing sizeThe type <strong>and</strong> mode of action of theload, the expected operating temperature,lubrication <strong>and</strong> <strong>maintenance</strong>requirements etc. all influence thechoice of bearing type <strong>and</strong> design.To determine the requisite size ofcomposite <strong>dry</strong> <strong>sliding</strong> bearing to beused, it is necessary to know the basicrating service life which is required for,or appropriate to, a given application.This depends on the type of machine,the duration of operation, the operatingconditions <strong>and</strong> the degree of operationalreliability required.pv operating rangeWhen selecting a suitable size of <strong>dry</strong><strong>sliding</strong> bearing Diagrams 1 <strong>and</strong> 2can be used to check whether a proposedbearing can be used under thegiven load <strong>and</strong> at the given <strong>sliding</strong>velocity. The data required – p (specificbearing load) <strong>and</strong> v (<strong>sliding</strong> velocity)– can be calculated using the equationsoverleaf. If it is found that theoperating data lie within range I of thepv diagram, the basic rating servicelife of the bearing can be determinedusing the equation given in the followingsection. If the data lie within rangeII or III of the diagram, either SKFshould be contacted, or pre-trialsmade to see whether the bearing canbe used. Alternatively, a different <strong>bearings</strong>hould be chosen so that thevalues for p <strong>and</strong> v fall within therange I.For flanged bushings it is necessaryto check the suitability of thebushing <strong>and</strong> flange separately.pv operating rangesIIIIIIBasic rating service life equation validQuasi-static range;SKF should be consulted before life equation is usedOperation possible, e.g. if heat removal very good;SKF should be consulted before life equation is usedpv operating rangefor POM composite<strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong>11