Composite dry sliding bearings â maintenance-free and space-saving

Composite dry sliding bearings â maintenance-free and space-saving

Composite dry sliding bearings â maintenance-free and space-saving

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

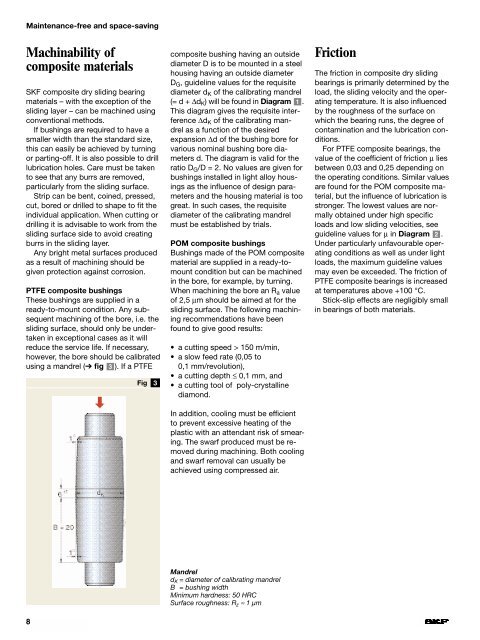

Maintenance-<strong>free</strong> <strong>and</strong> <strong>space</strong>-<strong>saving</strong>Machinability ofcomposite materialsSKF composite <strong>dry</strong> <strong>sliding</strong> bearingmaterials – with the exception of the<strong>sliding</strong> layer – can be machined usingconventional methods.If bushings are required to have asmaller width than the st<strong>and</strong>ard size,this can easily be achieved by turningor parting-off. It is also possible to drilllubrication holes. Care must be takento see that any burrs are removed,particularly from the <strong>sliding</strong> surface.Strip can be bent, coined, pressed,cut, bored or drilled to shape to fit theindividual application. When cutting ordrilling it is advisable to work from the<strong>sliding</strong> surface side to avoid creatingburrs in the <strong>sliding</strong> layer.Any bright metal surfaces producedas a result of machining should begiven protection against corrosion.PTFE composite bushingsThese bushings are supplied in aready-to-mount condition. Any subsequentmachining of the bore, i.e. the<strong>sliding</strong> surface, should only be undertakenin exceptional cases as it willreduce the service life. If necessary,however, the bore should be calibratedusing a m<strong>and</strong>rel (➔ fig 3 ). If a PTFEFig3composite bushing having an outsidediameter D is to be mounted in a steelhousing having an outside diameterD G , guideline values for the requisitediameter d K of the calibrating m<strong>and</strong>rel(= d + ∆d K ) will be found in Diagram 1 .This diagram gives the requisite interference∆d K of the calibrating m<strong>and</strong>relas a function of the desiredexpansion ∆d of the bushing bore forvarious nominal bushing bore diametersd. The diagram is valid for theratio D G /D = 2. No values are given forbushings installed in light alloy housingsas the influence of design parameters<strong>and</strong> the housing material is toogreat. In such cases, the requisitediameter of the calibrating m<strong>and</strong>relmust be established by trials.POM composite bushingsBushings made of the POM compositematerial are supplied in a ready-tomountcondition but can be machinedin the bore, for example, by turning.When machining the bore an R a valueof 2,5 µm should be aimed at for the<strong>sliding</strong> surface. The following machiningrecommendations have beenfound to give good results:• a cutting speed > 150 m/min,• a slow feed rate (0,05 to0,1 mm/revolution),• a cutting depth ≤ 0,1 mm, <strong>and</strong>• a cutting tool of poly-crystallinediamond.In addition, cooling must be efficientto prevent excessive heating of theplastic with an attendant risk of smearing.The swarf produced must be removedduring machining. Both cooling<strong>and</strong> swarf removal can usually beachieved using compressed air.FrictionThe friction in composite <strong>dry</strong> <strong>sliding</strong><strong>bearings</strong> is primarily determined by theload, the <strong>sliding</strong> velocity <strong>and</strong> the operatingtemperature. It is also influencedby the roughness of the surface onwhich the bearing runs, the degree ofcontamination <strong>and</strong> the lubrication conditions.For PTFE composite <strong>bearings</strong>, thevalue of the coefficient of friction µ liesbetween 0,03 <strong>and</strong> 0,25 depending onthe operating conditions. Similar valuesare found for the POM composite material,but the influence of lubrication isstronger. The lowest values are normallyobtained under high specificloads <strong>and</strong> low <strong>sliding</strong> velocities, seeguideline values for µ in Diagram 2 .Under particularly unfavourable operatingconditions as well as under lightloads, the maximum guideline valuesmay even be exceeded. The friction ofPTFE composite <strong>bearings</strong> is increasedat temperatures above +100 °C.Stick-slip effects are negligibly smallin <strong>bearings</strong> of both materials.M<strong>and</strong>reld K = diameter of calibrating m<strong>and</strong>relB = bushing widthMinimum hardness: 50 HRCSurface roughness: R z ≈ 1 µm8