Chhattisgarh State Power Generation Company Limited - Cseb.gov.in

Chhattisgarh State Power Generation Company Limited - Cseb.gov.in

Chhattisgarh State Power Generation Company Limited - Cseb.gov.in

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Chhattisgarh</strong> <strong>State</strong> <strong>Power</strong> <strong>Generation</strong><strong>Company</strong> <strong>Limited</strong>Petition for Approval ofCapital O&M, Civil & R&M Schemes for 2011-12/12-13December 2011

Petition for approval of capital schemes FY 2011-12/12-13CONTENTSPage1. ABBREVIATIONS 32. INTRODUCTION 43. CAPITAL INVESTMENTS ON EXISTING PLANTS 64. THE PROPOSALS 75. PRAYER 86. ANNEXURE – I 97. ANNEXURE – II 168. ANNEXURE – III 209. ANNEXURE – IV 3110. ANNEXURE – A 3511. ANNEXURE – B 3612. ANNEXURE –C 3813. ANNEXURE – D 41Page 2 of 46

Petition for approval of capital schemes FY 2011-12/12-131. ABBREVIATIONSACRONYMDEFINITIONA&G ExpensesAdm<strong>in</strong>istrative & General ExpensesCHPCOAL HANDLING PLANTCERCCentral Electricity Regulatory CommissionCSERC<strong>Chhattisgarh</strong> <strong>State</strong> Electricity Regulatory CommissionCSEB<strong>Chhattisgarh</strong> <strong>State</strong> Electricity BoardCSPGCL<strong>Chhattisgarh</strong> <strong>State</strong> <strong>Power</strong> <strong>Generation</strong> <strong>Company</strong> <strong>Limited</strong>CSPHCL<strong>Chhattisgarh</strong> <strong>State</strong> <strong>Power</strong> Hold<strong>in</strong>g <strong>Company</strong> <strong>Limited</strong>DPRDetailed Project ReportDSPM TPSDr. Shyama Prasad Mukherjee Thermal <strong>Power</strong> StationEA 2003 Electricity Act 2003FSAFuel Supply AgreementFYF<strong>in</strong>ancial YearGCVGross Calorific ValueGoCGGovernment of <strong>Chhattisgarh</strong>GFAGross Fixed AssetsGenco<strong>Generation</strong> <strong>Company</strong>HTPS KWHasdeo Thermal <strong>Power</strong> Station Korba WestKTPS KEBKorba Thermal <strong>Power</strong> Station Korba East BankMTPAMillion Tones Per AnnumO&MOperations and Ma<strong>in</strong>tenancePLFPlant Load FactorPFC<strong>Power</strong> F<strong>in</strong>ance CorporationR&M ExpensesRepair & Ma<strong>in</strong>tenance ExpensesRoEReturn on equitySECLSouth Eastern Coalfields <strong>Limited</strong>SHRStation Heat RatePage 3 of 46

Petition for approval of capital schemes FY 2011-12/12-132. INTRODUCTION<strong>Chhattisgarh</strong> <strong>State</strong> <strong>Power</strong> <strong>Generation</strong> <strong>Company</strong> <strong>Limited</strong> (CSPGCL), a successor company of<strong>Chhattisgarh</strong> <strong>State</strong> Electricity Board (CSEB) is for undertak<strong>in</strong>g the „generation function‟ of CSEBfrom 01.01.2009 <strong>in</strong> accordance with Transfer Scheme notified by <strong>State</strong> Government.CSPGCL is supply<strong>in</strong>g 100% of power generated by its power stations to <strong>Chhattisgarh</strong> <strong>Power</strong>Distribution <strong>Company</strong> <strong>Limited</strong> (CSPDCL) at the tariff decided by <strong>Chhattisgarh</strong> <strong>State</strong> ElectricityRegulatory Commission (CSERC). <strong>Chhattisgarh</strong> <strong>State</strong> Electricity Board (CSEB) was a part ofthe erstwhile Madhya Pradesh Electricity Board (MPEB) till 2000. It became a separate entity onthe formation of the <strong>State</strong> of <strong>Chhattisgarh</strong>. The board functioned as an <strong>in</strong>tegrated entity tillDecember 2008 when the <strong>State</strong> Government notified a transfer scheme for unbundl<strong>in</strong>g it. Thetransfer scheme resulted <strong>in</strong> the formation of five successor entities for undertak<strong>in</strong>g the functionsof the erstwhile board. <strong>Chhattisgarh</strong> <strong>State</strong> <strong>Power</strong> <strong>Generation</strong> <strong>Company</strong> <strong>Limited</strong> (CSPGCL) isone of the five successor entities, formed for undertak<strong>in</strong>g the „generation function‟ of CSEB.CSPGCL started operations on 1 st January 2009.CSPGCL’s <strong>Generation</strong> PortfolioApproximately 98% of CSPGCL‟s generation capacity (1900 MW) is located <strong>in</strong> Korba. Details ofCSPGCL‟s plants have been provided <strong>in</strong> the follow<strong>in</strong>g table.Details of Installed capacity for CSPGCL as on 1 st April 2011NO. NAME OF PLANT YR OF COMM. CONFIGURATION MWThermal1 KTPS Korba East *a TPS PH II 1966-68 4 X 50 200b TPS PH III 1976-81 2 X 120 2402 HTPS Korba West 1983-86 4 X 210 8403 DSPM TPS Korba 2007 2 X 250 500Hydro1 Hasdeo Bango HEP 1994-95 3 X 40 1202 Gangrel SHP 2004 4 X 2.5 103 Sikasar SHP 2006 2 X 3.5 74 M<strong>in</strong>i Micro H.P.S Korba 2003-09 2 X 0.85 1.70Co-<strong>Generation</strong>1 Kawardha Co-generation Plant 2006 1 X 6 6Total Installed Capacity (A+B+C) 1924.70KTPS Korba East - Refurbishment took place <strong>in</strong> 2002-05.Approximately 67% of CSPGCL capacity has completed 25 years or more <strong>in</strong> operations. It issubmitted that despite their age, the plants have performed well, meet<strong>in</strong>g most operationalbenchmarks set by <strong>Chhattisgarh</strong> <strong>State</strong> Electricity Regulatory Commission, however, at thesame time it may be appreciated that the old plants need fair degree of capital <strong>in</strong>vestment toma<strong>in</strong>ta<strong>in</strong> their operational worth<strong>in</strong>ess and to take care of statutory and safety requirements.Page 4 of 46

Petition for approval of capital schemes FY 2011-12/12-13Bus<strong>in</strong>ess PlanThe Bus<strong>in</strong>ess plan <strong>in</strong> compliance of the provisions of <strong>Chhattisgarh</strong> <strong>State</strong> Electricity RegulatoryCommission‟s (Terms & conditions of determ<strong>in</strong>ation of tariff accord<strong>in</strong>g to Multi-year tariffPr<strong>in</strong>ciples) Regulations, 2010 for the control period FY 2010-11 to 2012-13 was submitted <strong>in</strong>March 2010. Hon‟ble Commission passed its order on the same <strong>in</strong> June 2010. The petition andthe order, encompassed issues related to New projects, Renovation & Modernisation schemesand capital O&M and civil schemes.Hon‟ble Commission has desired that capital O&M and capital civil projections shall besubmitted plant wise and scheme wise. CSPGCL, on its part craved leave for such submissionon year to year basis as ascerta<strong>in</strong>ment of such needs <strong>in</strong> 2/3 year advance has got practicallimitations. Consider<strong>in</strong>g the issue, Hon‟ble Commission ordered as under :“2.56 Further, CSPGCL has stated that it is not possible to forecast such schemes forFY 2011-12 and FY 2012-13 <strong>in</strong> advance. Therefore, the Commission is not <strong>in</strong>cl<strong>in</strong>ed toapprove the <strong>in</strong>vestment <strong>in</strong> advance amount<strong>in</strong>g to Rs. 113.06 Cr and Rs. 119.52 Crenvisaged for FY 2011-2012 and FY 2012-2013 respectively. CSPGCL mayseparately submit scheme wise details for approval of the Commission under capitalO&M and capital civil for FY 2011-12 and FY 2012-13.”Further, while approv<strong>in</strong>g the schemes for 2010-11, Hon‟ble Commission disallowed anyprovision for cont<strong>in</strong>gencies and <strong>in</strong>stead provided:“ 2.57. The Commission has also disallowed the cont<strong>in</strong>gency provision of Rs 10 Crproposed for unforeseen capital nature work and is of the view that CSPGCL mayapproach the Commission with specific scheme for cont<strong>in</strong>gency works for itsapproval. The cont<strong>in</strong>gency work done due to emergency may be allowed by theCommission for capitalization after prudence check.”It is also submitted that qualify<strong>in</strong>g an expense as normal O&M expense or Capital O&Mexpense may not be subjected to a “Laxman Rekha” test. Such discretion pass through narrowmarg<strong>in</strong>s and sometimes the discretion may need review <strong>in</strong> the backdrop of details related to thecase. Probably <strong>in</strong> the same spirit, while disallow<strong>in</strong>g certa<strong>in</strong> schemes, the Hon‟ble Commissionordered:“2.55. Capital O&M and capital civil schemes not approved by the Commission areshown <strong>in</strong> Annexure – 2. CSPGCL may get these schemes implemented under normalO&M expenditure, if found necessary. However, if CSPGCL is conv<strong>in</strong>ced that a fewof these schemes should come under capital O&M and capital civil schemes, thenthey may approach the Commission with detailed justification.”In view of the all the above aspects, proposals have been categorized <strong>in</strong> three segments &submitted herewith for approval by the Hon‟ble Commission.Page 5 of 46

Petition for approval of capital schemes FY 2011-12/12-133. CAPITAL INVESTMENTS IN EXISTING PLANTSCivil SchemesCSPGCL <strong>in</strong>curs capital expenditure for a variety of civil works that are undertaken at the plantsand the residential colonies for its employees. The broad heads under which capital expenditureoccurs under civil schemes is as follows:• For Ash Ponds or Ash utilisation (<strong>in</strong>cludes erection of new Ash Bunds/ rais<strong>in</strong>g of height ofexist<strong>in</strong>g Ash Bunds for dispos<strong>in</strong>g ash, utilisation of Ash <strong>in</strong> fill<strong>in</strong>g low ly<strong>in</strong>g areas, structuralworks etc.)• Investment <strong>in</strong> basic <strong>in</strong>frastructural work.• Increas<strong>in</strong>g green cover at power plants and <strong>in</strong> nearby areas as per PCB or Governmentdirectives to ensure environment protection.Capital O&M schemesThe generation function is a technology <strong>in</strong>tensive and capital <strong>in</strong>tensive function. Capital<strong>in</strong>vestments are essential for smooth and efficient operation of the plants. Some times due tochange <strong>in</strong> technology, the exist<strong>in</strong>g equipment become obsolete and arrang<strong>in</strong>g spares for theexist<strong>in</strong>g equipment become extremely difficult. Some times equipments need replacement <strong>in</strong>order to meet the economical and energy sav<strong>in</strong>g operation. At other occasions some majorequipment need replacement on completion of their useful life as may be prescribed by themanufacturer / as per standard <strong>in</strong>dustry practice. Further, at times there are changes <strong>in</strong> lawsuch as emission standards prescribed by the Pollution Control Board, which require certa<strong>in</strong>capital <strong>in</strong>vestment. All these <strong>in</strong>vestments have been covered under the Capital head. Further asper CEA guidel<strong>in</strong>e (para 4.3.1 of Guidel<strong>in</strong>es for R&M/ LE Works Oct‟09) , the expenditure onsuch replacement which have a useful period of less than five years are to be covered asrout<strong>in</strong>e repair and ma<strong>in</strong>tenance activity. Due care has been taken that none of the scheme fallunder this criterion.Considerable effort has been made to prepare the scheme wise details and reasonability of thesame has been ensured through rigorous <strong>in</strong>ternal discussions and deliberations. As a resultant,fresh civil schemes worth only about Rs. 34.48 Cr. are be<strong>in</strong>g proposed and new Capital O&M isbe<strong>in</strong>g restricted to only 48.50 Cr. as aga<strong>in</strong>st last year approved schemes amount<strong>in</strong>g Rs. 35.11cr. (total cost) for Civil and Rs.50.06 cr. for O&M .It is submitted that the estimates shall not betreated as the ceil<strong>in</strong>g limits. Leave is also craved for submission of additional schemes as andwhen such exigencies arrive. The <strong>in</strong>stant values <strong>in</strong>dicate the m<strong>in</strong>imum capital <strong>in</strong>vestment toensure economical, smooth and efficient operation of the plant.Page 6 of 46

Petition for approval of capital schemes FY 2011-12/12-13Apart from the above new schemes, it is also submitted that the estimated cost of the alreadyapproved schemes have also been updated. Respect<strong>in</strong>g the direction by the Commission thatlook<strong>in</strong>g to the high Capex plan <strong>in</strong> the <strong>in</strong>stant control period, the company shall endeavour torestrict the capital expenses to bare m<strong>in</strong>imum level essential for smooth, safe and efficientoperation, CSPGCL has deferred execution of even some of the approved schemes for timebe<strong>in</strong>g and the time be<strong>in</strong>g requirement is be<strong>in</strong>g met through repair works <strong>in</strong>stead of majorreplacement. It may be appreciated that cost mentioned aga<strong>in</strong>st the schemes are estimatedcost and may like to change dur<strong>in</strong>g implementation. Hence CSPGCL may be allowed to executethe scheme on actual cost and variation <strong>in</strong> cost shall subsequently be submitted to the Hon‟blecommission for sett<strong>in</strong>g off tariff.Renovation & Modernisation Scheme :Apart from capital O&M & civil schemes, generat<strong>in</strong>g plants need to take up renovation &modernisation (R&M) work for better and safe operation of the plant. In this respect CSPGCL issubmitt<strong>in</strong>g scheme for augmentation, ma<strong>in</strong>tenance & up gradation of Fire Safety/Protectionsystem for Coal handl<strong>in</strong>g plant, HTPS, Korba West amount<strong>in</strong>g Rs. 15.60 Cr. Project report isenclosed as Annexure - IV4. THE PROPOSALSThe chapter provides <strong>in</strong>formation on the quantum of <strong>in</strong>vestment that will be undertaken byCSPGCL dur<strong>in</strong>g FY 2011-12 on capital O&M / Civil works. It is to submit that consider<strong>in</strong>g thetime required <strong>in</strong> procurement and manufactur<strong>in</strong>g of eng<strong>in</strong>eer<strong>in</strong>g <strong>in</strong>tensive items, <strong>in</strong>vestment maypartly spread to FY 2012-13. Proposals have been compiled on plant wise scheme wise basis,however based on the nature of proposals they have been bifurcated <strong>in</strong>to follow<strong>in</strong>g heads:• New Schemes for capital O&M work (<strong>in</strong>clud<strong>in</strong>g emergency works) - Annexure- I• New Schemes for capital Civil work (<strong>in</strong>clud<strong>in</strong>g emergency works) - Annexure -II• Update on already approved schemes - Annexure-III• New Scheme for R&M work (Project Report) - Annexure -IVApart from the above the CSPGCL submits that there are two critical schemes which areessential to ensure un<strong>in</strong>terrupted generation at Korba East and Korba West. These schemesrelate to the rais<strong>in</strong>g of Ash pond from 340 mtr to 343 mtr at Lotlota HTPS Korba West (cost<strong>in</strong>gRs. 1.7 Cr.) and 3 rd stage rais<strong>in</strong>g of Podimar ash bund Phase –II, Podimar A& B at KTPS KorbaEast cost<strong>in</strong>g Rs. 3 crs. These schemes are expected to be completed by Mar 2014 and work onthe schemes shall start <strong>in</strong> 2012-13. As no expenditure is expected <strong>in</strong> the FY 2011-12, hencethese schemes have not been <strong>in</strong>cluded <strong>in</strong> the above proposals. However at the same timelook<strong>in</strong>g to the criticality and importance of ash dump<strong>in</strong>g system (as is evident from the NTPCKorba crisis) it is imperative for the utility to <strong>in</strong>itiate plann<strong>in</strong>g and adm<strong>in</strong>istrative work <strong>in</strong> advance.Page 7 of 46

Petition for approval of capital schemes FY 2011-12/12-13Petitioner humbly request that commission may k<strong>in</strong>dly accord <strong>in</strong> pr<strong>in</strong>ciple approval to take upthese schemes forthwith.F<strong>in</strong>ancial projections of CapexAs per historical trend, the Civil and Capital O&M schemes are expected to be funded entirelyfrom <strong>in</strong>ternal accruals. However, subject to suitable market conditions, CSPGCL may exercisedebt f<strong>in</strong>anc<strong>in</strong>g as applicable under the relevant regulations. For above schemes, no grant isexpected from any source.5. PRAYER :-In light of the above submissions, it is prayed that the Hon‟ble Commission may k<strong>in</strong>dly allow theproposals summarised at para 4 „Proposals‟ of the petition. Further look<strong>in</strong>g to the unpredictablenature of such works leave is also craved for additional submissions as and when suchexigencies arise.CSPGCLThroughPlace : RaipurDate : ……(S.K. Tiwari)Super<strong>in</strong>tend<strong>in</strong>g Eng<strong>in</strong>eerO/o C.E. (C & CP)Page 8 of 46

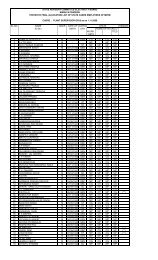

Petition for approval of capital schemes FY 2011-12/12-13Annexure –INEW CAPITAL O&M SCHEMES FOR FY 2011-12 / 2012-13(Amount <strong>in</strong> Rs.lacs. )S.N. <strong>Power</strong> house/Scheme TotalCostJustification/Remarks1 Furnituresa KTPS Korba East 15 Old furniture which have become irreparableneeds to be replaced. It is submitted that theb HTPS Korba West 15c Head Quarter 152 Computers &peripheralsTotal 45a KTPS Korba East 10b HTPS Korba West 16c Head Quarter 15Total 41furnitures have less life than the plant andmach<strong>in</strong>ery. The Depreciation rate allowed as perCERC schedule (adopted by CSER.C too) isabout 6%. Thus furniture gets fully depreciated bythe 15th year. The old furnitures needreplacement and as furnitures are part of grossfixed asset (as conventional ESAR 1983 and asper current <strong>Company</strong> account rules, both) thereplacement on completion of life shall also qualifyfor Capital expense. Some furniture is alsoneeded for new cells created as per the statutorynorms by Pollution Control Board.At head quarter additional furnitures are needed tocater the additional requirement of new officessuch as HR, C&CP, T&QA, F<strong>in</strong>ance created dueto reorganization of company. It may please beappreciated that considerable restra<strong>in</strong> has beenexercised <strong>in</strong> mak<strong>in</strong>g proposals, neither anyproposal for furniture nor computer has beenconsidered for DSPM TPS. It is requested thatproposal may please be allowed <strong>in</strong> toto.Grand Total 86Page 9 of 46

Petition for approval of capital schemes FY 2011-12/12-13KTPS,KORBA EAST (Amount <strong>in</strong> Rs.lacs. )S.N.AI1BI12Department/Division/SchemeMM IITM IITurb<strong>in</strong>e rotorrepair<strong>in</strong>gMM IIIBM IIIRe heater coilU#6PF l<strong>in</strong>e hangerU# 5&6TM III1 Equipment/Material forCapitalOverhaul of TGCIET&I IIEM II1 Installation ofnew batterywith charger &DCDB at 220 kvSwitchyard PH-IITotalCostJustification/Remarks171 There was one spare turb<strong>in</strong>e rotor available. Dur<strong>in</strong>g COHof Unit #2 <strong>in</strong> FY 10-11, the rotor was found damaged andwas replaced with the spare one. It is apprehended thatunit 3 rotor may also require replacement dur<strong>in</strong>g ensu<strong>in</strong>gCOH. The rotor taken out from U#2, is required to berepaired. Partial reblad<strong>in</strong>g static/dynamic balanc<strong>in</strong>g etc. isrequired to be done to make it usable. Cost of new rotorwill be above Rs. 10 Crore hence repair is better option.Advance will be required <strong>in</strong> FY 11-12 & completionexpected <strong>in</strong> 12-13.230 CPRI did RLA study <strong>in</strong> 2006. As per report, <strong>in</strong> five yearstime coils need to be replaced. The period is over andcoils need replacement to avoid frequent breakdowns.Expected completion <strong>in</strong> FY 12-13.10 Not replaced s<strong>in</strong>ce commission<strong>in</strong>g. Some of the hangersare not work<strong>in</strong>g. To avoid dust leakages and <strong>in</strong>crease <strong>in</strong>life of PF pipel<strong>in</strong>es, replacement is necessary.1427 The bear<strong>in</strong>g vibrations and eccentricity of TG set of U#5are runn<strong>in</strong>g very high . To rectify the problem BHEL hasrecommended Capital overhaul of TG set , to be taken upat the earliest. As recommended by them various TGequipments /material are required for Capital overhaul .20This <strong>in</strong>vestment is needed for system safety. In otherstations separate arrangement for DC supply to switchyard has been made long back. KTPS need to update thesystem.Page 10 of 46

Petition for approval of capital schemes FY 2011-12/12-132Replacement ofexist<strong>in</strong>g EPIC-IController withEPIC-III3 Retrofitt<strong>in</strong>g of6.6KV CGLmakeBreaker byvacuum C.B.III&C II1 On l<strong>in</strong>evibrationanalyz<strong>in</strong>gsystem.DI1EI1ET&I IIII&C IIIOxygenanalyzer .ServicesCTTraction motorfor 1400 HP DEloco.25 Exist<strong>in</strong>g EPIC-I controller have become obsolete & nospares are available from OEM & giv<strong>in</strong>g frequentproblems. It has become difficult to ma<strong>in</strong>ta<strong>in</strong> ESPs as perstr<strong>in</strong>gent pollution norms. New EPIC-III version is expectedto be helpful <strong>in</strong> controll<strong>in</strong>g of emission. Similar scheme forPH III has already been approved by Hon'ble Commission<strong>in</strong> Bus<strong>in</strong>ess Plan 2010-11. Expected to be implemented <strong>in</strong>FY 11-12/ 12-1350Exist<strong>in</strong>g CGL breakers are 20 years old & giv<strong>in</strong>g frequentproblems, hence replacement is essential.29 The exist<strong>in</strong>g system <strong>in</strong>stalled at Unit No.2 <strong>in</strong> 1995 hasbecome obsolete and it is difficult to ma<strong>in</strong>ta<strong>in</strong> the samedue to non availability of spares. It is necessary to replaceit with latest suitable system.20 O2 analyzer is required for ensur<strong>in</strong>g proper compliance ofpollution control norms. Last year Hon'ble Commission hasalready approved need of such analyzers for PH II for 15lakhs. If approved, expected commission<strong>in</strong>g for one unitis FY 11-12 and the other will be <strong>in</strong> 12-13. Amount<strong>in</strong>dicated is for one unit.120 The loco was purchased <strong>in</strong> 2007. There are 6 motors<strong>in</strong>stalled. Normally one motor and one alternator needs tobe procured as <strong>in</strong>itial spare for any eventuality, however atthe time of procurement no spare motor/ alternator waspurchased Instant proposal is deferred procurement of<strong>in</strong>itial spare (one motor & one alternator) .Now look<strong>in</strong>g tothe service rendered the spare motor/ alternator is a mustotherwise <strong>in</strong> any eventuality, the loco may go out ofservice. As there is only one loco of 1400 HP, <strong>in</strong> case ofoutage, shunt<strong>in</strong>g and timely unload<strong>in</strong>g of rack may geteffected, which may cause h<strong>in</strong>drance to coal supply to theplant.Page 11 of 46

Petition for approval of capital schemes FY 2011-12/12-13A100 MTcapacity weighbridge.On l<strong>in</strong>e ambientair qualitymonitor<strong>in</strong>gsystem.GRANDTOTAL(KTPS)10 Weigh bridge is required for Dry Fly Ash Handl<strong>in</strong>g system.There is only one weigh bridge available for the plant. Ascapsule trucks can not be allowed to move <strong>in</strong>side the plant,separate weigh bridge is essential. Also for 14 wheelvehicles 100MT weigh bridge will be needed. As per trafficrules capsule trucks are required to have weighment slipwith them to check overload<strong>in</strong>g status. Hence withoutweigh bridge facility capsule truck may not come to takeash from silos.100 The Pollution Control Board is <strong>in</strong>sist<strong>in</strong>g s<strong>in</strong>ce last 3-4 yearsfor Installation of this equipment. At present NTPC andBALCO have <strong>in</strong>stalled it <strong>in</strong> their area. Installation of sameto monitor ambient air quality of Korba City area has beenentrusted on KTPS, KEB/DSPM. Thus procurement isessential as per statutory requirement.2212HTPS,KORBA WEST (Amount <strong>in</strong> Rs.lacs. )Scheme/Division TotalCostTMD-I & II1 BFP UpgradedCartridge2 Preparation ofHP Module ofTurb<strong>in</strong>eBBMD-I AH&F1 Procurement ofpedestal of IDFan motor ofunit no-I & II ofHTPS, KorbaWest (Qty-1 set-2no.)2 Purchase of FDFan impellerblade for unitJustification/Remarks490 Hon'ble commission has pr<strong>in</strong>cipally consented forreplacement of BFP cartridges by upgraded cartridges <strong>in</strong>phased manner accord<strong>in</strong>gly procurement of Two nos.cartridges have been made aga<strong>in</strong>st the earlier approvedscheme for 2010-11. Two nos. more cartridges <strong>in</strong> 2011-12& 2 nos. <strong>in</strong> 2012-13 are to be procured. Cost <strong>in</strong>dicated isfor 2 nos.1000 HP module taken out from U#2 is required to be repairedfor emergency replacement <strong>in</strong> another Unit wheneverrequired.21 There are 2 nos pedestals <strong>in</strong>stalled for accommodat<strong>in</strong>gwhite metal bear<strong>in</strong>gs of both ends <strong>in</strong> each of I D Fanmotor. After service of 25 yrs these pedestals are proneto fail due to fatigue/ sudden enlargement of microscopiccracks developed dur<strong>in</strong>g service life. Therefore scheduledreplacement is essential. Presently no spare pedestal isavailable at site. At present one set (2nos.) are proposedfor replacement.37 Impeller of all 4 nos. FD Fan needed replacement. It hasbeen taken <strong>in</strong> phased manner. FD fan 2B was taken <strong>in</strong>2006, 1A <strong>in</strong> 2008 , 2A as approved <strong>in</strong> the last bus<strong>in</strong>essplan is be<strong>in</strong>g replaced <strong>in</strong> current year. Now f<strong>in</strong>ally 1 B isPage 12 of 46

Petition for approval of capital schemes FY 2011-12/12-13I&II: proposed for replacement <strong>in</strong> FY 2012-133 Supply and<strong>in</strong>stallation ofguillot<strong>in</strong>e gatesat ESP <strong>in</strong>let ofboilers of PH-I.CBMD-II AH&F1 PA Fan runnerwith shaft(2nos.)D TESTING -I1 ProtectionRelays of 220kVSwitchyard &L<strong>in</strong>e Feeder,Generatorprotection relays(8 nos.).EI&C-I1 Non contacttype water flowmeter:FCommunication1 On l<strong>in</strong>e leakagecurrent monitorkit for lightn<strong>in</strong>garrestors190 The guillot<strong>in</strong>e gates are required for isolation of <strong>in</strong>dividualpass of ESP, so as to enable to attend the outage of ESPfields dur<strong>in</strong>g runn<strong>in</strong>g of units this is essential due tochange <strong>in</strong> pollution norms from 150mg/nm3 to 50mg/nm3 ;which could not be achieved with field outages of ESP.Copy of CECB's letter 14.06.11 is enclosed. (Annexure –A)14 The shaft and runner of PA Fan 4A & 4F are <strong>in</strong> erodedcondition and needs to be replaced. The same have notbeen replaced s<strong>in</strong>ce commission<strong>in</strong>g.70 Electromechanical relays have given useful life above 25yrs; do not show repeatability & precision of operation asrequired <strong>in</strong> present day state of technology as be<strong>in</strong>gperformed by the Numerical microprocessor based relays.These new microprocessor based relay have capability tostore history/sequence of event, mak<strong>in</strong>g fault f<strong>in</strong>d<strong>in</strong>g &cause analysis very fast & tak<strong>in</strong>g preventive action.50 Meter<strong>in</strong>g of water consumption of HTPS, KW has nowbecome essential . Copy of CPCB (letter. No.552,dtd.11.03.10) & WRD, Govt. of CG (No.1177 dtd.05.04.10)are enclosed as Annexure-B, As per CPCBletter.11.03.10, to fulfill requirement of „Water pollutioncontrol Act- clause 4‟, it is statutory to <strong>in</strong>stall water metersfor measurement of water consumption.8 On l<strong>in</strong>e leakage current monitor portable kit is used forcondition monitor<strong>in</strong>g of live metal oxide surge arrestors. Itis suitable for measurement and analysis of resistiveleakage current of LA‟s <strong>in</strong> live condition without shut down,based on the measurement of 3rd Harmonic resistivecurrent with compensation for harmonics <strong>in</strong> the systemvoltage & reliable as per method B-2 of IEC-600995. Thissystem provides quick & reliable <strong>in</strong>formation about thehealth<strong>in</strong>ess of the LA and allows for stor<strong>in</strong>g of all themeasurement data <strong>in</strong> the field, provides customizedreports also. The leakage current <strong>in</strong>dicators of exist<strong>in</strong>gLAs are not work<strong>in</strong>g properly, these were supplied alongwith the Las are not reliable. Due to <strong>in</strong>accuracy of leakagecurrent <strong>in</strong>dicators, the health<strong>in</strong>ess of <strong>in</strong>stalled LAs can notbe ascerta<strong>in</strong>ed. There are as many 75 LAs <strong>in</strong>stalled <strong>in</strong>HTPS Korba West, so it is felt very much essential to havePage 13 of 46

Petition for approval of capital schemes FY 2011-12/12-132 Numerical BusBar protectionscheme of 400KVG1EMD-IIUAT &Transformers ofPH-II, HTPS,KWGRAND TOTAL(HTPS)at least one such kit for regular health monitor<strong>in</strong>g purposeof LAs of the station at HTPS Korba West and HBHPSBango. WRPC us also <strong>in</strong>sist<strong>in</strong>g to ensure regular &periodical test<strong>in</strong>g of health<strong>in</strong>ess of light<strong>in</strong>g arrestors byus<strong>in</strong>g special kit.92 ABB Sweden make bus bar differential relay model no.RADSS has been <strong>in</strong>stalled for 400 KV Switchyardprotections s<strong>in</strong>ce last 24 years and have become out oforder. A bus bar protection is a device which protects busbar aga<strong>in</strong>st short circuit and earth faults. It also securesthe system stability. A delayed tripp<strong>in</strong>g for bus bar faultscan also leads to network <strong>in</strong>stability, pole slip of near byGenerators and even total system collapse. The 400 KVsystem is hav<strong>in</strong>g two ma<strong>in</strong> buses (Bus-I and Bus-II) andone transfer bus. By provid<strong>in</strong>g this scheme faulty zone(Bus-I or Bus-II) isolated with <strong>in</strong> a very short time 20million seconds & other zone may rema<strong>in</strong> healthy. CEAvide letter dt. 09.06.11 has desired consideration of this asa special case with CSERC and approval on priority.200 3 nos. Unit Auxiliary transformers have already beenreplaced. Rema<strong>in</strong><strong>in</strong>g 5 Nos. have already served for morethan 25 years. They are required to be replaced <strong>in</strong> phasedmanner at present replacement of one no. is proposed.2172HBHPS, MACHADOLI (Amount <strong>in</strong> Rs.lacs )S.N.Scheme/DivisionTotalCostJustification/Remarks1 Motor for H.S.pump10 There are three no. H.S. pumps <strong>in</strong>stalled <strong>in</strong> 3x40 MWunits at HBHPS, motor of each Pump hav<strong>in</strong>gcapacity of 22 KW. These pumps are used to lift therotor and turb<strong>in</strong>e while start<strong>in</strong>g and stopp<strong>in</strong>g of units.One no. 22 KW spare motor has been utilized <strong>in</strong> airwashery pump motor now spare motor is notavailable at HBHPS. Outage of motor will causeoutage of units or damage of bear<strong>in</strong>gs henceprocurement of new motor is essential.Page 14 of 46

Petition for approval of capital schemes FY 2011-12/12-132 Dewater<strong>in</strong>g Pump& Dra<strong>in</strong>age Pump3 Installation ofFree Gov. Modeoperation System(FGMO);10 The pumps are used to throw out the leakage waterfrom the P.H. is to throw out the leakage water fromthe P.H. to the river <strong>in</strong> order to avoid flood<strong>in</strong>g <strong>in</strong> theP.H. The same are required to face any eventuality.360 At present at 3x40 MW units of HBHPS MachadoliAnalog <strong>gov</strong>ernors (EHG) are <strong>in</strong>stalled. As per CERC,New Delhi directive that Free Govern<strong>in</strong>g ModeOperation shall apply to all reservoir based hydrostations hav<strong>in</strong>g units of 10 MW capacity and above.For the compliance this equipment is required. (Copyof directive enclosed as Annexure C)Total 380Page 15 of 46

Petition for approval of capital schemes FY 2011-12/12-13ANNEXURE – IINEW CAPITAL SCHEMES FOR CIVIL WORK FOR FY 2011-12/12-13KTPS,KEB - CAPITAL CIVIL WORKS FOR ASH BUND / ASH UTILISATION(Amount <strong>in</strong> Rs. lacs )Sl.No.Brief Description ofproposed capital workTotalCostJustification/RemarksConstruction of new AshBund i/c WBM road,pedestals, etc1 Land Acquisition for new AshDyke2 Creation of ash dykecapacity without additionalland acquisition / heightrais<strong>in</strong>g, by shift<strong>in</strong>g ash fromash dyke to low ly<strong>in</strong>g areanear Pt. Ravi Shankar ShuklaNagar3 Creation of ash dykecapacity without additionalland acquisition / heightrais<strong>in</strong>g by shift<strong>in</strong>g ash fromash dyke to low ly<strong>in</strong>g areanear ITI Ash Bund300 Land is required for future Ash slurrydischarg<strong>in</strong>g arrangement. Scheme isexpected to be completed by FY 13-14.Estimated requirement for 2011-12 is Rs.100 lakhs100 Ash utilization works as per notification ofM<strong>in</strong>istry of Environment & Forest Govt. ofIndia. Scheme is expected to be completedby FY 12-13.200 Ash utilization works as per notification ofM<strong>in</strong>istry of Environment & Forest Govt. ofIndia. Scheme is expected to be completedby FY 12-13.GRAND TOTAL 600Page 16 of 46

Petition for approval of capital schemes FY 2011-12/12-13KTPS,KEBNEW CAPITAL CIVIL WORKS OTHER THAN ASH BUND / ASH UTILISATIONS.N.Brief Description ofproposed capitalwork1 Construction ofSewerage TreatmentPlant for AB Typecolony & CD typecolony2 Supply & Installation ofHDPE tanks <strong>in</strong> staffquarters of CDEF typecolony3 Lay<strong>in</strong>g of ris<strong>in</strong>g ma<strong>in</strong>for dr<strong>in</strong>k<strong>in</strong>g watersupply for 'AB' & 'CD'type colonyTotalCostGrand Total 390Justification(Amount <strong>in</strong> Rs.lacs )300 Execution of work as per requirement of CG<strong>State</strong> Environmental Conservation Board.Scheme is expected to be completed by FY12-13. (Copy of CPCB‟s letter no. 8882 Dt.30.03.10 Annexure D)30 The township was constructed with thepowerhouse, though package basedrenovation of power house took place longback, no package base renovation andrefurbishment of township took place. Eventhe water supply system is runn<strong>in</strong>g withmultiple patch works. Its creat<strong>in</strong>g60 dissatisfaction amongst employees andofficers. Such m<strong>in</strong>imum work is necessaryto just ma<strong>in</strong>ta<strong>in</strong> the reliability of water supplysystem. Scheme is expected to becompleted by FY 12-13.HTPS,KORBA WEST - CAPITAL CIVIL WORKS FOR ASH BUND / ASH UTILISATIONSl.No.Brief Description of proposedcapital workTotalcostJUSTIFICATIONRais<strong>in</strong>g of Ash Bund i/c WBM road, pedestals, etc1 Rais<strong>in</strong>g of pond "C" from RL 307to 310 M & pond 'B' from RL310 to 313 M at Ash bund unitI&II.270 For un<strong>in</strong>terrupted operation of Units I & IIand discharg<strong>in</strong>g of ash slurry. Expectedexpenditure FY 11-12 is 240 lakhs.Workfor pond 'B' <strong>in</strong> progress. Scheme isexpected to be completed <strong>in</strong> FY2012-13Page 17 of 46

Petition for approval of capital schemes FY 2011-12/12-132 Rais<strong>in</strong>g of Ash Bund Pond 'B'333.00 M to 336.00 M at Lotlota.3Rais<strong>in</strong>g of Ash Bund Pond 'A'337.00 M to 340.00 M at Lotlota.4 Land acquisition for new AshdykePrivate/Govt./Forest forUnit-III & IV5 Creation of ash dyke capacitywithout additional landacquisition / height rais<strong>in</strong>g byshift<strong>in</strong>g ash from ash dyke fordevelopment & reclamation ofwaste land <strong>in</strong> HTPS Colony6 Creation of ash dyke capacitywithout additional landacquisition / height rais<strong>in</strong>g byshift<strong>in</strong>g ash from from Pond 'B' &'C' and dry ash fill<strong>in</strong>g <strong>in</strong>abandoned pond A upto RL304.30 M at ash bund Unit I & II.7 Renovation of surge coal hopper<strong>in</strong>clud<strong>in</strong>g consultancy chargesand draw<strong>in</strong>g and design.8 Constn of nallah near conveyor4 over burden & construction ofreta<strong>in</strong><strong>in</strong>g wallGRAND TOTAL 1688143 Present capacity is likely to be exhausted.In order to <strong>in</strong>crease the capacity this workis required. Contract has been andawarded work is to be commenced.Scheme is expected to be completed <strong>in</strong>FY2011-12150 Present capacity is likely to be exhausted.In order to <strong>in</strong> crease the capacity this workis required. Scheme is expected to becompleted <strong>in</strong> FY2012-13200 Land is to be acquired for construction ofnew ash dyke for units 3 & 4 HTPS.Scheme is expected to be completed <strong>in</strong>FY2013-14220 Ash dyke capacity is proposed to be<strong>in</strong>creased by utiliz<strong>in</strong>g ash from dyke forreclamation of waste land <strong>in</strong> HTPS colony.Scheme is expected to be completed <strong>in</strong>FY2012-1360 Ash dyke capacity is proposed to be<strong>in</strong>creased by utiliz<strong>in</strong>g ash <strong>in</strong> fill<strong>in</strong>g ofabandoned pond. Scheme is expected tobe completed <strong>in</strong> FY2012-13600 Strengthen<strong>in</strong>g of RCC structure requiredfor un<strong>in</strong>terrupted coal supply to HTPS.Scheme is expected to be completed <strong>in</strong>FY2012-13.45 For smooth dra<strong>in</strong>age of flood & otherwater from LDCC, for smooth/ cont<strong>in</strong>uousoperation and required due to disposal ofoverburden by SECL. Scheme isexpected to be completed <strong>in</strong> FY2012-13.Page 18 of 46

Petition for approval of capital schemes FY 2011-12/12-13NEW SCHEMES - CAPITAL CIVIL WORKS OTHER THAN ASH UTILISATIONHTPS,KORBA WEST(Amount <strong>in</strong> Rs.lacs)S.N.Brief Description of proposedcapital work1 Construction of SewerageTreatment Plant at HTPS colonyKorba West2 Provid<strong>in</strong>g & fix<strong>in</strong>g HDPE tanks <strong>in</strong>staff quarters <strong>in</strong>clud<strong>in</strong>grenovation of external & <strong>in</strong>ternalwater supply system <strong>in</strong> colonycomplex.TotalCostJustification300 Execution of work as per requirement ofCG <strong>State</strong> Environmental ConservationBoard. Scheme is likely to be completedby FY 2013-14. Requirement for 2011-12is Rs. 50 lakhs.150 The township was constructed with powerhouse. Both are go<strong>in</strong>g to complete 25 yrs .Repairs <strong>in</strong> piecemeal are now not feltenough to ma<strong>in</strong>ta<strong>in</strong> proper dr<strong>in</strong>k<strong>in</strong>g watersupply. Such m<strong>in</strong>imum work is necessaryto ma<strong>in</strong>ta<strong>in</strong> reliable water supply. Schemeis likely to be completed by FY 2013-14.Requirement for 2011-12 is Rs. 75 lakhs.Grand Total 450S.NCAPITAL SCHEMES CIVIL WORKS FOR ASH BUND / ASH UTILISATIONDSPMTPS,KORBABrief Description of proposedcapital workTotalCost(Amount <strong>in</strong> Rs. lacs)Justification1 Rais<strong>in</strong>g of ash Dyke for lagoonNo-1 at Pandaripani/Gorhi<strong>in</strong>clud<strong>in</strong>g WBM road works andconsultancy320 For ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g un<strong>in</strong>terrupted powergeneration of units creation of space isutmost necessary for storage of ash.Grand Total 320Page 19 of 46

Petition for approval of capital schemes FY 2011-12/12-13ANNEXURE –IIIUPDATES OF CAPITAL O&M AND CIVIL SCHEMES ALREADY APPROVED BY THECSERC IN BUSINESS PLAN FOR 2010-11KTPS,KORBA EASTS.N.AIIMM IITM IIUPDATES OF ALREADY APPROVED CAPITAL O&M SCHEMESDepartment/Dn/Scheme1 New thrust Journalbrg.No.1 forTurb<strong>in</strong>e2 New boiler feedpumps.3 Recirculationvalves for BFP (2No)BIIMM IIITM III1 Acid TransferPump for DMPlant (2 Nos.)TotalCostJustification/Remarks(Amount Rs. <strong>in</strong> Lacs)22 Replacement of the Thrust Journal bear<strong>in</strong>g no.1 wasplanned dur<strong>in</strong>g capital overhaul of unit No.2, but dueto very high cost offered <strong>in</strong> budgetary offer ( Rs.1.75Crores), it could not be done. Now, it is proposed that<strong>in</strong>stead of complete set a new l<strong>in</strong>er shall be procuredand replaced. Earlier the scheme was approved forRs.35 lakhs , revised cost <strong>in</strong> <strong>in</strong>stant proposal is of Rs.22 lakhs.370 Scheme was approved for 2 nos. pumps at estimatedcost of Rs. 200 lakhs. However it is to state that 6pumps have rendered more than 30 years life . Iftender<strong>in</strong>g is done for one piece at a time then not onlyhigher rates may occur but later on <strong>in</strong>terchangeabilityand spare <strong>in</strong>ventory may also become issue. It isproposed to replace 6 no. complete systems(pumps, motors and lub oil system and 2 nos standbymotors) <strong>in</strong> phased manner (2 <strong>in</strong> 11-12, 2 <strong>in</strong> 12-13 and2 <strong>in</strong> 13-14). The cost <strong>in</strong>dicated is for two sets<strong>in</strong>clud<strong>in</strong>g lub oil system.45 Tender has been issued and order<strong>in</strong>g/commission<strong>in</strong>g will be carried out <strong>in</strong> FY 11-12/ FY 12-13. Earlier approved cost was Rs. 12 lakhs <strong>in</strong>dicatedfor one no. valve. Revised estimated cost is Rs. 45lakhs for 2 nos. valves4Already approved scheme. Expected to beimplemented <strong>in</strong> FY 11-12/12-13Page 20 of 46

Petition for approval of capital schemes FY 2011-12/12-132 BFP RecirculationvalveCIET&I III&C II25 Tender is be<strong>in</strong>g f<strong>in</strong>alised. Hence provision is kept forprocurement of 2 no. valves <strong>in</strong> two phases <strong>in</strong> FY 11-12/ FY 12-13.1 O2/Co2 monitors 15 O2/co2 analysers will be <strong>in</strong>stalled <strong>in</strong> phased manner<strong>in</strong> all the 4 units. At present it is proposed for one unitonly and expected to be implemented <strong>in</strong> FY 2011-12/12-13.2 Opacity meters. 30 Expected to be implemented <strong>in</strong> FY 11-12/12-133 Outdoor PLCCequipments & newcommunication<strong>in</strong>struments4 Upgradation ofDCS system.IIEM II1 Replacement ofOld Russian 0.4kvBreakers2 Replacement of6.6 kV old RussianMOCB3 Supply &replacement of GT4 Replacement ofRussian Isolatorsof Feeders30 Already approved scheme. Expected to beimplemented <strong>in</strong> FY 11-12/12-1375 Order has been placed and expected to beimplemented <strong>in</strong> the FY 2011-1230 Expected to be implemented <strong>in</strong> FY 11-12/12-1320 Already approved scheme. Expected to beimplemented <strong>in</strong> FY 11-12/12-13483 Order has been placed and expected to beimplemented <strong>in</strong> FY 11-12/12-13. Revised cost hasbeen <strong>in</strong>dicated200 Work could not be carried out as there was bigdifference <strong>in</strong> actual cost and the cost <strong>in</strong>dicated <strong>in</strong>petition/ order (Rs. 10 lakhs). As per prevail<strong>in</strong>gpractice, <strong>in</strong> order to make budget projections morerealistic, a token provision is made <strong>in</strong> the budget <strong>in</strong>which adm<strong>in</strong>istrative approval is requested and fullcost provision is made <strong>in</strong> the budget for the year <strong>in</strong>which actual expenditure is expected. As capitalbudget preparation and Capex plan f<strong>in</strong>alisation wasbe<strong>in</strong>g done side by side and last year was the firsttime that capex plan was be<strong>in</strong>g prepared,<strong>in</strong>advertently the token budget provision also gotreflected <strong>in</strong> the last year capex petition. Expected tobe implemented <strong>in</strong> 11-12/12-13Page 21 of 46

Petition for approval of capital schemes FY 2011-12/12-135 Installation of newEOT Crane100/25T at TGHall PH-26 Installation &commission<strong>in</strong>g ofgoods lift <strong>in</strong> boilerarea7 Motor and pumpset for WT plantDIET&I IIII&C III1 Diff. expansionprobe & itsmultifuctionelectronic card181 Scheme was earlier approved for Rs.10 lakhs. Earlier<strong>in</strong>advertently token amount of Rs. 10 lakhs got<strong>in</strong>dicated due to the similar reason as expla<strong>in</strong>ed at Sr.no.C II (4). It is now proposed to get exist<strong>in</strong>g cranerenovated and another EOT crane of 20/5T beprocured. Estimated cost for the renovation is 35lakhs and for new EOT crane is 146 lakhs. Expectedto be implemented <strong>in</strong> 11-12/12-1350 Actual cost is estimated to be 50 lakhs <strong>in</strong>stead of 5lakhs as approved earlier. Reason is similar to thatmentioned above at Sr. no.C II (4). Expected to beimplemented <strong>in</strong> 11-12/12-1310 Expected to be implemented <strong>in</strong> FY 11-12/12-1325Order for differential expansion probes placed.Expected to be implemented <strong>in</strong> 11-12.IIEM III1 0.4KV Breakers (5Nos.)2 6.6KV VCB (3Nos.)3 Generatorbush<strong>in</strong>gs4 ESP EpicController5 Replacement of220 V dc StationBattery6 GeneratorTransformer U#518 Price bid have been opened & revised cost isestimated to be Rs.18 lakhs <strong>in</strong>stead of alreadyapproved cost of Rs.15 lakhs.Expected to beimplemented <strong>in</strong> 11-12.50 Earlier petition was for 2 nos. based on historicalcost. Now the proposal is for 3 nos. on revisedupdated estimate. Price bids have been opened.Expected to be implemented <strong>in</strong> FY 11-12/12-13102 Material procured.Orig<strong>in</strong>al approved cost Rs.20 lakhs.63 Earlier approved cost was 12 lakhs. However updatedestimated cost is 63 lakhs due to reason asexpla<strong>in</strong>ed above at S.No.3 of section C-II(3) above.Expected to be implemented <strong>in</strong> FY 11-12/12-13.37 Offers aga<strong>in</strong>st tender have been technicallyscrut<strong>in</strong>ised. Revised cost is estimated to be Rs.37lakhs istead of already approved cost of Rs.10 lakhsdue to the reason as expla<strong>in</strong>ed at Sr.no.C II (4).775 Order has been placed. Expected to be implemented<strong>in</strong> FY 11-12/ 12-13Page 22 of 46

Petition for approval of capital schemes FY 2011-12/12-13IIITest<strong>in</strong>g1 ThermovisionCameraEMiscellaneous1 SpectrophotometerGrand Total 269329 Tender has been opened. Expected to beimplemented <strong>in</strong> FY 11-12/12-134 Scheme implementedS.N.KTPS,KORBA EAST , DEFERRED CAPITAL SCHEMESDepartment/Dn/SchemeTotalCostA MM II Rs.InlakhsTM II1 Extraction NRV forTurb<strong>in</strong>e2 95:5 Cu- NiCondenser Tubes3 R&M of VerticalBor<strong>in</strong>g Mach<strong>in</strong>e.4 MSRL Pip<strong>in</strong>g withfasteners.5 New Electric Hoistfor CW TransferPump HouseGrand Total 385Justification/Remarks50 Deferred due to very high rate <strong>in</strong> budgetory offer.200 Deferred as it would not be required <strong>in</strong> near futurelook<strong>in</strong>g to number of tubes plucked.70 Deferred at present as guaranteed/genu<strong>in</strong>e source ofRefurbishment could not be located.25 Physical <strong>in</strong>spection could not be carried out as thework <strong>in</strong>volves lot of digg<strong>in</strong>g/concrete break<strong>in</strong>g40 At present hoist has been made operative by repair<strong>in</strong>git.HTPS,KORBA WESTUPDATES OF ALREADY APPROVED CAPITAL O&M SCHEMES(Amount Rs. <strong>in</strong> Lacs)ParticularsTotalCostRemarksC2AH & FM D-IID Fan shaft &Impeller111 Orig<strong>in</strong>ally approved cost was 100 lakhs. ID fan shaftcost<strong>in</strong>g Rs. 81.58 lacs procured. Tender for impelleris <strong>in</strong> f<strong>in</strong>al stage. Expenditure of 29 lakhs. is expected<strong>in</strong> the year 2011-12.Page 23 of 46

Petition for approval of capital schemes FY 2011-12/12-133FD fan impellerbladeD TMD -I1GPreparation of HPmodule at BHELworksAH & FM D-II2 PA/FD fan37 Orig<strong>in</strong>ally approved cost was 36 lakhs. Material hasbeen received and shall be put <strong>in</strong> use <strong>in</strong> 2011-12700 Org<strong>in</strong>ally approved cost was Rs.700 lakhs. Materialhas been received279 Orders for FD fan cas<strong>in</strong>g cone, bear<strong>in</strong>gs, PA fanrunner with shaft & cas<strong>in</strong>g placed for about Rs. 29lakhs. Budgetory offer for the discharge duct fromOEM has been received and on the basis of thesame estimated cost has been revised. Amount<strong>in</strong>dicated is for one unitH12IJTMD-IILP turb<strong>in</strong>e 8thstage(L&R) for U#4BFP UpgradedCartridgeEMD- IHoist for ID fanmotorI&C-I2 ATRS equipment 16 Order placedL1EMD-IIReplacement of 400kV bus & l<strong>in</strong>eisolators HTPS, KW.367 Bus<strong>in</strong>ess plan value was 324.67 lakhs. Inadvertently10% advance already paid <strong>in</strong> 2008-09 was excluded.Blades have been procured490 Org<strong>in</strong>ally approved cost was Rs. 536 lakhs. Orderhas been placed.148 Orig<strong>in</strong>ally approved cost was Rs. 138 lakhs. Schemecompleted.130 Already approved scheme. Work could not becarried out as there was big difference <strong>in</strong> actual costand the cost <strong>in</strong>dicated <strong>in</strong> petition/ order. As perprevail<strong>in</strong>g practice, <strong>in</strong> order to make budgetprojections more realistic, a token provision is made<strong>in</strong> the budget <strong>in</strong> which adm<strong>in</strong>istrative approval isrequested and full cost provision is made <strong>in</strong> thebudget for the year <strong>in</strong> which actual expenditure isexpected. As capital budget preparation and Capexplan f<strong>in</strong>alisation was be<strong>in</strong>g done side by side andlast year was the first time that capex plan was be<strong>in</strong>gprepared, <strong>in</strong>advertantly the token budget provisionalso got reflected <strong>in</strong> the last year capex petition.Replacement of 9 nos. isolators are proposed.Tender is <strong>in</strong> process. Expected to be implemented <strong>in</strong>11-12/12-13Page 24 of 46

Petition for approval of capital schemes FY 2011-12/12-13M1N1P12Q1I&C -IIMultifunction testbench / labequipmentsTest<strong>in</strong>g -II400 kV control &protection panelCHP Inter-Ma<strong>in</strong>tStacker reclaimer-Slew<strong>in</strong>g r<strong>in</strong>g ,thyrister panel &hydraulic pack28 Orig<strong>in</strong>ally approved cost was Rs.20 lakhs. Schemecompleted56 Orig<strong>in</strong>ally approved cost was for Rs.20 lakhs.Indvertently <strong>in</strong> place of cost of scheme, tokenamount was quoted . Estimated cost as perbudgetory offer is be<strong>in</strong>g submitted for approval178 Orig<strong>in</strong>ally approved cost was 165 lakhs. Orders forsupply of Slew<strong>in</strong>g r<strong>in</strong>g & Thyrister panel have beenplaced. Tender for Hydraulic power pack has beenopened. Cost has been revised based on orderedcost.W<strong>in</strong>ch/Hoist 9 Indevertently <strong>in</strong> place of Hoist, W<strong>in</strong>ch was <strong>in</strong>dicated<strong>in</strong> bus<strong>in</strong>ees plan. Tender is <strong>in</strong> process.Workshop &GarrageBulldozer -155Eng<strong>in</strong>eTOTAL 258132 Scheme completed <strong>in</strong> July'11M2HTPS KORBA WEST- DEFERRED CAPITAL SCHEMES( EARLIER APPROVED BY CSERC)Up-gradation ofannunciation system40 Deferred. Proposed to be taken <strong>in</strong> renovation.S.No.UPDATES OF ALREADY APPROVED OTHER CAPITAL O&M SCHEMEOthersParticularsTotalCostRemarks(Amount Rs. <strong>in</strong> Lacs)Page 25 of 46

Petition for approval of capital schemes FY 2011-12/12-131 Provision for ABTmeters & monitor<strong>in</strong>gsystem to meetchange <strong>in</strong> law i.e.Intra state ABTregime.722 Scheme was approved for Rs. 310 lakhs. It isto state that earlier amount was <strong>in</strong>dicated onthe basis of budgetary offer for the ABT metersfor operational purpose. These metersamount<strong>in</strong>g Rs. 477 lakhs have been <strong>in</strong>stalled.Further 112 nos. meters for commercialpurpose are also be <strong>in</strong>stalled. Scheme isexpected to be completed by 2011-12Sl.No.AUPDATES OF ALREADY APPROVED CAPITAL CIVIL SCHEMESCAPITAL CIVIL WORKS FOR ASH BUND / ASH UTILISATIONKTPS,KORBA EAST (Rs. In lakhs )Brief Description ofproposed capitalworkRais<strong>in</strong>g of AshBund i/c WBM road,pedestals, etc1 Construction of WBMroad on top ofPodimar Phase I,Village road toPodimar Phase II, topof 4th stage rais<strong>in</strong>gand at other locationof bund.TotalrevisedcostRemarks34 Contract awarded for execution of works2 Rais<strong>in</strong>g of PodimarPhase I, rais<strong>in</strong>g ofPond "A" & "B" ofPhase IIBAsh Utilization &fill<strong>in</strong>g low ly<strong>in</strong>gareas1 Construction offlexible and rigidpavement from Balcoto ash silo area2 Construction of Ashmound over pond No400 Contract awarded for Podimar Phase -I andPond A & B of Podimar Phase-II, work <strong>in</strong>progress12 Work completed346 Work <strong>in</strong> Progress.Page 26 of 46

Petition for approval of capital schemes FY 2011-12/12-13CII of PAB RisdaPlantation work1 Plantation of 1 Lakhsplants for year 2009-10 and itsdevelopment for 3years at I.T.I ashbundGrand Total :- 86169 Plantation completed. Ma<strong>in</strong>tenance period ofplants to end <strong>in</strong> Mar-12KTPS,KORBA EASTS.NCAPITAL CIVIL WORKS OTHER THAN ASH UTILISATIONBrief Description ofproposed capitalworkRailway L<strong>in</strong>e1 Supply of rail andpo<strong>in</strong>t & cross<strong>in</strong>g etc.for renovation ofrailway track of KorbaEast<strong>Power</strong> House KorbaEast - Misc. works2 Provid<strong>in</strong>g protectionBridge <strong>in</strong> BCRWsystem3 Construction ofboundary wall at ashsilo area at anglestation D, nearlocation shed etc. asper requirement atother locations.Totalcost72 Works completedRemarks(Amount Rs. In lacs)35 Contract awarded & work <strong>in</strong> progress32Grand Total 139Boundary wall at ash silo area completedPage 27 of 46

Petition for approval of capital schemes FY 2011-12/12-13HTPS,KORBA WESTS.N.CAPITAL CIVIL WORKS FOR ASH BUND / ASH UTILISATIONBrief Description ofproposed capitalwork1 Construction of Roadand dra<strong>in</strong>age systemfor movement ofTruck for Ash SiloSystem i/c cost ofland unit I to 4 atHTPS KWB.2 Acquisition of landfrom WRD fortransportation of flyash near SILO3 IX stage Rais<strong>in</strong>g ofPond 'B' 307 to 310m PH I4 Rais<strong>in</strong>g of Pond Afrom 334 to 337 M atLotlota Ash dyke.5 Constn. of starterdyke for unit I & IInear village lotlota &adjacent villages ofDist. Korba i/c Villagewelfare activity6 Land acquisition108.261 Hact.for ashsilo and new ashbund land (private &revenue & forestland)7 Ash fill<strong>in</strong>g near Pond'C' <strong>in</strong> settl<strong>in</strong>g pond &plantationHorticulture.TotalrevisedcostTOTAL 3297Remarks21 Land from WRD to be transferred100 Land from WRD to be transferred(Amount Rs. In lacs)135 Orig<strong>in</strong>ally approved cost was 143 lakhs as perorder revised cost is Approx 115 lakhs. Actualexpenditure made approx 115 lakhs. Workscompleted120 Till march '11 expenditure of approx. 111 lakhsmade. Work <strong>in</strong> progress.1710 Till march '11 expenditure of approx. 1010.21lakhs made. Work <strong>in</strong> progress.1088 Orig<strong>in</strong>ally approved cost was 100 lakhs.Expenditure of 1037.52 lakhs has been made.Revised cost is 1087.52 lakhs. Cost has beenescalated due to actual payment made toForest Deptt., revenue Deptt. andcompensation rates fixed by Revenue Deptt..Work is <strong>in</strong> progress.123 Orig<strong>in</strong>ally approved cost was 105 lakhs.Expenditure of 111.95 lakhs has been made.Cost revised based on contract awardedPage 28 of 46

Petition for approval of capital schemes FY 2011-12/12-13HTPS,KORBA WEST(Amount Rs. In lacs)CAPITAL CIVIL SCHEMES OTHER THAN ASH UTILISATIONSl.No.Brief Description ofproposed capitalworkTotalcostJustification/ REMARKS1 Installation of 35 HP 4Nos. pumps atKailash Vihar PumpHouse.15DEFERREDSN1AHydel Projects-STATUS OF APPROVED CAPITAL CIVIL WORKBrief Discription ofproposed capitalworkHASDEO BANGOHEPInstallation ofPressure Filter &construction of watertreatment plant atHBHEP, Machadoli,Bango.Total for Bango HEPTotalcostREMARKS(Amount <strong>in</strong> Rs. Lacs.)25.00 Agency is be<strong>in</strong>g traced.25.00D1M<strong>in</strong>i Micro Hydel atHTPSRenovation of RadialGate & Sluice gate ofMHP and rais<strong>in</strong>g ofhoist<strong>in</strong>g arrangementTotal for M<strong>in</strong>i MicroHydel at HTPS40.00 Agency is be<strong>in</strong>g traced.40.00Page 29 of 46

Petition for approval of capital schemes FY 2011-12/12-13DEFERRED CAPITAL SCHEMES FOR HYDEL PROJECTS EARLIER APPROVEDBY CSERC2B1AHASDEO BANGOHEPProtection work byconstruct<strong>in</strong>g, chutedra<strong>in</strong> & reta<strong>in</strong><strong>in</strong>g wallfor safe disposal ofwater from securitypost to switch yard atMachadoli, Bango.Total Bango HEP 10.00Sikasar HEP (2x3.5MW)Approach road toHostel build<strong>in</strong>g atSikasar10.00 deferred26.00 deferredPage 30 of 46

Petition for approval of capital schemes FY 2011-12/12-13NEW CAPITAL RENOVATION & MODERNISTAION SCHEMEAnnexure –IVPROJECT REPORT FOR FIRE PROTECTION SYSTEM OF INTERNAL COALHANDLING PLANT AT 4X210 MW UNIT #1 TO 4, HTPS, KORBA WEST.01. DESCRIPTION:The site for 4x210MW Korba West Thermal <strong>Power</strong> is located <strong>in</strong> the district of Bilaspur <strong>in</strong>Chattisgarh at a distance of about 15 km from Korba Railway Station. The Korba Railway station is on theChampa-Korba-Gervra Road section of the South Eastern Railway. A broad gauge railway l<strong>in</strong>e with asid<strong>in</strong>g connects exist<strong>in</strong>g power station on the East Bank with Korba Railway station is exist<strong>in</strong>g and can beutilized for transport<strong>in</strong>g material. The site is about 6 Kms from the exist<strong>in</strong>g <strong>Power</strong> House No II situated onthe eastern bank of Hasdeo River and is connected by an all weather road <strong>in</strong>terl<strong>in</strong>ked with the state &National High ways.The <strong>Power</strong> Stations unit # No. 1 to 4 of 210 MW was commissioned <strong>in</strong> the year from 1982 to 1986.As per the Project report of the DCPL, the consultant for the then MPEB, has summarized the FireProtection system <strong>in</strong> their “Detailed Project Report”, which are reproduced as belowThis system has been designed consider<strong>in</strong>g four (4) nos. 210 MW units. The hydrant systemconsists of a large network of pipes, both underground and over-ground, which feeds pressurized waterto outdoor and <strong>in</strong>door hydrant valves. These hydrant valves are located throughout the entire powerstation and also at strategic locations with<strong>in</strong> power house and other build<strong>in</strong>gs. Hose pipes of suitablelengths, fitted with standard accessories like branch pipes, nozzles etc, are kept <strong>in</strong> the hose houses. Incase of fire, these hoses are coupled to the hydrant vales and water jet is directed towards the fire. Water<strong>in</strong> the complete hydrant system as well as <strong>in</strong> the H.V Spr<strong>in</strong>kler system is kept pressurized by automatichydro pneumatic water pressur<strong>in</strong>g arrangement consist<strong>in</strong>g of a jockey pump, air compressor and hydropneumatictank. In the event of fire tak<strong>in</strong>g place when the hydrant valves are opened <strong>in</strong> any part of thenetwork, the fall <strong>in</strong> the header pressure will br<strong>in</strong>g the pumps <strong>in</strong>to operation automatically to supply waterto the hydrant system. Failure to start the pump on demand shall result <strong>in</strong> further fall <strong>in</strong> header pressureand this shall actuate the next pump to start automatically and soon. Thus an automatic sequentialstart<strong>in</strong>g arrangement has been <strong>in</strong>corporated <strong>in</strong> the system design. Pumps can also be started manually <strong>in</strong>case of emergency but can be stopped only manually.02. BRIEF SYNOPSIS OF FIRE PROTECTION SYSTEM HISTORYThe implementation towards the aforesaid schemes of augmentation/Up-gradation of fire safety system ofTransformers & cable vault galleries <strong>in</strong>side the power plant was <strong>in</strong>itiated by the erstwhile MPEB on thePage 31 of 46

Petition for approval of capital schemes FY 2011-12/12-13basis of the guidel<strong>in</strong>es issued by the CEA to all the BOARDS. Accord<strong>in</strong>gly the orders were issued to thefollow<strong>in</strong>g firms for Transformers & cable vault galleries <strong>in</strong>side the power plant of Korba West.SR NO DESCRIPTION FIRM’S NAME ORDER NO ORDER VALUE(01) Fire protectionsystem for outdoorhydrants, HVWS(group-A),M/s.PragatiEngg. Pvt. Ltd.,Kolkatta07-01/ KW/235-A/4356Dated 29-11-1982Rs.1,16,80,875.10AndRs. 30,86,454/-TOTAL RS=1,47,67,329/-SETTLED AFTERARBITRATION(02) Fire protectionsystem of cablevault and cablegalleries with firedetection andHVWS system of4x210 MWKWB,TPSM/s ACE TurnKey fireprotection P Ltd.Bombay07-01/KW/235D/2153Dated30.03.89Rs.73,85,976.50REVISEDRs.1,30,70,854/-SHORTCLOSED(03) Fire protectionsystem of CHP of4x210 MWKWB,TPSM/s Matther &Platt07-01/ KW/235 C /2475Dated18.05.88Rs. 62,85,205.36SHORTCLOSED03. PROBLEMSAs Per the recommendations of plann<strong>in</strong>g commission and as emphasized by Central ElectricityAuthority for implementation of fire protection system as per prevail<strong>in</strong>g practice at Thermal <strong>Power</strong> Stationwas <strong>in</strong>itiated by erstwhile MPEB. But the same could not be implemented and the order was short closed.As per Central Electricity Authority and IS-3034-1993, clause No. 8.12.2.6, stipulate the provisions of FireSafety /protection systems of “Coal Handl<strong>in</strong>g Plant”.Accord<strong>in</strong>gly to implement the aforesaid system of Fire Protection system <strong>in</strong> Internal CoalHandl<strong>in</strong>g Plant as per the advanced & latest requirement <strong>in</strong> l<strong>in</strong>e with the IS/NFPA/Tariff Advisorycommittee {TAC} has been considered to protect the fire Hazard as per factory rules <strong>in</strong> Thermalpower station of HTPS Korba West.It is pert<strong>in</strong>ent to mention here that implementation of fire protection system is necessary to avoid /m<strong>in</strong>imise loss of men & material <strong>in</strong> the event of fire. Further recently <strong>in</strong> the month of March 2010Page 32 of 46

Petition for approval of capital schemes FY 2011-12/12-13implementation of the this system has been committed to the Vidhansabha of <strong>Chhattisgarh</strong> <strong>in</strong> responseto the Dhyanakarshana suchna no. 365.04. ENGINEERING SOLUTIONAs technology advances and older plants venture <strong>in</strong>to the 21 st century, plant upgrades areessential. These upgrades <strong>in</strong>clude the reliable, fast response and trouble free fire protectionsystem along with plant‟s fire and hazard detection to ensure the earliest possible detection ofany potential hazards <strong>in</strong> Coal Handl<strong>in</strong>g Plant. In Brief these systems are as below :-(A) For all coal conveyors, the follow<strong>in</strong>g system is to be provided ,Medium Velocity Water Spray System for coal conveyors toprotect both forward<strong>in</strong>g and return belt of both sides.Fire Detection and alarm system with L<strong>in</strong>ear Heat Sens<strong>in</strong>g Cable.(B) For Transfer Po<strong>in</strong>ts the follow<strong>in</strong>g system to be provided,05. ESTIMATED COSTWater curta<strong>in</strong> system.Sounder cum Flash light sensor(C) For Control Room, the follow<strong>in</strong>g system to be providedFire Detection and alarm system by provid<strong>in</strong>g Smoke sensors withelectronic hooterConsider<strong>in</strong>g base year 2011-12 the estimated cost based on budgetory proposalcompris<strong>in</strong>g of various system requied for the fire safety/ protection system of Coal Handl<strong>in</strong>gPlant at 4x210 MW Korba West HTPP, is Rs. 15,59,73,039/- say Rs. 15.60 cr. (Rs. Fifteen CroreFifty sixty lakhs Only).06. COST ANALYSIS & BENEFITSThe cost estimates based on the budgetary proposal compris<strong>in</strong>g of various systemsrequired for the Fire safety/Protection System of Coal Handl<strong>in</strong>g Plant at 4x210 MW KorbaWest HTPP is Rs. 15,59,73,039/- (Rs. Fifteen Crore Fifty N<strong>in</strong>e Lac Seventy Three ThousandThirty N<strong>in</strong>e Only).No direct cost benefit, the provision of Automatic fire protection system shall ensure thereliable, fast response and trouble free fire protection system along with plant‟s fire and hazarddetection to ensure the earliest possible detection of any fire hazards. Thus, the valuableequipments of the Plant and operat<strong>in</strong>g personnel neargy shall be protected from fire hazard.S<strong>in</strong>ce the requirement of the Fire Protection systems is statutory as per the factory act, guidel<strong>in</strong>esof CEA and Plann<strong>in</strong>g commission, direct cost benefit analysis <strong>in</strong> terms of Pay Back period couldnot be drawn.Page 33 of 46

Petition for approval of capital schemes FY 2011-12/12-1307. JUSTIFICATIONFrom the above, it is clear that Capital Investment of Rs. 15,59,73,039/- (Rs. Fifteen CroreFifty N<strong>in</strong>e Lac Seventy Three Thousand Thirty N<strong>in</strong>e Only) for FPS system of Coal Handl<strong>in</strong>gPlant at 4x210 MW Korba West HTPP, is essential/justified as per the requirement of the FactoryAct, Central electricity authority & as per the Plann<strong>in</strong>g Commission, therefore, the calculation ofpay-back period with respect to the capital <strong>in</strong>vestment does not seem to be reasonable.08. PHASING OF FUND :-Year 2011-2012 2012-2013 2013-14Rs. <strong>in</strong> Crore. 04.00 Cr 08.00 Cr 03.60 Cr.09. Source of fund<strong>in</strong>gThe Fund<strong>in</strong>g of 70 percent shall be arranged through loan from f<strong>in</strong>ancial <strong>in</strong>stitutionand balance 30 percent shall be arranged from own resources.---Page 34 of 46

Petition for approval of capital schemes FY 2011-12/12-13Page 35 of 46

Petition for approval of capital schemes FY 2011-12/12-13Page 36 of 46

Petition for approval of capital schemes FY 2011-12/12-13Page 37 of 46

Petition for approval of capital schemes FY 2011-12/12-13Page 38 of 46

Petition for approval of capital schemes FY 2011-12/12-13Page 39 of 46

Petition for approval of capital schemes FY 2011-12/12-13Page 40 of 46

Petition for approval of capital schemes FY 2011-12/12-13Page 41 of 46

Petition for approval of capital schemes FY 2011-12/12-13Page 42 of 46

Petition for approval of capital schemes FY 2011-12/12-13Page 43 of 46

Petition for approval of capital schemes FY 2011-12/12-13Page 44 of 46

Petition for approval of capital schemes FY 2011-12/12-13Page 45 of 46

Petition for approval of capital schemes FY 2011-12/12-13Page 46 of 46