SCHEMPP-HIRTH FLUGZEUGBAU GmbH

SCHEMPP-HIRTH FLUGZEUGBAU GmbH

SCHEMPP-HIRTH FLUGZEUGBAU GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SCHEMPP</strong>-<strong>HIRTH</strong> <strong>FLUGZEUGBAU</strong> <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Ventus-2a WARTUNGSHANDBUCH / MAINTENANCE MANUAL<br />

Ventus-2b<br />

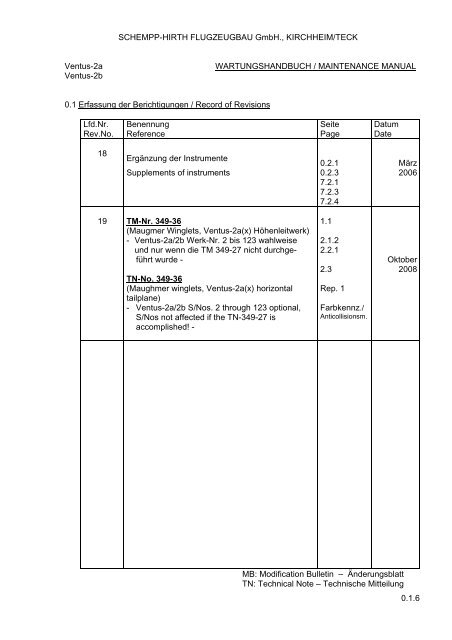

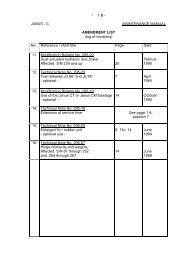

0.1 Erfassung der Berichtigungen / Record of Revisions<br />

Lfd.Nr.<br />

Rev.No.<br />

18<br />

19<br />

Benennung<br />

Reference<br />

Ergänzung der Instrumente<br />

Supplements of instruments<br />

TM-Nr. 349-36<br />

(Maugmer Winglets, Ventus-2a(x) Höhenleitwerk)<br />

- Ventus-2a/2b Werk-Nr. 2 bis 123 wahlweise<br />

und nur wenn die TM 349-27 nicht durchge-<br />

führt wurde -<br />

TN-No. 349-36<br />

(Maughmer winglets, Ventus-2a(x) horizontal<br />

tailplane)<br />

- Ventus-2a/2b S/Nos. 2 through 123 optional,<br />

S/Nos not affected if the TN-349-27 is<br />

accomplished! -<br />

Seite<br />

Page<br />

0.2.1<br />

0.2.3<br />

7.2.1<br />

7.2.3<br />

7.2.4<br />

1.1<br />

2.1.2<br />

2.2.1<br />

2.3<br />

Rep. 1<br />

Farbkennz./<br />

Anticollisionsm.<br />

Datum<br />

Date<br />

März<br />

2006<br />

Oktober<br />

2008<br />

MB: Modification Bulletin – Änderungsblatt<br />

TN: Technical Note – Technische Mitteilung<br />

0.1.6

<strong>SCHEMPP</strong>-<strong>HIRTH</strong> <strong>FLUGZEUGBAU</strong> <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Ventus-2a MAINTENANCE MANUAL<br />

Ventus-2b<br />

1. Description of components and systems<br />

NOTE:<br />

Further descriptions and assembly are provided on sections 1.4, 1.5, and 7<br />

of the Flight Manual.<br />

1.1 Airframe<br />

The model Ventus-2a and Ventus-2b are single-seat high performance sailplanes,<br />

constructed from fiber reinforced plastic (FRP), featuring wingflaps<br />

and a T-tail (with fixed horizontal stabilizer and elevator).<br />

Wing<br />

The wing shells are a CFRP/foam-sandwich with spar flanges made from<br />

carbon fiber rovings and shear webs constructed as a CFRP/foam-sandwich.<br />

Fuselage<br />

This is a pure carbon fiber lay-up with a Kevlar and glass fiber reinforcement<br />

in the cockpit area for high energy absorbtion.<br />

Horizontal tailplane<br />

The horizontal tailplane consists of a fixed stabilizer with elevator.<br />

The stabilizer is a GFRP/foam-sandwich, the elevator halves are a pure<br />

carbon fiber lay-up.<br />

Vertical tail<br />

Both fin and rudder are constructed as a glass fiber/foam-sandwich.<br />

October 2008<br />

Revision 19 TN-No. 349-36 1.1

<strong>SCHEMPP</strong>-<strong>HIRTH</strong> <strong>FLUGZEUGBAU</strong> <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Ventus-2a MAINTENANCE MANUAL<br />

Ventus-2b<br />

325 ± 25 mm<br />

-2.5°<br />

0.23°<br />

Ventus-2a - 6.35 m[ 20.83 ft ]<br />

Ventus-2b - 6.58 m[ 21.59 ft ]<br />

Tail jacked up such that a wedge-shaped block,<br />

100 : 3.125 for model "Ventus-2a" and 100 : 4.4<br />

for model "Ventus-2b", placed on the rear top<br />

fuselage, is horizontal along its upper edge.<br />

138 mm<br />

126 mm<br />

3°<br />

FLAPS<br />

set at "S1" (up)<br />

set at "0" (neutral)<br />

set at "L" (down)<br />

44<br />

AILERONS (flaps set at "0")<br />

RIGGING DATA AND CONTROL SURFACE DEFLECTIONS<br />

October 2008<br />

Revision 19 TN-No. 349-36 2.1.2

<strong>SCHEMPP</strong>-<strong>HIRTH</strong> <strong>FLUGZEUGBAU</strong> <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Ventus-2a MAINTENANCE MANUAL<br />

Ventus-2b<br />

2.2 Weights and hinge moments of control surfaces<br />

After repair work or repainting, the hinge moment of a component must not<br />

and its weight should not exceed the following values:<br />

Component Weight Residual moment<br />

Rudder with mass<br />

balance<br />

1 Elevator half with mass<br />

balance without fitting<br />

Flap / inboard<br />

aileron<br />

Mid aileron with<br />

mass balance<br />

3.90 - 4.80 kg<br />

8.60 - 10.58 lb<br />

1.00 - 1.25 kg<br />

2.20 - 2.76 lb<br />

1.50 - 1.85 kg<br />

3.31 - 4.08 lb<br />

2.00 - 2.50 kg<br />

4.41 - 5.51 lb<br />

Outbd. aileron 0.54 - 0.66 kg<br />

1.19 - 1.46 lb<br />

(-3.00) - (1.00) cmkg<br />

(-0.22) - (0.07) ftlb<br />

0.25 - 1.40 cmkg<br />

0.02 - 0.10 ftlb<br />

7.00 - 8.50 cmkg<br />

0.51 - 0.61 ftlb<br />

2.70 - 3.50 cmkg<br />

0.20 - 0.25 ftlb<br />

1.50 - 1.90 cmkg<br />

0.11 - 0.14 ftlb<br />

If the values shown in the above table are exceeded, it will be necessary to<br />

add an additional balance weight forward of the hinge axis as follows:<br />

1. After repair work - in the area of the repair<br />

2. After repainting - in the repainted area<br />

After complete repainting – distributed along the whole length of the<br />

component (if there was no mass balance attached) or near or next<br />

existing mass balance.<br />

Exceeding the value in the above weight table because of additional mass<br />

balance is permissible up to 15%, provided the residual moment within the<br />

tolerance.<br />

October 2008<br />

Revision 19 TN-No. 349-36 2.2.1

<strong>SCHEMPP</strong>-<strong>HIRTH</strong> <strong>FLUGZEUGBAU</strong> <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Ventus-2a MAINTENANCE MANUAL<br />

Ventus-2b<br />

2.3 Play in the control circuits<br />

With the cockpit controls fixed, the play at the control surfaces must not exceed<br />

the following values:<br />

Inboard +/- 2.0 mm measured 126 mm behind hinge axis<br />

aileron: (+/- 0.08 in.) (4.96 in.)<br />

Between inbd.<br />

and mid +/- 2.0 mm measured 106 mm behind hinge axis<br />

aileron: (+/- 0.08 in.) (4.17 in.)<br />

Between mid<br />

and outbd. +/- 1.0 mm measured 88 mm behind hinge axis<br />

aileron: (+/- 0.04 in.) (3.46 in.)<br />

Elevator: +/- 3.0 mm measured 138 mm behind hinge axis<br />

(+/- 0.12 in.) (5.43 in.)<br />

If there is excessive play in the hinge bearings and/or linkages, they must be<br />

replaced or the manufacturer should be contacted regarding possible measures<br />

to reduce the play.<br />

The rudder control circuit is an open circuit, operated directly by control cables,<br />

and is therefore not subject to play.<br />

October 2008<br />

Revision 19 TN-No. 349-36 2.3

<strong>SCHEMPP</strong>-<strong>HIRTH</strong> <strong>FLUGZEUGBAU</strong> <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Ventus-2a MAINTENANCE MANUAL<br />

Ventus-2b<br />

880<br />

130 130 130<br />

130 130 130 130<br />

70<br />

120<br />

80 80 80 80<br />

ANTI-COLLISION MARKINGS (optional)<br />

PROPOSAL 1 PROPOSAL 2 PROPOSAL 3 PROPOSAL 4<br />

October 2008<br />

Revision 19 TN-No. 349-36<br />

80 80 80<br />

25<br />

20°

<strong>SCHEMPP</strong>-<strong>HIRTH</strong> <strong>FLUGZEUGBAU</strong> <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Ventus-2a REPAIR INSTRUCTIONS<br />

Ventus-2b<br />

REPAIR INSTRUCTIONS FOR „Ventus-2a“ AND „Ventus-2b“<br />

The components of these sailplanes are constructed as follows:<br />

1. Wing<br />

CFRP/foam-sandwich, with DIVINICELL H60,<br />

thickness 6 mm and 8 mm (0.24 and 0.31 in.)<br />

2. Ailerons<br />

Inboard:<br />

Mid and<br />

CFRP/foam-sandwich, with DIVINICELL H60,<br />

thickness 4 mm (0.16 in.)<br />

outboard: Pure CFRP-shell<br />

3. Winglet<br />

Pure GFRP/CFRP-shell<br />

4. Fuselage<br />

5. Fin<br />

Forward section: Pure CFRP/Kevlar/GFRP-shell<br />

Aft section: Pure CFRP-shell<br />

GFRP/foam-sandwich, with DIVINICELL H60,<br />

thickness 6 mm (0.24 in.)<br />

6. Rudder<br />

GFRP/foam-sandwich, with DIVINICELL H60,<br />

thickness 4 mm (0.16 in.)<br />

7. Horizontal stabilizer<br />

GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 6 mm (0.24 in.)<br />

8. Elevator halves<br />

Pure CFRP-shell<br />

October 2008<br />

Revision 19 TN-No. 349-36 - 1 -