Download the complete EMCO Catalogue here.. - PVL Ltd

Download the complete EMCO Catalogue here.. - PVL Ltd

Download the complete EMCO Catalogue here.. - PVL Ltd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

WELCOME TO <strong>EMCO</strong> CONTROLSWELCOME TO <strong>EMCO</strong> CONTROLS<strong>EMCO</strong> Controls is a Danish instrumentation company.The factory is placed in Hørsholm near Copenhagen, not far from Hamlet's Elsinore.From <strong>the</strong> premises in Hørsholm, domestic and export sales as well as manufacturing areconducted. We employ skilled people with many years of experience in manufacturing ofmechanical instruments.<strong>EMCO</strong> Controls originates back to 1966 and has right from <strong>the</strong> beginning been recognizedas a manufacturer of process control equipment including switches and indicators for levelmeasurement.ENGINEERINGDesign and engineering of our instruments are based on recognized international standards.Our work is supported by <strong>the</strong> latest version of Autodesk Inventor with 3 D solid modellingand computer programmes developed by our engineers.Our instruments are manufactured according to <strong>the</strong> EU Pressure Equipment Directive (PED)97/23 EC and CE marked when required by <strong>the</strong> process conditions.We continually strive to provide high quality sensors with design innovation to meet ourcustomers' requirements.MANUFACTURINGOur CNC machines for turning and milling are equipped with EDGECAM.QUALITY ASSURANCEA quality system according to ISO 9001-2000 has been implemented in order to manufactureaccording to a quality defined by international standards, by our customers and ourselves.CUSTOMER SEGMENTShipbuilding. • Power plants, incineration units, combustion units.General food industry. • Water treatment plants. • Pharmaceutical industry.Chemical industry. • General liquid handling industry.2WWW.<strong>PVL</strong>.CO.UK

CONSTRUCTION AND DESIGN OF INSTRUMENTS FOR FLOW, LEVEL AND TEMPERATUREQUALITY SENSORS WITHDESIGN INNOVATIONHISTORY<strong>EMCO</strong> liquid level switches have been manufactured since 1973 serving customers reliably inmany different industries including <strong>the</strong> shipbuilding industry.The present liquid level switch is developed by our engineers backed up by more than 30 yearsof know-how gained by close corporation with our valid customers.The initial stage of <strong>the</strong> new development was to set up <strong>the</strong> requirements to <strong>the</strong> design of <strong>the</strong>level switch. 5 major requirements were identified:1. Easy electrical and mechanical mounting2. Good corrosion resistance of <strong>the</strong> switch housing3. Modern design4. Low manufacturing costs5. High degree of flexibilityThe engineers within <strong>the</strong> company were able to solve 4 outof <strong>the</strong> 5 major requirements. The design of <strong>the</strong> level switchwas done by an industrial designer.ENGINEERING BASED ONINTERNATIONAL STANDARDSWWW.<strong>PVL</strong>.CO.UK3

LEVEL SWITCHAPPLICATIONThe <strong>EMCO</strong> level switch is designed to control <strong>the</strong> liquid level in vessels containing corrosive ornon-corrosive liquids.ALARM DUTYThe standard level switch with float code 01 is used for signalling high or low alarm points.The signal may be used for plant shut down or emergency override control.Level switch with float code 05 is intended for side mounting with alarm pointwith difficult accessibility.Level switch with float code 04 is for vertical mounting on top of <strong>the</strong> vessel. Level switcheswith long levers f. d. code 50 are used for alarm duty with unstable liquid surface or withinsulated vessels requiring long levers undisturbed movement.Liquid level interface, minimum difference in density 0,2PUMP/VALVE CONTROLTwo level switches with float code 01 are used for pump control w<strong>here</strong> one switch starts <strong>the</strong>pump by activating a holding relay and <strong>the</strong> o<strong>the</strong>r switch brakes <strong>the</strong>holding relay when <strong>the</strong> desired liquid level has been reached.4WWW.<strong>PVL</strong>.CO.UK

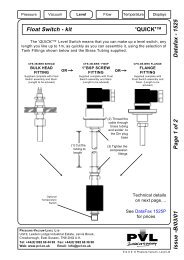

CONSTRUCTION AND DESIGN OF INSTRUMENTS FOR FLOW, LEVEL AND TEMPERATUREFUNCTIONThe <strong>EMCO</strong> float switch can be mounted horizontally or vertically, but horizontal mounting is<strong>the</strong> most common.The float lever carries a permanent magnet which is opposed by a similar magnet mounted in<strong>the</strong> switch housing. The magnets having <strong>the</strong> same pole directed toward each o<strong>the</strong>r are separatedby a non magnetic diaphragm. The glandless construction offers excellent sealing.CONSTRUCTIONThe <strong>EMCO</strong> Float switch consists of 3 main parts :1. Housing with switch, electrical or pneumatic2. Mounting flange3. FloatThe modular construction of <strong>the</strong> <strong>EMCO</strong> float level switch offers excellent flexibility to suitcustomers' requirements.FEATURES• Easy to install • Very high flexibility • Fast delivery• Type approved by Det Norske Veritas, Lloyds Register of Shipping and Bureau VeritasApplicable for high temperaturesWWW.<strong>PVL</strong>.CO.UK5

TECHNICAL SPECIFICATIONSTECHNICAL SPECIFICATIONSSwitch housing:Stainless steel, option aluminiumWetted parts:Stainless steel AISI 316, as option PP and PTFESpecific gravity: Standard min 0,7 option. 0,5Max. working presssure:<strong>EMCO</strong> flange 40 barStandard flange 100 barStandard flanges to DIN or ANSI/ASME normMax.working temperature:Depending on switch typeEnclosure: IP 65,IP 68 with 3x1,5 mm 2 ships cableElectrical gland connection :Option:M20 x 1,5 mmHirschmann, Schaltbau or o<strong>the</strong>r make of connector6WWW.<strong>PVL</strong>.CO.UK

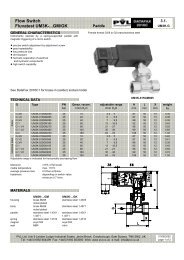

HOUSINGCODE MATERIAL SWITCH TYPE PROTECTION CABLELENGTH*Stainless steel housing is standard 1aluminiumelectricalIP 652stainless steelelectricalIP 653aluminiumelectricalIP 68 submersible3 meters*4stainless steelelectricalIP 68 submersible3 meters*5aluminiumpneumatic6stainless steelpneumaticSWITCHES*o<strong>the</strong>r lengths on requestCODE DIAGRAM SWITCH RATING TEMPERATUTREElectricalSPDTSilver contacts10250 V ac 2A24 V dc 0,7A(1,3 A)liquid : 225°Cambient : 80°CElectricalSPDT,Gold contacts1130 V dc 300 mAliquid: 225 O Cambient: 80 O CElectricalSPDT,Silver contacts122A 250 V ac0,7A 24 V dc(1,3A)liquid: 225 O Cambient: 80 O CInductiveNAMUREEX ia ll C T613Level undercontrol point output 3mALevel above output 1mAPower supply: 8V dcliquid: 150 O Cambient: 80 O CPneumaticpressure 3-8 bar.16Level below switch pointoutput logic 1 Kv: 0,8(pressure output)liquid: 120 O Cambient: 60 O CPneumaticpressure 3-8 bar.17Level below switch pointlogic 0 max. Kv: 0,8(no pressure output)liquid: 120 O Cambient: 60 O CWWW.<strong>PVL</strong>.CO.UK7

MOUNTING FLANGE<strong>EMCO</strong> FLANGES<strong>EMCO</strong> flanges are delivered in 2 versions :1. The heavy duty flange (standard) with flange diameter of122 mm. with 4 Ø 13 mm bolt holes on a BCD of 92 mm.2. The light duty flange with flange diameter of 102 mm.with 4 Ø 7 mm. bolt holes on a BCD of 92 mm.The different types of counter flanges are shown on page 11A flat gasket for general use is available. The gasket is to be mounted between <strong>the</strong> level switchand <strong>the</strong> counter flange. For corrosive liquids special gaskets are available including PTFE and Viton.Mounting kit containing <strong>the</strong> gasket and 4 bolts is to be specified separately.STANDARD FLANGESFlange standards: DIN and ANSI/ASME o<strong>the</strong>rs on requestFlange sizes:DN 65, DN 80, DN 100, 3”, 4”, o<strong>the</strong>rs on requestFlange facing: Flat facing DIN 2526, tongue and groove DIN 2512,Flat face FF, raised face RF or ring type joint RTJ to ANSI B 16.5Pressure rating:PN 16, PN 40, PN 100, 150 lbs, 300lbs, 600 lbsFlange material: stainless steel AISI 316For reduced cost loose flanges in carbon steel are available as an option.BELLOWS SEALS<strong>EMCO</strong> and standard flanges are available with bellowsseals for applications w<strong>here</strong> <strong>the</strong>re is a risk that particlesin <strong>the</strong> liquid or viscous liquids will obstruct <strong>the</strong> freemovement of <strong>the</strong> float. The bellows is made ofNeoprene which reduces <strong>the</strong> operating temperature to 80° C.8WWW.<strong>PVL</strong>.CO.UK

FLOATSCODE L HYSTERESIS h 1 h 2MM MM MM MMSide mounted, Standard lever0121012-15Side mounted, Long lever253035405060708090100250300350400500600700800900100025385265981131461681932238161931545658648111117223334445788104112112Topmounted, Variable hysteresis033000max.variableTopmounted,Cranked lever04min. 15210min. 100max. 550Side mounted, Cranked lever05H1min. 100max. 550min. 40210min. 100Float for liquid interface detection: code 35LID.Floats in PP and PTFE are limited in number of available types, ask for separate data sheet.WWW.<strong>PVL</strong>.CO.UK9

FLOATSCODE L HYSTERESIS h 1 h 2 H 1 H 2 STOPMM MM MM MM MM MM POSSide mounted, Variablehysteresis0237057108160212262295– 94– 43+ 9+ 61+ 111+ 144– 151– 49– 6+ 40+ 100+ 158+ 193– 2001-41-51-61-71-81-92576128180230263– 94– 43+ 9+ 61+ 111+ 144– 119– 49– 6+ 40+ 100+ 158+ 193– 1622-42-52-62-72-82-92880132182215– 43+ 9+ 61+ 111+ 144– 71– 6+ 40+ 100+ 158+ 193– 1143-53-63-73-83-92779129162+ 9+ 61+ 111+ 144– 18+ 40+ 100+ 158+ 193– 544-64-74-84-92777110+ 61+ 111+ 144+ 34+ 100+ 158+ 193– 35-75-85-92558+ 111+ 144+ 86+ 158+ 193+ 416-86-9026109506109506341117+ 318+ 560- 315- 557+ 372+ 614- 370- 6101-91-910WWW.<strong>PVL</strong>.CO.UK

CONSTRUCTION AND DESIGN OF INSTRUMENTS FOR FLOW, LEVEL AND TEMPERATUREACCESSORIESCOUNTER FLANGES CODE MATERIALWith weld neck380460Carbon steelAISI 316 stainless steelFor weld in490510Carbon steelAISI 316 stainless steelTesterL0M0Carbon steelAISI 316 stainless steelType L0 and M0LL0LM0Carbon steelAISI 316 stainless steelType LL0 and LM0WWW.<strong>PVL</strong>.CO.UK11

FLOATS CHAMBERSFLOAT CHAMBERSA huge variety of models are available on request including different level switch mountingflanges and process connections. Please ask for separatedrawing for models not shown below.Type H0/J0 – cut away shown with low levelCODEMATERIALWith code 380/460 mounting flangeH0ID0IA0J0KD0KA0Carbon steel with 1” butt weld endsCarbon steel with DN 25 PN 40 flanges (DIN)Carbon steel with 1” 300 lbs RF flanges (ANSI)AISI 316 with 1” butt weld endsAISI 316 with DN 25 PN 40 flanges (DIN)AISI 316 with 1” 300 lbs RF flanges (ANSI)With code L0/M0 testerH0/L0ID0/L0IA0/L0J0/M0KD0/M0KA0/M0Carbon steel with 1” butt weld endsCarbon steel with DN 25 PN 40 flanges (DIN)Carbon steel with 1” 300 lbs RF flanges (ANSI)AISI 316 with 1” butt weld endsAISI 316 with DN 25 PN 40 flanges (DIN)AISI 316 with 1” 300 lbs RF flanges (ANSI)12WWW.<strong>PVL</strong>.CO.UK

FLOAT CHAMBERS WITH STANDARD FLANGE SWITCH CONNECTION<strong>EMCO</strong> float chamber code VER-H with vertical butt weld endprocess connectionsSwitch connection: DN 80 or 3"Process connection: 33,7 or 60,31" or 2"Pressure rating:up to PN 100 or 600 lbs<strong>EMCO</strong> float chamber code VER-I with vertical flangedprocess connectionsSwitch connection: DN 80 or 3"Process connection: DN 25 or DN 501" or 2"Pressure rating:up to PN 100 or 600 lbs<strong>EMCO</strong> float chamber code HORR-I with horizontal flanged processconnections pointing to <strong>the</strong> rightSwitch connection: DN 80 or 3"Process connection: DN 25 or DN 501" or 2"Pressure rating:up to PN 100 or 600 lbs<strong>EMCO</strong> float chamber code HORL-I with horizontal flanged processconnections pointing to <strong>the</strong> leftSwitch connection: DN 80 or 3"Process connection: DN 25 or DN 501" or 2"Pressure rating:up to PN 100 or 600 lbs<strong>EMCO</strong> float chamber code HOR-I with horizontal flanged processconnections pointing backwardsSwitch connection: DN 80 or 3"Process connection: DN 25 or DN 501" or 2"Pressure rating:up to PN 100 or 600 lbs<strong>EMCO</strong> float chamber code HORD-I with horizontal flanged processand drain connections and vertical drain connectionsSwitch connection: DN 80 or 3"Process connection: DN 25 or DN 501" or 2"Pressure rating:up to PN 100 or 600 lbsWWW.<strong>PVL</strong>.CO.UK13

HOW TO ORDERCONTACT HOUSEAluminium IP65Stainless steel IP65 (standard)Aluminium IP68*Stainless steel IP68*Pneumatic*IP68 with 3 meter cableCODEHEAVY DUTY1standard 2349CODELIGHT DUTYSWITCH TYPEMicro switch, silverMicro switch, goldDPDT, silverNamur, inductivePneumatic logic 1Pneumatic logic 0101112131617MOUNTINGStandard flange (DIN as ANSI)Standard flange with bellows (DIN as ANSI)<strong>EMCO</strong> flange<strong>EMCO</strong> flange with bellowsBNENFNGNANDNFLOATSStandard leverLong leverVariableVariableVariableTopmounted variableTopmountedCranked lever0125-1000202610295030405ACCESSORIES For code FN/GN mounting flanges and AN/DN mounting flangesCounter flange weld neck carbon steelCounter flange weld neck stainless steel AISI 316Counter flange carbon steelCounter flange stainless steel AISI 316Tester carbon steelTester stainless steel AISI 316Tester carbon steelTester stainless steel AISI 316Float chamber carbon steel with 1” butt weld ends/with testerFloat chamber carbon steel with DN 25 PN 40 flanges (DIN)/with testerFloat chamber carbon steel with 1” 300 lbs RF flanges (ANSI)/with testerFloat chamber AISI 316 with 1” butt weld ends/with testerFloat chamber AISI 316with DN 25 PN 40 flanges (DIN)/with testerFloat chamber AISI 316 with 1” 300 lbs RF flanges (ANSI)/with testerFN/GNAN/DN380 38460 46490 49510 51L0LM0MLL0LLLM0LMH0 H0/L0 H H/LID0 ID0/L0 ID ID/LAI0 IA0/L0 AI IA/LJ0 J0/M0 J J/MJD0 JD0/M0 JD JD/MJA0 JA0/M0 JA JA/MMOUNTING KITSGeneral purpose gasket and 4 pcs M 12 x 30 bolts (standard)Viton gasket and 4 pcs M 12 x 30 boltsPTFE gasket and 4 pcs M 12 x 30 boltsGeneral purpose gasket and 4 pcs M 6 x 30 bolts (standard)Viton gasket and 4 pcs M 6 x 30 boltsPTFE gasket and 4 pcs M 6 x 30 boltsFN1FN2FN3AN1AN2AN314EXAMPLE: <strong>EMCO</strong> Float Switch type 210FN01-380-FN1 is a float switch with a SPDT switch silver plated contact, <strong>EMCO</strong> flangemounting, standard lever, counter flange with weld neck in carbon steel and general purpose gasket.WWW.<strong>PVL</strong>.CO.UK

0-01-017-0Distributed in <strong>the</strong> UK by Pressure Vacuum Level <strong>Ltd</strong>, Crowborough, East Sussex, TN6 2NQE-mail: sales@pvl.co.uk · www.pvl.co.uk · Tel: 01892 664499 · Fax: 01892 663690