Number 3 - Geological Curators Group

Number 3 - Geological Curators Group

Number 3 - Geological Curators Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

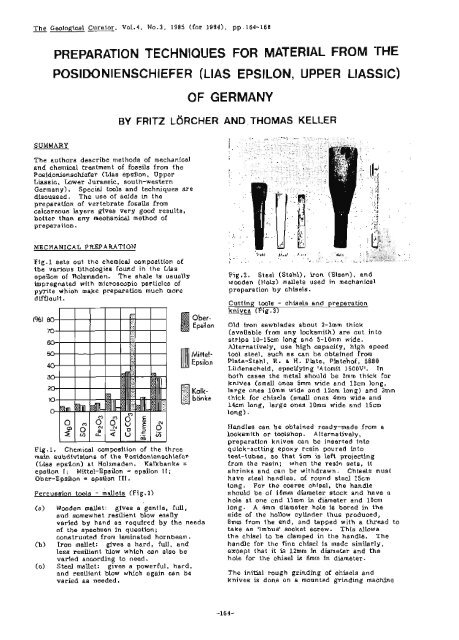

- The <strong>Geological</strong> W, Vo1.4, No.3, 1985 (for 1984), pp.164-168PREPARATION TECHNIQUES FOR MATERIAL FROM THEPOSIDONIENSCHIEFER (LIAS EPSILON, UPPER LIASSIC)OF GERMANYBY FRlTZ LORCHER AND THOMAS KELLEFiSUMMARYThe authors describe methods of mechanicaland chemical treatment of fossils from thePosidonienschiefer (Lias epsilon. UpperLiassic, Lower Jurassic, south-westeinGermany). Special tools and techniques arediscussed. he use of acids in thepreparation of vertebrate fossils fromcalcareous layers gives very good results,better than any mechanical method ofpreparation.MECHANICAL PREPARATIONFig.1 sets out the chemical composition ofthe various lithologies found in the Liasepsilon of Holzmaden. The shale is usuallyimoreenated with microscopic particles ofpyrite which makemuch moredifficult.Fig.1. Chemical composition of the threemain subdivisions of the Posidonienschiefer(Lias epsilon) at Holzmaden. Kalkhanke =epsilon I; Mittel-Epsilon = epsilon 11;Ober-Epsilon = epsilon 111.Percussion tools - mallets (Fig.2)IOber-EpsilonaMittel-Epsilon(a) Wooden mallet: gives a gentle, full,and somewhat resilient blow easilyvaried by hand as required by the needsof the specimen in question;constructed from laminated hornbeam.(b) Iron mallet: gives a hard, full, andless resilient blow which can also bevaried according to need.(c) Steel mallet: gives a powerful, hard,and resilient blow which again can bevaried as needed.Fig.2. Steel (Stahl), iron (Eisen), andwooden (Holz) mallets used in mechanicalpreparation by chisels.cut tin^ tools - chisels and preparationknives (Fig.3)Old iron sawblades about 2-3mm thick(available from any locksmith) are cut intostrips 10-15cm long and 5-10mm wide.Alternatively, use high capacity, high speedtool steel, such as can be obtained fromPlate-Stahl, R. s H. Plate, Platehof, 5880Liidenscheid, specifying 'Atomit 1500V'. Inboth cases the metal should be 2mm thick forknives (small ones 5mm wide and 12cm long,large ones l0mm wide and 12cm long) and 3mmthick for chisels (small ones 4mm wide and14cm long, large ones lOmm wide and 15cmlong).Handles can be obtained ready-made from alocksmith or toolshop. Alternatively,preparation knives can be inserted intoquick-setting epoxy resin poured intotest-tubes, so that 5cm is left projectingfrom the resin; when the resin sets, itshrinks and can be withdrawn. Chisels musthave steel handles, of round steel 15cmlong. For the coarse chisel, the handleshould be of 16mm diameter stock and have ahole at one end llmm in diameter and l0cmlong. A 4mm diameter hole is bored in theside of the hollow cylinder thus produced,8mm from the end, and tapped with a thread totake an 'Imbus' socket screw. This allowsthe chisel to be clamped in the handle. Thehandle for the fine chisel is made similarly,except that it is 12mm in diameter and thehole for the chisel is 6mm in diameter.The initial rough grinding of chisels andknives is done on a mounted grinding machine