en/ACS800-04/U4 Hardware Manuals - VAE ProSys sro

en/ACS800-04/U4 Hardware Manuals - VAE ProSys sro

en/ACS800-04/U4 Hardware Manuals - VAE ProSys sro

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ACS800</strong>-<strong>04</strong> Drive Modules0.55 to 200 kW<strong>ACS800</strong>-<strong>U4</strong> Drive Modules0.75 to 200 HP<strong>Hardware</strong> Manual3AFE68372984 Rev E ENEFFECTIVE: 31.03.2008© 2008 ABB Oy. All Rights Reserved.

2NEW (page 24): Type codeThe table below contains the new option code definition for the Safe torque offfunction.CodeDescription+Q967 Safe torque off (STO)CHANGED (page 25): Main circuit and control / DiagramX41 - Prev<strong>en</strong>tion of unexpected start (+Q950, AGPS board) or Safe torque off(+Q967, ASTO board)NEW (page 49): Emerg<strong>en</strong>cy stopNote: If you add or modify the wiring in the drive safety circuits, <strong>en</strong>sure that theappropriate standards (e.g. IEC 61800-5-1, EN 62061, EN/ISO 13849-1 and -2) andthe ABB guidelines are met. After making the changes, verify the operation of thesafety function by testing it.NEW (page 51): Safe torque offThe drive supports the Safe torque off (STO) function according to standardsEN 61800-5-2:2007; EN/ISO 13849-1:2008, IEC 61508, and EN 62061:2005. Thefunction also corresponds to an uncontrolled stop in accordance with category 0 ofEN 602<strong>04</strong>-1 and prev<strong>en</strong>tion of unexpected start-up of EN 1037.The STO may be used where power removal is required to prev<strong>en</strong>t an unexpectedstart. The function disables the control voltage of the power semiconductors of thedrive output stage, thus prev<strong>en</strong>ting the inverter from g<strong>en</strong>erating the voltage requiredto rotate the motor (see the diagram below). By using this function, short-timeoperations (like cleaning) and/or maint<strong>en</strong>ance work on non-electrical parts of themachinery can be performed without switching off the power supply to the drive.Update Notice

3Update Notice

4WARNING! The Safe torque off function does not disconnect the voltage of the mainand auxiliary circuits from the drive. Therefore maint<strong>en</strong>ance work on electrical partsof the drive or the motor can only be carried out after isolating the drive system fromthe main supply.Note: The Safe torque off function can be used for stopping the drive in emerg<strong>en</strong>cystop situations. In the normal operating mode, use the Stop command instead. If arunning drive is stopped by using the function, the drive will trip and stop by coasting.If this is not acceptable, e.g. causes danger, the drive and machinery must bestopped using the appropriate stopping mode before using this function.Note concerning perman<strong>en</strong>t magnet motor drives in case of a multiple IGBTpower semiconductor failure: In spite of the activation of the Safe torque offfunction, the drive system can produce an alignm<strong>en</strong>t torque which maximally rotatesthe motor shaft by 180/p degrees. p d<strong>en</strong>otes the pole pair number.Note: If you add or modify the wiring in the drive safety circuits, <strong>en</strong>sure that theappropriate standards (e.g. IEC 61800-5-1, EN 62061, EN/ISO 13849-1 and -2) andthe ABB guidelines are met. After making the changes, verify the operation of thesafety function by testing it.CHANGED (pages 67-68): Connecting the control cables / TerminalsFrame sizes R2 to R4:X41 - Terminal for optional Prev<strong>en</strong>tion of unexpected start (+Q950) or optional Safetorque off (+Q967)Frame sizes R5 and R6:X41 for Prev<strong>en</strong>tion of unexpected start (+Q950, AGPS board) or for Safe torque off(+Q967, ASTO board)NEW (page 77): Safe torque off (+Q967), ASTO boardWARNING! Dangerous voltages can be pres<strong>en</strong>t at the ASTO board ev<strong>en</strong> wh<strong>en</strong> the24 V supply is switched off. Follow the Safety instructions on the first pages of thismanual and the instruction in this chapter wh<strong>en</strong> working on the ASTO board.Make sure that the drive is disconnected from the mains (input power) and the24 V source for the ASTO board is switched off during installation andmaint<strong>en</strong>ance. If the drive is already connected to the mains, wait for 5 min afterdisconnecting mains power.Update Notice

5Connect the optional ASTO board as follows:• Remove the cover of the <strong>en</strong>closed ASTO unit by undoing the fixing screws (1).• Ground the ASTO unit via the bottom plate of the <strong>en</strong>closure or via terminal X1:1 ofthe ASTO board.• Connect the cable delivered with the kit betwe<strong>en</strong> terminal block X2 of the ASTOboard (2) and drive terminal block X41.• Connect a cable betwe<strong>en</strong> connector X1 of the ASTO board (3) and the 24 Vsource.• Fast<strong>en</strong> the cover of the ASTO unit back with screws.12X2X124 V3Note: Location of the X41 terminal block varies according to the drive frame size,see page 67.Note: Maximum cable l<strong>en</strong>gth betwe<strong>en</strong> ASTO terminal block X2 and drive terminalblock is restricted to 3 m.For technical data, see section ASTO-11C in chapter Technical data.Update Notice

6The diagram below shows the connection betwe<strong>en</strong> the ASTO board and the drivewh<strong>en</strong> it is ready. For an example diagram of a complete Safe torque off circuit, seepage 3 (in this Update Notice).3AUA0000069101NEW (page 84): Installation check-listThe following step has be<strong>en</strong> added to the ELECTRICAL INSTALLATION procedure:Modules with the Safe torque off option (+967) only (ASTO board): The Safe torque offcircuit is completed and the supply voltage for ASTO-11C board is 24 V.Update Notice

7NEW (page 109): ASTO-11CNominal input voltage 24 V DCNominal input curr<strong>en</strong>t 40 mA (20mA per channel)X1 terminal sizes 4 x 2.5 mm 2Nominal output curr<strong>en</strong>t 0.4 AX2 terminal block type JST B4P-VHAmbi<strong>en</strong>t temperature 0...50°CRelative humidity Max. 90%, no cond<strong>en</strong>sation allowedDim<strong>en</strong>sions (with 167 x 128 x 52 mm (Height x Weight x Depth)<strong>en</strong>closure)Weight (with <strong>en</strong>closure) 0.75 kgNEW (page 109): Ambi<strong>en</strong>t conditionsModules with option +Q967: the installation site altitude in operation is 0 to 2000 m.Operationinstalled for stationary useInstallation site altitude [...]Modules with option +Q967:0 to 2000 mCHANGED (page 117): Dim<strong>en</strong>sional drawings / What this chapter containsDim<strong>en</strong>sional drawings of the <strong>ACS800</strong>-<strong>04</strong>/<strong>U4</strong>, flange mounting kits, AGPS board andASTO board are shown below. The dim<strong>en</strong>sions are giv<strong>en</strong> in millimetres and [inches].NEW/CHANGED (page 129): Dim<strong>en</strong>sional drawings / AGPS and ASTOboardsThe dim<strong>en</strong>sions of the AGPS and ASTO boards are the same.Update Notice

8Update Notice

5Safety instructionsWhat this chapter containsThis chapter contains the safety instructions which you must follow wh<strong>en</strong> installing,operating and servicing the drive. If ignored, physical injury or death may follow, ordamage may occur to the drive, the motor or driv<strong>en</strong> equipm<strong>en</strong>t. Read the safetyinstructions before you work on the unit.Use of warnings and notesThere are two types of safety instructions throughout this manual: warnings andnotes. Warnings caution you about conditions which can result in serious injury ordeath and/or damage to the equipm<strong>en</strong>t. They also tell you how to avoid the danger.Notes draw att<strong>en</strong>tion to a particular condition or fact, or give information on asubject. The warning symbols are used as follows:Dangerous voltage warning warns of high voltage which can causephysical injury and/or damage to the equipm<strong>en</strong>t.G<strong>en</strong>eral warning warns about conditions, other than those caused byelectricity, which can result in physical injury and/or damage to theequipm<strong>en</strong>t.Electrostatic discharge warning warns of electrostatic discharge whichcan damage the equipm<strong>en</strong>t.Hot surface warning warns of hot surfaces which can cause physicalinjury.Safety instructions

6Installation and maint<strong>en</strong>ance workThese warnings are int<strong>en</strong>ded for all who work on the drive, motor cable or motor.WARNING! Ignoring the following instructions can cause physical injury or death, ordamage to the equipm<strong>en</strong>t:• Only qualified electricians are allowed to install and maintain the drive.• Never work on the drive, the motor cable or the motor wh<strong>en</strong> main power isapplied. After switching off the input power, always wait for 5 min to let theintermediate circuit capacitors discharge before you start working on the drive,the motor or the motor cable.Always <strong>en</strong>sure by measuring with a multimeter (impedance at least 1 Mohm)that:1. voltage betwe<strong>en</strong> drive input phases U1, V1 and W1 and the frame is close to0V2. voltage betwe<strong>en</strong> terminals UDC+ and UDC- and the frame is close to 0 V.• Do not work on the control cables wh<strong>en</strong> power is applied to the drive or to theexternal control circuits. Externally supplied control circuits may causedangerous voltages inside the drive ev<strong>en</strong> wh<strong>en</strong> the main power on the drive isswitched off.• Do not make any insulation or voltage withstand tests on the drive or drivemodules.• Wh<strong>en</strong> reconnecting the motor cable, always check that the phase order iscorrect.Note:• The motor cable terminals on the drive are at a dangerously high voltage wh<strong>en</strong>the input power is on, regardless of whether the motor is running or not.• The brake control terminals (UDC+, UDC-, R+ and R- terminals) carry adangerous DC voltage (over 500 V).• Dep<strong>en</strong>ding on the external wiring, dangerous voltages (115 V, 220 V or 230 V)may be pres<strong>en</strong>t on the terminals of relay outputs RO1 to RO3 or on the optionalAGPS board (Prev<strong>en</strong>tion of Unexpected Start).• The Prev<strong>en</strong>tion of Unexpected Start function does not remove the voltage fromthe main and auxiliary circuits.• At installation sites above 2000 m (6562 ft), the terminals of the RMIO boardand optional modules attached to the board do not fulfil the Protective ExtraLow Voltage (PELV) requirem<strong>en</strong>ts stated in EN 50178.Safety instructions

7GroundingThese instructions are int<strong>en</strong>ded for all who are responsible for the grounding of thedrive.WARNING! Ignoring the following instructions can cause physical injury, death,increased electromagnetic interfer<strong>en</strong>ce and equipm<strong>en</strong>t malfunction:• Ground the drive, motor and adjoining equipm<strong>en</strong>t to <strong>en</strong>sure personnel safety inall circumstances, and to reduce electromagnetic emission and interfer<strong>en</strong>ce.• Make sure that grounding conductors are adequately sized as required bysafety regulations.• In a multiple-drive installation, connect each drive separately to protectiveearth (PE).• In first <strong>en</strong>vironm<strong>en</strong>t (EU EMC Directive): make a 360° high frequ<strong>en</strong>cygrounding of the motor cable <strong>en</strong>try at the cabinet lead-through.• Do not install a drive with EMC filter option +E202 or +E200 on an ungroundedpower system or a high resistance-grounded (over 30 ohms) power system.Note:• Power cable shields are suitable for equipm<strong>en</strong>t grounding conductors onlywh<strong>en</strong> adequately sized to meet safety regulations.• As the normal leakage curr<strong>en</strong>t of the drive is higher than 3.5 mA AC or 10 mADC (stated by EN 50178, 5.2.11.1), a fixed protective earth connection isrequired.Safety instructions

8Mechanical installation and maint<strong>en</strong>anceThese instructions are int<strong>en</strong>ded for all who install and service the drive.WARNING! Ignoring the following instructions can cause physical injury or death,or damage to the equipm<strong>en</strong>t:• Handle the unit carefully.• The drive is heavy. Do not lift it alone. Place the unit only on its back.• Beware of hot surfaces. Some parts, such as heatsinks of powersemiconductors, remain hot for a while after disconnection of the electricalsupply.• Make sure that dust from borings and grindings does not <strong>en</strong>ter the drive wh<strong>en</strong>installing. Electrically conductive dust inside the unit may cause damage ormalfunctioning.• Ensure suffici<strong>en</strong>t cooling.• Do not fast<strong>en</strong> the drive by riveting or welding.Printed circuit boardsWARNING! Ignoring the following instructions can cause damage to the printedcircuit boards:• The printed circuit boards contain compon<strong>en</strong>ts s<strong>en</strong>sitive to electrostaticdischarge. Wear a grounding wrist band wh<strong>en</strong> handling the boards. Do nottouch the boards unnecessarily.Fibre optic cablesWARNING! Ignoring the following instructions can cause equipm<strong>en</strong>t malfunctionand damage to the fibre optic cables:• Handle the fibre optic cables with care. Wh<strong>en</strong> unplugging optic cables, alwaysgrab the connector, not the cable itself. Do not touch the <strong>en</strong>ds of the fibres withbare hands as the fibre is extremely s<strong>en</strong>sitive to dirt. The minimum allowedb<strong>en</strong>d radius is 35 mm (1.4 in.).Safety instructions

9OperationThese warnings are int<strong>en</strong>ded for all who plan the operation of the drive or operatethe drive.WARNING! Ignoring the following instructions can cause physical injury or death,or damage to the equipm<strong>en</strong>t:• Before adjusting the drive and putting it into service, make sure that the motorand all driv<strong>en</strong> equipm<strong>en</strong>t are suitable for operation throughout the speed rangeprovided by the drive. The drive can be adjusted to operate the motor atspeeds above and below the speed provided by connecting the motor directlyto the power line.• Do not activate automatic fault reset functions of the Control Program ifdangerous situations can occur. Wh<strong>en</strong> activated, these functions will reset thedrive and resume operation after a fault.• Do not control the motor with the disconnecting device (means); instead, usethe control panel keys and , or commands via the I/O board of the drive.The maximum allowed number of charging cycles of the DC capacitors (i.e.power-ups by applying power) is five in t<strong>en</strong> minutes.Note:• If an external source for start command is selected and it is ON, the drive (withStandard / Motion Control Program) will start immediately after fault resetunless the drive is configured for 3-wire (a pulse) start/stop.• Wh<strong>en</strong> the control location is not set to Local (L not shown in the status row ofthe display), the stop key on the control panel will not stop the drive. To stopthe drive using the control panel, press the LOC/REM key and th<strong>en</strong> the stopkey .Safety instructions

10Perman<strong>en</strong>t magnet motorThese are additional warnings concerning perman<strong>en</strong>t magnet motor drives. Ignoringthe instructions can cause physical injury or death, or damage to the equipm<strong>en</strong>t.Installation and maint<strong>en</strong>ance workWARNING! Do not work on the drive wh<strong>en</strong> the perman<strong>en</strong>t magnet motor is rotating.Also, wh<strong>en</strong> the supply power is switched off and the inverter is stopped, a rotatingperman<strong>en</strong>t magnet motor feeds power to the intermediate circuit of the drive and thesupply connections become live.Before installation and maint<strong>en</strong>ance work on the drive:• Stop the motor.• Ensure that the motor cannot rotate during work. Prev<strong>en</strong>t the start-up of anydrives in the same mechanical group by op<strong>en</strong>ing the “prev<strong>en</strong>tion of unexpectedstart” switch and padlocking it. Make sure that no other system, like hydrauliccrawling drives, are able to rotate the motor directly or through any mechanicalconnection like felt, nip, rope, etc.• Ensure that there is no voltage on the drive power terminals:Alternative 1) Disconnect the motor from the drive with a safety switch or by othermeans. Measure that there is no voltage pres<strong>en</strong>t on the drive input or outputterminals (U1, V1, W1, U2, V2, W2, UDC+, UDC-).Alternative 2) Measure that there is no voltage pres<strong>en</strong>t on the drive input or outputterminals (U1, V1, W1, U2, V2, W2, UDC+, UDC-). Ground the drive outputterminals temporarily by connecting them together as well as to the PE.Alternative 3) If possible, both of the above.Start-up and operationWARNING! Do not run the motor over the rated speed. Motor overspeed leads toovervoltage which may damage or explode the capacitors in the intermediate circuitof the drive.Controlling a perman<strong>en</strong>t magnet motor is only allowed using the <strong>ACS800</strong> Perman<strong>en</strong>tMagnet Synchronous Motor Drive Control Program, or other control programs inscalar control mode.Safety instructions

11Table of cont<strong>en</strong>ts<strong>ACS800</strong> Single Drive <strong>Manuals</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2Safety instructionsWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Use of warnings and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Installation and maint<strong>en</strong>ance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Mechanical installation and maint<strong>en</strong>ance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Printed circuit boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Fibre optic cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Perman<strong>en</strong>t magnet motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Installation and maint<strong>en</strong>ance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Start-up and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Table of cont<strong>en</strong>tsAbout this manualWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Int<strong>en</strong>ded audi<strong>en</strong>ce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Categorization according to the frame size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Categorization according to the + code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Cont<strong>en</strong>ts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Installation and commissioning flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21<strong>ACS800</strong>-<strong>04</strong>/<strong>U4</strong>What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23Type code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24Main circuit and control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26Printed circuit boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26Planning the cabinet assemblyTable of cont<strong>en</strong>ts

12What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27Cabinet construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27Disposition of the devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27Grounding of mounting structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27Free space around the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28Cooling and degrees of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29Prev<strong>en</strong>ting the recirculation of hot air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30Outside the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30Inside the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31Cabinet layout example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31Cabinet heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32Mounting the optional control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32Installing the control panel directly on the cabinet door . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32Control panel mounting platform kit (RPMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33EMC requirem<strong>en</strong>ts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33Mechanical installationUnpacking the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35Delivery check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36Requirem<strong>en</strong>ts for the installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37Flange mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38Planning the electrical installationWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41Motor selection and compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41Protecting the motor insulation and bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42Requirem<strong>en</strong>ts table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43Perman<strong>en</strong>t magnet synchronous motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46Supply connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46Disconnecting device (means) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46EEA / Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47US . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47Main contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47Thermal overload and short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47Thermal overload protection of the drive and the input and motor cables . . . . . . . . . . . . . . .47Thermal overload protection of the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48Protection against short-circuit in the motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48Protection against short-circuit inside the drive or in the supply cable . . . . . . . . . . . . . . . . . .48Ground fault protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49Emerg<strong>en</strong>cy stop devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49Prev<strong>en</strong>tion of Unexpected Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50Selecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51G<strong>en</strong>eral rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51Alternative power cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52Table of cont<strong>en</strong>ts

13Motor cable shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52Additional US requirem<strong>en</strong>ts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53Armored cable / shielded power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53Power factor comp<strong>en</strong>sation capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54Equipm<strong>en</strong>t connected to the motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54Installation of safety switches, contactors, connection boxes, etc. . . . . . . . . . . . . . . . . . . . . 54Bypass connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54Before op<strong>en</strong>ing a contactor (DTC control mode selected) . . . . . . . . . . . . . . . . . . . . . . . . . . . 55Protecting the relay output contacts and att<strong>en</strong>uating disturbances in case of inductive loads . . . . 55Selecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56Relay cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56Control panel cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56Connection of a motor temperature s<strong>en</strong>sor to the drive I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57Installation sites above 2000 metres (6562 feet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57Routing the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57Control cable ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58Electrical installationWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59Checking the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59Input cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59Motor and motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59IT (ungrounded) systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60Power cable connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61Connecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61Grounding the motor cable shield at the motor <strong>en</strong>d . . . . . . . . . . . . . . . . . . . . . . . . . . . 62Frame sizes R2 to R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63Frame size R5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63Frame size R6: Cable lug installation [16 to 70 mm2 (6 to 2/0 AWG) cables] . . . . . . . 64Power cable protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65Frame size R5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65Frame size R6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66Warning sticker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66Connecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67360 degrees grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69Wh<strong>en</strong> the outer surface of the shield is covered with non-conductive material . . . . . . 69Connecting the shield wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69Cabling of I/O and fieldbus modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70Pulse <strong>en</strong>coder module cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70Installation of optional modules and PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71Fibre optic link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71External +24 V power supply for the RMIO board via terminal X34 . . . . . . . . . . . . . . . . . . . . . . . . 71Parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71Connecting +24 V external power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71Prev<strong>en</strong>tion of Unexpected Start, AGPS board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74Table of cont<strong>en</strong>ts

14Motor control and I/O board (RMIO)What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77Note on terminal labelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77Note on external power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77Parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77External control connections (non-US) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78External control connections (US) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79RMIO board specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80Analogue inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80Constant voltage output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80Auxiliary power output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80Analogue outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80Relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81DDCS fibre optic link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8124 V DC power input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81Installation checklistChecklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83Maint<strong>en</strong>anceWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85Maint<strong>en</strong>ance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85Heatsink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86Fan replacem<strong>en</strong>t (R2, R3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86Fan replacem<strong>en</strong>t (R4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87Fan replacem<strong>en</strong>t (R5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88Fan replacem<strong>en</strong>t (R6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89Additional fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89Replacem<strong>en</strong>t (R2, R3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89Replacem<strong>en</strong>t (R4, R5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90Replacem<strong>en</strong>t (R6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90Reforming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90Technical dataWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91IEC data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94Temperature derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94Table of cont<strong>en</strong>ts

15Altitude derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94Cooling characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94Cooling requirem<strong>en</strong>ts for flange mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95Frame sizes R2 to R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95Frame sizes R5 and R6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96Calculation example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97gG fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98Ultrarapid (aR) fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99Quick guide for selecting betwe<strong>en</strong> gG and aR fuses . . . . . . . . . . . . . . . . . . . . . . . . . 100Cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101Cable <strong>en</strong>tries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102Dim<strong>en</strong>sions, weights and noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102NEMA data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1<strong>04</strong>Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1<strong>04</strong>Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1<strong>04</strong>Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105Cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106Cable <strong>en</strong>tries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107Dim<strong>en</strong>sions, weights and noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107Input power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107Motor connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108Effici<strong>en</strong>cy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108Degrees of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108AGPS-11C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109Ambi<strong>en</strong>t conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110Applicable standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111Compliance with the EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111Compliance with the EN 61800-3 (20<strong>04</strong>) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111First <strong>en</strong>vironm<strong>en</strong>t (drive of category C2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111Second <strong>en</strong>vironm<strong>en</strong>t (drive of category C3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112Second <strong>en</strong>vironm<strong>en</strong>t (drive of category C4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112Machinery Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112“C-tick” marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113Compliance with IEC 61800-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113First <strong>en</strong>vironm<strong>en</strong>t (drive of category C2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113Second <strong>en</strong>vironm<strong>en</strong>t (drive of category C3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114Second <strong>en</strong>vironm<strong>en</strong>t (drive of category C4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114Marine type approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114UL/CSA markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115UL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115Equipm<strong>en</strong>t warranty and liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115Product protection in the US . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116Table of cont<strong>en</strong>ts

16Dim<strong>en</strong>sional drawingsWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117Frame size R2 (with optional control panel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118Frame size R3 (with optional control panel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119Frame size R4 (with optional control panel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120Frame size R5 (with optional control panel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121Frame size R6 (with optional control panel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122Flange mounting kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123Flange mounting kit for frame size R2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124Flange mounting kit for frame size R3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125Flange mounting kit for frame size R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126Flange mounting kit for frame size R5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127Flange mounting kit for frame size R6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128AGPS board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129Resistor brakingWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131Availability of brake choppers and resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131How to select the correct drive/chopper/resistor combination . . . . . . . . . . . . . . . . . . . . . . . . . . . .131Optional brake chopper and resistor(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132Resistor installation and wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134Protection of frame sizes R2 to R5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135Protection of frame size R6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136Brake circuit commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136Table of cont<strong>en</strong>ts

17About this manualWhat this chapter containsCompatibilityInt<strong>en</strong>ded audi<strong>en</strong>ceThis chapter describes the int<strong>en</strong>ded audi<strong>en</strong>ce and cont<strong>en</strong>ts of this manual. Itcontains a flowchart of steps in checking the delivery, installing and commissioningthe drive. The flowchart refers to chapters/sections in this manual and othermanuals.The manual is compatible with <strong>ACS800</strong>-<strong>04</strong>/<strong>U4</strong> (frame sizes R2...R6).This manual is int<strong>en</strong>ded for people who plan the installation, install, commission, useand service the drive. Read the manual before working on the drive. The reader isexpected to know the fundam<strong>en</strong>tals of electricity, wiring, electrical compon<strong>en</strong>ts andelectrical schematic symbols.This manual is writt<strong>en</strong> for readers worldwide. Both SI and imperial units are shown.Special US instructions for installations within the United States that must beinstalled per the National Electrical Code and local codes are marked with (US).Categorization according to the frame sizeSome instructions, technical data and dim<strong>en</strong>sional drawings which concern onlycertain frame sizes are marked with the symbol of the frame size R2, R3... or R6.The frame size is not marked on the drive designation label. To id<strong>en</strong>tify the framesize of your drive, see the rating tables in chapter Technical data.Categorization according to the + codeThe instructions, technical data and dim<strong>en</strong>sional drawings which concern onlycertain optional selections are marked with + codes, e.g. +E202. The optionsincluded in the drive can be id<strong>en</strong>tified from the + codes visible on the typedesignation label of the drive. The + code selections are listed in chapter <strong>ACS800</strong>-<strong>04</strong>/<strong>U4</strong> in section Type code.About this manual

18Cont<strong>en</strong>tsThe chapters of this manual are briefly described below.Safety instructions give safety instructions for the installation, commissioning,operation and maint<strong>en</strong>ance of the drive.About this manual lists the steps in checking the delivery and installing andcommissioning the drive and refers to chapters/sections in this manual and othermanuals for particular tasks.<strong>ACS800</strong>-<strong>04</strong>/<strong>U4</strong> describes the drive.Planning the cabinet assembly guides in planning the installation of a drive moduleinto a user-defined cabinet.Mechanical installation instructs how to place and mount the drive.Planning the electrical installation instructs on the motor and cable selection, theprotections and the cable routing.Electrical installation shows how to wire the drive.Motor control and I/O board (RMIO) shows the external control connections to theI/O board.Installation checklist contains a list for checking the mechanical and electricalinstallation of the drive.Maint<strong>en</strong>ance contains prev<strong>en</strong>tive maint<strong>en</strong>ance instructions.Technical data contains the technical specifications of the drive, e.g. the ratings,sizes and technical requirem<strong>en</strong>ts, provisions for fulfilling the requirem<strong>en</strong>ts for CEand other markings and warranty policy.Dim<strong>en</strong>sional drawings contains the dim<strong>en</strong>sional drawings of the drive.Resistor braking describes how to select, protect and wire brake choppers andresistors. The chapter also contains the technical data.About this manual

19Installation and commissioning flowchartTaskId<strong>en</strong>tify the frame size of your drive: R2, R3, R4, R5or R6.SeeTechnical data: IEC data or NEMA dataPlan the installation.Check the ambi<strong>en</strong>t conditions, ratings, requiredcooling air flow, input power connection, compatibilityof the motor, motor connection, and other technicaldata.Select the cables.Technical dataPlanning the electrical installationOption manual (if optional equipm<strong>en</strong>t isincluded)Unpack and check the units.Check that all necessary optional modules andequipm<strong>en</strong>t are pres<strong>en</strong>t and correct.Only intact units may be started up.Mechanical installation: Unpacking the unitIf the converter has be<strong>en</strong> non-operational formore than one year, the converter DC linkcapacitors need to be reformed. Ask ABB forinstructions.Check the installation site.Mechanical installation: Before installationTechnical dataIf the drive is about to be connected to an IT(ungrounded) system, check that the drive is notequipped with EMC filtering.<strong>ACS800</strong>-<strong>04</strong>/<strong>U4</strong>: Type codeFor instructions on how to disconnect the EMCfiltering, contact ABB.Install the drive in a cabinet.Mechanical installationRoute the cables.Planning the electrical installation: Routing thecablesCheck the insulation of the motor and the motorcable.Electrical installation: Checking the insulation ofthe assemblyAbout this manual

20TaskConnect the power cables.Connect the control and the auxiliary control cables.SeeElectrical installation, Motor control and I/Oboard (RMIO), Resistor braking (optional) andthe optional module manual delivered with themodule.Check the installation.Installation checklistCommission the drive.Appropriate Firmware ManualCommission the optional brake chopper (if pres<strong>en</strong>t).Resistor brakingOperating of the drive: start, stop, speed control etc.Appropriate Firmware ManualProduct and service inquiriesProduct trainingAddress any inquiries about the product to your local ABB repres<strong>en</strong>tative, quotingthe type code and serial number of the unit in question. A listing of ABB sales,support and service contacts can be found by navigating to www.abb.com/drives andselecting Drives – Sales, Support and Service network on the right pane.For information on ABB product training, navigate to www.abb.com/drives and selectDrives – Training courses on the right pane.Providing feedback on ABB Drives manualsYour comm<strong>en</strong>ts on our manuals are welcome. Go to www.abb.com/drives, th<strong>en</strong>select successively Drives – Docum<strong>en</strong>t Library – <strong>Manuals</strong> feedback form on the rightpane.About this manual

21Terms and abbreviationsTerm/AbbreviationCDP312RDDCSEMCFrame (size)IGBTI/OAGPSRDCORDIORFIRINTRMIORPMPExplanationDrive control panelDistributed Drives Communication System; a protocol used in optical fibrecommunication inside and betwe<strong>en</strong> ABB drives.Electromagnetic CompatibilitySize of the frame into which the drive module is assembled. Severalsupply modules with differ<strong>en</strong>t nominal powers may have the same framesize. The term refers to modules that have a similar mechanicalconstruction.To determine the frame size of a drive module, refer to the rating tables inchapter Technical data.Insulated Gate Bipolar Transistor; a voltage-controlled semiconductor typewidely used in inverters due to their easy controllability and high switchingfrequ<strong>en</strong>cy.Input/OutputGate driver Power Supply board. An optional board used to implem<strong>en</strong>t thePrev<strong>en</strong>tion of Unexpected Start function.DDCS communication option moduleDigital I/O Ext<strong>en</strong>sion ModuleRadio-frequ<strong>en</strong>cy interfer<strong>en</strong>ceMain circuit boardMotor control and I/O board. The external I/O control signals areconnected to RMIO.Control panel mounting platform kitAbout this manual

22About this manual

23<strong>ACS800</strong>-<strong>04</strong>/<strong>U4</strong>What this chapter containsThis chapter describes the operating principle and construction of the drive in short.LayoutThe <strong>ACS800</strong>-<strong>04</strong>/<strong>U4</strong> (frame sizes R2 to R6) is an IP20 drive module for controllingAC motors. It is to be installed into a cabinet by the customer with wall fast<strong>en</strong>ing.Control panel CDP312R(optional)Frame size R2Option slotsPower cableterminalPEHeatsinkLocation of the compon<strong>en</strong>ts vary dep<strong>en</strong>ding on the frame size.<strong>ACS800</strong>-<strong>04</strong>/<strong>U4</strong>

24Type codeThe type code contains information on the specifications and configuration of thedrive. The first digits from left express the basic configuration (e.g. <strong>ACS800</strong>-<strong>04</strong>-0016-3). The optional selections are giv<strong>en</strong> thereafter, separated by + signs (e.g.+E202). The main selections are described below. Not all selections are available forall types. For more information, refer to <strong>ACS800</strong> Ordering Information[3AFE64556568 (English)], available on request.SelectionAlternativesProduct series<strong>ACS800</strong> product seriesType <strong>04</strong> Drive module. Wh<strong>en</strong> no options are selected: IP20, no control panel, noEMC filter, Standard Control Program, brake chopper in frame sizes R2,R3, and R4 (only 690 V), boards without coating, one set of manuals.<strong>U4</strong> Drive module (USA). Wh<strong>en</strong> no options are selected: UL op<strong>en</strong> type, nocontrol panel, no EMC filter, Standard Control Program, brake chopper inframe sizes R2, R3, and R4 (only 690 V), boards without coating, one setof manuals.SizeSee Technical data: IEC data or NEMA data.Voltage range(nominal rating in bold)2 208/220/230/240 V AC3 380/400/415 V AC5 380/400/415/440/460/480/500 V AC7 525/575/600/690 V AC+ optionsControl panel J400 Control panel CDP312R assembled on the drive moduleJ414 Control panel holder for frame sizes R2, R3 and R4 (not to be used withoption J400)Construction C132 Marine drive (coated boards included)C135 Flange mounting. Flange mounting plate assembled. IP55 for heat sinkside and IP20 for drive front side.Filter E200 EMC/RFI filter for second <strong>en</strong>vironm<strong>en</strong>t TN (grounded) system, drivecategory C3E202 EMC/RFI filter for first <strong>en</strong>vironm<strong>en</strong>t TN (grounded) system, drive categoryC2. (Not available for 690 V units.)E210 EMC/RFI filter for second <strong>en</strong>vironm<strong>en</strong>t TN/IT (grounded/ungrounded)system, drive category C3 (frame size R6 only)Resistor braking D150 Brake chopper. Included as standard in frame sizes R2, R3 and R4 (only690 V).Safety Q950 Prev<strong>en</strong>tion of Unexpected Start: AGPS board and 3 m connection wire.Fieldbus K... Refer to <strong>ACS800</strong> Ordering Information [3AFE64556568 (English)].I/OL...Control program N...Manual language R...Specialities P901 Coated boardsP9<strong>04</strong> Ext<strong>en</strong>ded warranty<strong>ACS800</strong>-<strong>04</strong>/<strong>U4</strong>

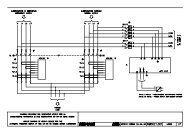

25Main circuit and controlDiagramThis diagram shows the control interfaces and the main circuit of the drive. Locationof terminals vary dep<strong>en</strong>ding on the drive frame size.DriveExternal control viaanalogue/digitalinputs and outputsPrev<strong>en</strong>tion of UnexpectedStart (AGPS board)X41Motorcontrol andI/O board(RMIO)Slot1Slot2X33Optional module 1: RMBA, RAIO, RDIO,RDNA, RLON, RIBA, RPBA, RCAN, RCNA,RMBP, RETA, RRIA or RTACOptional module 2: RTAC, RAIO, RRIA orRDIODDCS communication option module 3:RDCO-01, RDCO-02 or RDCO-03The fibre optic channels provided by theRDCO module can be used for fieldbusconnection (Nxxx fieldbus adapter modules),PC connection (DriveWare® PC tools) orAdvant Fieldbus 100 connection (e.g.AC 800M, AC80)Input power~ = ~ =Output powerBrake chopper in frame sizes R2, R3 and690 V frame R4 (optional in other framesizes).R- UDC+ UDC-R+<strong>ACS800</strong>-<strong>04</strong>/<strong>U4</strong>

26OperationThis table describes the operation of the main circuit in short.Compon<strong>en</strong>tSix-pulse rectifierCapacitor bankIGBT inverterDescriptionConverts the three-phase AC voltage to DC voltage.Energy storage which stabilizes the intermediate circuit DC voltage.Converts the DC voltage to AC voltage and vice versa. The motoroperation is controlled by switching the IGBTs.Printed circuit boardsThe drive contains the following printed circuit boards as standard:• main circuit board (RINT)• motor control and I/O board (RMIO)• EMC filter board (RRFC) wh<strong>en</strong> EMC equipm<strong>en</strong>t is selected or varistor board(RVAR) otherwise.Motor controlThe motor control is based on the Direct Torque Control (DTC) method. Two phasecurr<strong>en</strong>ts and DC link voltage are measured and used for the control. The third phasecurr<strong>en</strong>t is measured for earth fault protection.<strong>ACS800</strong>-<strong>04</strong>/<strong>U4</strong>

27Planning the cabinet assemblyWhat this chapter containsThis chapter guides in planning the installation of a drive module into a user-definedcabinet. The issues discussed are ess<strong>en</strong>tial for safe and trouble-free use of the drivesystem.Note: The installation examples in this manual are provided only to help the installerin designing the installation. The installation must always be designed and madeaccording to applicable local laws and regulations. ABB does not assume anyliability whatsoever for any installation which breaches the local laws and/or otherregulations.Cabinet constructionThe cabinet frame must be sturdy <strong>en</strong>ough to carry the weight of the drivecompon<strong>en</strong>ts, control circuitry and other equipm<strong>en</strong>t installed in it.The cabinet must protect the drive module against contact and meet therequirem<strong>en</strong>ts for dust and humidity (see chapter Technical data).Disposition of the devicesFor easy installation and maint<strong>en</strong>ance, a spacious layout is recomm<strong>en</strong>ded. Suffici<strong>en</strong>tcooling air flow, obligatory clearances, cables and cable support structures allrequire space.For layout examples, see section Cabinet layout example.Grounding of mounting structuresMake sure all cross-members or shelves on which compon<strong>en</strong>ts are mounted areproperly grounded and the connecting surfaces left unpainted.Note: Ensure that the modules are properly grounded through their fast<strong>en</strong>ing pointsto the installation base.Planning the cabinet assembly

28Free space around the unitThe modules can be installed side by side. Recomm<strong>en</strong>ded free space above andbelow the drive to <strong>en</strong>able cooling air flow, service and maint<strong>en</strong>ance is shown belowin millimetres and [inches].The temperature of the cooling air <strong>en</strong>tering the unit must not exceed the maximumallowed ambi<strong>en</strong>t temperature. See section Ambi<strong>en</strong>t conditions in chapter Technicaldata.200 [7.9]300 [12]IP20 (UL op<strong>en</strong> type)Planning the cabinet assembly

29Cooling and degrees of protectionThe cabinet must have <strong>en</strong>ough free space for the compon<strong>en</strong>ts to <strong>en</strong>sure suffici<strong>en</strong>tcooling. Observe the minimum clearances giv<strong>en</strong> for each compon<strong>en</strong>t.The air inlets and outlets must be equipped with gratings that• guide the air flow• protect against contact• prev<strong>en</strong>t water splashes from <strong>en</strong>tering the cabinet.The drawing below shows two typical cabinet cooling solutions. The air inlet is at thebottom of the cabinet, while the outlet is at the top, either on the upper part of thedoor or on the roof.Air outletAir inletArrange the cooling air flow through the modules so that the requirem<strong>en</strong>ts giv<strong>en</strong> inchapter Technical data are met:• cooling air flowNote: The values in Technical data apply to continuous nominal load. If the load is cyclic or lessthan nominal, less cooling air is required.• allowed ambi<strong>en</strong>t temperature• the air inlet and outlet sizes required for the module cooling and recomm<strong>en</strong>dedfilter material (if used).In addition to the above, the heat dissipated by cables and other additionalequipm<strong>en</strong>t must also be v<strong>en</strong>tilated.The internal cooling fans of the modules are usually suffici<strong>en</strong>t to keep the compon<strong>en</strong>ttemperatures low <strong>en</strong>ough in IP22 (UL type 1) cabinets.Planning the cabinet assembly

30In IP54 (UL type 12) cabinets, thick filter mats are used to prev<strong>en</strong>t water splashesfrom <strong>en</strong>tering the cabinet. This <strong>en</strong>tails the installation of additional coolingequipm<strong>en</strong>t, such as a hot air exhaust fan.The installation site must be suffici<strong>en</strong>tly v<strong>en</strong>tilated.Prev<strong>en</strong>ting the recirculation of hot airNormal vertical mountingFlange mountingCabinet (side view)HOTAREAMain air flow outMainairflowoutHOT AREACabinet (side view)Air flow outAir baffleplatesAir baffleplateCOOL AREACOOL AREAMain air flow inMainairflowinAir flow inOutside the cabinetPrev<strong>en</strong>t hot air circulation outside the cabinet by leading the outcoming hot air awayfrom the area where the inlet air to the cabinet is tak<strong>en</strong>. Possible solutions are listedbelow:• gratings that guide air flow at the air inlet and outlet• air inlet and outlet at differ<strong>en</strong>t sides of the cabinet• cool air inlet in the lower part of the front door and an extra exhaust fan on theroof of the cabinet.Planning the cabinet assembly

31Inside the cabinetPrev<strong>en</strong>t hot air circulation inside the cabinet with leak-proof air baffle plates. Nogaskets are usually required.Wh<strong>en</strong> several modules are installed vertically in one cabinet, the hot air from onemodule must not be allowed to <strong>en</strong>ter another module. In a cabinet with multiplemodules, a practical way of achieving this is to install a mounting plate to separatethe cool area (at the front part of the cabinet) from the hot area (back part). Themounting plate can be fast<strong>en</strong>ed to two vertical pillars on both left and right. Since theair outlet at the top of the modules points directly upwards, the air must be guided tothe hot area. See cabinet layout examples below.Cabinet layout exampleVertical mountingAC switch fuseAC fuse basesAC fusesAirflow guidesdu/dt filterHot areaCool areaModulesMountingplatesMotor cable <strong>en</strong>triesFront view of three R2modules in cabinetSide view of three R3modules in cabinetPlanning the cabinet assembly

32Cabinet heatersUse a cabinet heater if there is a risk of cond<strong>en</strong>sation in the cabinet. Although theprimary function of the heater is to keep the air dry, it may also be required forheating at low temperatures. Wh<strong>en</strong> placing the heater, follow the instructionsprovided by its manufacturer.Mounting the optional control panelThe optional control panel CDP312R is factory assembled on the drive module.Thepanel can also be fast<strong>en</strong>ed directly to the cabinet door or to a mounting platform.Installing the control panel directly on the cabinet doorFast<strong>en</strong> the control panel from the back side with two screws of one of the followingtypes:• standard screw with nominal diameter of 4 mm (0.16 in.)• tapping screw with nominal diameter of 4.2 mm (0.17 in.) DIN 7981 C, DIN 7982C, DIN 7983 C or DIN 7976 C• PT screw for thermoplastics with nominal diameter of 4 mm (0.16 in.).View from outside the cabinet doorCabinet door4...8 mm(0.16...0.31 in.)Control panelTight<strong>en</strong>ing torque:1 Nm (0.74 lbf ft)10 mm (0.39 in.)Control panel footprintPlanning the cabinet assembly

33Control panel mounting platform kit (RPMP)For installation of the mounting platform, see Control Panel Mounting Platform Kit(RPMP) Installation Guide [3AFE64677560 (English)].EMC requirem<strong>en</strong>tsG<strong>en</strong>erally, the fewer and smaller the holes in the cabinet, the better the interfer<strong>en</strong>ceatt<strong>en</strong>uation. The maximum recomm<strong>en</strong>ded diameter of a hole in galvanic metalcontact in the covering cabinet structure is 100 mm. Special att<strong>en</strong>tion must be paidto the cooling air inlet and outlet gratings.The best galvanic connection betwe<strong>en</strong> the steel panels is achieved by welding themtogether as no holes are necessary. If welding is not possible, the seams betwe<strong>en</strong>the panels are recomm<strong>en</strong>ded to be left unpainted and equipped with specialconductive EMC strips to provide adequate galvanic connection. Usually, reliablestrips are made of flexible silicon mass covered with a metal mesh. The nontight<strong>en</strong>edtouch-contact of the metal surfaces is not suffici<strong>en</strong>t, so a conductivegasket betwe<strong>en</strong> the surfaces is required. The maximum recomm<strong>en</strong>ded distancebetwe<strong>en</strong> assembly screws is 100 mm.Suffici<strong>en</strong>t high-frequ<strong>en</strong>cy grounding network must be constructed in the cabinet toavoid voltage differ<strong>en</strong>ces and forming of high-impedance radiator structures. A goodhigh-frequ<strong>en</strong>cy grounding is made with short flat copper braids for low inductance.One-point high-frequ<strong>en</strong>cy grounding cannot be used due to the long distances insidethe cabinet.First <strong>en</strong>vironm<strong>en</strong>t EMC compliance *) of the drive requires 360° high frequ<strong>en</strong>cygrounding of the motor cable shields at their <strong>en</strong>tries. The grounding can beimplem<strong>en</strong>ted by a knitted wire mesh scre<strong>en</strong>ing as shown below.Cable tiesBare cable shieldKnitted wire meshLead-through plateCableCabinet bottom plate*) First <strong>en</strong>vironm<strong>en</strong>t EMC compliance is defined in section CE marking in chapter Technical data.Planning the cabinet assembly

34360° high frequ<strong>en</strong>cy grounding of the control cable shields is recomm<strong>en</strong>ded at their<strong>en</strong>tries. The shields can be grounded by means of conductive shielding cushionspressed against the cable shield from both directions:Bare cable shieldShielding cushion(conductive)Cabinet bottom plateCable grommetCablePlanning the cabinet assembly

35Mechanical installationUnpacking the unitThe drive is delivered in a box that also contains:• plastic bag containing: screws (M3), clamps and cable lugs (2 mm 2 , M3) forgrounding the control cable scre<strong>en</strong>s• residual voltage warning stickers• hardware, firmware and other module manuals• delivery docum<strong>en</strong>ts.Unpack the unit of frame sizes R2 to R5 as follows.TearMechanical installation

36Delivery checkCheck that there are no signs of damage. Before attempting installation andoperation, check the information on the type designation label of the drive to verifythat the unit is of the correct type. The label includes IEC rating, C-UL US, CSA,C-tick and CE markings, a type code and a serial number, which allow individualrecognition of each unit. The first digit of the serial number refers to themanufacturing plant. The next four digits refer to the unit’s manufacturing year andweek, respectively. The remaining digits complete the serial number so that thereare no two units with the same serial number.The type designation label is attached to the heat sink and the serial number label tothe upper part of the back plate of the unit.Type designation labelSerial number labelBefore installationCheck the installation site according to the requirem<strong>en</strong>ts below. See Dim<strong>en</strong>sionaldrawings for frame details.Requirem<strong>en</strong>ts for the installation siteSee Technical data for the allowed operation conditions of the drive.FloorThe floor/material below the cabinet should be non-flammable.Mechanical installation

37Installation procedure1. Mark the locations for the four holes. The mounting points are shown inDim<strong>en</strong>sional drawings. With frame sizes R2...R5, use the mounting template cutfrom the package.2. Fix the screws or bolts to the marked locations.3. Position the drive onto the screws on the cabinet wall. Note: Lift the drive by itschassis (R6: by its lifting holes).4. Tight<strong>en</strong> the screws in the cabinet wall securely.1Mechanical installation

38Flange mountingThe flange mounting plate is factory assembled on the drive. With flange mounting,the degree of protection is IP55 for the heat sink side and IP20 for the drive frontside. The drive front side must always be housed in a cabinet.R6 with flange mounting plateConnect a drive with flange mounting plate as follows:1. Make the appropriate mounting and screw holes for the drive into the mountingplate. The sizes and locations of the holes vary according to the frame size. Seechapter Dim<strong>en</strong>sional drawings. Screw holes can be replaced with rivet nuts.Recomm<strong>en</strong>ded type is closed M6 rivet nut, L = 23 mm, code 23351060030 /Rivkle provided by Böllhoff (www.boellhoff.de).2. Lift the drive by its lifting lugs and place it into the mounting hole.3. Fix the washers and screws (M6) delivered with the drive (MRP code 6839<strong>04</strong>19).The tight<strong>en</strong>ing torque is 2 Nm.Note: The flange mounting kit does not ground the drive. The drive needs to begrounded according to instructions giv<strong>en</strong> in chapter Electrical installation.Note: Maximum allowed vibration for the drive has not be<strong>en</strong> tested with flangemounting. If the drive is exposed to vibration, it is recomm<strong>en</strong>ded to fix the drive alsofrom the normal mounting holes located on the heat sink. See section Installationprocedure.Mechanical installation

39R6 flange mounting12Lifting lugMounting plate3WasherScrewMechanical installation

40Mechanical installation

41Planning the electrical installationWhat this chapter containsThis chapter contains the instructions that you must follow wh<strong>en</strong> selecting the motor,cables, protections, cable routing and way of operation for the drive system.Note: The installation must always be designed and made according to applicablelocal laws and regulations. ABB does not assume any liability whatsoever for anyinstallation which breaches the local laws and/or other regulations. Furthermore, ifthe recomm<strong>en</strong>dations giv<strong>en</strong> by ABB are not followed, the drive may experi<strong>en</strong>ceproblems that the warranty does not cover.Motor selection and compatibility1. Select the motor according to the rating tables in chapter Technical data. Use theDriveSize PC tool if the default load cycles are not applicable.2. Check that the motor ratings lie within the allowed ranges of the drive controlprogram:• motor nominal voltage is 1/2 ... 2 · U N of the drive• motor nominal curr<strong>en</strong>t is 1/6 ... 2 · I 2hd of the drive in DTC control and0 ... 2 · I 2hd in scalar control. The control mode is selected by a drive parameter.3. Check that the motor voltage rating meets the application requirem<strong>en</strong>ts:• If no resistor braking is in use, the motor voltage rating is U N .U N = rated input voltage of the drive• If frequ<strong>en</strong>t or long term brake cycles will be used, the motor voltage rating isU ACeq .U ACeq = U DC /1.35whereU ACeq is the equival<strong>en</strong>t AC power source voltage of the drive in V AC.U DC is the maximum DC link voltage of the drive in V DC.For resistor braking: U DC = 1.2 × 1.35 × U N .See note 6 below the Requirem<strong>en</strong>ts table.4. Consult the motor manufacturer before using a motor in a drive system where themotor nominal voltage differs from the AC power source voltage.Planning the electrical installation