E - VAE ProSys sro

E - VAE ProSys sro

E - VAE ProSys sro

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

RegulationsConcerning the Setting up of InstallationsApart from the basic "Regulations for the Setting upof Power Installations" DIN VDE* 0100 and for "TheRating of Creepage Distances and Clearances" DINVDE 0110 Part 1 and Part 2 the regulations "TheEquipment of Power Installations with ElectricalComponents" DIN VDE 0160 in conjunction with DINVDE 0660 Part 500 have to be taken into dueconsideration.Further attention has to be paid to DIN VDE 0113Part 1 and Part 200 in case of the control of workingand processing machines. If operating elements areto be mounted near parts with dangerous contactvoltage DIN VDE 0106 Part 100 is additionallyrelevant.If the protection against direct contact according toDIN VDE 0160 is required, this has to be ensured bythe user (e.g. by incorporating the elements in aswitch-gear cabinet). The devices are designed forpollution severity 2 in accordance with DIN VDE 0110Part 1. If higher pollution is expected, the devicesmust be installed in appropriate housings.The user has to guarantee that the devices and thecomponents belonging to them are mountedfollowing these regulations. For operating themachines and installations, other national andinternational relevant regulations, concerningprevention of accidents and using technical workingmeans, also have to be met.The ABB Procontic devices are designed accordingto IEC 1131 Part 2. Meeting this regulation, they areclassified in overvoltage category II which is inconformance with DIN VDE 0110 Part 2.For the direct connection of ABB Procontic devices,which are powered with or coupled to AC linevoltages of overvoltage category III, appropriateprotection measures corresponding to overvoltagecategory II according to IEC-Report 664/1980 andDIN VDE 0110 Part 1 are to install.Equivalent standards:DIN VDE 0110 Part 1 ⇔ IEC 664DIN VDE 0113 Part 1 ⇔ EN 60204 Part 1DIN VDE 0660 Part 500 ⇔ EN 60439-1 ⇔IEC 439-1E2Process display and control/ Device Manual/ Issue: 07.01

Contents1 Product Overview..........................................................................................81.1 Product range ................................................................................................................................81.2 Overview machine terminals with text display ...............................................................................91.3 Overview machine terminals with graphics display......................................................................101.4 Software concept of text terminals...............................................................................................111.4.1 Conveying, Moving, Positioning ............................................................................................111.4.2 Displaying, parameterizing, dosing, regulating......................................................................111.4.3 Monitoring and control...........................................................................................................111.4.4 Recording ..............................................................................................................................121.4.5 Printing ..................................................................................................................................121.4.6 Menu structure ......................................................................................................................121.4.7 Languages.............................................................................................................................131.5 Software concept of graphic terminals.........................................................................................141.6 Accessories .................................................................................................................................151.6.1 Programming leads ...............................................................................................................151.6.2 Connection leads to automation devices...............................................................................151.6.3 Function modules, additional libraries ...................................................................................151.6.4 Barcode reader units .............................................................................................................152 Communication ...........................................................................................172.1 Protocol Driver CS31 ...................................................................................................................172.2 Protocol Driver T200 - HI-Protocol...............................................................................................172.3 Protocol Driver Modbus RTU .......................................................................................................172.3.1 Modbus RTU Master .............................................................................................................172.3.2 Modbus RTU Slave ...............................................................................................................172.3.3 Format for Modbus RTU........................................................................................................182.4 Protocol Driver ARCNET .............................................................................................................192.4.1 Terminal interfacing via ARCNET .........................................................................................193 Mounting Instructions and Installation .....................................................203.1 Guidelines for Engineering / Installation ......................................................................................203.2 Interference suppression / installation guidelines ........................................................................213.2.1 Shielding cables / leads.........................................................................................................223.3 Instructions for Mounting and Installation ....................................................................................243.3.1 Mounting Diagram MT-60......................................................................................................263.3.2 Mounting Diagram MT-40......................................................................................................273.3.3 Mounting Diagram MT-91......................................................................................................283.3.4 Mounting Diagram MT-121....................................................................................................28Process display and control/ Device Manual/ Issue: 07.013E

3.4 Overview of connection assignments...........................................................................................293.5 Fieldbus interface of variant MT-91/ MT-121 ARCNET ...............................................................333.5.1 Cable type .............................................................................................................................333.5.2 Fieldbus plug .........................................................................................................................333.5.3 Connection ............................................................................................................................333.5.4 Cable length and number of participants...............................................................................353.5.5 Technical data of the ARCNET interface card.......................................................................363.6 Printer connection ........................................................................................................................373.7 Connecting a barcode reader.......................................................................................................373.7.1 PIN assignment for barcode interface (socket X6) ................................................................383.7.2 Data transfer to the PLC........................................................................................................383.8 Operation of alarm relay...............................................................................................................383.9 DIL switches S1 ...........................................................................................................................394 Installation on the PLC................................................................................404.1 Installation on AC31 active COM1 ...............................................................................................404.2 Installation on the T200................................................................................................................424.3 Connection to 07KP93 - AC31 with Modbus-RTU .......................................................................454.3.1 Modbus RTU Master .............................................................................................................454.3.2 Modbus RTU Slave ...............................................................................................................464.3.3 Installation overview ..............................................................................................................464.3.4 Connection via V.24 on X2 ....................................................................................................474.3.5 Connection via V.24 on X4 ....................................................................................................474.3.6 Connection via RS-485 on X2 ...............................................................................................484.3.7 Connection via RS-485 on X4 ...............................................................................................484.3.8 Connection via RS-422 on X2 ...............................................................................................494.3.9 Connection via RS-422 on X4 ...............................................................................................504.4 Connection to AC 31 with Modbus-RTU ......................................................................................514.4.1 Installation on X2 ...................................................................................................................514.4.2 Installation on X4 ...................................................................................................................524.5 Connection to AC 41/ AC 51 with Modbus RTU ..........................................................................534.5.1 Installation on X4 ...................................................................................................................534.5.2 Installation on X4 ...................................................................................................................534.6 Connection 07MK62 - T200 with Modbus-RTU ...........................................................................544.6.1 Connection via V.24 on X2 ....................................................................................................544.6.2 Connection via V.24 on X4 ....................................................................................................544.7 Connection to KR / KT31 with Modbus-RTU................................................................................554.7.1 Connection V.24 on X2..........................................................................................................554.7.2 Connection V.24 on ...............................................................................................................554.8 Installation on ABB AC 31 via ARCNET ......................................................................................564.8.1 Setting the Node-ID/ station address.....................................................................................564.9 Optical indication, LED token .......................................................................................................564.9.1 Block 5F_ARC resp. 5F_ARC94 ...........................................................................................57E4Process display and control/ Device Manual/ Issue: 07.01

4.9.2 Structure of the ARCNET telegram .......................................................................................574.9.3 Program example for interfacing a terminal to an ABB PLC .................................................585 Setting up.....................................................................................................615.1 Brief initiation ...............................................................................................................................615.1.1 PC Program...........................................................................................................................615.1.2 MT .........................................................................................................................................615.1.3 Control system ......................................................................................................................625.1.4 System Connection ...............................................................................................................625.1.5 System test............................................................................................................................625.1.6 Extensions.............................................................................................................................625.2 Starting-up and self test of text terminals.....................................................................................645.3 Error messages after the start .....................................................................................................645.4 Configuration during operation of text terminals ..........................................................................655.4.1 Country code .........................................................................................................................655.4.2 Passwort................................................................................................................................655.4.3 Setting the clock ....................................................................................................................665.4.4 Programming.........................................................................................................................665.4.5 Brightness control of the display ...........................................................................................675.4.6 Printer configuration ..............................................................................................................675.4.7 Configuration of the serial interface.......................................................................................685.4.8 Relay control .........................................................................................................................695.4.9 Driver specific settings ..........................................................................................................695.4.10 Text offset (language offset)..................................................................................................705.4.11 Save configuration (only for devices with flash EPROM) ......................................................705.5 Starting-up and self test of graphic terminals...............................................................................715.5.1 Messages during startup phase 1 (boot program) ................................................................715.5.2 Messages during starting phase 2 (driver start) ....................................................................725.5.3 Basic Mask ............................................................................................................................735.5.4 Error messages from protocol driver .....................................................................................735.6 Configuration during operation - graphic terminals......................................................................745.6.1 General..................................................................................................................................745.6.2 General settings ....................................................................................................................755.6.3 Protocol specific settings.......................................................................................................835.6.4 Test menu .............................................................................................................................835.7 Startup keys of graphic terminals.................................................................................................896 Function description of PLC-Mode............................................................906.1 General ........................................................................................................................................906.1.1 Address declaration for CS31 ...............................................................................................916.1.2 Address declaration for T200 in PLCPlus-G .........................................................................936.1.3 Address declaration for Modbus............................................................................................95Process display and control/ Device Manual/ Issue: 07.015E

6.1.4 Address declaration Modbus-Master in PLCPlus-G ..............................................................976.1.5 Address declaration Modbus-Master in SPSPlus WIN..........................................................996.2 Description of Functions / Overview...........................................................................................1016.2.1 Shifting, Moving, Positioning ...............................................................................................1016.2.2 Display Functions ................................................................................................................1026.3 Reference Section - Functions...................................................................................................1046.3.1 Key functions .......................................................................................................................1046.4 Control words (LED's) ................................................................................................................1066.4.1 LED’s ...................................................................................................................................1096.4.2 Static control word ...............................................................................................................1106.4.3 Dynamic control word ..........................................................................................................1116.5 Text registers .............................................................................................................................1126.6 Number of fault words (only graphic terminals)..........................................................................1146.7 Acknowledgement (only graphic terminals) ...............................................................................1146.8 Any variables..............................................................................................................................1156.8.1 Programming variables in the process picture (only graphic terminals) ..............................1156.8.2 Programming display / edit variables within texts................................................................1156.9 Text programming / special functions ........................................................................................1196.10 Fault bit processing in the PLC-Mode ........................................................................................1206.10.1 Global Parameterizing of representation and sorting ..........................................................1216.10.2 Variables in dynamic faults (only graphic terminals) ...........................................................1216.10.3 Fault list / Rotation...............................................................................................................1216.10.4 Reset of the fault processing ...............................................................................................1226.10.5 Text related parameterizing.................................................................................................1226.11 Fault menu .................................................................................................................................1227 Operation....................................................................................................1237.1 General performance of display .................................................................................................1237.2 Keyboard definitions...................................................................................................................1247.2.1 Keyboard description...........................................................................................................1277.3 Allocation of Alarm LEDs ...........................................................................................................1367.4 Display and edit menus..............................................................................................................1367.4.1 Requirements for menu text ................................................................................................1367.4.2 Effect ...................................................................................................................................1367.5 Dynamic menu branching ..........................................................................................................1377.5.1 Programming of a branch ....................................................................................................1387.5.2 Parameterizing of the return ................................................................................................1397.6 Help text processing / info key ...................................................................................................1407.6.1 Activation of the help function..............................................................................................1407.6.2 "I" key ..................................................................................................................................1407.6.3 Programming of a help text .................................................................................................1417.7 History ........................................................................................................................................1427.7.1 Memory required for variables.............................................................................................142E6Process display and control/ Device Manual/ Issue: 07.01

7.7.2 History timeout ....................................................................................................................1427.7.3 Calling up the history...........................................................................................................1437.7.4 History basic menu..............................................................................................................1437.7.5 Leaving the history ..............................................................................................................1447.7.6 Deleting the history..............................................................................................................1447.7.7 Structure of history buffer ....................................................................................................1468 INDEX .........................................................................................................149Process display and control/ Device Manual/ Issue: 07.017E

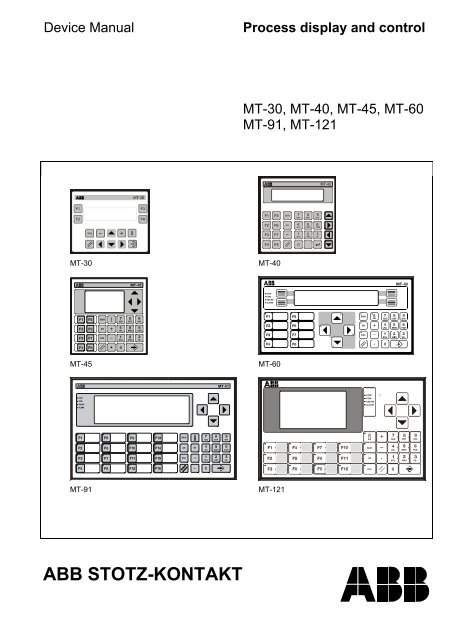

1 Product Overview1.1 Product range• Terminal MT-30 / MT-40 / MT-45 / MT-60 / MT-91 / MT-121• Programming lead• Connecting lead to the automation devices• Depending on the protocol driver, a data handling block, if required• Barcode wand if required (only MT-91 / MT-121)• Barcode scanner if required (only MT-91 / MT-121)E8Process display and control/ Device Manual/ Issue: 07.01

1.2 Overview machine terminals with text displayFunction/ Equipment MT-30 MT-40 MT-60Display type LCD VFD LCDNumber of lines 2 2 4Number of characters/lines 20 20 40Character height [mm] 5 5 5Type of keyboardMembrane keyboard with pressure point; Operating cycle > 1 MillionFunction keysFreely markable/ numberSoftkeysCursor keysAlphanumeric keysLED keysFunction keysCursor keys/ Movement keysCharacter setsLatin/ EuropeanCyrillic (capital letters)Greek (capital letters)Printer and programminginterface V.24Communications interface(galvanically isolated)TTYV.24RS485/RS4224--yesno8--yesyes8+4yes/84yesyes----84333yesyesyesyesyesnonononono yes yesyesno galvanic isolationOptionyesno galvanic isolationOptionyesOptionOptionMemory size [KByte] 128 32 128Number of texts 6000 1000 6000Type of memoryRAMEEPROMEPROMFlash-EPROMReal time clockBattery bufferedCapacitor buffered/ DataretentionFirmware modesSTS-ModesSPS-ModesSupply voltageNominal valueRange---yes----yes-yes-----yesyes---yesyes-yes/>4 T.24 VDC18,5...30,2 VDC according to EN 61131-2Current consumption [ca. mA] 300 250Ambient temperaturesStorageOperation-25°C...+70°C0°C...+50°CEnclosure frontAluminium plate with polyester foil; sealing; window; acrylic glassReal panel of enclosure Plastic Chromium plated steel plateProtection type, frontrearIP 54IP 20IP 54IP 20IP 65IP 20Relative humidityInterference resistanceInterference emissionEN-50082-2EN-50081-1EN 50082-2EN 50082-2EN 50082-2EN 50082-1DimensionsWidth [mm]Height [mm]Depth [mm]Installation depth [ca. mm]144112471071441446512528814470110Weight [kg] 0.4 0,45 1,1yesyesProcess display and control/ Device Manual/ Issue: 07.019E

1.3 Overview machine terminals with graphics displayFunction/ Equipment MT-45 MT-91 MT-121Display LCD VFD graphics display LCD graphics displayPixel 128x64 256x64 240x128Background illuminationdimming/ automaticallyLED- / -self-luminousyes / -CFLyes / yesContrast setting Trimmpoti - key combinationKeyboardsealed keypad (actuating cycle> 1 million)Keyboard illumination - yesFunction keysassignable / numbersoftkeysCursor keysAlphanumeric keys8yes / 8-yesyes16yes / 16-yesyes12yes / 12-yesyes8 (Stop, COM, Online, Alarm,Shift, Alt, Ctrl, Info )System LED´s - 4 (STOP, COM, ONLINE,ALARM)Function key LED ´s - 16 12/ with automatic dimmingNumber of binary inputs /- 8 (for floating contacts, pushbuttons, switches)electrical values (optional)30VDC / 5mANumber of binary outputs/- 4 /electrical valuesmax. 30 V, 500 mA, 30 W / 60VArelay output/- 1 alarm relayelectrical valuesmax. 30 V, 500 mA, 30 W/30VAReal time clock / data hold timeyes (capacitor buffered, maintenance free) / ≥ 4 daysPrinter and programmingyesinterface V.24Communication interfaceoptionally TTY, RS-232-C, RS-485/422Interface for barcode reader - RS-232, 5V supply for readerProgram memory capacity [kByte]4x128Number of protocol drivers3 (loaded from PC software)RAM / buffered [kByte]2x32 / yes (≥ 4 days)Protocol memory [kByte]12 / 200...900 messages approx.Configuration memory [kByte] 448Configuration memory typeFlash-EPROMNumber of process pictures3x1003x100Bitmap representation-yesBar graph/ pointer graph/-yesdifference bar graph functionNumber of texts / messages max. 5900Number of fault messages512 (bit control)Character sets3 (free definition)IBM code table 437 pre-defined in 3 sizesFonts (Number)lines, char./ line, height6x86x1212x2118x3138, 21, 4,5 mm5, 21, 5 mm3, 10, 10 mm2, 7, 15 mm38, 42, 8 mm5, 42, 12 mm3, 20, 21 mm2, 14, 31 mmSupply voltagenominal value24 V DC with reverse voltage protectionrange19,2...30,0 V DC acc. to DIN EN 611312Power consumption [mA],300 mA 400 mAtypically3-10, 40, 4 mm6, 20, 10 mm4, 13, 15 mmEnclosure front FR4 with polyester foil aluminium sheet with polyester foilEnclosure back plastic chrome steel sheetProtection type, frontrearIP 54IP 20IP 65IP 20Ambient temperature -20...+50 °C 0...+40 °CStorage temperature -25...+60 °CRelative Humidity80% at 25 °C, without condensationInterference resistance EN 50082-2Dimensions (wxhxd)Mounting cut-out (wxh)Wall thicknessInstallation depth144x144x65 mm138 (+1) x 138 (+1) mm≤ 40 mm125 mm312x192x79 mm300 (+/- 0,5) x 180 (+/- 0,5) mm< 8 mm120 mmWeight [kg] 0,6 2,0E10Process display and control/ Device Manual/ Issue: 07.01

1.4 Software concept of text terminalsBy means of the serial connection and the special adaptation to the respective PLC resp. host system, theoperating software PLC-Mode achieves a very high functionality. Additionally, this connection saves wiringexpenditure.The following mentioned functions are valid in principle for all devices. The differences are determined only by thevarious design of construction and display.1.4.1 Conveying, Moving, PositioningFunction and cursor keys are sent quickly and directly to the PLC resp. to the host.1.4.2 Displaying, parameterizing, dosing, regulatingSimple adjustment of the display and edit menus by internal recall via function key. In every menu amaximum of 15 variables, actual values as well as nominal values, can be programmed very simply.For this the following display formats are available:– signed decimal (16 bit)– unsigned decimal (16 bit)– decimal as double word (32 bit)– fixed point display– hexadecimal– bit display– ASCII (max. 20 characters)– indirect text (text variables)The reading of variables and data conversion is automatically made in the corresponding PLCformat.1.4.3 Monitoring and controlFault bit processingFault 1Fault 240PLCAddresscontrol word+515 data wordsresp. registersPLC-Mode deviceBasis address fault bit (BS)Fault 1 - text BSFault 2 - text BS+1...Fault 240 - text BS+239PresentationFault headFault message 1Fault message 2Fault message 3...Fault message 31PresentationNew value First value PriorityThe terminals contain a high-functional fault bit processing with record function. 32 from 240/ 512 faults can beprocessed simultaneously. The faults can be displayed as a new value, first value or priority.Process display and control/ Device Manual/ Issue: 07.0111E

1.4.4 RecordingThe devices contain a record memory / history with time and date. The messages / faults are filed with all information(variables etc.).1.4.5 PrintingDevices with printer interfaces can print– instant messages– display contents– fault messages– the history1.4.6 Menu structureFunction and Soft KeysF-Key xF-Key yCursorCursorMenu 1Text nText n+1...Menu 2Text mText m+1...Softkey vSoftkey wCursorCursorMenu 1Text nText n+1...Menu 1Text nText n+1...Complex menu structures can be produced very simply. The function keys can each be assigned to one menu.There can be any number of texts per menu. The B-keys ( screen keys, softkeys at MT-60, MT-82A) can beassigned differently in every menu, to recall other menus or to carry out control functions.E12Process display and control/ Device Manual/ Issue: 07.01

1.4.6.1 Dynamic menu branchingMenu structure(Text 10)→Hall A →Hall B →Hall C(Text 200)Hall A→Pump →Motor →Valve(Text 300)Hall B→Pump →Motor →Valve(Text 400)Hall C→Pump →Motor →Valve(Text 210)Hall A Pump→On →Off(Text 220)Hall A Motor→On→Off(Text 230)Hall A Valve→On→Off(Text 232)Hall AValve On(Text 234)Hall AValve OffBy means of this function, tree-structured architectures can be created without large-scale PLC programming.The several elements are shown to the user with an arrow in the first position. With the keys "cursor left" and"cursor right", the cursor can be placed from arrow to arrow. He selects by operating the key and thedisplay changes to the next menu text.1.4.7 LanguagesNot only system texts, but also operating texts created by the user can be switched to another language.Every device contains a set of three languages. The default combination is German, English and French: refer tothe appendix "Languages and fonts" for other sets.Process display and control/ Device Manual/ Issue: 07.0113E

1.5 Software concept of graphic terminalsDisplay• pixel graphics for background (except MT-45!)• semi-graphic character set (fully configurable) in 3 character sizes• display protection with parametric assignment for display OFF time by operator and PLCCommunication• transparent active control through the terminal via controller specific protocol, cutting complexities of programmingfor communication.• implementation of several protocols within one device (switching at system configuration level).Delivering, moving, positioningFunction and cursor key offer direct and fast input into the PLC or process control systemDisplay, parameters, metering, regulating• simple and comfortable generation of display and parameter menus• 25 formatted process variables per process display for selection♦ numeric data formats with input limitation and linear scaling♦ bar graph, cursor graph (linked directly to the process variables)♦ differential bar graph with dynamic tool centre point♦ all scale factors from PLC• automatic data readout and conversion at the terminal• direct input via barcode (scanner or pen).Monitoring and control• fault processing per single bit, rendered as new or first value or priority with internal confirmation to enter field inPLC• convenient protocol functions in the internal protocol memory, history with up to 900 entries.Menu structures• simple generation of menu structures (parameter masks, tree structures) without PLC program• direct activation of internal functions through function keys.E14Process display and control/ Device Manual/ Issue: 07.01

Programming• generating process images, fault texts etc. through PC programs in SAA standard• generating or changing characters. This provides for the use of any type of character (such as Cyrillic, Greek,Japanese…)• importing pixel graphics in bitmap format.Firmware downloadDownload of the complete firmware with• protocol drivers• system languages• character sets.1.6 Accessories1.6.1 Programming leadstype: VB 30cable length: 5 mconnector:PC side 9 pin sub-D socketMT-50 / MT-120 side 25 pin sub-D plug1.6.2 Connection leads to automation devicesThe information about the connection leads to the PLC systems can be found in Chapter "Installation to the PLC".1.6.3 Function modules, additional librariesAs a rule, specific function modules or program libraries will not be required for communication with the device.Where they are required for specific protocols or interfaces, you can find their parameters set out in Chapter"Installation to the PLC".1.6.4 Barcode reader unitsA barcode reader can be plugged directly into the MT if required. The reader should have the following specifications:• integral barcode decoder• 5V power supply / max. 250mA• RS-232-C or RS-232-TTL interface• no preamble (header)• (0Dh, 13d) as postamble (trailer)• ASCII coded characters (20h...7Fh)• interface parameter7 data biteven parity1 stop bit9600 baudProcess display and control/ Device Manual/ Issue: 07.0115E

The following barcode readers have been tested with the devices and can be supplied:• Handheld barcode laser scannerWelch Allyn Pistolgrip reader 5700/A-02,connecting lead 42204747-01, (9 pin sub-D connector, male)light source:670nm red lightinterface type:RS-232-TTLprogramming:- RS-232 interface- 9600 baud, 7 data bits, parity bit even, 1 stop bit- preamble, none- postamble, CR (Carriage Return)- other settings, Welch Allyn standard settingsterminal assignment: 2 - TxD, 5 - GND, 9 - +5Vpower consumption:115mA for 5V power supply• Barcode-CCD-ScannerWelch Allyn Touchreader3400/B-122,connecting lead: 42204747-01, (9 pin sub-D connector, male)light source:670nm red lightinterface type:RS-232-TTLprogramming:- RS-232 interface- 9600 baud, 7 data bits, parity bit even, 1 stop bit- preamble, none- postamble, CR (Carriage Return)- other settings, Welch Allyn standard settingsterminal assignment: 2 - TxD, 5 - GND, 9 - +5Vpower consumption:115mA for 5V power supply• Barcode wandWelch Allyn Wandconnecting lead:light source:interface type:programming:terminal assignment:power consumption:6180/A-21QJX, (X = connector code)specify when ordering, 9 pin sub-D connector (male)660nm, red lightRS-232-TTL- 9600 baud, 7 data bits, parity even, 1 stop bit- preamble, STX- postamble, CR (Carriage Return)- other settings, Welch Allyn standard settings2 - TxD - blue, 5 - GND - white, 9 - +5V - red22mA for 5V power supply• Barcode slot readerWelch Allyn Slot Reader 6480/A-A48X22, (X = connector code)connecting lead:specify when ordering, 9 pin sub-D connector (male)light source:660nm, red lightinterface type:RS-232-Cprogramming:- 9600 baud, 7 data bits, parity even, 1 stop bit- preamble, none- postamble, CR (Carriage Return)- other settings, Welch Allyn standard settings terminal assignment:2 - TxD - yellow, 5 - GND - white, 9 - +5V - redpower consumption:75mA for 5V power supplyE16Process display and control/ Device Manual/ Issue: 07.01

2 Communication2.1 Protocol Driver CS31The communication with the ABB Procontic CS31/ AC31 (07 KR 91, 07 KT 92, 07 KT 93, 07 KT 94) is made via theserial interface COM 1.The memory access is made to any word and double word flags.Attention: For performance reason you should use the Modbus protocol via COM2 (07 KT 94).2.2 Protocol Driver T200 - HI-ProtocolThe MT can be couples to the ABB Procontic T200 with the HI-Protocol.The communication protocol is the HI-Protocol and furthermore as communication module data words in the WRrangeresp. the MW-range with ABB Procontic T200. These data words are read and written cyclically with the taskcodes 40h and 42h. The MT is procedure master, the PLC slave.The coupling is possible to:• CPU Interface (RS-232 with CTS)• ABB KP60 (RS-232 or RS-422; see mode switch info in the system description of ABB Procontic T200)2.3 Protocol Driver Modbus RTUTested connections:• AC31 with 07KP93• T200 with 07MK62• AC31 COM2• AC41/ 51 COM1There are two firmware versions for controls with Modbus RTU Protocol:• SPS-Mode Modbus RTU Master• SPS-Mode Modbus RTU Slave2.3.1 Modbus RTU MasterFor a simplification of the ABB AC31 addressing via the Modbus Protocol a special routine was developed, thismake a direct parameterizing of the variables possible.2.3.2 Modbus RTU SlaveThe "Modbus RTU" described in the "Modicon Modbus Protocol Reference Guide" serves as communicationprotocol. The interface parameters are adjustable. Access to the memory of a special type in the PLC is made withreference numbers:BXXXXFour position addressMemory type: 4 - Memory registere.g. Flag register 1 = 40001Detailed information can be found in Chapter "Function description PLC Mode/General"Process display and control/ Device Manual/ Issue: 07.0117E

2.3.3 Format for Modbus RTUGenerally the message format of the Modbus RTU is:T1 T2 T3 Address Function Date Checksum T1 T2 T3with T1...T3:Break periods between two telegrams. The receiver waits for a new address after a breakperiod of at least three and a half character transfer periods.Address:Remark:Function:Substation number of the communication partner.The address is set via the substation number of the PLC Mode device.The following are used by the PLC Mode device from a great number of function of the Modbusprotocol. The type of function code is influenced by the address entry.CodeFunction01 Read spools and discrete output flags. This function code is used if the address isprefixed with a "0". e.g. for reading and display of the first 16 flags #00001XXXX02 Reading of discrete inputs by a "1" prefixe.g. reading of the first 16 input flags #10001XXXX03 Reading of one of more output registersPrefixed by a "4". e.g. reading of the first register and decimal output#40001UUUUU04 Reading of an input register prefixed by a "3"05 Setting of a marker06 Writing of a single register15 Writing of a number of flags is the same as Code 116 Writing of a number of register is the same as Code 317 Detecting of the AEG PLC / diagnosisAttention: Memory types "1" (discrete input flag) and "3" (input register) can only be read; i.e. they mustnot be used in the "Basic definitions" or "variable editing"Check sum: Fault detection operates with CRC-16 and the polynome x 16 +x 15 +x 2 +1E18Process display and control/ Device Manual/ Issue: 07.01

2.4 Protocol Driver ARCNETARCNET: Attached Resource Computer NetworkBecause of its speed, calculable reaction times and its flexible data packet size, ARCNET is applicable in thesensor/ actor area as well as in the process or cell bus level. Bus, star and tree topologies can be realized.Token Passing ProcedureToken is passed independently of the net topology to the node of the respective next higher ID. Each station gets astation ID between 1 and 255 (each number only one time). Data packet size flexible up to 508 byte; then tokenmust be passed. Because of the flexibility, the net data rate is up to 71%. Protocol safety is not a problem becauseof checksums in the data packet (16 Bit CRC) and handshake protocol between sender and receiver.Multimaster operationNew participants can always be signed on or cancelled. If token is lost then the network is reconfigured. Timebehaviour is deterministic. Applicable transmission media are coaxial cables, twisted pair or optical fibrewaveguides. Networks can be expanded by HUB´s and transmission media can be changed. With Coaxial cables2,5 Mbps max. 16 km can be achieved and with twisted pair 6 km. Standards: ATA / ANSI 878.1, 878.2 and 878.32.4.1 Terminal interfacing via ARCNETTo achieve simple and effective data transmission to visualisation systems a protocol according to Modbus RTUwas developed. In the PLC program, beside the ARCNET blocks AINIT, AREC, ASEND, ASEND+, and APOLL theconnecting element 5F_ARC (for 07KT92/93) or 5F_ARC94 (for 07KT94 ) is used. 5F_ARC and 5F_ARC94 arefunctionally identical.These connection element call via the block CALLC a C subroutine which interprets the received data.The protocol works according to a master/ slave principle, the terminal is always the master and the PLC is alwaysthe slave. Data that is sent and received is configured in the terminal. A standard program is always used in thePLC. Several masters can be connected to one PLC; in that case, the PLC program must be expanded withseveral 5F_ARC or 5F_ARC94. Additionally to this protocol a communication between the PLCs according to theblock descriptions ASEND, ASEND+ and AREC can be realized.The coupling can be made to all operating devices with ARCNET interface.Process display and control/ Device Manual/ Issue: 07.0119E

3 Mounting Instructions and Installation3.1 Guidelines for Engineering / InstallationThe following guidelines provide instructions for the safe integration of the product into larger systems or installations.• Regulations for safety and accident prevention must be observed for each application.• Devices may only be used when they are fitted and the enclosure is closed.• Provision must be made to enable that the products can be isolated from power at any time (for fixed installationsvia an all pole mains isolator switch or fuse); protective conductors must be grounded.• Supply voltages must comply with the specifications in the manual and tolerances must be observed.Caution:• Malfunctions may occur if the specified tolerances are either not met or exceeded!• Provisions must be made to ensure that the installation / the system is not triggered into dangerous orundefined states by power failures or interruptions.• Emergency stopping devices must remain effective in all operational situations and states.• Connection leads (particularly data transfer leads) must be provided and installed in such a way that theinstallation / system cannot be affected by capacitance or inductive interference. Measures must betaken so that undefined states cannot develop, even when leads are interrupted.• The products must be installed in such a way that unintentional activation of functions is avoided.• Wherever malfunctions may cause damage to equipment or to staff, additional external safety fail-safeswitching must be provided (such as limit switches, mechanical latches etc.).E20Process display and control/ Device Manual/ Issue: 07.01

3.2 Interference suppression / installation guidelinesPlease note carefully !The terminals are electronic devices which incorporate the latest technology. Their robust mechanical constructionas well the electronic components are designed for industrial use.Even so, it is necessary to observe certain basic measures when setting up such devices in industrial installationsto safeguard failure free operation:Interference voltages which can reach the device via supply and signal leads as well as electrostatic electricitythrough contact should be discharged through the ground terminal (such as the screw terminal at the rear of thehousing).This ground terminal must have a low resistance copper lead, kept as short as possible, either linked with the earthcontinuity conductor (yellow/green) or included in the equipotential grounding (permissible diameter of the cable :2,5mm² - 4mm² for terminal connectors, 10mm² for bolt type screw connectors, ·≥ 10mm² for equipotentialgrounding).If this is not observed, the high level of resistance to interference or damage which is a feature of the device maybe rendered ineffective.When the location for fitting the device is selected, it is important to maximise distance from areas of electromagneticfield disturbance. This is particularly important where frequency converters are in use.Under certain circumstances, it may be advisable to screen ‘disturbancy emitters’ with metal plates.Inductors in the vicinity (such as contactor, relay and magnetic valve coils) must be switched through fused links(such as RC links), particularly if they are connected to the same power supply.Power supplies and data leads should be routed to steer clear of interference.This may be achieved, for example, by not running them parallel to high power cables which give rise to interference.The following note applies to all devices which have been tested according to EN 50081-2; see the appendedDeclaration of EG-Conformity.Warning !This is a class A equipment. This equipment may cause radio interference in residential areas. In this case the usercan be required to take appropriate measures and he will have to pay the costs for them.Process display and control/ Device Manual/ Issue: 07.0121E

3.2.1 Shielding cables / leadsShielding measures are important to reduce (dampen) magnetic, electric or electromagnetic interference fields.Types of shielding :For shielded leads, you should use only cables or leads with braided shielding (recommended coverage > 80%).Foil shielding should not be used, since foil does not dampen all frequencies equally.In addition, foil shielding may be damaged through tension and compression during fitting and operation whichwould reduce effectiveness.Single sided or double sided connection of shielding:As a rule, optimal damping of all incoming interference frequencies can only be achieved by using the doublesided connection method!Using the single sided connection method may be more favourable if:− there is a potential difference and an equipotential bonding conductor cannot be installed− only foil shielded leads are available.Shielding connectors:A low impedance connection to ground or to equipotential grounding is of special importance, to ensure that theinterference current from the shielded cable does not itself carry a source of interference.When using sub-D connectors, you should always bring the shielding into contact with the metallic or metallisedconnector casing of the sub-D connector.Do not, under any circumstances, solder the shielding to pin 1 of the connector strip.There are a few exceptions to this rule, see guidelines for connection.Some controllers have connector casings which are not optimally connected to ground. In such a case, it would bean advantage to isolate the screening at the sub-D connector of the PLC and link it with the shortest possible lead(0.75mm 2 ...1.5mm 2 ) directly to the protective ground conductor.For stationary use, we recommend that the shielded cable is fully insulated and in contact with the PE bar orequipotential bonding.The screening end at the interface will not be fixed in this case!When screening is treated in this way, make sure cable clips which provide good contact all around the shieldbraiding are used.E22Process display and control/ Device Manual/ Issue: 07.01

Examples for connections:1. Shielding of serial coupling to controller in double sided contact.With additional equipotential bonding lead (10mm² required).PLCMTEquipotential leadCentralpointgroundingAs a rule, double sided contact will result in the optimal damping of all connected interference frequencies.The power supply to the machine terminal may also be through the supply of the PLC.2. Shielding the serial coupling to controller through single sided contact.Without equipotential bonding lead.PLCMTPotential differenceCentral groundingpointIn this case, the equipotential flow would be across the shielding, if the shield connection was double sided.This must definitely be avoided, since the resulting interference impulses could be fed into the devices via thedata input lead.Where shielding is single sided, the shield connection must be made on the side of lowest impedance as nearas possible to the central grounding (connection A in the example).Before commissioning, it is necessary to check the installation instructions specified by the manufacturer for safeoperation. They should be reconciled with the recommendations here.Screen connection with MT-30:Via 6.3 mm flat connector (not included in delivery).Process display and control/ Device Manual/ Issue: 07.0123E

3.3 Instructions for Mounting and InstallationRemove the terminal from the packaging. Items supplied are:− the MT− mounting elements• two for MT-40 and MT-45• four for MT-30• six for MT-60• eight for MT-91 and MT-120− this manual where applicableFitting can be directly into− cabinet doors or− operating panels.Selection of fitting position according to:− optimal height for operator− good lighting, so that the display is easy to read− suitable ventilation to be used in case of high ambient temperatures.− Avoid mounting in the immediate vicinity of switchgear or power converters.Prepare an opening with the following dimensions:Device Width Height Fitting depth Thickness/materialMT-30 138 +1 mm 106 + 1 mm 105 mm approx. max. 18 mmMT-40, MT-45 138 +1 mm 138 + 1 mm 125 mm approx. up to 40 mmMT-60283 ± 0.5 mm 139 ± 0.5 mm 110 mm approx. max. 18 mmConst. variation IMT-60283 ± 0.5 mm 79 + 0.5 mm 110 mm approx. max. 18 mmConst. variation II+ 3 holes(see diagram)MT-91 300 mm 180 mm 130 mm approx. max. 10 mmMT-121 300 ± 0.5 mm 180 ± 0.5 mm 120 mm approx. max. 8 mmExchange the labelling strip before the installation:The labelling stripes are to be changed at the rear of the device.• Pull out paper-tapes carefully with a tweezers. Do not press into the slot with a sharp tool because the front foilwill be damaged!• Inscribe the paper-tapes• Carefully insert again (at an angle of approx. 45 degrees):• in doing this, do not apply any pressure on the front panel• angling the corners simplifies insertionIf you produce new stripes, these must correspond in size to the original stripes (see appendix, "Labelling strips").They may not protrude over the rubber seal.E24Process display and control/ Device Manual/ Issue: 07.01

Fit the device using the mounting elements:− Fix the clamps at even distances in the gaps of the casing.Optimal spacing:• MT-30, MT-40, MT-45 one mounting element per side• MT-60, MT-91, MT-121 three mounting elements to the upper and lower sidesas well as one mounting element to each of the sidesthemselves.− Finger tighten the screws.− Check the position of the display, and take special care to check the correct seat of the sealing rubber.− Now tighten the clamping screws with a torque of 60N/cm.Caution:IP 65 (or IP 54 for MT-40 and MT-45) will be achieved by• quality installation and fitting• use of a flat and smooth mounting surface (after the clamping screws have been tightened)• the specified torque setting.Process display and control/ Device Manual/ Issue: 07.0125E

3.3.1 Mounting Diagram MT-60Construction variation ISide viewMounting cut-outConstruction variation IISide viewMounting cut-outE26Process display and control/ Device Manual/ Issue: 07.01

3.3.2 Mounting Diagram MT-303.3.3 Mounting Diagram MT-40, MT-45max. 40mm144138+1138+1ca. 65mm144mit Bu-Stecker ca. 125mmDimensions of opening for installation in mmProcess display and control/ Device Manual/ Issue: 07.0127E

3.3.4 Mounting Diagram MT-91Dimensions of opening for installation in mm3.3.5 Mounting Diagram MT-121Dimensions of opening for installation in mmE28Process display and control/ Device Manual/ Issue: 07.01

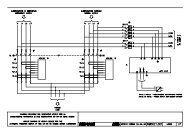

3.4 Overview o f connection assignmentsBack wall MT-30Back wall MT-40Process display and control/ Device Manual/ Issue: 07.0129E

Back wall MT-60Back wall MT-91 / MT-121E30Process display and control/ Device Manual/ Issue: 07.01

Back wall MT-91 / MT-121 ARCNETProcess display and control/ Device Manual/ Issue: 07.0131E

Connections:Identification Significance FunctionX1 1 + 24 V supply energy supply to terminal3 GND supplyX2 2 RXD printer andsetting 3 TXD programming interfaceRS-232-C 5 *CTS7 GND14 programming15 V.2416 GND programming17 GND V.24X2 9 RxD- communication TTYsetting 11 lin1TTY 12 lout113 TxD-22 lin223 lout224 RxD+25 TxD+X3 1 output 1a relay output2 output 1b (only MT-60, MT-91, MT-121)X4 2 TxD communication RS-232variant 3 RxDRS-232-C 5 GND7 *CTS8 *RTSX4 9 TxD A communication RS-422/485variant 3 TxD BRS-422/485 6 RxD A4 RxD BX5 1 input 1 (max. 30V dc) pushbuttons or switches2 input 2 (max. 30V dc) (only MT-91, MT-121, optional)3 input 3 (max. 30V dc)4 input 4 (max. 30V dc)5 input 5 (max. 30V dc)6 input 6 (max. 30V dc)7 input 7 (max. 30V dc)8 input 8 (max. 30V dc)10 / 22 output 1 (max. 60V dc)11 / 23 output 2 (max. 60V dc)12 / 24 output 3 (max. 60V dc)13 / 25 output 4 (max. 60V dc)14 0 V (input 1-8)X6 2 RxD barcode reader unit3 TxD (only MT-91, MT-121)5 GND7 *RTS8 *CTS9 + 5 V Signals marked "*" are "0" active.Connections which are not listed are left unconnected.E32Process display and control/ Device Manual/ Issue: 07.01

3.5 Fieldbus interface of variant MT-30/ MT-45/ MT-91/ MT-121 ARCNET3.5.1 Cable typeCable: RG 62DC resistance:1.12 Ohm / 100 mCharacteristic impedance: 93 Ohm / 1 MHzMaximum cable attenuation: 1.8 dB / 100 m3.5.2 Fieldbus plugConnection:BNC plug with 75 Ohm characteristic impedanceorBNC connecting element (T-form) with 75 Ohm characteristic impedance3.5.3 ConnectionConnection at the end of the cableTerminatingresistor93 OhmConnecting element75 OhmBNC connection75 OhmRG 62Coaxial cablecharacteristic impedance93 OhmX14BNC socket75 OhmTerminalPicture: fieldbus connection to the terminal.Terminal is at the end of the cable.Process display and control/ Device Manual/ Issue: 07.0133E

Connection between the ends of the cableBNC connection75 OhmConnecting element75 OhmBNC connection75 OhmRG 62RG 62Coaxial cablecharacteristicimpedance 93 OhmCoaxial cablecharacteristicimpedance 93 OhmX14BNC socket75 OhmTerminalPicture: fieldbus connection to the terminal..The terminal is between the ends of the cable.E34Process display and control/ Device Manual/ Issue: 07.01

3.5.4 Cable length and number of participantsThis information applies to coaxial cable RG 62The transmitter output signal is 9dB higher than the signal required by the receiver.The connection of each further terminal (node) causes a loss 0.43dB.The cable RG 62 weakens the signal by 0.6dB per 30m at 5MHz.Requirement : usage of less than 19 participants on one cable.Number ofparticipantsLoss by participant Remainingsignal powerMaximumcable length2 0.43 dB 8.57 dB 435 m3 0.86 dB 8.14 dB 413 m4 1.29 dB 7.71 dB 391 m5 1.72 dB 7.28 dB 370 m6 2.15 dB 6.85 dB 348 m7 2.58 dB 6.42 dB 326 m8 3.01 dB 5.99 dB 304 m9 3.44 dB 5.56 dB 282 m10 3.87 dB 5.13 dB 260 m11 4.30 dB 4.70 dB 238 m12 4.73 dB 4.27 dB 217 m13 5.16 dB 3.84 dB 195 m14 5.59 dB 3.41 dB 173 m15 6.02 dB 2.98 dB 151 m16 6.45 dB 2.55 dB 130 m17 6.88 dB 2.12 dB 108 m18 7.31 dB 1.69 dB 86 m19 7.74 dB 1.26 dB 64 mProcess display and control/ Device Manual/ Issue: 07.0135E

3.5.5 Technical data of the ARCNET interface cardARCNET interface cardTransmission medium Coaxial cable, RG 62,Characteristic impedance 93 OhmConnectionsBNC socket, 75 Ohm for connection of a coaxial cableFunction indication1 diagnosis LED´sController COM 20020clock frequency 20 MHzInterface driverHCY9088AR by SMSCor A60152 by MITNode impedance≤1.2 kΩNode distance≥ 1mOperating element8 pole DIP switchfor setting the station address (Node-ID)Supply voltage +5Vtype 350 mAmax. 550 mAAmbient temperature0..50°CE36Process display and control/ Device Manual/ Issue: 07.01

3.6 Printer connectionWith communication interface RS-232 only for devices with optional interface V.24 on X4.In this case, communication interface is X4!3.7 Connecting a barcode readerA barcode reader may be connected directly to a MT-91/ MT-121 . The following specifications are required for areader:• integrated barcode decoder• 5V power supply / max. 250mA• RS-232-C or RS-232- TTL interface• no preamble or header label• (0Dh, 13d) as preamble or trailer• ASCII code characters (20h...7Fh)• interface parameter7 data bitseven parity1 stop bit9600 baudProcess display and control/ Device Manual/ Issue: 07.0137E

3.7.1 PIN assignment for barcode interface (socket X6)X6View PIN Signal name Description123456789-RxDTxDGND-*RTS*CTS+5Vinput leadoutput leaddata reference potentialrequest to send*clear to send*supply voltageSignals marked "*" are "0" active.3.7.2 Data transfer to the PLCTo input values through the barcode reader, the active (blinking) cursor must be on an input variable declared in Aformat. A screen form generated through PLCPlus consequently could look like this:batch number :personnel code :#EAAAAAAAAAAAA#EAAAAAAAAAAAAThe barcode input is saved from the address specified in the format (see A format). The address data (called and in the example) are given in the usual PLC specific format.If the barcode unit is used for entering a barcode of a length which matches the format, then• the code will be entered in both display and controller• the cursor will be set to the next editable variable (as happens after pressing the ENTER key)• in addition, the following bits are entered into the controller:"PLC address function key field"+00 Bit15Bit14Bit13Bit12Bit11Bit10Bit9Bit8Bit7Bit6Bit5Bit4Bit3Bit2Bit1Bit0meaningx x x x 1 x x x x x 1 x x x x x input through bar codereader unitIf the length of the code which has been entered deviates from that of the set format (is longer or shorter), thecursor will stop at the position of the last character which has been entered, to indicate this to the operator.However, if this value needs to be entered into the controller, the operator will have to confirm this by pressing theENTER key or scan the barcode again or else key the entry manually.3.8 Operation of alarm relay(not MT-40 and MT-45)The operation of the alarm relay can be set in the configuration menu:Alarm − the relay will be added in at the flashing of LED 4 (see fault bit processing)Keys − the relay is activated with the keys (function, cursor and display keys)E38Process display and control/ Device Manual/ Issue: 07.01

3.9 DIL switches S1The DIL switches serve to preset the display and have to be set before the system start.DIL switches 1...5: MT-40, MT-60 address adjustment (substation number)MT-45, MT-91, MT-121 no function┌───┬───┬───┬───┬───┬──────┐ ┌───┬───┬───┬───┬───┬──────┐│ 1 │ 2 │ 3 │ 4 │ 5 │ Adr.│ │ 1 │ 2 │ 3 │ 4 │ 5 │ Adr.│├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│OFF│OFF│OFF│OFF│OFF│ 1 │ │OFF│OFF│OFF│OFF│ON │ 17 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│ON │OFF│OFF│OFF│OFF│ 2 │ │ON │OFF│OFF│OFF│ON │ 18 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│OFF│ON │OFF│OFF│OFF│ 3 │ │OFF│ON │OFF│OFF│ON │ 19 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│ON │ON │OFF│OFF│OFF│ 4 │ │ON │ON │OFF│OFF│ON │ 20 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│OFF│OFF│ON │OFF│OFF│ 5 │ │OFF│OFF│ON │OFF│ON │ 21 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│ON │OFF│ON │OFF│OFF│ 6 │ │ON │OFF│ON │OFF│ON │ 22 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│OFF│ON │ON │OFF│OFF│ 7 │ │OFF│ON │ON │OFF│ON │ 23 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│ON │ON │ON │OFF│OFF│ 8 │ │ON │ON │ON │OFF│ON │ 24 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│OFF│OFF│OFF│ON │OFF│ 9 │ │OFF│OFF│OFF│ON │ON │ 25 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│ON │OFF│OFF│ON │OFF│ 10 │ │ON │OFF│OFF│ON │ON │ 26 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│OFF│ON │OFF│ON │OFF│ 11 │ │OFF│ON │OFF│ON │ON │ 27 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│ON │ON │OFF│ON │OFF│ 12 │ │ON │ON │OFF│ON │ON │ 28 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│OFF│OFF│ON │ON │OFF│ 13 │ │OFF│OFF│ON │ON │ON │ 29 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│ON │OFF│ON │ON │OFF│ 14 │ │ON │OFF│ON │ON │ON │ 30 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│OFF│ON │ON │ON │OFF│ 15 │ │OFF│ON │ON │ON │ON │ 31 │├───┼───┼───┼───┼───┼──────┤ ├───┼───┼───┼───┼───┼──────┤│ON │ON │ON │ON │OFF│ 16 │ │ON │ON │ON │ON │ON │ 32 │└───┴───┴───┴───┴───┴──────┘ └───┴───┴───┴───┴───┴──────┘┌───┬───┬─────────────────────┐┌───┬───┬─────────────────────┐│ 6 │ON │ Keyboard ││ 7 │ON │ Clear memory ││ ├───┼─────────────────────┤│ │ │ !Programming plug ││ │OFF│ no keyboard(KA80) │├───┼───┼─────────────────────┤│ ├───┼─────────────────────┤│ 8 │ON │ Keyboard test ││ │OFF│ Conf.menu disabled │└───┴───┴─────────────────────┘└───┴───┴─────────────────────┘The default setting is:┌───┬───┬───┬───┬───┬───┬───┬───┐│ 1 │ 2 │ 3 │ 4 │ 5 │ 6 │ 7 │ 8 │├───┼───┼───┼───┼───┼───┼───┼───┤│OFF│OFF│OFF│OFF│OFF│ON │OFF│OFF│└───┴───┴───┴───┴───┴───┴───┴───┘Process display and control/ Device Manual/ Issue: 07.0139E

4 Installation on the PLC4.1 Installation on AC31 active COM1Standard communication interface:V.24/ RS-232-CThe communication with the ABB Procontic AC31 (07 KR 91, 07 KT 92, 07 KT 93, 07 KT 94) and to T200 with 07KP 62 is made on the serial interface COM1 (COM2 with special software). The memory access is made to anydouble word flags.To connect the device with the ABB Procontic AC31, both devices must have the same interface parameters. Theinterface parameters are adjustable, the defaults are:9600 baud8 data bits1 stop bitnon parityInstallation on X2The connection cable VB-85 is supplied as an accessory.MTX225pole Sub-DAC31COM19pole Sub-DScreen connection onconnector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.E40Process display and control/ Device Manual/ Issue: 07.01

Installation on X4The connection cable VB-86 is supplied as an accessory.MTX49pole Sub-DAC31COM19pole Sub-DScreen connection onconnector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.Process display and control/ Device Manual/ Issue: 07.0141E

4.2 Installation on the T200Standard communication interface:V.24/ RS-232-CThe interface parameters are adjustable, the defaults are:19200 baud7 data bits1 stop biteven parityPlease note that the interface parameters and the device addresses of both devices must correspond.E42Process display and control/ Device Manual/ Issue: 07.01

Installation via V.24/RS-232With a communication processor ABB KP the CTS handshake is not necessary. When using a CPU interface theCTS handshake must be adjusted.Installation on X2The connection cable VB13 is supplied as an accessory.MTX225-pole Sub-DPLC15-pole Sub-DScreen connection onconnector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.Process display and control/ Device Manual/ Issue: 07.0143E

Installation on X4The connection cable VB-43 is supplied as an accessory.MTX49-pole Sub-DPLC15-pole Sub-DScreen connectionon connector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.Caution:With the physically last terminal in the bus, termination must be made with a termination resistor.S3 1 2ON ONE44Process display and control/ Device Manual/ Issue: 07.01

4.3 Connection to 07KP93 - AC31 with Modbus-RTUThe following interfacing possibilities exist:• Modbus RTU Master for 07 KT 94 and new systems with Modbus on COM2 or withMK 92• Modbus RTU Slave for MK 92 as master4.3.1 Modbus RTU MasterProVicomExicomVariablesFaults/ KeysAC 31KR 31AC 31KR 31AC 31KR 31Access from the MT is made as Modbus RTU Master to the multi-slave PLCsPerformance class Multislave Variables Faults Function keysText Yes Any PLC 1 PLC 1 PLCGraphic Yes Any PLC 2 PLCs 1 PLCNote:For key functions with graphic devices also the sending function can be used. With that keyscan be transferred into all slaves as values.Now it is also possible to operate variables in several AC31 / KP93 slaves.Following parameters are allowed:Format Telegram type Address AC31 Address section Modbus-Basic-addresshexMW Word flags Register (XXMWggg,kk), (MW00,00)...(MW255,15) 2000MD Double wordflagsKWWordconstants*KD Double wordconstants*RegisterRegisterRegister(MWggg,kk)(XXMDggg,kk),(MDggg,kk)(XXKWggg,kk),(KWggg,kk)(XXKDggg,kk).(KDgg,kk)M Binary flags Binary Data (XXMggg,kk),(Mggg,kk)* no write accessXX Station number 0...31ggg Group number 0...31kk Channel number 0...15(MD00,00)...(MD31,15) 4000(KW00,00)...(KW39,15) 3000(KD00,00)...(KD07,15) 5000(M00,00)...(M255,15) 2000If no station number was defined, those AC31 will be addressed, witch Modbus address correspond with thepreset station number of the terminal. (Text terminals with DIL, Graphic terminals with the configuration menu).Process display and control/ Device Manual/ Issue: 07.0145E

4.3.2 Modbus RTU SlaveAC 31MK 92RS-422/485MT MT MTThe MK 92 must be parameterized as master.• Communication interface: RS-232 with CTS• Notes:Programming expanse in PLC4.3.3 Installation overviewThe function block MOD_INIT initializes the MODBUS coupler and realizes the operating mode SLAVEMOD_INITFREICOMMSLVBAUDParameters:FREI BINÄR A, E, S, M, K Release of the block processingCOM WORT KW Interface identification (3 or 4)MSLV WORT KW 0 = Master, 1...254 Slave-AddressBAUD WORT KW Baudrate (1200, 2400, 4800, 9600)E46Process display and control/ Device Manual/ Issue: 07.01

4.3.4 Connection via V.24 on X2The connection cable VB-57 is supplied as an accessory.MTX225-pole Sub-D07KP93 - AC3115-pole Sub-DScreen connection onconnector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.4.3.5 Connection via V.24 on X4The connection cable VB-58 is supplied as an accessory.MTX49-pole Sub-D07KP93 - AC3115-pole Sub-DScreen connection onconnector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.Process display and control/ Device Manual/ Issue: 07.0147E

4.3.6 Connection via RS-485 on X2MTX225-pole Sub-D07KP93 - AC3115-pole Sub-DCable requirments:twisted pair andscreenedScreen connection onconnector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.4.3.7 Connection via RS-485 on X4MTX49-pole Sub-D07KP93 - AC3115-pole Sub-DCable requirments:twisted pair andscreenedScreen connection onconnector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.E48Process display and control/ Device Manual/ Issue: 07.01

4.3.8 Connection via RS-422 on X2MTX225-pole Sub-D07KP93 - AC3115-pole Sub-DCable requirments:twisted pair andscreenedScreen connection onconnector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.Process display and control/ Device Manual/ Issue: 07.0149E

4.3.9 Connection via RS-422 on X4MTX49-pole Sub-D07KP93 - AC3115-pole Sub-DCable requirments:twisted pair andscreenedScreen connection onconnector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.E50Process display and control/ Device Manual/ Issue: 07.01

4.4 Connection to AC 31 with Modbus-RTU4.4.1 Installation on X2Interface cable VB-85 can be supplied as an accessory.MTAC31X2COM225-pole Sub-D9-pole Sub-DScreen connection toconnector enclosureRefer to Device Manual, Chapter "Suppression measures /Installation guidelines" for screening and interferenceimmunity.Process display and control/ Device Manual/ Issue: 07.0151E

4.5 Connection to AC 41/ AC 51 with Modbus RTU4.5.1 Installation on X4MTX29pole Sub-DAC41/ AC51MINI-DIN 8poleScreen connection toconnector enclosureRefer to Device Manual, Chapter "Suppression measures /Installation guidelines" for screening and interferenceimmunity.4.5.2 Installation on X4MTX49pole Sub-DAC41/ AC51MINI-DIN 8poleScreen connection toconnector enclosureRefer to Device Manual, Chapter "Suppression measures /Installation guidelines" for screening and interferenceimmunity.Process display and control/ Device Manual/ Issue: 07.0153E

4.6 Connection 07MK62 - T200 with Modbus-RTU4.6.1 Connection via V.24 on X2MTX225-pole Sub-D07MK62 - T2009-pole Sub-DScreen connection onconnector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.4.6.2 Connection via V.24 on X4MTX49-pole Sub-D07MK62 - T2009-pole Sub-DScreen connection onconnector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.E54Process display and control/ Device Manual/ Issue: 07.01

4.7 Connection to KR / KT31 with Modbus-RTU4.7.1 Connection V.24 on X2MTX225-pole Sub-DKR / KT319-pole Sub-DScreen connection onconnector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.4.7.2 Connection V.24 onMTX49-pole Sub-DKR / KT319-pole Sub-DScreen connection onconnector caseRefer to chapter "Interference suppression / installation guidelines" with regard to the screening/ interferenceresistance.Process display and control/ Device Manual/ Issue: 07.0155E

4.8 Installation on ABB AC 31 via ARCNETThe technical data of the ARCNET interface can be found in the chapter titled "Mounting instructions and installation/Fieldbus interface of variant MT-91/ MT-121 ARCNET"To connect the device to the ARCNET interface the following steps must be made:4.8.1 Setting the Node-ID/ station addressThe DIP switch S2 serves for the definition of the Node-ID (node resp. station number).The Node-ID has to be between 1 and 255 (with a Node-ID of 0, all DIP switches off, the ARCNET controller wouldneither receive nor send any token).DIP position:S21 2 3 4 5 6 7 8 Node-IDOn Off Off Off Off Off Off Off 1Off On Off Off Off Off Off Off 2On On Off Off Off Off Off Off 3...........................On Off On On On On On On 253Off On On On On On On On 254On On On On On On On On 2554.8.2 Optical indication, LED tokenThe lighting up of this LED token signals that a token has been received from another station. The bus connectionis OK.E56Process display and control/ Device Manual/ Issue: 07.01

4.8.3 Block 5F_ARC resp. 5F_ARC945F_ARCFREIT_I1T_O1ERROP0FREI Bit ReleaseT_I1 Word 1. effective data flag receiveT_O1 Word 1. effective data flag sendERR Word ErrorOP0 1. Operand in operand memory (KW00,00)The telegrams consist of an ARCNET head (CP,DIN,JOB_NR) and the MODBUS RTU telegram which may notexceed the maximum of 125 words. For sending and receiving in the PLC, a space of 125 flag words for each(sending and receiving) must be kept free. All telegrams are send with the DIN identification 5F and the effectivedata size (AREC/ASEND) 125 (maximum size). As Job-no. always the ARCNET address of the respectiveparticipant is used. This Job-No. is written in the ASEND resp. ASEND+ blocks and in the AREC.Example: If the master (terminal) has the ARCNET address of 1 and the PLC has the ARCNET address 2 then inthe PLC program in AREC Jobnumber = 1 and in ASEND Jobnumber = 1.4.8.4 Structure of the ARCNET telegramSender Receiver CP DIN MASTERLowMASTERHighCounter Counter Slave FCT Effectivedata03 5F xx 00 aa aa yy zz0 1 2 3 4 5 6 7 8 9 10-256Counter / aaaa :Master / xx :Slave / yy :FCT / zz :Counter, refreshed by the master and written the slave to avoid telegram doubling - thiscounter is not used for the checksum. The counter is the 1. word in the received telegram.This word must be assigned to the 1. word in the response telegramARCNET address of master == JOB-No in AREC/ASEND blockARCNET address of slave, starting from here begins the MODBUS-RTU telegram (seechapter format of Modbus RTU )function codeProcess display and control/ Device Manual/ Issue: 07.0157E

4.8.5 Program example for interfacing a terminal to an ABB PLCInitialising ARCNET+--------+¦AINIT ¦M 255,15-------¦0/1 DONE+-----M 250,00KW 10,00-------¦TO ERR+-----M 250,01¦ NODE+-----MW 250,00¦ STAT+-----MW 250,01¦ DIAG+-----MW 250,02¦ TOS+-----M 250,02¦ TOND+-----MW 250,03¦ TOJN+-----MW 250,04¦ LEV+-----MW 250,05¦ RECO+-----M 250,03+--------+; KW 10,00 = 200 (Equivalent to 200msec)+--------+¦VRZ ¦K 00,01--------¦FREI ¦M 250,02-------¦ZV ¦K 00,00--------¦ZR ¦KW 01,01-------¦DIFF ¦K 00,00--------¦S ¦KW 01,00-------¦ZW ¦K 00,00--------¦R Z+-----MW 130,00+--------+; K 00,00 = 0; K 00,01 = 1; KW 01,00 = 0; KW 01,01 = 1+--------+¦AWT ¦M 250,02-------¦0/1 ¦MW 130,01------¦0 ¦MW 250,03------¦1 +-----MW 130,01+--------+;Sending data packets from buffer to ARCNET+--------+¦APOLL ¦¦ ¦+--------+E58Process display and control/ Device Manual/ Issue: 07.01

ArcNet reading procedure of the PLC;Reading the data packets from ARCNET terminal;(MT -Terminal (Nr.3) -> ABB-SPS Nr.1);N0= ArcNet-Adr. Terminal;#J0=ArcNet-Adr. Terminal+--------+¦AREC ¦# +00001--------------------------------¦#JOB ¦+--------+ ¦ UJOB+-----M 250,04¦ZUDKW ¦ ¦ ¦# +00003-------¦# V+---------------¦N0 ¦+--------+ ¦ ¦#H 005F---------------------------------¦#D0 ¦# +00003--------------------------------¦#J0 ¦# +00125--------------------------------¦#L0 ¦MW 220,00-------------------------------¦MW0 JR0+-----M 250,05+--------+;Declaration of the terminal's own ARCNET address (DIP switch);Decoding the received telegram+--------+ +--------+¦ZUDKW ¦ ¦WAND ¦# +00001-------¦# V+-----¦ ¦ +--------++--------+ ¦ ¦ ¦ ¦=? ¦MW 220,01-----------------+---¦ +-----¦Z1=? ¦¦ +--------+ ¦ Q+-----M 251,14+------------------¦Z2 ¦+--------+;Assigning serial number to send+--------+¦=W ¦MW 220,00------¦ +-----MW 228,00+--------+Process display and control/ Device Manual/ Issue: 07.0159E

5 Setting up5.1 Brief initiationThis section provides the support for starting up the device in a simple way. The setup which is described below isonly suitable for test purposes; for a permanent installation, it is important to follow the guidelines in Chapter"Mounting instructions and installation".For the first test, you will require− 1 MT− 1 lead VB-30 for downloading system and texts via PC− 1 lead for coupling the device to the PLC (according to interface and type of coupling)− 1 floppy disk "Configuration Software SPSPlus (PLCPlus) (Installation Disk 1)Additionally for graphic devices− 1 floppy disk "Drivers" (Installation Disk 2)In addition, a power supply of 24V dc / min. 0,5 A has to be provided.5.1.1 PC ProgramInstall the program on the hard drive of your PC.− Place the floppy disk into drive A: or B:.− Change the drive.− Enter "INSTALL".The installation is now controlled by the menu:− Enter drive and path.− From the components, select the demo configuration of your protocol driver.− Select the interface. Make sure that there is no mouse driver installed for this interface.− Select the further settings according to your system.− Start your program with the input SPSPlus (PLCPlus) .The PC is now ready for programming.5.1.2 MT− Join a 24V power supply to the MT (connector X1)MT-30, MT-40, MT-60:− The device starts with a self test. The coupling mode and firmware version is then indicated− After successful memory test the display indicates"No communication for the control" .Usually a demo configuration is loaded into the device before delivery, so that the device does not have to beconfigured first.MT-45, MT-91, MT-121:− The device will start with a self test, which indicates the version of the initial program loader (IPL) of the MT.− If no system has been loaded, it will have to be loaded first via PLCPlus.− Join PC and MT via the VB-30 lead.− Program the system:− via the configuration menu (subheading "Programming texts/system?")− directly when starting up the device (see Chapter "Setting up / Startup keys").Process display and control/ Device Manual/ Issue: 07.0161E