EN / ACS850-04 (1.1 to 45 kW) Hardware Manual - VAE ProSys sro

EN / ACS850-04 (1.1 to 45 kW) Hardware Manual - VAE ProSys sro

EN / ACS850-04 (1.1 to 45 kW) Hardware Manual - VAE ProSys sro

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

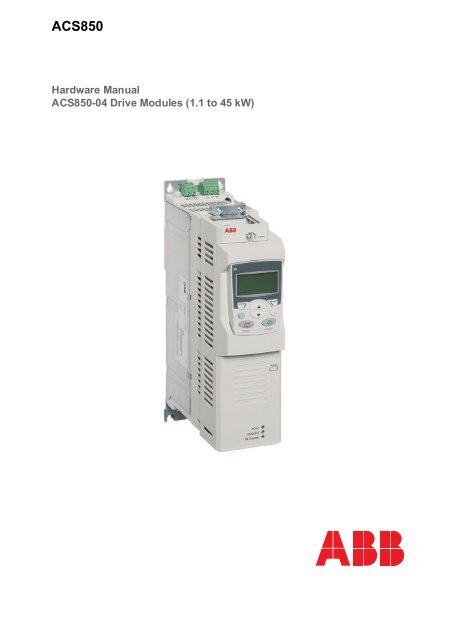

<strong>ACS850</strong>-<strong>04</strong> Drive Modules<strong>1.1</strong> <strong>to</strong> <strong>45</strong> <strong>kW</strong><strong>Hardware</strong> <strong>Manual</strong>3AUA0000<strong>04</strong>5496 Rev D <strong>EN</strong>EFFECTIVE: 2009-07-20© 2009 ABB Oy. All Rights Reserved.

5Safety instructionsWhat this chapter containsThis chapter contains safety instructions which you must follow when installing,operating and servicing the drive. If ignored, physical injury or death may follow, ordamage may occur <strong>to</strong> the drive, the mo<strong>to</strong>r, or driven equipment. Read the safetyinstructions before you work on the unit.Use of warnings and notesThere are four types of safety instructions used in this manual:Electricity warning warns of high voltage which can cause physicalinjury and/or damage <strong>to</strong> the equipment.General warning warns about conditions, other than those caused byelectricity, which can result in physical injury and/or damage <strong>to</strong> theequipment.Electrostatic discharge warning warns of electrostatic discharge whichcan damage the equipment.Hot surface warning warns of component surfaces that may becomehot enough <strong>to</strong> cause burns if <strong>to</strong>uched.Safety instructions

6Installation and maintenance workThese warnings are intended for all who work on the drive, mo<strong>to</strong>r cable or mo<strong>to</strong>r.WARNING! Ignoring the following instructions can cause physical injury or death, ordamage <strong>to</strong> the equipment.Only qualified electricians are allowed <strong>to</strong> install and maintain the drive.• Never work on the drive, the mo<strong>to</strong>r cable or the mo<strong>to</strong>r when input power isapplied. After disconnecting the input power, always wait for 5 minutes <strong>to</strong> let theintermediate circuit capaci<strong>to</strong>rs discharge before you start working on the drive,the mo<strong>to</strong>r or the mo<strong>to</strong>r cable.Always ensure by measuring with a multimeter (impedance at least 1 Mohm)that:1. There is no voltage between the drive input phases U1, V1 and W1 and theground.2. There is no voltage between terminals UDC+ and UDC– and the ground.3. There is no voltage between terminals R+ and R– and the ground.• Drives controlling a permanent magnet mo<strong>to</strong>r: A rotating permanent magnetmo<strong>to</strong>r feeds power <strong>to</strong> the drive causing the drive <strong>to</strong> become live even when it iss<strong>to</strong>pped and the supply power switched off. Before maintenance work on thedrive,– disconnect the mo<strong>to</strong>r from the drive by using a safety switch– prevent the start-up of any other mo<strong>to</strong>rs in the same mechanical system– lock the mo<strong>to</strong>r shaft– measure that the mo<strong>to</strong>r is in fact de-energised, then connect the U2, V2 andW2 terminals of the drive <strong>to</strong> each other and <strong>to</strong> the PE.• Do not work on the control cables when power is applied <strong>to</strong> the drive or <strong>to</strong> theexternal control circuits. Externally supplied control circuits may carrydangerous voltages even when the input power of the drive is switched off.• Do not make any insulation or voltage withstand tests on the drive.• If a drive whose varis<strong>to</strong>rs or internal EMC filters are not disconnected isinstalled on an IT power system (an ungrounded power system or a highresistance grounded [over 30 ohms] power system), the drive will be connected<strong>to</strong> earth potential through the varis<strong>to</strong>rs/filters. This may cause danger ordamage the drive.• If a drive whose varis<strong>to</strong>rs or internal EMC filter are not disconnected is installedon a corner-grounded TN system, the drive will be damaged.Notes:• Even when the mo<strong>to</strong>r is s<strong>to</strong>pped, dangerous voltages are present at the powercircuit terminals U1, V1, W1 and U2, V2, W2, and UDC+, UDC–, R+, R–.Safety instructions

7• Depending on the external wiring, dangerous voltages (115 V, 220 V or 230 V)may be present on the terminals of the relay outputs of the drive.• The drive supports the “Safe Torque Off” function. See page 42.WARNING! Ignoring the following instructions can cause physical injury or death, ordamage <strong>to</strong> the equipment.• The drive is not field repairable. Never attempt <strong>to</strong> repair a malfunctioning drive;contact your local ABB representative or Authorized Service Center forreplacement.• Make sure that dust from drilling does not enter the drive during the installation.Electrically conductive dust inside the drive may cause damage or lead <strong>to</strong>malfunction.• Ensure sufficient cooling.WARNING! The printed circuit boards contain components sensitive <strong>to</strong> electrostaticdischarge. Wear a grounding wrist band when handling the boards. Do not <strong>to</strong>uchthe boards unnecessarily.Safety instructions

9Table of contentsSafety instructionsWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Use of warnings and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Installation and maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Start-up and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Table of contentsAbout this manualWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15Intended audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15Categorization according <strong>to</strong> the frame size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15Categorization according <strong>to</strong> the + code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15Installation and commissioning flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19Operation principle and hardware descriptionWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21Operation principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21Main circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21Mo<strong>to</strong>r control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23Power connections and control interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24Type designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26Planning the cabinet assemblyWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27Cabinet construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27Disposition of the devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27Grounding of mounting structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27Main dimensions and free space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28Cooling and degrees of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29Preventing the recirculation of hot air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31Outside the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31Inside the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31Cabinet heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31Table of contents

10Mechanical installationContents of the package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33Delivery check and drive module identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35Requirements for the installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36Direct wall mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36DIN rail mounting (Frames A and B only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36Mains choke installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37EMC filter installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37Braking resis<strong>to</strong>r installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37Planning the electrical installationWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39Mo<strong>to</strong>r selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39Supply connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39Supply disconnecting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39Other regions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40Thermal overload and short circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40Thermal overload protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40Protection against short-circuit in mo<strong>to</strong>r cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40Protection against short-circuit in the supply cable or the drive . . . . . . . . . . . . . . . . . . . . . . .40Operating time of the fuses and circuit breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40Circuit breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40Mo<strong>to</strong>r thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40Ground fault protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41Emergency s<strong>to</strong>p devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41Safe Torque Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42Selecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43General rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43Alternative power cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44Mo<strong>to</strong>r cable shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44Protecting the relay output contacts and attenuating disturbances in case of inductive loads . . . . .44Considering the PELV requirements at sites above 2000 m (6562 ft) . . . . . . . . . . . . . . . . . . . . . . .<strong>45</strong>Selecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46Relay cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46Control panel cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46Connection of a mo<strong>to</strong>r temperature sensor <strong>to</strong> the drive I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46Routing the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46Control cable ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47Electrical installationWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49Removing the cover assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49Checking the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51Table of contents

12Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80Cooling characteristics, noise levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80Supply cable fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81AC input (supply) connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82DC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82Mo<strong>to</strong>r connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82JCU Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85Degrees of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86Applicable standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88Compliance with the European Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88Compliance with the European EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88Compliance with <strong>EN</strong> 61800-3 (20<strong>04</strong>), category C2 . . . . . . . . . . . . . . . . . . . . . . . . . . . .88Compliance with <strong>EN</strong> 61800-3 (20<strong>04</strong>), category C3 . . . . . . . . . . . . . . . . . . . . . . . . . . . .89Compliance with <strong>EN</strong> 61800-3 (20<strong>04</strong>), category C4 . . . . . . . . . . . . . . . . . . . . . . . . . . . .89Compliance with the Machinery Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89C-Tick marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89UL marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90UL checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90Patent protection in the US . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90Mains chokesWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91When is a mains choke required? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91Selection table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91Installation guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92EMC filtersWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93When is an EMC filter required? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93Selection table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94JFI-A1/JFI-B1 (Frame A/B, category C3) installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95Installation guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95Mounting procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96JFI-A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96JFI-B1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97JFI-0x (Frames A…D, category C2) installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98Installation guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98Table of contents

13du/dt and common mode filteringWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99When is du/dt or common mode filtering required? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99Filter types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100du/dt filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100Common mode filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101du/dt filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101Common mode filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101Resis<strong>to</strong>r brakingWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103Braking choppers and resis<strong>to</strong>rs with the <strong>ACS850</strong>-<strong>04</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103Braking choppers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103Braking resis<strong>to</strong>r selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103Chopper data / Resis<strong>to</strong>r selection table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1<strong>04</strong>Resis<strong>to</strong>r installation and wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105Contac<strong>to</strong>r protection of drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105Braking circuit commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106Dimension drawingsWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107Frame size A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108Frame size B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109Frame size C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110Frame size D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111Mains chokes (type CHK-0x) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112EMC filters (type JFI-x1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113JFI-A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113JFI-B1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114EMC filters (type JFI-0x) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115Braking resis<strong>to</strong>rs (type JBR-xx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117Further informationProduct and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119Table of contents

15About this manualWhat this chapter containsCompatibilityIntended audienceThis chapter describes the intended audience and contents of this manual. Itcontains a flowchart of steps in checking the delivery, installing and commissioningthe drive. The flowchart refers <strong>to</strong> chapters/sections in this manual and othermanuals.The manual is compatible with <strong>ACS850</strong>-<strong>04</strong> drive modules of frame sizes A <strong>to</strong> D.This manual is intended for people who plan the installation, install, commission, useand service the drive. Read the manual before working on the drive. The reader isexpected <strong>to</strong> know the fundamentals of electricity, wiring, electrical components andelectrical schematic symbols.This manual is written for readers worldwide. Both SI and imperial units are shownwherever appropriate.Categorization according <strong>to</strong> the frame sizeSome instructions, technical data and dimensional drawings which concern onlycertain frame sizes are marked with the symbol of the frame size A, B, C or D. Theframe size is marked on the drive designation label. The frame size of each drivetype is also indicated in the rating tables in chapter Technical data.Categorization according <strong>to</strong> the + codeThe instructions, technical data and dimensional drawings which concern onlycertain optional selections are marked with + codes, e.g. +L500. The optionsincluded in the drive can be identified from the + codes visible on the typedesignation label of the drive. The + code selections are listed in chapter Operationprinciple and hardware description under Type designation.ContentsThe chapters of this manual are briefly described below.Safety instructions give safety instructions for the installation, commissioning,operation and maintenance of the drive.About this manual lists the steps in checking the delivery and installing andcommissioning the drive and refers <strong>to</strong> chapters/sections in this manual and othermanuals for particular tasks.About this manual

16Operation principle and hardware description describes the drive module.Planning the cabinet assembly guides in planning the installation of the drive modulein<strong>to</strong> a user-defined cabinet.Mechanical installation instructs how <strong>to</strong> place and mount the drive.Planning the electrical installation instructs on the mo<strong>to</strong>r and cable selection, theprotections and the cable routing.Electrical installation instructs on how <strong>to</strong> wire the drive.Installation checklist contains a list for checking the mechanical and electricalinstallation of the drive.Maintenance lists periodic maintenance actions along with work instructions.Technical data contains the technical specifications of the drive, e.g. the ratings,sizes and technical requirements, provisions for fulfilling the requirements for CEand other markings and warranty policy.Mains chokes details the optional mains chokes available for the drive.EMC filters details the EMC filtering options available for the drive.du/dt and common mode filtering lists the du/dt and common mode filtering optionsavailable for the drive.Resis<strong>to</strong>r braking describes how <strong>to</strong> select, protect and wire braking resis<strong>to</strong>rs.Dimension drawings contains the dimensional drawings of the drive and connectedequipment.About this manual

17Installation and commissioning flowchartTaskIdentify the frame size of your drive: A, B, C or D.SeeDrive designation label or Technical data:Ratings (page 77)Plan the installation.Check the ambient conditions, ratings, requiredcooling air flow, input power connection, compatibilityof the mo<strong>to</strong>r, mo<strong>to</strong>r connection, and other technicaldata.Select the cables.Planning the cabinet assembly (page 27)Planning the electrical installation (page 39)Technical data (page 77)Option manual (if optional equipment isincluded)Unpack and check the units.Check that all necessary optional modules andequipment are present and correct.Only intact units may be started up.Mechanical installation: Contents of thepackage (page 33)If the converter has been non-operational formore than one year, the converter DC linkcapaci<strong>to</strong>rs need <strong>to</strong> be reformed. Ask ABB formore information.Check the installation site.Mechanical installation: Before installation(page 35)Technical data (page 77)Install the drive in a cabinet.Mechanical installation: Installation procedure(page 36)Route the cables.Planning the electrical installation: Routing thecables (page 46)Check the insulation of the supply cable, the mo<strong>to</strong>rand the mo<strong>to</strong>r cable, and the resis<strong>to</strong>r cable (ifpresent).Electrical installation: Checking the insulation ofthe assembly (page 51)If the drive is about <strong>to</strong> be connected <strong>to</strong> an IT(ungrounded) system, disconnect the internalvaris<strong>to</strong>rs and EMC filters. Also note that using anEMC filter is not allowed in an IT (ungrounded]system.Safety instructions: Installation andmaintenance work (page 6)Electrical installation: Power cable connection(page 52)About this manual

18TaskConnect the power cables.Connect the control and the auxiliary control cables.SeeElectrical installation: Power cable connection:(page 52) and Connecting the control cables:(page 62)For optional equipment:Mains chokes (page 91)EMC filters (page 93)Resis<strong>to</strong>r braking (page 103)<strong>Manual</strong>s for any optional equipmentCheck the installation. Installation checklist (page 69)Commission the drive.Appropriate Firmware <strong>Manual</strong>Commission the braking chopper if required. Resis<strong>to</strong>r braking (page 103)Operating of the drive: start, s<strong>to</strong>p, speed control etc.Appropriate Firmware <strong>Manual</strong>About this manual

19Terms and abbreviationsTerm/AbbreviationCHK-xxEMCFIO-01FIO-11FIO-21F<strong>EN</strong>-01F<strong>EN</strong>-11F<strong>EN</strong>-21F<strong>EN</strong>-31FCAN-0xFDNA-0xF<strong>EN</strong>A-0xFLON-0xFPBA-0xExplanationSeries of optional mains chokes for the <strong>ACS850</strong>.Electromagnetic Compatibility.Optional digital I/O extension for the <strong>ACS850</strong>.Optional analog I/O extension for the <strong>ACS850</strong>.Optional analog/digital I/O extension for the <strong>ACS850</strong>.Optional TTL encoder interface for the <strong>ACS850</strong>.Optional absolute encoder interface for the <strong>ACS850</strong>.Optional resolver interface for the <strong>ACS850</strong>.Optional HTL encoder interface for the <strong>ACS850</strong>.Optional CANopen adapter for the <strong>ACS850</strong>.Optional DeviceNet adapter for the <strong>ACS850</strong>.Optional Ethernet/IP adapter for the <strong>ACS850</strong>.Optional LONWORKS ® adapter for the <strong>ACS850</strong>.Optional PROFIBUS DP adapter for the <strong>ACS850</strong>.Frame (size) Size of the drive module. This manual deals with <strong>ACS850</strong>-<strong>04</strong> frames A, B,C and D. To determine the frame size of a drive module, refer <strong>to</strong> the drivedesignation label attached <strong>to</strong> the drive, or the rating tables in chapterTechnical data.FSCA-0xIGBTI/OJBR-xxJCUJFI-xxJMURFIOptional Modbus adapter for the <strong>ACS850</strong>.Insulated Gate Bipolar Transis<strong>to</strong>r; a voltage-controlled semiconduc<strong>to</strong>r typewidely used in inverters due <strong>to</strong> their easy controllability and high switchingfrequency.Input/Output.Series of optional braking resis<strong>to</strong>rs for the <strong>ACS850</strong>.The control unit of the drive module. The JCU is installed on <strong>to</strong>p of thepower unit. The external I/O control signals are connected <strong>to</strong> the JCU, oroptional I/O extensions mounted on it.Series of optional EMC filters for the <strong>ACS850</strong>.The memory unit attached <strong>to</strong> the control unit of the drive.Radio-frequency interference.About this manual

20About this manual

21Operation principle and hardware descriptionWhat this chapter containsOperation principleThis chapter describes the operating principle and construction of the <strong>ACS850</strong>-<strong>04</strong>drive module in short.Main circuitThe main circuit of the drive module is shown below.AC supplyCHK-xx mains choke (see chapter Mains chokeson page 91)UDC+ UDC-U1 V1 W1~=+ –<strong>ACS850</strong>-<strong>04</strong>JFI-xx EMC filter (see chapter EMC filters on page93)RectifierCapaci<strong>to</strong>r bankInverter=~U2 V2 W2 R- R+Braking chopper (see chapter Resis<strong>to</strong>r braking onpage 103)NOCHxxxx-xx du/dt filter (seechapter du/dt and common modefiltering on page 99)Mo<strong>to</strong>r outputJBR-xx braking resis<strong>to</strong>r (see chapter Resis<strong>to</strong>rbraking on page 103)Operation principle and hardware description

23LayoutDrive module, frame size AJCU Control Unit with coverassembly removedDC connectionAC supply connectionPower unitJCU Control Unit withoptional coverassemblyExternal 24 V powerinputRelay outputs+24 V outputDigital inputsSlots 1 and 2 foroptional I/O extensionsand encoder/resolverinterfaceDigital input/outputsAnalog inputsAnalog outputsSlot 3 for optionalfieldbus adapterMo<strong>to</strong>r and brakingresis<strong>to</strong>r connectionsDrive-<strong>to</strong>-drive linkSafe Torque OffconnectionControl panel/PCconnectionMemory unit (JMU)Operation principle and hardware description

24Power connections and control interfacesThe diagram shows the power connections and control interfaces of the drive.Slot 1 / Slot 2FIO-01 (Digital I/Oextension)FIO-11 (Analog I/Oextension)FIO-21 (Digital/Analog I/Oextension)F<strong>EN</strong>-01 (Incremental [TTL]encoder interface)F<strong>EN</strong>-11 (Absolute encoderinterface)F<strong>EN</strong>-21 (Resolver interface)F<strong>EN</strong>-31 (Incremental [HTL]encoder interface)Note: No twoencoder/resolver interfacesof the same type can beconnected at a timeSlot 3 (Fieldbus adapter)FCAN-0x (CANopen)FDNA-0x (DeviceNet)F<strong>EN</strong>A-0x (Ethernet/IP)FLON-01 (LONWORKS ® )FSCA-01 (Modbus)FPBA-0x (PROFIBUS DP)FxxFxxFxxxSlot 1Slot 2Slot 3Control unit (JCU)Memory unit (seepage 75)External power inputXPOW*Relay outputs (3 pcs) XRO1…324 V DC output XD24*Digital inputs (6 pcs)XDI*Digital input/outputs (2 pcs) XDIO*Analog inputsXAI*Analog outputsXAODrive-<strong>to</strong>-drive linkXD2DSafe Torque OffXSTOControl panel or PCFor more information on theseconnections, see page 62. Forspecifications, see page 83.*Programmable3-phase powersupplyPEL1L2L3PEU1V1W1Power unitBrakingchopperR-UDC+R+ UDC-U2V2W2M3 ~AC mo<strong>to</strong>rBraking resis<strong>to</strong>r (optional)t°Operation principle and hardware description

25Type designationThe type designation contains information on the specifications and configuration ofthe drive. The first digits from left express the basic configuration (e.g. <strong>ACS850</strong>-<strong>04</strong>-<strong>04</strong>A8-5). The optional selections are given thereafter, preceded by + signs (e.g.+L501). The main selections are described below. Not all selections are necessarilyavailable for all types; refer <strong>to</strong> <strong>ACS850</strong> Ordering Information, available on request.See also section Delivery check and drive module identification on page 35.SelectionAlternativesProduct series<strong>ACS850</strong> product seriesType <strong>04</strong> Drive module. When no options are selected: IP20 (UL Open Type), plainfront cover, no control panel, no mains choke (frames A and B), internalmains choke (frames C and D), no EMC filter, internal braking chopper,coated boards, Safe Torque Off, Standard Control Program, QuickInstallation Guide (multilingual), Quick Start-up Guide (multilingual), CDcontaining all manualsSizeRefer <strong>to</strong> Technical data: Ratings.Voltage range 5 380…480 V+ optionsFilters E... +E200: EMC filter, C3, 2nd Environment, Unrestricted (Earthed network)(External with frames A and B, internal with frames C and D)Control panel and frontcover optionsJ... +0C168: No drive module front cover, no control panel+J400: Control panel mounted on drive module front cover+J410: Control panel with door mounting platform kit including 3 m cable+J414: Control panel mounting platform on drive module (no controlpanel included)Fieldbus K... +K<strong>45</strong>1: FDNA-01 DeviceNet adapter+K<strong>45</strong>4: FPBA-01 PROFIBUS DP adapter+K<strong>45</strong>7: FCAN-01 CANopen adapter+K466: F<strong>EN</strong>A-01 Ethernet/IP adapter+K<strong>45</strong>8: FSCA-01 Modbus adapterI/O extensions andfeedback interfacesL...+L500: FIO-11 analog I/O extension+L501: FIO-01 digital I/O extension+L502: F<strong>EN</strong>-31 HTL encoder interface+L516: F<strong>EN</strong>-21 resolver interface+L517: F<strong>EN</strong>-01 TTL encoder interface+L518: F<strong>EN</strong>-11 absolute encoder interface+L519: FIO-21 analog/digital I/O extensionPrograms N... +N697: Crane control programSpecialities P... +P9<strong>04</strong>: Extended warrantyPrinted hardware andfirmware manuals inspecified language(English manuals may bedelivered even if anotherlanguage is selected)R...+R700: English+R701: German+R702: Italian+R703: Dutch+R7<strong>04</strong>: Danish+R705: Swedish+R706: Finnish+R707: French+R708: Spanish+R709: Portuguese+R711: Russian+R712: Chinese+R714: Turkish00579470Operation principle and hardware description

26Ordering informationFor a complete listing of options and accessories available for the <strong>ACS850</strong>-<strong>04</strong>, refer<strong>to</strong> <strong>ACS850</strong> Ordering Information (available on request).Operation principle and hardware description

27Planning the cabinet assemblyWhat this chapter containsThis chapter guides in planning the installation of a drive module in<strong>to</strong> a user-definedcabinet. The issues discussed are essential for safe and trouble-free use of the drivesystem.Note: The installation examples in this manual are provided only <strong>to</strong> help the installerin designing the installation. Please note that the installation must, however,always be designed and made according <strong>to</strong> applicable local laws andregulations. ABB does not assume any liability whatsoever for any installationwhich breaches the local laws and/or other regulations.Cabinet constructionThe cabinet frame must be sturdy enough <strong>to</strong> carry the weight of the drivecomponents, control circuitry and other equipment installed in it.The cabinet must protect the drive module against contact and meet therequirements for dust and humidity (see the chapter Technical data).Disposition of the devicesFor easy installation and maintenance, a spacious layout is recommended. Sufficientcooling air flow, obliga<strong>to</strong>ry clearances, cables and cable support structures allrequire space.For a layout example, see section Cooling and degrees of protection below.Grounding of mounting structuresMake sure all cross-members or shelves on which drive system components aremounted are properly grounded and the connecting surfaces left unpainted.Note: Ensure that the components are properly grounded through their fasteningpoints <strong>to</strong> the installation base.Note: It is recommended that the EMC filter (if present) and the drive module bemounted on the same mounting plate.Planning the cabinet assembly

28Main dimensions and free space requirementsThe modules can be installed side by side. The dimensions of the drive modules aswell as free space requirements are presented below. For more details, refer <strong>to</strong>chapter Dimension drawings.Frame DFrame C Frame B Frame APlanning the cabinet assembly

29Note: EMC filters of type JFI-x1 mounted directly above the drive module do notincrease the free space requirements. (For EMC filters of type JFI-0x, see thedimension drawing of the filters on page 115.)200 mm [7.9”]300 mm [12”]The temperature of the cooling air entering the unit must not exceed the maximumallowed ambient temperature (see Ambient conditions in the chapter Technicaldata). Consider this when installing heat-generating components (such as otherdrives, mains chokes and braking resis<strong>to</strong>rs) nearby.Cooling and degrees of protectionThe cabinet must have enough free space for the components <strong>to</strong> ensure sufficientcooling. Observe the minimum clearances given for each component.The air inlets and outlets must be equipped with gratings that• guide the air flow• protect against contact• prevent water splashes from entering the cabinet.The drawing below shows two typical cabinet cooling solutions. The air inlet is at thebot<strong>to</strong>m of the cabinet, while the outlet is at the <strong>to</strong>p, either on the upper part of thedoor or on the roof.Planning the cabinet assembly

30Air outletAir inletArrange the cooling of the modules so that the requirements given in chapterTechnical data are met:• cooling air flowNote: The values in Technical data apply <strong>to</strong> continuous nominal load. If the load is less thannominal, less cooling air is required.• allowed ambient temperature.Make sure the air inlets and outlets are sufficient in size. Please note that in addition<strong>to</strong> the power loss of the drive module, the heat dissipated by cables and otheradditional equipment must also be ventilated.The internal cooling fans of the modules are usually sufficient <strong>to</strong> keep the componenttemperatures low enough in IP22 cabinets.In IP54 cabinets, thick filter mats are used <strong>to</strong> prevent water splashes from enteringthe cabinet. This entails the installation of additional cooling equipment, such as ahot air exhaust fan.The installation site must be sufficiently ventilated.Planning the cabinet assembly

31Preventing the recirculation of hot airCabinet (side view)HOTAREAMain airflow outAir baffle platesCOOL AREAMain airflow inCabinet heatersOutside the cabinetPrevent hot air circulation outside the cabinet by leading the outcoming hot air awayfrom the area where the inlet air <strong>to</strong> the cabinet is taken. Possible solutions are listedbelow:• gratings that guide air flow at the air inlet and outlet• air inlet and outlet at different sides of the cabinet• cool air inlet in the lower part of the front door and an extra exhaust fan on theroof of the cabinet.Inside the cabinetPrevent hot air circulation inside the cabinet with leak-proof air baffle plates. Nogaskets are usually required.Use a cabinet heater if there is a risk of condensation in the cabinet. Although theprimary function of the heater is <strong>to</strong> keep the air dry, it may also be required forheating at low temperatures. When placing the heater, follow the instructionsprovided by its manufacturer.Planning the cabinet assembly

32Planning the cabinet assembly

33Mechanical installationContents of the packageThe drive is delivered in a cardboard box. To open, remove any banding and lift the<strong>to</strong>p off the box.Mechanical installation

34The box contains:• <strong>ACS850</strong>-<strong>04</strong> drive module, with fac<strong>to</strong>ry-installed options• three cable clamp plates (two for power cabling, one for control cabling) withscrews• screw-type terminal blocks <strong>to</strong> be attached <strong>to</strong> the headers on the JCU Control Unitand the power unit• EMC filter (+E200) if ordered (with frames A and B only)• control panel mounting kit (+J410) if ordered• Printed Quick Guides, printed manuals if ordered, manuals CD.EMC/RFI filter, control panelmounting kit(Underneath the drive module –lift out the module and openleft-hand side flap <strong>to</strong> access)Compartments forcable clamp platesCompartment forterminal blocks andmanuals<strong>ACS850</strong>-<strong>04</strong> drive moduleMechanical installation

35Delivery check and drive module identificationCheck that there are no signs of damage. Before attempting installation andoperation, check the information on the type designation label of the drive module <strong>to</strong>verify that the unit is of the correct type. The label is located on the left-hand side ofthe drive module.Type code + options(see page 25)CompliancemarkingsFrame sizeRatingsSerial numberBefore installationThe first digit of the serial number refers <strong>to</strong> the manufacturing plant. The 2nd and 3rddigit indicate the year of manufacture, while the 4th and 5th digits indicate the week.Digits 6 <strong>to</strong> 10 are a running integer starting every week at 00001.Check the installation site according <strong>to</strong> the requirements below. Refer <strong>to</strong> Dimensiondrawings for frame details.Requirements for the installation siteSee Technical data for the allowed operation conditions of the drive.The <strong>ACS850</strong>-<strong>04</strong> is <strong>to</strong> be mounted in an upright position. The wall the drive is <strong>to</strong> bemounted on must be as even as possible, of non-flammable material and strongenough <strong>to</strong> carry the weight of the drive. The floor/material below the drive must benon-flammable.Mechanical installation

36Installation procedureDirect wall mounting1. Mark the locations for the four holes. The mounting points are shown inDimension drawings.2. Fix the screws or bolts <strong>to</strong> the marked locations.3. Position the drive on<strong>to</strong> the screws on the wall. Note: Only lift the drive by itschassis.4. Tighten the screws.DIN rail mounting (Frames A and B only)1. Click the drive <strong>to</strong> the rail as shown in Figure a below. To detach the drive, pressthe release lever on <strong>to</strong>p of the drive as shown in Figure b.2. Fasten the lower edge of the drive <strong>to</strong> the mounting base through the two fasteningpoints.ab12Mechanical installation

37Mains choke installationSee the chapter Mains chokes on page 91.EMC filter installationSee the chapter EMC filters on page 93.Braking resis<strong>to</strong>r installationSee the chapter Resis<strong>to</strong>r braking on page 103.Mechanical installation

38Mechanical installation

39Planning the electrical installationWhat this chapter containsMo<strong>to</strong>r selectionSupply connectionThis chapter contains the instructions that you must follow when selecting the mo<strong>to</strong>r,cables, protections, cable routing and way of operation for the drive. If therecommendations given by ABB are not followed, the drive may experienceproblems that the warranty does not cover.Note: The installation must always be designed and made according <strong>to</strong> applicablelocal laws and regulations. ABB does not assume any liability whatsoever for anyinstallation which breaches the local laws and/or other regulations.Select the (3-phase AC induction) mo<strong>to</strong>r according <strong>to</strong> the rating table in the chapterTechnical data. The table lists the typical mo<strong>to</strong>r power for each drive type.Only one permanent magnet synchronous mo<strong>to</strong>r can be connected <strong>to</strong> the inverteroutput. It is recommended <strong>to</strong> install a safety switch between the permanent magnetmo<strong>to</strong>r and the drive output in order <strong>to</strong> isolate the mo<strong>to</strong>r from the drive duringmaintenance work on the drive.Use a fixed connection <strong>to</strong> the AC power line.WARNING! As the leakage current of the device typically exceeds 3.5 mA, a fixedinstallation is required according <strong>to</strong> IEC 61800-5-1.Supply disconnecting deviceInstall a hand-operated input disconnecting device (disconnecting means) betweenthe AC power source and the drive. The disconnecting device must be of a type thatcan be locked <strong>to</strong> the open position for installation and maintenance work.EuropeIf the drive is used in an application which must meet the European Union MachineryDirective according <strong>to</strong> standard <strong>EN</strong> 602<strong>04</strong>-1 Safety of Machinery, the disconnectingdevice must be one of the following types:• a switch-disconnec<strong>to</strong>r of utilization category AC-23B (<strong>EN</strong> 60947-3)• a disconnec<strong>to</strong>r that has an auxiliary contact that in all cases causes switchingdevices <strong>to</strong> break the load circuit before the opening of the main contacts of thedisconnec<strong>to</strong>r (<strong>EN</strong> 60947-3)Planning the electrical installation

40• a circuit breaker suitable for isolation in accordance with <strong>EN</strong> 60947-2.Other regionsThe disconnecting means must conform <strong>to</strong> the applicable safety regulations.Thermal overload and short circuit protectionThermal overload protectionThe drive protects itself and the input and mo<strong>to</strong>r cables against thermal overloadwhen the cables are dimensioned according <strong>to</strong> the nominal current of the drive. Noadditional thermal protection devices are needed.WARNING! If the drive is connected <strong>to</strong> multiple mo<strong>to</strong>rs, a separate thermal overloadswitch or a circuit breaker must be used for protecting each cable and mo<strong>to</strong>r. Thesedevices may require a separate fuse <strong>to</strong> cut off the short-circuit current.Protection against short-circuit in mo<strong>to</strong>r cableThe drive protects the mo<strong>to</strong>r cable and the mo<strong>to</strong>r in a short-circuit situation when themo<strong>to</strong>r cable is dimensioned according <strong>to</strong> the nominal current of the drive. Noadditional protection devices are needed.Protection against short-circuit in the supply cable or the driveProtect the supply cable with fuses or circuit breakers. Fuse recommendations aregiven in the chapter Technical data. When placed at the distribution board, standardIEC gG fuses or UL type T fuses will protect the input cable in short-circuit situations,restrict drive damage and prevent damage <strong>to</strong> adjoining equipment in case of a shortcircuit inside the drive.Operating time of the fuses and circuit breakersCheck that the operating time of the fuse is below 0.5 seconds. The operatingtime depends on the type, the supply network impedance, and the cross-sectionalarea, material and length of the supply cable. US fuses must be of the “non-timedelay” type.Circuit breakersThe protective characteristics of circuit breakers depend on the supply voltage aswell as the type and construction of the breakers. There are also limitationspertaining <strong>to</strong> the short-circuit capacity of the supply network. Your local ABBrepresentative can help you in selecting the breaker type when the supply networkcharacteristics are known.Mo<strong>to</strong>r thermal protectionAccording <strong>to</strong> regulations, the mo<strong>to</strong>r must be protected against thermal overload andthe current must be switched off when overloading is detected. The drive includes amo<strong>to</strong>r thermal protection function that protects the mo<strong>to</strong>r and switches off the currentwhen necessary. Depending on a drive parameter value, the function either moni<strong>to</strong>rsPlanning the electrical installation

41a calculated temperature value (based on a mo<strong>to</strong>r thermal model) or an actualtemperature indication given by mo<strong>to</strong>r temperature sensors. The user can tune thethermal model further by feeding in additional mo<strong>to</strong>r and load data.PTC sensors can be connected directly <strong>to</strong> the <strong>ACS850</strong>-<strong>04</strong>. See page 64 in thismanual, and the appropriate Firmware <strong>Manual</strong> for the parameter settings concerningmo<strong>to</strong>r thermal protection.Ground fault protectionThe drive is equipped with an internal ground fault protective function <strong>to</strong> protect theunit against ground faults in the mo<strong>to</strong>r and the mo<strong>to</strong>r cable. This is not a personalsafety or a fire protection feature. The ground fault protective function can bedisabled with a parameter, refer <strong>to</strong> the appropriate Firmware <strong>Manual</strong>.The optional EMC filter includes capaci<strong>to</strong>rs connected between the main circuit andthe frame. These capaci<strong>to</strong>rs and long mo<strong>to</strong>r cables increase the ground leakagecurrent and may cause fault current circuit breakers <strong>to</strong> function.Emergency s<strong>to</strong>p devicesFor safety reasons, install the emergency s<strong>to</strong>p devices at each opera<strong>to</strong>r controlstation and at other operating stations where emergency s<strong>to</strong>p may be needed.Note: Pressing the s<strong>to</strong>p key on the control panel of the drive does not generate anemergency s<strong>to</strong>p of the mo<strong>to</strong>r or separate the drive from dangerous potential.Planning the electrical installation

42Safe Torque OffThe drive supports the Safe Torque Off function according <strong>to</strong> standardspr<strong>EN</strong> 61800-5-2; <strong>EN</strong> 954-1 (1997); IEC/<strong>EN</strong> 602<strong>04</strong>-1: 1997; <strong>EN</strong> 61508: 2002 and<strong>EN</strong> 1037: 1996.The Safe Torque Off function disables the control voltage of the powersemiconduc<strong>to</strong>rs of the drive output stage, thus preventing the inverter fromgenerating the voltage required <strong>to</strong> rotate the mo<strong>to</strong>r (see diagram below). By usingthis function, short-time operations (like cleaning) and/or maintenance work on nonelectricalparts of the machinery can be performed without switching off the powersupply <strong>to</strong> the drive.<strong>ACS850</strong>-<strong>04</strong>+24 VXSTO:1XSTO:2Safe Torque Offconnection on JCUActivationswitchXSTO:3XSTO:4UDC+ControlcircuitOutput stage(1 phase shown)U2/V2/W2UDC-Notes:• The contacts of the activation switch mus<strong>to</strong>pen/close within 200 ms of each other.• The maximum cable length between the driveand the activation switch is 25 m (82 ft)WARNING! The Safe Torque Off function does not disconnect the voltage of themain and auxiliary circuits from the drive. Therefore maintenance work on electricalparts of the drive or the mo<strong>to</strong>r can only be carried out after isolating the drive systemfrom the main supply.Note: If a running drive is s<strong>to</strong>pped by using the Safe Torque Off function, the drivewill cut off the mo<strong>to</strong>r supply voltage and the mo<strong>to</strong>r will coast <strong>to</strong> s<strong>to</strong>p.For further information on the function, refer <strong>to</strong> Safe Torque Off Function, ApplicationGuide (3AFE68929814 [English]).Planning the electrical installation

43Selecting the power cablesGeneral rulesDimension the supply (input power) and mo<strong>to</strong>r cables according <strong>to</strong> localregulations.• The cable must be able <strong>to</strong> carry the drive load current. See the chapter Technicaldata for the rated currents.• The cable must be rated for at least 70 °C (US: 75 °C [167 °F]) maximumpermissible temperature of conduc<strong>to</strong>r in continuous use.• The inductance and impedance of the PE conduc<strong>to</strong>r/cable (grounding wire) mustbe rated according <strong>to</strong> permissible <strong>to</strong>uch voltage appearing under fault conditions(so that the fault point voltage will not rise excessively when a ground faul<strong>to</strong>ccurs).• 600 VAC cable is accepted for up <strong>to</strong> 500 VAC.• Refer <strong>to</strong> the chapter Technical data for EMC requirements.Symmetrical shielded mo<strong>to</strong>r cable must be used (see the figure below) <strong>to</strong> meet theEMC requirements of the CE and C-tick marks.A four-conduc<strong>to</strong>r system is allowed for input cabling, but shielded symmetrical cableis recommended. To operate as a protective conduc<strong>to</strong>r, the shield conductivity mustbe as follows when the protective conduc<strong>to</strong>r is made of the same metal as the phaseconduc<strong>to</strong>rs:Cross-sectional area of one phase conduc<strong>to</strong>r(S)S < 16 mm 2Minimum cross-sectional area of protectiveconduc<strong>to</strong>r (S p )S16 mm 2 < S < 35 mm 2 16 mm 235 mm 2 < S S/2Compared <strong>to</strong> a four-conduc<strong>to</strong>r system, the use of symmetrical shielded cablereduces electromagnetic emission of the whole drive system as well as mo<strong>to</strong>rbearing currents and wear.The mo<strong>to</strong>r cable and its PE pigtail (twisted shield) should be kept as short aspossible in order <strong>to</strong> reduce electromagnetic emission, as well as stray currentsoutside the cable and capacitive current.Planning the electrical installation

44Alternative power cable typesPower cable types that can be used with the drive are represented below.Mo<strong>to</strong>r cable(also recommended for supply cabling)Symmetrical shielded cable: three phase conduc<strong>to</strong>rs anda concentric or otherwise symmetrically constructed PEconduc<strong>to</strong>r, and a shieldNote: A separate PE conduc<strong>to</strong>r is required if theconductivity of the cable shield is not sufficient for thepurpose. See section General rules above.PE conduc<strong>to</strong>rand shieldShieldShieldPEPEAllowed for supply cablingShieldA four-conduc<strong>to</strong>r system: three phase conduc<strong>to</strong>rs anda protective conduc<strong>to</strong>r.PEPEMo<strong>to</strong>r cable shieldTo function as a protective conduc<strong>to</strong>r, the shield must have the same cross-sectionalarea as a phase conduc<strong>to</strong>r when they are made of the same metal.To effectively suppress radiated and conducted radio-frequency emissions, theshield conductivity must be at least 1/10 of the phase conduc<strong>to</strong>r conductivity. Therequirements are easily met with a copper or aluminium shield. The minimumrequirement of the mo<strong>to</strong>r cable shield of the drive is shown below. It consists of aconcentric layer of copper wires with an open helix of copper tape. The better andtighter the shield, the lower the emission level and the bearing currents.Insulation jacketCopper wire screenHelix of copper tapeInner insulationCable coreProtecting the relay output contacts and attenuating disturbances in caseof inductive loadsInductive loads (relays, contac<strong>to</strong>rs, mo<strong>to</strong>rs) cause voltage transients when switchedoff.The relay outputs on the drive are protected with varis<strong>to</strong>rs (250 V) agains<strong>to</strong>vervoltage peaks. In addition, it is highly recommended <strong>to</strong> equip inductive loadsPlanning the electrical installation

<strong>45</strong>with noise attenuating circuits (varis<strong>to</strong>rs, RC filters [AC] or diodes [DC]) in order <strong>to</strong>minimize the electromagnetic emissions at switch-off. If not suppressed, thedisturbances may connect capacitively or inductively <strong>to</strong> other conduc<strong>to</strong>rs in thecontrol cable and form a risk of malfunction in other parts of the system.Install the protective component as close <strong>to</strong> the inductive load as possible, not at therelay output.Varis<strong>to</strong>rRelay output230 VACRC filterRelay output230 VACDiodeRelay output24 VDCConsidering the PELV requirements at sites above 2000 m (6562 ft)The relay outputs of the drive do not fulfill the Protective Extra Low Voltage (PELV)requirements at installation sites above 4000 meters (13123 feet) if used with avoltage greater than 48 V. At installation sites between 2000 meters (6562 feet) and4000 meters (13123 feet), PELV requirements are not fulfilled if one or two relayoutputs are used with a voltage greater than 48 V and the remaining relay output(s)are used with a voltage lower than 48 V.Planning the electrical installation

46Selecting the control cablesIt is recommended that all control cables be shielded.Double-shielded twisted pair cable is recommended for analog signals. For pulseencoder cabling, follow the instructions given by the encoder manufacturer. Use oneindividually-shielded pair for each signal. Do not use a common return for differentanalog signals.Double-shielded cable is the best alternative for low-voltage digital signals butsingle-shielded twisted multipair cable (Figure b) is also usable.aDouble-shielded twistedpair cablebSingle-shielded twistedmultipair cableRun analog and digital signals in separate cables.Relay-controlled signals, providing their voltage does not exceed 48 V, can be run inthe same cables as digital input signals. It is recommended that the relay-controlledsignals be run as twisted pairs.Never mix 24 VDC and 115/230 VAC signals in the same cable.Relay cableThe cable type with braided metallic screen (e.g. ÖLFLEX by Lapp Kabel, Germany)has been tested and approved by ABB.Control panel cableThe cable connecting the control panel <strong>to</strong> the drive must not exceed 3 metres inlength. The cable type tested and approved by ABB is used in control panel optionkits.Connection of a mo<strong>to</strong>r temperature sensor <strong>to</strong> the drive I/OSee page 64.Routing the cablesRoute the mo<strong>to</strong>r cable away from other cable routes. Mo<strong>to</strong>r cables of several drivescan be run in parallel installed next <strong>to</strong> each other. It is recommended that the mo<strong>to</strong>rcable, input power cable and control cables be installed on separate trays. Avoidlong parallel runs of mo<strong>to</strong>r cables with other cables in order <strong>to</strong> decreaseelectromagnetic interference caused by the rapid changes in the drive outputvoltage.Planning the electrical installation

47Where control cables must cross power cables make sure they are arranged at anangle as near <strong>to</strong> 90 degrees as possible. Do not run extra cables through the drive.The cable trays must have good electrical bonding <strong>to</strong> each other and <strong>to</strong> thegrounding electrodes. Aluminium tray systems can be used <strong>to</strong> improve localequalizing of potential.A diagram of the cable routing is below.Supply cableSupply cablemin 200 mm (8”) 90°min 300 mm (12”)Mo<strong>to</strong>r cableDriveControl cablesmin 500 mm (20”)Braking resis<strong>to</strong>r cable90°Mo<strong>to</strong>r cable90°min 500 mm (20”)Control cable ducts24 V 230 V24 V230 VNot allowed unless the 24 Vcable is insulated for 230 V orinsulated with an insulationsleeving for 230 V.Lead 24 V and 230 V controlcables in separate ducts insidethe cabinet.Planning the electrical installation

48Planning the electrical installation

49Electrical installationWhat this chapter containsThis chapter describes the electrical installation procedure of the drive.WARNING! The work described in this chapter may only be carried out by a qualifiedelectrician. Follow the Safety instructions on the first pages of this manual. Ignoringthe safety instructions can cause injury or death.Make sure that the drive is disconnected from the supply (input power) duringinstallation. If the drive is already connected <strong>to</strong> the supply, wait for 5 minutesafter disconnecting the input power.Removing the cover assemblyThe cover assembly needs <strong>to</strong> be removed before the installation of optional modulesand the connection of control cabling. Follow this procedure <strong>to</strong> remove the coverassembly. The numbers refer <strong>to</strong> the illustrations below.• Press the tab (1) slightly with a screwdriver.• Slide the lower cover plate slightly downwards and pull it out (2).• Disconnect the panel cable (3) if present.• Remove the screw (4) at the <strong>to</strong>p of the cover assembly.• Carefully pull the lower part of the base outwards by the two tabs (5).Refit the cover in reverse order <strong>to</strong> the above procedure.Electrical installation

5021<strong>45</strong>3Electrical installation

51Checking the insulation of the assemblyDriveDo not make any voltage <strong>to</strong>lerance or insulation resistance tests (e.g. hi-pot ormegger) on any part of the drive as testing can damage the drive. Every drive hasbeen tested for insulation between the main circuit and the chassis at the fac<strong>to</strong>ry.Also, there are voltage-limiting circuits inside the drive which cut down the testingvoltage au<strong>to</strong>matically.Supply cableCheck the insulation of the supply (input) cable according <strong>to</strong> local regulations beforeconnecting <strong>to</strong> the drive.Mo<strong>to</strong>r and mo<strong>to</strong>r cableCheck the insulation of the mo<strong>to</strong>r and mo<strong>to</strong>r cable as follows:1. Check that the mo<strong>to</strong>r cable is connected <strong>to</strong> the mo<strong>to</strong>r, and disconnected from thedrive output terminals U2, V2 and W2.2. Measure the insulation resistance between each phase conduc<strong>to</strong>r and theProtective Earth conduc<strong>to</strong>r using a measuring voltage of 500 V DC. Theinsulation resistance of an ABB mo<strong>to</strong>r must exceed 10 Mohm (reference value at25 °C or 77 °F). For the insulation resistance of other mo<strong>to</strong>rs, please consult themanufacturer’s instructions. Note: Moisture inside the mo<strong>to</strong>r casing will reducethe insulation resistance. If moisture is suspected, dry the mo<strong>to</strong>r and repeat themeasurement.ohmU1MV13~W1 PEBraking resis<strong>to</strong>r assemblyCheck the insulation of the braking resis<strong>to</strong>r assembly (if present) as follows:1. Check that the resis<strong>to</strong>r cable is connected <strong>to</strong> the resis<strong>to</strong>r, and disconnected fromthe drive output terminals R+ and R-.2. At the drive end, connect the R+ and R- conduc<strong>to</strong>rs of the resis<strong>to</strong>r cable <strong>to</strong>gether.Measure the insulation resistance between the combined conduc<strong>to</strong>rs and the PEconduc<strong>to</strong>r by using a measuring voltage of 1 kV DC. The insulation resistancemust be higher than 1 Mohm.R+ohmR-PEElectrical installation

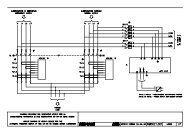

52Power cable connectionPower cable connection diagramFor alternatives, see Planning the electricalinstallation: Supply disconnecting device(page 39).L1 L2 L3(PE)1)(PE)2)CHK-xx mains choke (optional). See the chapterMains chokes (page 91).JFI-xx EMC filter (optional). See the chapterEMC filters (page 93).The UDC+/UDC– connec<strong>to</strong>rs can be used forcommon DC configurations. See page 59.<strong>ACS850</strong>-<strong>04</strong>UDC+ UDC–U1 V1 W1PEU2 V2 W2R– R+du/dt filter(s) (optional).See the chapter du/dtand common modefiltering (page 99).3)U1V13 ~Mo<strong>to</strong>rW1PEOptional braking resis<strong>to</strong>r(see the chapter Resis<strong>to</strong>rbraking [page 103])Notes:• If shielded supply (input) cable is used, and the conductivity of the shield is not sufficient (see sectionSelecting the power cables on page 43), use a cable with a ground conduc<strong>to</strong>r (1) or a separate PE cable(2).• For mo<strong>to</strong>r cabling, use a separate ground cable (3) if the conductivity of the cable shield is not sufficient(see section Selecting the power cables on page 43) and the cable has no symmetrical ground conduc<strong>to</strong>rs.Electrical installation

53ProcedureCabling drawings with tightening <strong>to</strong>rques for each frame size are presented onpages 56 <strong>to</strong> 58.1. Frame sizes C and D only: Remove the two plastic connec<strong>to</strong>r covers at the <strong>to</strong>pand bot<strong>to</strong>m of the drive. Each cover is fastened with two screws.2. On IT (ungrounded) systems and corner grounded TN systems, remove thefollowing screws <strong>to</strong> disconnect the internal varis<strong>to</strong>rs and EMC filters:• VAR (frames A and B, located close <strong>to</strong> the supply terminals)• EMC, VAR1 and VAR2 (frames C and D, located on the front of the powerunit).WARNING! If a drive whose varis<strong>to</strong>rs/filters are not disconnected is installed on anIT system (an ungrounded power system or a high resistance grounded [over 30ohms] power system), the system will be connected <strong>to</strong> earth potential through thevaris<strong>to</strong>rs/filters of the drive. This may cause danger or damage the drive.If a drive whose varis<strong>to</strong>rs/filters are not disconnected is installed on a cornergrounded TN system, the drive will be damaged.3. Fasten the two cable clamp plates included <strong>to</strong> the drive (see page 55), one atthe <strong>to</strong>p, one at the bot<strong>to</strong>m. The clamp plates are identical. Using the cable clampplates as shown below will provide better EMC compliance, as well as act as astrain relief for the power cables.4. Strip the power cables so that the shields are bare at the cable clamps.5. Twist the ends of the cable shield wires in<strong>to</strong> pigtails.6. Strip the ends of the phase conduc<strong>to</strong>rs.7. Connect the phase conduc<strong>to</strong>rs of the supply cable <strong>to</strong> the U1, V1 and W1terminals of the drive.Connect the phase conduc<strong>to</strong>rs of the mo<strong>to</strong>r cable <strong>to</strong> the U2, V2 and W2terminals.Connect the conduc<strong>to</strong>rs of the resis<strong>to</strong>r cable (if present) <strong>to</strong> the R+ and R–terminals.With frame size C or D, attach the screw terminal lugs included <strong>to</strong> theconduc<strong>to</strong>rs first. Crimp lugs can be used instead of the screw lugs.8. Tighten the cable clamps on<strong>to</strong> the bare cable shields.9. Crimp a cable lug on<strong>to</strong> each shield pigtail. Fasten the lugs <strong>to</strong> ground terminals.Note: Try <strong>to</strong> work out a compromise between the length of the pigtail and thelength of unshielded phase conduc<strong>to</strong>rs as both should ideally be as short aspossible.10. Cover visible bare shield and pigtail with insulating tape.Electrical installation

5411. With frame size C or D, cut suitable slots on the edges of the connec<strong>to</strong>r covers<strong>to</strong> accommodate the supply and mo<strong>to</strong>r cables. Refit the covers. (Tighten thescrews <strong>to</strong> 3 N·m [25 lbf·in]).12. Secure the cables outside the unit mechanically.13. Ground the other end of the supply cable shield or PE conduc<strong>to</strong>r(s) at thedistribution board. In case a mains choke and/or an EMC filter is installed, makesure the PE conduc<strong>to</strong>r is continuous from the distribution board <strong>to</strong> the drive.Grounding the mo<strong>to</strong>r cable shield at the mo<strong>to</strong>r endFor minimum radio frequency interference, ground the cable shield 360 degrees atthe lead-through of the mo<strong>to</strong>r terminal box360 degrees groundingConductive gasketsor ground the cable by twisting the shield so that the flattened shield is wider than1/5 of its length.b > 1/5 · aabElectrical installation

55Installation of power cable clamp platesTwo identical power cable clamp plates are included with the drive. The picturebelow depicts a frame size A drive; the installation is similar with other frame sizes.Note: Pay attention <strong>to</strong> supporting the cables adequately within the installationenclosure especially if not using the cable clamps.Frames A and B: 1.5 N·m (13 lbf·in)Frames C and D: 3 N·m (25 lbf·in)1.5 N·m (13 lbf·in)Electrical installation

56Power cable connection – frame size ASupplycableCable clamp on bare shield1.5 N·m (13 lbf·in)Below cable clamp, cover bareshield with insulating tape1.5 N·m (13 lbf·in)0.5 … 0.6 N·m (4.4 … 5.3 lbf·in)0.5 … 0.6 N·m (4.4 … 5.3 lbf·in)1.5 N·m (13 lbf·in)Above cable clamp, cover bareshield with insulating tapeCable clamp on bare shield1.5 N·m (13 lbf·in)Mo<strong>to</strong>r cableBraking resis<strong>to</strong>r cableElectrical installation

57Power cable connection – frame size BSupplycableCable clamp on bare shield1.5 N·m (13 lbf·in)Below cable clamp, cover bareshield with insulating tape1.5 N·m (13 lbf·in)U1 V1 W11.2 … 1.5 N·m (10.6 … 13.3 lbf·in)U2 V2 W2 R- R+1.5 N·m (13 lbf·in)Above cable clamp, cover bareshield with insulating tapeCable clamp on bare shield1.5 N·m (13 lbf·in)Mo<strong>to</strong>r cableBraking resis<strong>to</strong>r cableElectrical installation

58Power cable connection – frame sizes C and D (connec<strong>to</strong>r covers removed)Cable clamp on bare shield1.5 N·m (13 lbf·in)SupplycableBelow cable clamp, cover bareshield with insulating tapeScrew lug detail15 N·m (11 lbf·ft)Frame C:3 N·m (25 lbf·in)Frame D:18 N·m (160 lbf·in)U1 V1 W115 N·m(11 lbf·ft)3N·m(25 lbf·in)Direct lug connectionInstead of using the screw lugsincluded, the conduc<strong>to</strong>rs of powercables can be connected <strong>to</strong> the driveterminals by removing the screwlugs and using crimp lugs.U2 V2 W2R- R+3N·m(25 lbf·in)15 N·m(11 lbf·ft)Frame C:3 N·m (25 lbf·in)Frame D:18 N·m (160 lbf·in)Cable clamp onbare shield1.5 N·m(13 lbf·ft)Above cable clamp,cover bare shield withinsulating tapeMo<strong>to</strong>r cableBraking resis<strong>to</strong>r cableElectrical installation

59DC connectionThe UDC+ and UDC– terminals are intended for common DC configurations of anumber of <strong>ACS850</strong> drives, allowing regenerative energy from one drive <strong>to</strong> be utilisedby the other drives in mo<strong>to</strong>ring mode.One or more drives are connected <strong>to</strong> the AC supply depending on the powerrequirement. In case two or more drives are connected <strong>to</strong> the AC supply, each ACconnection must be equipped with a mains choke <strong>to</strong> ensure even current distributionbetween the rectifiers. The diagram below shows two configuration examples.AC supplyUDC+~~UDC+~~UDC+~~UDC–UDC–UDC–M3~M3~M3~AC supplyMains chokesUDC+UDC–~~UDC+UDC–~~UDC+UDC–~~M3~M3~M3~Electrical installation

60Each drive has an independent DC capaci<strong>to</strong>r pre-charging circuit.UDC+ UDC-U1~V1 W1=+ –<strong>ACS850</strong>-<strong>04</strong>=~Pre-charging circuitU2V2 W2The ratings of the DC connection are given on page 82.Electrical installation

61Installation of optional modulesOptional modules such as fieldbus adapters, I/O extensions and encoder interfacesordered using option codes (see Type designation on page 25) are pre-installed atthe fac<strong>to</strong>ry. Instructions for installing additional modules in<strong>to</strong> the slots on the JCUControl Unit (see page 24 for the available slots) are presented below.Mechanical installation• Remove the cover assembly from on the JCU Control Unit (refer <strong>to</strong> page 49).• Remove the protective cover (if present) from the connec<strong>to</strong>r of the slot.• Insert the module carefully in<strong>to</strong> its position on the drive.• Fasten the screw.Note: Correct installation of the screw is essential for fulfilling the EMC requirementsand for proper operation of the module.Electrical installationSee section Grounding and routing the control cables on page 62. See theappropriate option manual for specific installation and wiring instructions.Electrical installation