NA-SUL CA-1089 - King Industries, Inc.

NA-SUL CA-1089 - King Industries, Inc.

NA-SUL CA-1089 - King Industries, Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>NA</strong>-<strong>SUL</strong> ® <strong>CA</strong>-<strong>1089</strong>Our Most Versatile Rust Inhibitorfor Rust Preventives, Industrial Lubricants & Metalworking

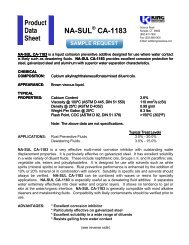

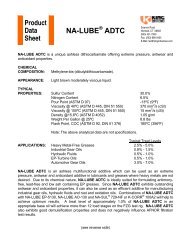

<strong>NA</strong>-<strong>SUL</strong> ® <strong>CA</strong>-<strong>1089</strong>With over six decades experience in rust and corrosion inhibition with hundreds ofproducts developed, it takes a lot to call one particular inhibitor “our most versatile”,yet <strong>NA</strong>-<strong>SUL</strong> <strong>CA</strong>-<strong>1089</strong> fits that bill. Part of that versatility is the fact that it is extremelyeffective in both industrial lubricants and rust preventives. Additionally, it is compatiblewith a wide range of additives and base stocks. It offers formulators:Excellent rust inhibition with outstanding demulsibilityExcellent non-staining propertiesExcellent filterability, both dry and wetExcellent thermal and hydrolytic stabilityExcellent solubility in highly paraffinic base stocksTYPI<strong>CA</strong>L PROPERTIESChemical CompositionAppearanceCalcium alkylnapthalenesulfonate/carboxylatein light mineral oilClear brown, viscous liquidCalcium Content 2.2%Viscosity @ 40°<strong>CA</strong>STM D 445, DIN 51 550Viscosity @ 100° <strong>CA</strong>STM D 445, DIN 51 550Density @ 25°<strong>CA</strong>STM D 4052Weight per Gallon @ 25°CFlash Point, CO<strong>CA</strong>STM D 92, DIN 513762500 mm 2 /s (cSt)36 mm 2 /s (cSt)0.96 g/ml8.0 lbs.165°CNOTE: The above data are not specifications.TYPI<strong>CA</strong>L TREAT LEVELSHydraulic Fluids (HF-0, HF-2) 0.05% to 0.5%Circulating Oils 0.05% to 1.0%Paper Machine Oils 0.25% to 1.0%Rust Preventives 1.0% to 15.0 %<strong>King</strong> <strong>Industries</strong>, <strong>Inc</strong>.Science RoadNorwalk, CT 06852 203-866-5551Email:lad@kingindustries.comDewatering Fluids 1.0 % to 10.0%TABLE OF CONTENTSPerformance in Industrial Lubricants Page 2Performance in Rust Preventives Page 3

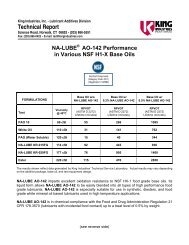

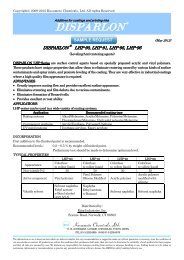

<strong>NA</strong>-<strong>SUL</strong> <strong>CA</strong>-<strong>1089</strong> Performance In Industrial Lubricants<strong>NA</strong>-<strong>SUL</strong> <strong>CA</strong>-<strong>1089</strong> was specifically designed for use in the more highly refined, new generationbase oils where it imparts outstanding steel corrosion protection, demulsibility and filtration.Since its introduction, it has proven to be an outstanding corrosion inhibitor for:High performance hydraulic fluidsPaper machine oilsCompressor oilsWindmill (Turbine) lubricantsIndustrial gear oilsGreasesIn addition to previous mentioned attributes, <strong>NA</strong>-<strong>SUL</strong> <strong>CA</strong>-<strong>1089</strong> when used in industriallubricants with carefully selected additives even exhibits friction reducing properties.Performance In Hydraulic FluidsThe test data that follow compare the performance of an HF-0 type package for hydraulicfluids with and without <strong>NA</strong>-<strong>SUL</strong> <strong>CA</strong>-<strong>1089</strong>. <strong>NA</strong>-<strong>SUL</strong> <strong>CA</strong>-<strong>1089</strong> was incorporated into the packageat 4.5% and 2.0% replacing oil. The concentrations of all other additives were held constant.Testing was conducted at a package treat level of 0.8% in an ISO VG 46 Group II oil.HF-0 Type PackageTestsw/o <strong>NA</strong>-<strong>SUL</strong><strong>CA</strong>-<strong>1089</strong>w/ 4.5% <strong>NA</strong>-<strong>SUL</strong><strong>CA</strong>-<strong>1089</strong>w/ 2.0% <strong>NA</strong>-<strong>SUL</strong><strong>CA</strong>-<strong>1089</strong>Treat Level of Additive Package, % 0.8Base OilISO VG 46 (Group II)Additive Package Color Light Amber Light Amber Light AmberSteel Corrosion (ASTM D 665, DIN 51 585) A & B Fail Pass PassDemulsibility (ASTM D 1401, DIN 51 599)Oil-Water-EmulsionTime (minutes)Four Ball Wear (ASTM D 4172)41-34-53039-39-2101 hour, 75°C, 40 kg, 1200 rpm, Scar Diameter (mm) 0.42 0.40 0.4140-39-110Copper Corrosion (ASTM D 130, DIN 51 759)3 hours, 100°C3 hours, 135°C3 hours, 160°C1b1b1b1b1b1b1b1b1bCincinnati Milacron Thermal Stability (ASTM D 2070)CM Color Class: CopperSteelViscosity Change, %Acid Number Change (mg KOH/g)Rod Weight of Deposit, Steel / Copper (mg/200ml)Rod Metal Loss, Steel / Copper (mg/200ml)Total Sludge (mg/100 ml)Whatman Precipitate (mg/100 ml)Millipore Precipitate (mg/100 ml)1.51.51.80.230.1 / 0.10.2 / 0.65.52.72.81.01.51.30.300.2 / 0.30.0 / 0.21.750.41.21.01.52.10.360.2 / 0.70.0 / 0.13.650.752.8Hydrolytic Stability (Beverage Bottle) (ASTM D 2619)Copper Loss (mg/cm 2 )Total Acidity of Water Layer (mg KOH)Copper Appearance ( ASTM D 130)0.290.912a0.301.101b0.050.701bAFNOR Filtration (wet)Filterability Index Plugged 1.27 1.34FZG A/8.3/90 (ASTM D 5182, DIN 51 354 Part 2)Damage Load Stage 12 12 12Page2As shown, inclusion of the <strong>NA</strong>-<strong>SUL</strong> <strong>CA</strong>-<strong>1089</strong> in the formulation imparted excellent steel corrosionprotection, demulsibility and AFNOR filtration properties while the package without the<strong>NA</strong>-<strong>SUL</strong> <strong>CA</strong>-<strong>1089</strong> failed those tests. The improved AFNOR filtration performance is attributedto the excellent dispersancy characteristics of the <strong>CA</strong>-<strong>1089</strong>.

<strong>NA</strong>-<strong>SUL</strong> ® <strong>CA</strong>-<strong>1089</strong> Performance In Rust Preventives<strong>NA</strong>-<strong>SUL</strong> <strong>CA</strong>-<strong>1089</strong> is an excellent rust inhibitor for a broad range of rust preventiveapplications where it offers:Remarkable non-staining performance in stacked stain testing in all oils tested.Highly recommended for protection of coiled steel and closely stacked steel parts.Outstanding performance in both cyclic and constant humidity testing, making itan excellent choice for most parts storage applications.Outstanding water displacement and demulsibility performance including acidicand basic aqueous fluids. A perfect choice for difficult dewatering fluids.Excellent solubility in paraffinic oils, PAO, esters and vegetable oils. A versatileadditive that can be used in a variety of products using different base stocks.Performance In Paraffinic ISO VG 32 Based FormulationsTestsFormulations2.0% <strong>CA</strong>-<strong>1089</strong>98.0% Oil #15.0% <strong>CA</strong>-<strong>1089</strong>95.0% Oil #110.0% <strong>CA</strong>-<strong>1089</strong>90.0% Oil #1Average Film ThicknessMeasured by weight (m) 2.8 2.8 3.0Salt Fog (ASTM B 117)Average Hours to Failure 3-5 5-10 12-15Humidity Cabinet (ASTM D 1748)Average Hours to Failure 150 250 450Performance In Solvent-Based FormulationsTestsFormulations3.0% <strong>CA</strong>-<strong>1089</strong>20.0% Oil #177.0% Solvent5.0% <strong>CA</strong>-<strong>1089</strong>20.0% Oil #175.0% Solvent10.0% <strong>CA</strong>-<strong>1089</strong>20.0% Oil #170.0% SolventAverage Film ThicknessMeasured by weight (m) 1.8 2.0 2.4Salt Fog (ASTM B 117)Average Hours to Failure 5-10 5-10 16-20Humidity Cabinet (ASTM D 1748)Average Hours to Failure 300 500 -<strong>NA</strong>-<strong>SUL</strong> <strong>CA</strong>-<strong>1089</strong> PerformanceAccelerated Stacked Stain TestCONTACT<strong>King</strong> <strong>Industries</strong>, <strong>Inc</strong>.USA HeadquartersScience RoadNorwalk, CT 06850FORMULATIONS 10.0% <strong>CA</strong>-<strong>1089</strong>90.0% Oil #1Stack Stain7-Day AcceleratedPassOil #1 - Paraffinic Group I - ISO VG 32 (150 SUS)Oil #2 - Paraffinic Group II - ISO VG 46 (220 SUS)5.0% <strong>CA</strong>-<strong>1089</strong>95.0% Oil #2Pass5% <strong>NA</strong>-<strong>SUL</strong> <strong>CA</strong>-<strong>1089</strong>95% Group II ParaffinicISO VG 46 (220 SUS)5% Commercial RP95% Group II ParaffinicISO VG 46 (220 SUS)PH: 203-866-5551FAX: 203-866-0425Email:LAD@kingindustries.com<strong>King</strong> <strong>Industries</strong> - EuropeNoordkade 642741 EZ Waddinxveen,The NetherlandsPH: +31 182-631360FAX: +31 182-621002Email: info@kingintl.nlDISCLAIMERSThe results shown reflect data generated by <strong>King</strong> <strong>Industries</strong>’ Technical Service Laboratory. Actual results may vary depending onthe additive package, base oil, and test equipment design.The conditions of your use and application of our products, technical assistance and information (whether verbal, written or by way ofproduct evaluations), including any suggested formulations and recommendations, are beyond our control. Therefore, it is imperativethat you test our products, technical assistance and information to determine to your own satisfaction whether they are suitable for yourintended uses and applications. Such testing has not necessarily been done by <strong>King</strong> <strong>Industries</strong>, <strong>Inc</strong>. ("<strong>King</strong>"). The facts, recommendationsand suggestions herein stated are believed to be reliable; however, no guaranty or warranty of their accuracy is made. EXCEPTAS STATED, THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED, OF MERCHANTABILITY, FITNESS OR OTHERWISE. KINGSHALL NOT BE HELD LIABLE FOR SPECIAL, INCIDENTAL, CONSEQUENTIAL OR EXEMPLARY DAMAGES. Any statement inconsistentherewith is not authorized and shall not bind <strong>King</strong>. Nothing herein shall be construed as a recommendation to use any product(s) in conflict with patents covering any material or its use. No license is implied or granted under the claims of any patent. Sales or useof all products are pursuant to Standard Terms and Conditions stated in <strong>King</strong> sales documents.LAD-<strong>CA</strong><strong>1089</strong>-DEC2011