ZX-100K - Wolf Kunststoff-Gleitlager GmbH

ZX-100K - Wolf Kunststoff-Gleitlager GmbH

ZX-100K - Wolf Kunststoff-Gleitlager GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

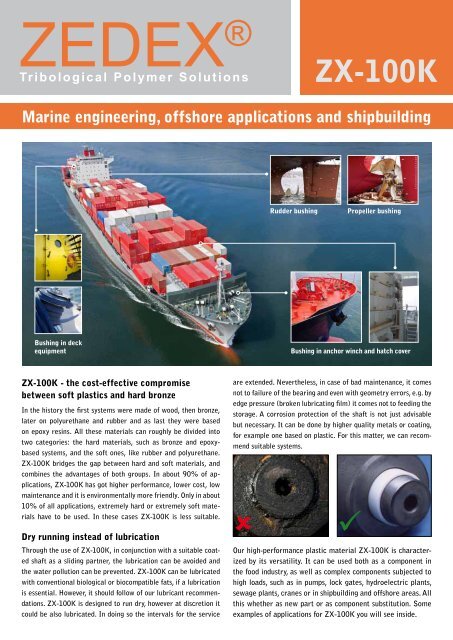

ZEDEX ®Tr i b o l o g i c a l P o l y m e r S o l u t i o n s<strong>ZX</strong>-<strong>100K</strong>Marine engineering, offshore applications and shipbuildingRudder bushingPropeller bushingBushing in deckequipmentBushing in anchor winch and hatch cover<strong>ZX</strong>-<strong>100K</strong> - the cost-effective compromisebetween soft plastics and hard bronzeIn the history the first systems were made of wood, then bronze,later on polyurethane and rubber and as last they were basedon epoxy resins. All these materials can roughly be divided intotwo categories: the hard materials, such as bronze and epoxybasedsystems, and the soft ones, like rubber and polyurethane.<strong>ZX</strong>-<strong>100K</strong> bridges the gap between hard and soft materials, andcombines the advantages of both groups. In about 90% of applications,<strong>ZX</strong>-<strong>100K</strong> has got higher performance, lower cost, lowmaintenance and it is environmentally more friendly. Only in about10% of all applications, extremely hard or extremely soft materialshave to be used. In these cases <strong>ZX</strong>-<strong>100K</strong> is less suitable.Dry running instead of lubricationThrough the use of <strong>ZX</strong>-<strong>100K</strong>, in conjunction with a suitable coatedshaft as a sliding partner, the lubrication can be avoided andthe water pollution can be prevented. <strong>ZX</strong>-<strong>100K</strong> can be lubricatedwith conventional biological or biocompatible fats, if a lubricationis essential. However, it should follow of our lubricant recommendations.<strong>ZX</strong>-<strong>100K</strong> is designed to run dry, however at discretion itcould be also lubricated. In doing so the intervals for the serviceare extended. Nevertheless, in case of bad maintenance, it comesnot to failure of the bearing and even with geometry errors, e.g. byedge pressure (broken lubricating film) it comes not to feeding thestorage. A corrosion protection of the shaft is not just advisablebut necessary. It can be done by higher quality metals or coating,for example one based on plastic. For this matter, we can recommendsuitable systems.ûüOur high-performance plastic material <strong>ZX</strong>-<strong>100K</strong> is characterizedby its versatility. It can be used both as a component inthe food industry, as well as complex components subjected tohigh loads, such as in pumps, lock gates, hydroelectric plants,sewage plants, cranes or in shipbuilding and offshore areas. Allthis whether as new part or as component substitution. Someexamples of applications for <strong>ZX</strong>-<strong>100K</strong> you will see inside.

Material characteristics<strong>ZX</strong>-<strong>100K</strong> is a thermoplastic polymer compound, which, despiteits high strength is also extremely tough and very elastic.Compared to previous known bearing materials such asbronze, rubber or epoxy resin based systems, it shows partiallydistinct advantages.Advantages over bronze●●Lower component costs●●Dry running and lack of lubrication permitted●●Longer working life (less wear)●●Water lubrication, low maintenance●●No pollution caused from grease leakage●●Honeycomb structures possible at abrasive particles●●Higher damping, lower noise generation,●●Longer maintenance intervals, lower costs●●Lighter●●Protects the shaft●●Reduction of edge pressingAdvantages over rubber●●Dry running and lack of lubrication permitted●●Higher compressive strength, higher stiffness●●No stick-slip, Lower friction and wear●●Higher precision●●Higher chemical and oil resistance●●Easier assemblingAdvantages over epoxy resin based systems●●Higher wear resistance, lower friction coefficients●●Higher impact and vibration resistance●●Less sensitive to overload●●Less edge pressures●●Higher chemical and water resistance●●Shorter delivery times●●Insensitive to abrasive particles●●Lower costsResistance to sea waterSea water temperatures up to 70°C have no chemical influenceson <strong>ZX</strong>-<strong>100K</strong>. Physical effects, such as for example waterabsorption are very low, in fact almost no water (max. 0.3%)is absorbed. The maximum water absorption of 0.3 weightpercent results in a maximum volume increment of 0.1%. Theabsorbed water does not act as plasticizer and does not affectthe mechanical properties.Chemical resistance<strong>ZX</strong>-<strong>100K</strong> is resistant to mineral acids, salt solutions, aqueousalkaline solutions with pH