The Journal of Pandrol Rail Fastenings 2008 - Pandrol USA

The Journal of Pandrol Rail Fastenings 2008 - Pandrol USA

The Journal of Pandrol Rail Fastenings 2008 - Pandrol USA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

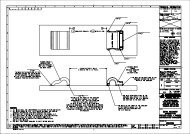

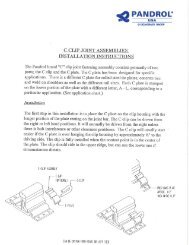

DIRECT FIXATION ASSEMBLIESnoted the economic benefit <strong>of</strong> the <strong>Pandrol</strong> SFCsystem. <strong>The</strong> SFC system was thus adopted as astandard system for the project, with theGerman system as back up.Questions were raised about the use <strong>of</strong> the<strong>Pandrol</strong> SFC on the German concrete slabsystem, RHEDA 2000. Because <strong>of</strong> thesedifferent opinions, further local andinternational verifications such as local advisorymeetings took place to clear these questions.Further performance tests on the <strong>Pandrol</strong> SFCsystem were made in a 3rd party laboratory,SNCF in France.<strong>The</strong> advisory committees came out withthe same opinions as former meetings and theperformance test at SNCF confirmed the results<strong>of</strong> the test in Korea, proving compatibility <strong>of</strong>the <strong>Pandrol</strong> SFC system with Rheda 2000 track.In fact, these verifications revealedadvantages <strong>of</strong> the <strong>Pandrol</strong> SFC system. <strong>The</strong>signal system <strong>of</strong> the KTX project, which camefrom French TGV technology, requires highelectrical insulation because the signals aretransmitted via the rail, which is different fromthe German system which uses independentcables. In the electric insulation test made inAugust 2007 at test tracks made for KTX Phase2, <strong>Pandrol</strong> SFC showed 15 ~ 20 times higherelectrical resistance than the German system.Pouring concreteThis meant that the <strong>Pandrol</strong> system could beused even with the track circuit lenght morethan 1500 metres which is required for the KTX2 project.In addition to better electrical insulation,the <strong>Pandrol</strong> SFC proved to have easier andsimpler adjustability for track geometry which isimportant for concrete slab track.After all these procedures, the contract forthe supply <strong>of</strong> the <strong>Pandrol</strong> SFC systems toSampyo, the contractor for the trackconstruction <strong>of</strong> section 4 <strong>of</strong> the project, wasLoading manufacured concrete sleepers pre assembledwith the <strong>Pandrol</strong> SFC systemawarded in Sep 2007. Construction <strong>of</strong> the KTXPhase 2 project will be done in two sections,section 4 and section 5. <strong>The</strong> contract forsection 5 is expected to be awarded in <strong>2008</strong>.Supplies <strong>of</strong> <strong>Pandrol</strong> SFC systems to Sampyo forSection 4 started in November 2007 and haveprogressed smoothly so far. As <strong>of</strong> July <strong>2008</strong>,30% <strong>of</strong> the track construction <strong>of</strong> section 4 hadbeen completed with exceptional speed <strong>of</strong> 500meters per day. ■Completed track14