T R A N SVE R S E T H R U ST E R - Schottel GmbH

T R A N SVE R S E T H R U ST E R - Schottel GmbH

T R A N SVE R S E T H R U ST E R - Schottel GmbH

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

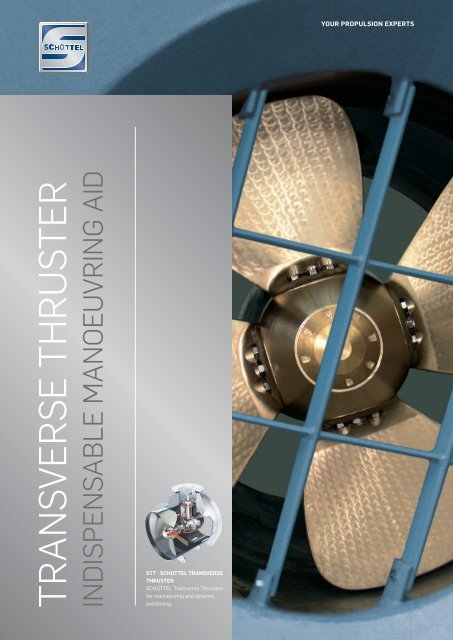

YOUR PROPULSION EXPERT<strong>ST</strong>RAN<strong>SVE</strong>RSE THRU<strong>ST</strong>ERINDISPENSABLE MANOEUVRING AID<strong>ST</strong>T · SCHOTTEL TRAN<strong>SVE</strong>RSETHRU<strong>ST</strong>ERSCHOTTEL Transverse Thrustersfor manoeuvring and dynamicpositioning.

2 3INDISPENSABLE FORMANOEUVRING ANDDYNAMIC POSITIONINGTransverse thrusters are installed in the bow or stern in orderto improve manoeuvrability of the ship. Depending on the typeof vessel, the range of application for transverse thrusters extendsfrom brief docking and undocking in ports with a limitednumber of operating hours every year up to continuous operationunder extreme load conditions in demanding offshore applicationswith dynamic positioning.INDIVIDUALLY TAILOREDCONFIGURATION<strong>ST</strong>T with electric motorThe transverse thrusters are individually configured bySCHOTTEL project engineers to suit the particular application.Light manoeuvring duties allow high specific thrusterperformance with the propeller running at a peripheralspeed of up to 33 m/s. In tough offshore applications, thepropellers operate at lower blade tip speeds.CHOICE OF PRIME MOVERSSCHOTTEL Transverse Thrusters can be powered by dieselengines, electric motors or hydraulic motors. Electric motorsare included optionally in the scope of supply. The prime movercan be connected either horizontally or vertically and thusincorporated optimally into the naval architectural design.<strong>ST</strong>T with hydraulic motorWhen fixed-pitch propellers are used, electric and hydraulicmotors allow the direction of thrust to be reversed. An additionalreversing gearbox is required if the thruster is poweredby a diesel engine.The transverse thruster types <strong>ST</strong>T 1 to 5 are available witheither fixed-pitch or controllable-pitch propellers. Thrusterswith controllable-pitch propellers can be powered in the sameway as those with fixed-pitch propellers – however it is notnecessary to equip a diesel engine with a reversing gearbox inthis case.<strong>ST</strong>T with diesel engine

4 5MAXIMUM RELIABILITYIN ALL APPLICATIONSSCHOTTEL TRAN<strong>SVE</strong>RSETHRU<strong>ST</strong>ERS IN YACHTSSCHOTTEL TRAN<strong>SVE</strong>RSETHRU<strong>ST</strong>ERS IN MERCHANT SHIPSParticularly for use in yachts, SCHOTTEL has systematicallyanalysed the causes of noise, focusing on minimizing noiseemission during operation of the transverse thruster.SCHOTTEL has achieved this by using larger gear reductionsto reduce the propeller blade tip speed to well below 30 m/s.At the same time, the number of blades has been increasedto four, and the pressure pulses on the tunnel wall reducedby means of individual propeller design.In addition to the mechanical system of the transversethruster, SCHOTTEL optionally offers frequency-controlleddrive motors. In this way, the motor speed and thus also thepropeller speed can be variably adjusted.In merchant ships, SCHOTTEL Transverse Thrusters are indispensablefor short-term manoeuvring in harbours. Here,transverse thrusters with fixed pitch propellers are mainlyused. With these systems, too, SCHOTTEL optionally offerselectric drive motors.In contrast to the frequency-controlled electric motors, thespeed can be set here in 3 steps:(100 -85 -70 -0 -70 -85 -100 %).The power range of SCHOTTEL Transverse Thrusters forthis application lies between 100 kW and 1400 kW. Theadvantage of using 3-step electric motors lies in the simpledesign and ease of operation and maintenance. Furthermore,these systems represent a cost-effective alternative tofrequency-controlled drive motors.MOTOR YACHT TRIPLE SEVEN1 x SCHOTTEL Transverse Thruster Type <strong>ST</strong>T 170 T-LK (200 kW)23400 TDW PRODUCT TANKER MT AVALON1 x SCHOTTEL Transverse Thruster Type <strong>ST</strong>T 3 CP (800 kW)

<strong>ST</strong>T · Transverse ThrusterSCHOTTEL TRAN<strong>SVE</strong>RSETHRU<strong>ST</strong>ERS IN THE HIGH POWERRANGE FOR OFFSHORE VESSEL<strong>ST</strong>he toughest requirements made on transverse thrusters arefound in offshore applications. Here, vessels are exposed to thefull force of wind, waves and current. Dynamic positioningunder these difficult conditions therefore requires particularlyrobust and powerful manoeuvring aids.In order to meet the demanding requirements, these systemsare equipped with ample reserves. The propeller blade tipspeed and propeller load have been reduced to a minimum.This substantially increases the service life of the drive sealsand bearings, and of the propeller hub and blades.<strong>ST</strong>EERING SY<strong>ST</strong>EMPropulsion systems are only as good as their steering. Optimallyadapted data exchange between the different components,together with a user interface that has been made as intuitiveas possible, ensures simple operation – even with frequentchanges of master.The electric steering system for the propeller pitch control ofthe drives can be integrated into a range of shipboard electricpower systems. Diverse interfaces, such as DP, joystick andVDR interfaces, are integrated into the control cabinets,thereby fulfilling the requirements of fleet operators in theoffshore sector.The propulsion units can optionally be supplied with electricdrive motors. The power range of these high-performancedrives lies between 350 kW and 1500 kW.OSV GRAMPIAN TALISMAN4 x SCHOTTEL Transverse Thruster Type <strong>ST</strong>T 2 CP (590 kW each)SCHOTTEL TRAN<strong>SVE</strong>RSE THRU<strong>ST</strong>ER WITH SCHOTTEL <strong>ST</strong>EERING SY<strong>ST</strong>EMComplete systems from a single source

6 7RELIABILITY AND HIGHE<strong>ST</strong>QUALITY ARE OUR TOP PRIORITYTo ensure the best possible protection of the gearbox housing,the SCHOTTEL Transverse Thruster is sand-blasted and theunderwater housing is provided with an abrasion-resistantcoating (Ceramic S-Metal). This coating gives extremely highresistance to erosion and cavitation, and offers excellentprotection against abrasion and electrolytic corrosion.Stiffening rings around the tunnel and appropriately thicktunnel material minimize distortion during welding into thehull. Preparations for the weld seams at the ends of thetunnel simplify installation by the shipyard.All SCHOTTEL Transverse Thrusters are fitted with a durablestainless steel wearing ring in the path of the propeller. Thisadditional equipment reduces the wear on the tunnel and increasesthe service life of the transverse thruster. Anotherpositive side-effect: the use of the wearing ring achieves anadditional thickening of the tunnel in the area of the propeller.This decreases the amount of vibration and noise.State-of-the-art production facilities, ...MODERN MANUFACTURING –EFFICIENT PROCESSESFor SCHOTTEL, the customer is at the centre of our activities.All our corporate processes are geared towards respondingquickly and flexibly to our customers’ requirements.... with a high proportion of in-house manufacturing, ...That is why SCHOTTEL attaches great importance to keepinga large portion of our manufacturing in-house. This not onlysaves time and simplifies our business processes, but alsosafeguards our know-how and ensures consistently high quality.State-of-the-art manufacturing facilities are indispensableprerequisites for top quality. The machines and systems usedat SCHOTTEL’s German production plants in Spay and Wismarand at our Chinese subsidiary in Suzhou operate with outstandingprecision and make a major contribution to the constanthigh quality of our products. Exhaustive trial runs on the testbed ensure that only first-class products leave the SCHOTTELworks.... means consistently high quality and flexibility in meeting our customers’requirements.

<strong>ST</strong>T · Transverse ThrusterOSV VOS PIONEER2 x SCHOTTEL Transverse Thruster Type <strong>ST</strong>T 1 FP (450 kW each)TRAINING VESSEL HANSE EXPLORER1 x SCHOTTEL Transverse Thruster Type <strong>ST</strong>T 170 LK (300 kW)CONTAINER VESSEL TAIPAN1 x SCHOTTEL Transverse Thruster Type <strong>ST</strong>T 2 CP (700 kW)RESEARCH VESSEL PLANET4 x SCHOTTEL Transverse Thruster Type <strong>ST</strong>T 170 LK (350 kW each)70 T BP ASD TUG DIHECISIETE1 x SCHOTTEL Transverse Thruster Type <strong>ST</strong>T 110 LK (200 kW)IMR GRANT CANDIES2 x SCHOTTEL Transverse Thruster Type <strong>ST</strong>T 4 CP (1000 kW each)67 T BP TERMINAL TUG BULLDOG1 x SCHOTTEL Transverse Thruster Type <strong>ST</strong>T 170 T-LK (185 kW)OSV HARVEY DISCOVERY2 x SCHOTTEL Transverse Thruster Type <strong>ST</strong>T 3 CP (821 kW each)

PROFESSIONALPARTNERSHIP –THROUGHOUT THEVESSEL’S LIFEAs a SCHOTTEL customer, you benefit fromindividual, in-depth advice and support at allstages of a project, from planning and commissioningthrough to preventive maintenance.A dense worldwide service network is readyto offer assistance and ensures the swiftsupply of spare parts – along with experiencedSCHOTTEL technicians if required.The name of SCHOTTEL traditionally standsfor quality in engineering, with over 90 yearsof experience in design and the precisionworkmanship of a family-owned enterprise.Our innovative propulsion systems are abyword for reliability and high performanceand set standards in global shipping.YOU CAN FIND US HERESCHOTTEL <strong>GmbH</strong>Mainzer Str. 99D-56322 Spay / RheinGermanyTel.: +49 (2628) 61 0Fax: +49 (2628) 61 30024 h Service Hotline+49 (171) 47 29 154For further adresses: www.schottel.de© SCHOTTEL 08/2010