SCH O TTEL A ZIM U TH TH RU STERS - Schottel GmbH

SCH O TTEL A ZIM U TH TH RU STERS - Schottel GmbH

SCH O TTEL A ZIM U TH TH RU STERS - Schottel GmbH

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

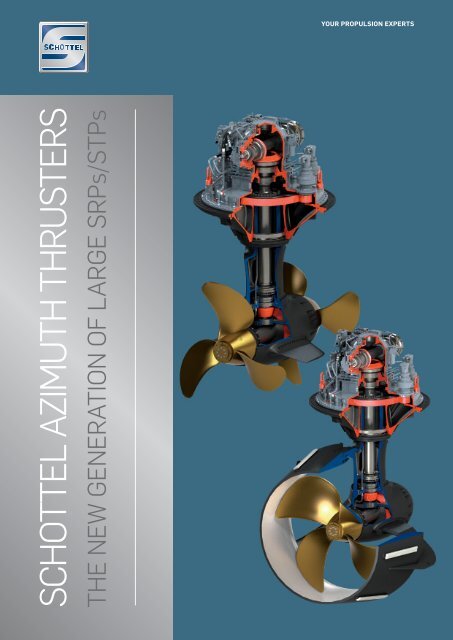

YOUR PROPULSION EXPERTS<strong>SCH</strong>O<strong>TTEL</strong> A<strong>ZIM</strong>U<strong>TH</strong> <strong>TH</strong><strong>RU</strong><strong>STERS</strong><strong>TH</strong>E NEW GENERATION OF LARGE SRPs/STPs

SRP · RudderpropellerSTP · Twin PropellerFOR DEMANDING APPLICATIONSOFFSHOREThe new thruster generation is ideal for any kind of offshore operation.Robustness, compactness, eco-friendliness and ease ofmaintenance are a prerequisite for ships working in the harshoffshore environment. All thrusters are prepared for integrationof the <strong>SCH</strong>O<strong>TTEL</strong> Condition Monitoring System S-COM whichallows foresighted maintenance planning.TUGSTug operation profiles are becoming more and more demandingand require high power on a space-restricted platform. With itsimproved hydrodynamic and compact design, the new thrusterseries offers the optimum answer to these demands.FERRIES<strong>SCH</strong>O<strong>TTEL</strong> azimuth thrusters have proven their uniqueness inmany ferries, already providing excellent manoeuvrability toeach vessel. Not only the SRP but even more so the <strong>SCH</strong>O<strong>TTEL</strong>Twin Propeller is in many cases the first choice thanks to itscompact design and high efficiency.

4 5HYDRAULIC CLUTCHThe new thruster generation comes with an independent,hydraulically operated multi-disc clutch, which not only engagesand disengages the drive train from the thruster but also drivesthe hydraulic units of the thruster, making it practically selfcontained.To improve the ease of maintenance and simplify the system asmuch as possible, the clutch is installed separately outside thegearbox and uses the same type of oil for operation and coolingas is used for lubrication of the thruster. No additional auxiliaryunits are needed to operate the clutch.Hydraulic clutchwith pulley to drivethe steering pump

SRP · RudderpropellerSTP · Twin PropellerHYDRAULIC MULTI-DISC BRAKEIn addition to the hydraulically operated clutch, the newthruster generation comes with a hydraulically operated multidischolding brake, which is used to block the propeller fromturning during service and maintenance work.The brake basically follows the same principle as the hydraulicclutch except that it has a fixed outer part fitted to the gearboxhousing.Like the clutch, the brake is a separate system outside theupper gearbox and is fully self-contained, requiring nomechanical interface or auxiliary units outside the thruster.The brake, too, uses the same type of oil as used for thrusterlubrication.Multi-dischydraulic brake

6 7LATEST DEVELOPMENTSSLIPPING CLUTCH<strong>SCH</strong>O<strong>TTEL</strong> offers a new hydraulic slipping clutch, which can bemounted on the upper gearbox instead of the standard clutch.To sustain the ease of maintenance, the clutch comes in a separatehousing which provides a power take-off for driving thehydraulic steering equipment. Thus the complete thruster is asself-contained as with the standard clutch, but needs only aminimum of mechanical and electrical interfaces.In addition to the engaging and disengaging function of a standardclutch, the slipping clutch offers the possibility of controlling thepropeller rpm from almost zero to the idle speed of the engineand is thus an ideal add-on for diesel direct-driven DP 2 vesselswith fixed pitch propellers, double-ended ferries and tugboatsusing an engine with high idle speed.PTO driveLow noiseSlipping clutchHydraulic steering pumpattached to the slippingclutch PTOWet runningwithout wear,slippingoperationSensors formonitoringSelf-contained system oil supplyclosed system, trouble-free operationFUNCTIONAL PRINCIPLE100 %SPEEDPM’s full speed100 %Clutch fully engagedPM speed alterationPrime mover fromidle to full speedPrime mover idling &clutch modulating30 %0 %PM idlingClutchmodulating0 % 30 % COPILOT LEVER POSITION 100 %0 %

SRP · RudderpropellerSTP · Twin PropellerSTATE OF <strong>TH</strong>E ARTSTEERING AND CONTROLWith the <strong>SCH</strong>O<strong>TTEL</strong> Operation Diagnosis System S-ODS thecrew can retrieve all relevant system data for further diagnosisor analysis. Thanks to the intuitive user interface, these data canbe quickly and easily sent to the <strong>SCH</strong>O<strong>TTEL</strong> Service Team or toFleet Management. This analytical tool makes the on-boardassignment of a service technician unnecessary. Deviations fromthe optimum operating condition (e.g. fuel or energy consumption)can be identified and corrected by on-board personnel and settingscan be calibrated. This form of interactive communicationenables malfunctions to be quickly and efficiently rectified anddowntimes to be significantly minimized.The system can also be retrofitted on older plants. The quickestand most efficient form of system analysis is via secure remoteaccess (satellite, UMTS). Alternatively, the data can also beconventionally transferred using a USB stick and then by e-mail.ADVANTAGES OF S-ODS• Optimization/avoidance of service assignments due to up-frontanalysis of faults• On-line diagnosis by remote access• Optimization of maintenance intervals• Detailed fault analysis• Intuitive alarm and fault history for maintenance optimization• Reduction of failure risk and off-hire periods• Parameters can also be optimized by on-board personnel• Simple system diagnosis• Communication link to Fleet ManagementThe <strong>SCH</strong>O<strong>TTEL</strong> Copilot lever has been redesigned taking thelatest ergonomic expertise into account. All necessary functionsare available on a smaller platform.

PROFESSIONALPARTNERSHIP –<strong>TH</strong>ROUGHOUT <strong>TH</strong>EVESSEL’S LIFEAs a <strong>SCH</strong>O<strong>TTEL</strong> customer, you benefit fromindividual, in-depth advice and support at allstages of a project, from planning and commissioningthrough to preventive maintenance.A dense worldwide service network is readyto offer assistance and ensures the swiftsupply of spare parts – along with experienced<strong>SCH</strong>O<strong>TTEL</strong> technicians if required.The name of <strong>SCH</strong>O<strong>TTEL</strong> traditionally standsfor quality in engineering, with over 90 yearsof experience in design and the precisionworkmanship of a family-owned enterprise.Our innovative propulsion systems are abyword for reliability and high performanceand set standards in global shipping.YOU CAN FIND US HERE<strong>SCH</strong>O<strong>TTEL</strong> <strong>GmbH</strong>Mainzer Str. 99D-56322 Spay / RheinGermanyTel.: +49 (2628) 61 0Fax: +49 (2628) 61 30024 h Emergency Hotline+49 (171) 47 29 154For further addresses: www.schottel.de© <strong>SCH</strong>O<strong>TTEL</strong> 02/2013