Climate protection needs energy efficient data centers - Stulz GmbH

Climate protection needs energy efficient data centers - Stulz GmbH

Climate protection needs energy efficient data centers - Stulz GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

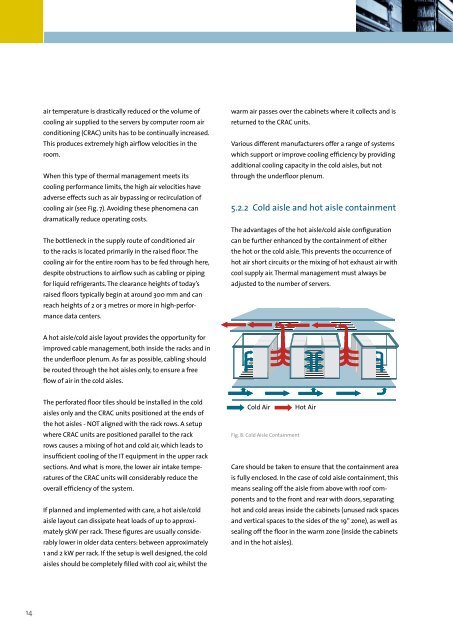

air temperature is drastically reduced or the volume ofcooling air supplied to the servers by computer room airconditioning (CRAC) units has to be continually increased.This produces extremely high airflow velocities in theroom.When this type of thermal management meets itscooling performance limits, the high air velocities haveadverse effects such as air bypassing or recirculation ofcooling air (see Fig. 7). Avoiding these phenomena candramatically reduce operating costs.The bottleneck in the supply route of conditioned airto the racks is located primarily in the raised floor. Thecooling air for the entire room has to be fed through here,despite obstructions to airflow such as cabling or pipingfor liquid refrigerants. The clearance heights of today’sraised floors typically begin at around 300 mm and canreach heights of 2 or 3 metres or more in high-performance<strong>data</strong> <strong>centers</strong>.warm air passes over the cabinets where it collects and isreturned to the CRAC units.Various different manufacturers offer a range of systemswhich support or improve cooling efficiency by providingadditional cooling capacity in the cold aisles, but notthrough the underfloor plenum.5.2.2 Cold aisle and hot aisle containmentThe advantages of the hot aisle/cold aisle configurationcan be further enhanced by the containment of eitherthe hot or the cold aisle. This prevents the occurrence ofhot air short circuits or the mixing of hot exhaust air withcool supply air. Thermal management must always beadjusted to the number of servers.A hot aisle/cold aisle layout provides the opportunity forimproved cable management, both inside the racks and inthe underfloor plenum. As far as possible, cabling shouldbe routed through the hot aisles only, to ensure a freeflow of air in the cold aisles.The perforated floor tiles should be installed in the coldaisles only and the CRAC units positioned at the ends ofthe hot aisles - NOT aligned with the rack rows. A setupwhere CRAC units are positioned parallel to the rackrows causes a mixing of hot and cold air, which leads toinsufficient cooling of the IT equipment in the upper racksections. And what is more, the lower air intake temperaturesof the CRAC units will considerably reduce theoverall efficiency of the system.If planned and implemented with care, a hot aisle/coldaisle layout can dissipate heat loads of up to approximately5kW per rack. These figures are usually considerablylower in older <strong>data</strong> <strong>centers</strong>: between approximately1 and 2 kW per rack. If the setup is well designed, the coldaisles should be completely filled with cool air, whilst theCold Air Hot AirFig. 8: Cold Aisle ContainmentCare should be taken to ensure that the containment areais fully enclosed. In the case of cold aisle containment, thismeans sealing off the aisle from above with roof componentsand to the front and rear with doors, separatinghot and cold areas inside the cabinets (unused rack spacesand vertical spaces to the sides of the 19“ zone), as well assealing off the floor in the warm zone (inside the cabinetsand in the hot aisles).14