Energy savings and environmental benefits of high light reflectance ...

Energy savings and environmental benefits of high light reflectance ...

Energy savings and environmental benefits of high light reflectance ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

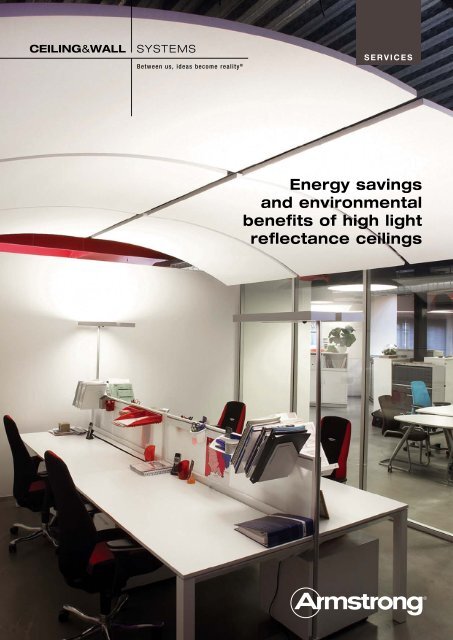

High <strong>light</strong> <strong>reflectance</strong> ceilingsLighting is the leading source <strong>of</strong> energy consumption in mostbuildings. As a result, energy efficient <strong>light</strong>ing systems arebecoming increasingly important in corporate environments,especially as owners must stay within energy budgets dictatedby national <strong>and</strong> local codes.Lighting systems also have an effect on a building’s occupants.Systems that provide a s<strong>of</strong>ter, more evenly-distributed <strong>light</strong>can help create an environment <strong>of</strong> visual comfort in a space,reducing eyestrain <strong>and</strong> increasing employee effectiveness.The three most common <strong>light</strong>ing options are: direct ordown<strong>light</strong>ing, indirect or up<strong>light</strong>ing, <strong>and</strong> direct/indirect ora combination <strong>of</strong> task <strong>and</strong> ambient <strong>light</strong>ing.While each <strong>of</strong>fers advantages <strong>and</strong> disadvantages, indirect<strong>light</strong>ing systems are growing in popularity because theyovercome many <strong>of</strong> the shortcomings <strong>of</strong> direct systems byproviding a <strong>light</strong> source with fewer shadows <strong>and</strong> less glare.Indirect <strong>light</strong>ing has also grown due to lower costs, morecompact systems, less obtrusive designs, simplified installation,<strong>and</strong> broader <strong>and</strong> deeper product lines.High Light Reflectance CeilingsThe ceiling is an integral part <strong>of</strong> an indirect <strong>light</strong>ing systembecause it must reflect the <strong>light</strong> that strikes it back into thespace. The ability <strong>of</strong> a ceiling to reflect <strong>light</strong> is indicated by itsLight Reflectance or LR value. LR values range from 0.00 to1.00 <strong>and</strong> denote the percent <strong>of</strong> <strong>light</strong> striking the panel thatis reflected.For example, an LR or 0.75 means the panel reflects 75% <strong>of</strong> the<strong>light</strong> striking it. Most commonly installed acoustical ceilings havean LR <strong>of</strong> 0.70 to 0.81. High <strong>light</strong> <strong>reflectance</strong> or Hi-LR ceilingshave an LR <strong>of</strong> 0.83 or <strong>high</strong>er.In general, increasing the <strong>reflectance</strong> <strong>of</strong> a ceiling has avery positiveimpact on the <strong>light</strong>ing <strong>and</strong> energy use <strong>of</strong> a building, especially whenused in conjunction with an indirect <strong>light</strong>ing system.Light Reflectance ResearchTo substantiate the effects <strong>of</strong> increasing the ceiling <strong>reflectance</strong>in typical <strong>of</strong>fice plans, Brinjac Engineering, a multi-disciplineconsulting engineering firm based in Harrisburg, PA, conductedtwo studies, one on work plane illuminance <strong>and</strong> the other onenergy consumption.In the first study, four room configurations were selected astypical <strong>of</strong>fice spaces: a 10’ x 10’ private <strong>of</strong>fice, a 100’ x 30’open <strong>of</strong>fice, a 60’ x 60’ open <strong>of</strong>fice, <strong>and</strong> an irregular shapedopen <strong>of</strong>fice.Two different <strong>light</strong> fixtures were used: a direct recessed 2’ x 2’parabolic tr<strong>of</strong>fer <strong>and</strong> an indirect pendant. All variables were heldconstant <strong>and</strong> only the ceiling <strong>reflectance</strong> was changed from 75%up to 90%. No day<strong>light</strong>ing or task <strong>light</strong>ing was taken into effect.Work Plane IlluminanceThe study results showed that for direct fixtures, workplaneilluminance achieved modest increases ranging from 2% to 5%when increasing the ceiling <strong>reflectance</strong> from 75% to 90%.Finding: Compared to a 75% reflective ceiling, the 90%reflective ceiling achieved an average increase <strong>of</strong> nearly 22% inwork plane illuminance with indirect <strong>light</strong>ing.This increase in <strong>light</strong> level means <strong>light</strong>ing costs can be loweredby using fewer fixtures in the space or by using the samenumber <strong>of</strong> fixtures but at lower wattage levels.Figure 1 demonstrates the difference <strong>high</strong> <strong>light</strong> <strong>reflectance</strong>ceilings can make in workplace illuminance when used withindirect <strong>light</strong>ing.Figure 1: Work Plane IlluminanceCellingReflectanceWork planeIlluminance(footc<strong>and</strong>les)Increasein <strong>light</strong> level75% 52.0 Reference78% 54.3 4%81% 56.6 9%84% 59.0 13%87% 61.6 18%90% 63.3 22%60’ x 60’ x 10’ open <strong>of</strong>fice, 12’ luminaire spacingThe study also showed that compared to 75% reflectiveceilings, 90% reflective ceilings enhanced the <strong>benefits</strong> <strong>of</strong>indirect <strong>light</strong>ing by improving <strong>light</strong>ing uniformity. Poor uniformityleads to visual discomfort.<strong>Energy</strong> SavingsIn the second study, a new <strong>light</strong>ing design was created tooptimize the layout with 90% reflective ceiling tile using the samespaces <strong>and</strong> indirect <strong>light</strong> fixtures as the first study.These results were compared against a layout <strong>of</strong> 2’ x 2’recessed parabolic tr<strong>of</strong>fers with st<strong>and</strong>ard spacing. The resultswere then compared against each other to determine thechange in energy use that was achieved with the <strong>high</strong>er valuefor the ceiling tile.Finding: The 90% reflective ceiling allowed spacing betweenindirect luminaire sections to be increased, thus reducing thetotal number <strong>of</strong> luminaires needed to achieve <strong>light</strong> levels similarto the 75% ceiling.

Finding: The 90% reflective ceiling <strong>and</strong> indirect fixtures yieldeda 23% lower <strong>light</strong>ing power density than the 75% reflectiveceiling layout <strong>and</strong> a 21% lower <strong>light</strong>ing power density than theparabolic tr<strong>of</strong>fer layout.Using the same open <strong>of</strong>fice configurations, the effects <strong>of</strong> thereduced <strong>light</strong>ing load on the HVAC system were then modeledusing two different s<strong>of</strong>tware programs.Finding: The reduction in <strong>light</strong>ing power density obtained by the90% reflective ceiling enabled an average HVAC energy cost<strong>savings</strong> <strong>of</strong> up to 9% over the layout with a 75% reflective ceiling<strong>and</strong> 7% over the tr<strong>of</strong>fer layout.Based on these results, there is a significant impact on theHVAC system by reducing the in-room heat generated by the<strong>light</strong>ing load through the use <strong>of</strong> a <strong>high</strong><strong>light</strong> <strong>reflectance</strong> ceiling.This impact can be positive in the form <strong>of</strong> energy <strong>savings</strong>,especially if the building is incooling year-round, as manybuildings are.Tax DeductionsAs a result <strong>of</strong> their energy-saving potential, Hi-LR ceilingshave a significant impact on the <strong>Energy</strong> Policy Act <strong>of</strong> 2005(EPAct 2005), which establishes a tax deduction for expensesincurred for energy-efficient commercial building properties.Lighting systems are one <strong>of</strong> the focuses <strong>of</strong> the act because<strong>of</strong> their ease <strong>and</strong> availability <strong>of</strong> upgrading, <strong>and</strong> the knownachievements in energy efficiency that will be gained.The tax deduction for <strong>light</strong>ing systems can be as <strong>high</strong> as 60¢per square foot.In the Brinjac study, power densities using <strong>high</strong> <strong>light</strong> <strong>reflectance</strong>ceilings ranged from 0.83 to 0.92 watts per square foot. Evenusing the worst case <strong>of</strong> 0.92, this is nearly a 30% decreasecompared to the Act’sminimum requirement <strong>of</strong> 1.3 watts persquare foot for <strong>of</strong>fice space. The associated tax deductionis $0.40 per square foot.For private buildings, the owner that paid for the installation<strong>of</strong> the <strong>light</strong>ing system can claim the deduction. In the case <strong>of</strong>publicly owned buildings, the person primarily responsible fordesigning it can claim the deduction.The deduction currently applies only for property that is put intoservice between January 1, 2006 <strong>and</strong> December 31, 2007.However, it is believed the legislation will be extended after itscurrent termination date.LEED ® CreditsIn addition to energy <strong>savings</strong> <strong>and</strong> tax deductions, <strong>high</strong> <strong>light</strong><strong>reflectance</strong> ceilings can also contribute to LEED points,especially in the <strong>Energy</strong> <strong>and</strong> Atmosphere category under EACredit 1.0 (Optimize <strong>Energy</strong> Performance). In the Brinjac study,for example, energy points were achievedby nothing more thanincreasing the <strong>light</strong> <strong>reflectance</strong>.Based on the spaces used in the study, the reduction in totalbuilding energy consumption as defined by LEEDNC 2.2 couldbe as <strong>high</strong> as 10.6% when optimizing the <strong>light</strong>ing layout with90% reflective ceilings. This <strong>savings</strong> qualifies for 1 point in a newbuilding or 3 points in anexisting building.Hi-LR ceilings are also a factor in the Indoor EnvironmentalQuality category by contributing to EQCredit 8.1, 8.2 (Day<strong>light</strong><strong>and</strong> Views). This is because <strong>high</strong> <strong>light</strong> <strong>reflectance</strong> ceilings can“extend” natural day<strong>light</strong>ing into a space.And, Hi-LR ceiling systems can contribute in the Materials<strong>and</strong> Resources category in the following areas: MR Credit2.1, 2.2 (Construction Waste Management), MR Credit 4.1,4.2 (Recycled Content), MR Credit 5.1, 5.2 (Local/RegionalMaterials), <strong>and</strong> MR Credit 6.0 (Rapidly Renewable Materials).Seeing the LightAs indicated by the Brinjac study, architects <strong>and</strong> designersshould look at the ceiling system as an integral element<strong>of</strong> a building’s energy reduction strategy. The overall costimpact compared to potential energy <strong>savings</strong> make <strong>high</strong><strong>light</strong> <strong>reflectance</strong> ceilings a viable solution forachieving energyreductions without the need for more costly new technology.

Integrated Ceiling SolutionThe ability to provide the <strong>benefits</strong> <strong>of</strong> a <strong>high</strong> <strong>light</strong> <strong>reflectance</strong> ceilingalong with desired acoustic <strong>and</strong> aesthetic requirements can easilybe accomplished through the use <strong>of</strong> an integrated ceiling systemsuch asthe TECH ZONE Ceiling System from Armstrong.TECH ZONE is a <strong>high</strong> <strong>light</strong> <strong>reflectance</strong> ceiling system thatorganizes all the <strong>light</strong> fixtures, air diffusers <strong>and</strong> sprinkler headsin a linear 6-inch-wide technical “zone” to create a clean,uncluttered ceiling visual. The totally integrated ceiling systemuses only st<strong>and</strong>ard components, while still deliveringthe desiredquantity <strong>and</strong> quality <strong>of</strong> <strong>light</strong> <strong>and</strong> air into the space. The lineartechnical “zone” is prequalified for fit <strong>and</strong> finish <strong>and</strong> visuallycoordinates with the look <strong>of</strong> Armstrong Optima ® <strong>and</strong> Ultima ®fine-textured ceiling panels.When used with indirect pendant <strong>light</strong>ing, the combination <strong>of</strong>TECH ZONE <strong>and</strong> Hi-LR Optimaor Ultima ceiling panels cancontribute LEED ® points for day<strong>light</strong>ing <strong>and</strong> energy consumption.In addition, both panels are recyclable as part <strong>of</strong> the ArmstrongCeiling Recycling Program.Resourcesn TechLine at 1-877-ARMSTRONG (1-877-276-7876)n Brinjac Engineering Research Study, “<strong>Energy</strong> <strong>and</strong>Environmental Effects <strong>of</strong> High Light Reflectance Ceilingsin Offices,” 2006 at armstrong.com/performancen CEU Course: “<strong>Energy</strong> Savings <strong>and</strong> EnvironmentalBenefits <strong>of</strong> High Light Reflectance Ceilings”at armstrong.com/ceun Armstrong Web Site:Product Selector Tool at armstrong.com/ceilingsn armstrong.com/ceilings (search keyword: <strong>light</strong>)08/2011 - VELVET expérience - Armstrong Building Products - RCS Besançon B 784 131 575United Kingdom / Republic <strong>of</strong> Irel<strong>and</strong>Armstrong World Industries Ltd.Building Products DivisionArmstrong House, 38 Market Square, Uxbridge UB8 1NG0800 371849 (UK)1800 409002 (ROI)Fax +44 (0) 1895 274287sales-support@armstrong.comwww.armstrong-ceilings.co.ukwww.armstrong-ceilings.iefreefoneDubai | United Arab EmiratesArmstrong Building Products L.L.C.P.O. Box 73831Phone +971 43 397 099Fax +971 43 397 088info-dubai@armstrong.comwww.armstrong.aeCertified printerPEFC/10-31-1427