Reducing the Risk of Fire on Your Farm - Ontario Ministry of ...

Reducing the Risk of Fire on Your Farm - Ontario Ministry of ...

Reducing the Risk of Fire on Your Farm - Ontario Ministry of ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

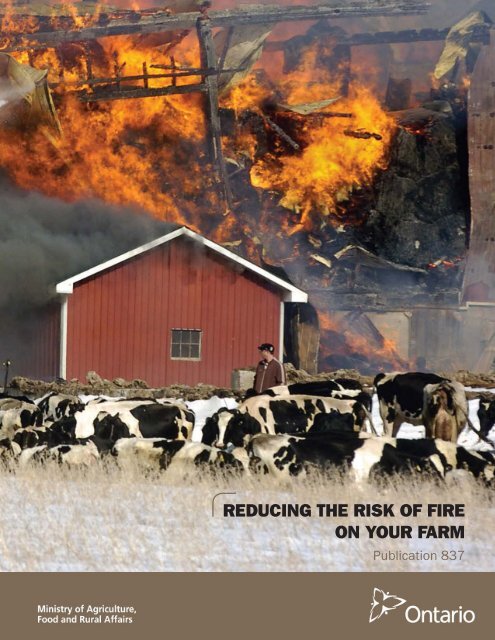

REDUCING THE RISK OF FIREON YOUR FARMPublicati<strong>on</strong> 837

REDUCING THE RISK OF FIRE ON YOUR FARMEditorArlene Roberts<strong>on</strong>, <strong>Ontario</strong> <strong>Ministry</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Agriculture, Food and Rural Affairs (OMAFRA)Co-EditorsDan McD<strong>on</strong>ald, P. Eng., OMAFRADaniel Ward, P. Eng., OMAFRAAcknowledgementsThe authors would like to thank <str<strong>on</strong>g>the</str<strong>on</strong>g> members <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> Technical Advisory Committee <strong>on</strong> <strong>Farm</strong> <str<strong>on</strong>g>Fire</str<strong>on</strong>g>s (TACFF)for <str<strong>on</strong>g>the</str<strong>on</strong>g>ir invaluable c<strong>on</strong>tributi<strong>on</strong>s to <str<strong>on</strong>g>the</str<strong>on</strong>g> project.Thank you to John Johns<strong>on</strong>, P. Eng., Civil Systems Engineer, OMAFRA (retired) for his expertise anddedicati<strong>on</strong> to <str<strong>on</strong>g>the</str<strong>on</strong>g> project.Need technical or business informati<strong>on</strong>?C<strong>on</strong>tact <str<strong>on</strong>g>the</str<strong>on</strong>g> Agricultural Informati<strong>on</strong> C<strong>on</strong>tact Centre at 1-877-424-1300 or ag.info.omafra@<strong>on</strong>tario.caA complete listing <str<strong>on</strong>g>of</str<strong>on</strong>g> all OMAFRA products and services are available at www.<strong>on</strong>tario.ca/omafraTo obtain copies <str<strong>on</strong>g>of</str<strong>on</strong>g> this or any o<str<strong>on</strong>g>the</str<strong>on</strong>g>r OMAFRA publicati<strong>on</strong>, please order:• Online at www.service<strong>on</strong>tario.ca/publicati<strong>on</strong>s• By ph<strong>on</strong>e through <str<strong>on</strong>g>the</str<strong>on</strong>g> Service<strong>Ontario</strong> C<strong>on</strong>tact CentreM<strong>on</strong>day to Friday, 8:30 AM to 5:00 PM• 416-326-5300• 416-325-3408 (TTY)• 1-800-668-9938 Toll-free across Canada• 1-800-268-7095 TTY Toll-free across <strong>Ontario</strong>• In pers<strong>on</strong> at Service<strong>Ontario</strong> Centres across <strong>Ontario</strong>DisclaimerThis document is intended for informati<strong>on</strong>al purposes <strong>on</strong>ly. This document is not intended to provideengineering, legal or o<str<strong>on</strong>g>the</str<strong>on</strong>g>r advice. <strong>Farm</strong>ers are advised to c<strong>on</strong>sult <str<strong>on</strong>g>the</str<strong>on</strong>g>ir own pr<str<strong>on</strong>g>of</str<strong>on</strong>g>essi<strong>on</strong>al engineer or lawyer asapplicable to determine <str<strong>on</strong>g>the</str<strong>on</strong>g> best course <str<strong>on</strong>g>of</str<strong>on</strong>g> acti<strong>on</strong> or legal requirements applicable to <str<strong>on</strong>g>the</str<strong>on</strong>g>ir individual farm.Published by <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Ministry</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Agriculture, Food and Rural Affairs© Queen’s Printer for <strong>Ontario</strong>, 2011Tor<strong>on</strong>to, CanadaISBN 978-1-4435-5601-903-11-3MFr<strong>on</strong>t cover photo: ©2010 Waterloo Regi<strong>on</strong> Record, <strong>Ontario</strong>, CanadaAussi disp<strong>on</strong>ible en français.ii

PrefacePrefaceIn recent years, fires in <strong>Ontario</strong> farm buildings have become an increasing c<strong>on</strong>cern resulting in losses <str<strong>on</strong>g>of</str<strong>on</strong>g> morethan $30 milli<strong>on</strong> per year. Additi<strong>on</strong>al losses to <str<strong>on</strong>g>the</str<strong>on</strong>g> farm operati<strong>on</strong> include equipment, livestock or poultry lostin <str<strong>on</strong>g>the</str<strong>on</strong>g> blaze, business interrupti<strong>on</strong>, loss <str<strong>on</strong>g>of</str<strong>on</strong>g> producti<strong>on</strong> and extreme stress <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> farm family. Although <str<strong>on</strong>g>the</str<strong>on</strong>g>re arefire risks to <str<strong>on</strong>g>the</str<strong>on</strong>g> home, this document focuses <strong>on</strong> farm buildings. The growth <str<strong>on</strong>g>of</str<strong>on</strong>g> larger-scale farming operati<strong>on</strong>shas increased <str<strong>on</strong>g>the</str<strong>on</strong>g> need to address this problem as <str<strong>on</strong>g>the</str<strong>on</strong>g> financial cost to replace <str<strong>on</strong>g>the</str<strong>on</strong>g>se larger facilities has increased.Operators need to perform a risk assessment <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>ir farm buildings to c<strong>on</strong>sider <str<strong>on</strong>g>the</str<strong>on</strong>g> operati<strong>on</strong>al impact a firecould cause <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>ir farm. As part <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> risk assessment, direct specific attenti<strong>on</strong> toward <str<strong>on</strong>g>the</str<strong>on</strong>g> safety <str<strong>on</strong>g>of</str<strong>on</strong>g> familyand employees, and <str<strong>on</strong>g>the</str<strong>on</strong>g> level <str<strong>on</strong>g>of</str<strong>on</strong>g> compliance with Codes requirements. All parties involved with designing,c<strong>on</strong>structing and operating farm buildings must understand <str<strong>on</strong>g>the</str<strong>on</strong>g> importance <str<strong>on</strong>g>of</str<strong>on</strong>g> following best managementpractices to protect <str<strong>on</strong>g>the</str<strong>on</strong>g>se large investments and <str<strong>on</strong>g>the</str<strong>on</strong>g> people working in <str<strong>on</strong>g>the</str<strong>on</strong>g> facilities.In 2007, <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Ontario</strong> <strong>Ministry</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Agriculture, Food and Rural Affairs (OMAFRA) struck a Technical AdvisoryCommittee <strong>on</strong> <strong>Farm</strong> <str<strong>on</strong>g>Fire</str<strong>on</strong>g>s (TACFF) to address <str<strong>on</strong>g>the</str<strong>on</strong>g> fire safety risks. The purpose <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> committee was to reduce<str<strong>on</strong>g>the</str<strong>on</strong>g> potential for life and property loss by identifying <str<strong>on</strong>g>the</str<strong>on</strong>g> regulatory requirements and best management practicesin <str<strong>on</strong>g>the</str<strong>on</strong>g> industry.Members <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> committee include:• Building <str<strong>on</strong>g>of</str<strong>on</strong>g>ficials• Canadian <strong>Farm</strong> Builders Associati<strong>on</strong>• Electrical Safety Authority• <strong>Farm</strong> building c<strong>on</strong>tractors and farm building design engineers• Insurance industry• <strong>Ontario</strong> Associati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g> Chiefs• <strong>Ontario</strong> <strong>Ministry</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Agriculture, Food and Rural Affairs• <strong>Ontario</strong> <strong>Ministry</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Municipal Affairs and Housing• <strong>Ontario</strong> Office <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g> Marshal• <strong>Ontario</strong> Porkiii

ivREDUCING THE RISK OF FIRE ON YOUR FARM

Introducti<strong>on</strong>Introducti<strong>on</strong>The guide examines <str<strong>on</strong>g>the</str<strong>on</strong>g> major causes <str<strong>on</strong>g>of</str<strong>on</strong>g> farm building fires and what can be d<strong>on</strong>e to reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> associatedrisks. The c<strong>on</strong>cepts <str<strong>on</strong>g>of</str<strong>on</strong>g> fire safety and how <str<strong>on</strong>g>the</str<strong>on</strong>g>y are applied are covered. Strategies are also discussed, using bestmanagement practices, to reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> impact <strong>on</strong> property and business in <str<strong>on</strong>g>the</str<strong>on</strong>g> event that a fire does occur.<str<strong>on</strong>g>Reducing</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>Risk</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g> <strong>on</strong> <strong>Your</strong> <strong>Farm</strong> was developed for c<strong>on</strong>siderati<strong>on</strong> in relati<strong>on</strong> to farm buildings suchas livestock barns, grain and equipment storage facilities, and o<str<strong>on</strong>g>the</str<strong>on</strong>g>r similar farm buildings <str<strong>on</strong>g>of</str<strong>on</strong>g> low humanoccupancy. The recommendati<strong>on</strong>s pertain to both existing and new c<strong>on</strong>structi<strong>on</strong>, supplementing <str<strong>on</strong>g>the</str<strong>on</strong>g> applicablerequirements <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> Nati<strong>on</strong>al <strong>Farm</strong> Building Code <str<strong>on</strong>g>of</str<strong>on</strong>g> Canada, 1995, (NFBCC) as referenced by <strong>Ontario</strong>’sBuilding Code (<str<strong>on</strong>g>the</str<strong>on</strong>g> Building Code), a regulati<strong>on</strong> made under <str<strong>on</strong>g>the</str<strong>on</strong>g> Building Code Act, 1992. The NFBCC establishesminimum requirements for fire protecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> farm buildings <str<strong>on</strong>g>of</str<strong>on</strong>g> low human occupancy.The Building Code Act, 1992 requires that a building permit be obtained before any c<strong>on</strong>structi<strong>on</strong>, renovati<strong>on</strong> orchange <str<strong>on</strong>g>of</str<strong>on</strong>g> use is undertaken. Using this guide does not relieve <str<strong>on</strong>g>the</str<strong>on</strong>g> operator from compliance with <str<strong>on</strong>g>the</str<strong>on</strong>g> prescribedadministrative process or <str<strong>on</strong>g>the</str<strong>on</strong>g> technical requirements in <str<strong>on</strong>g>the</str<strong>on</strong>g> NFBCC. This guide is intended to explain <str<strong>on</strong>g>the</str<strong>on</strong>g>principles and c<strong>on</strong>cepts <str<strong>on</strong>g>of</str<strong>on</strong>g> fire safety, and how <str<strong>on</strong>g>the</str<strong>on</strong>g>y relate to <str<strong>on</strong>g>the</str<strong>on</strong>g> farm and farming practices.There are o<str<strong>on</strong>g>the</str<strong>on</strong>g>r Codes and regulati<strong>on</strong>s to be respected when building, renovating or operating farm buildings.For example, <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Ontario</strong> Electrical Safety Code requires that all electrical equipment used in <strong>Ontario</strong> displaya Canadian electrical approval stamp – Canadian Standards Associati<strong>on</strong> (CSA) and Underwriters Laboratory<str<strong>on</strong>g>of</str<strong>on</strong>g> Canada (ULC). If liquid or gaseous petroleum products are used <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> farm, <str<strong>on</strong>g>the</str<strong>on</strong>g>re are Codes specifyingrequirements for <str<strong>on</strong>g>the</str<strong>on</strong>g> safe storage and handling <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>se products. These Codes are enforced by <str<strong>on</strong>g>the</str<strong>on</strong>g> TechnicalStandards and Safety Authority (TSSA). The operator is resp<strong>on</strong>sible for understanding <str<strong>on</strong>g>the</str<strong>on</strong>g>se requirementsas well as o<str<strong>on</strong>g>the</str<strong>on</strong>g>r governing regulati<strong>on</strong>s <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> farm.The guide is intended to highlight best management practices. To fur<str<strong>on</strong>g>the</str<strong>on</strong>g>r reduce risk, <str<strong>on</strong>g>the</str<strong>on</strong>g>re are instances whererequirements greater than those c<strong>on</strong>tained in <str<strong>on</strong>g>the</str<strong>on</strong>g> NFBCC are specified. Do not rely <strong>on</strong> <str<strong>on</strong>g>Reducing</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>Risk</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g><strong>on</strong> <strong>Your</strong> <strong>Farm</strong> as a substitute for specialized legal or pr<str<strong>on</strong>g>of</str<strong>on</strong>g>essi<strong>on</strong>al advice in c<strong>on</strong>necti<strong>on</strong> with any particular matter.The user is solely resp<strong>on</strong>sible for any use or applicati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> this guide. Although <str<strong>on</strong>g>the</str<strong>on</strong>g> guide has been carefullywritten, <str<strong>on</strong>g>the</str<strong>on</strong>g> authors, committee and <str<strong>on</strong>g>the</str<strong>on</strong>g> government <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>Ontario</strong> do not accept any legal resp<strong>on</strong>sibility for <str<strong>on</strong>g>the</str<strong>on</strong>g>c<strong>on</strong>tents <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> guide or for any c<strong>on</strong>sequences, including direct or indirect liability, arising from its use.v

viREDUCING THE RISK OF FIRE ON YOUR FARM

CONTENTSCONTENTS1.0 Leading Causes <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>Farm</strong> Building <str<strong>on</strong>g>Fire</str<strong>on</strong>g>s. ................................................ 1Mechanical/Electrical Failure. .................................................................. 2Misuse <str<strong>on</strong>g>of</str<strong>on</strong>g> Igniti<strong>on</strong> Source or Igniting Equipment ................................................... 3Design, C<strong>on</strong>structi<strong>on</strong> or Maintenance Deficiency. ................................................... 3O<str<strong>on</strong>g>the</str<strong>on</strong>g>r Factors that C<strong>on</strong>tribute to <str<strong>on</strong>g>the</str<strong>on</strong>g> Impact <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g>s. ................................................ 42.0 Preventative Maintenance to Reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>Risk</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g> ................................. 5General Operating Practices. ................................................................... 5Electrical Systems. ........................................................................... 6Mechanical Systems .......................................................................... 9Heating Appliance Systems. ................................................................... 103.0 Preventing <str<strong>on</strong>g>Fire</str<strong>on</strong>g> Spread ................................................................ 13<str<strong>on</strong>g>Fire</str<strong>on</strong>g> Separati<strong>on</strong>. ............................................................................ 13<str<strong>on</strong>g>Fire</str<strong>on</strong>g> Compartments ......................................................................... 16<str<strong>on</strong>g>Fire</str<strong>on</strong>g> Stopping. ............................................................................. 18Spatial Separati<strong>on</strong>. .......................................................................... 23Flame Spread. ............................................................................. 24Electrical Code C<strong>on</strong>siderati<strong>on</strong>s. ................................................................ 27Heating System C<strong>on</strong>siderati<strong>on</strong>s ................................................................ 294.0 <str<strong>on</strong>g>Reducing</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> Impact <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g> ........................................................... 31Detecti<strong>on</strong> and Suppressi<strong>on</strong> Systems. ............................................................ 31<str<strong>on</strong>g>Fire</str<strong>on</strong>g> Department Access. ..................................................................... 32Water Supply for <str<strong>on</strong>g>Fire</str<strong>on</strong>g> Fighting. ................................................................ 35Evacuati<strong>on</strong>. ............................................................................... 375.0 Assessing <strong>Your</strong> <str<strong>on</strong>g>Risk</str<strong>on</strong>g> ................................................................... 43Summary. ................................................................................... 44vii

viiiREDUCING THE RISK OF FIRE ON YOUR FARM

1.0 Leading Causes <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>Farm</strong> Building <str<strong>on</strong>g>Fire</str<strong>on</strong>g>s1.0 Leading Causes <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>Farm</strong> Building <str<strong>on</strong>g>Fire</str<strong>on</strong>g>sThe Office <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g> Marshal manages a database <strong>on</strong> all fire and explosi<strong>on</strong> occurrences in <strong>Ontario</strong>. Datareported by fire departments for 2004 – 2007 were analyzed for occurrences involving farm buildings to identifycomm<strong>on</strong> causes and what can be learned to reduce <str<strong>on</strong>g>the</str<strong>on</strong>g>m. Figure 1 shows a very large swine facility after it wasdestroyed by fire, in less than <strong>on</strong>e hour.Figure 1.0. This large swine barn was completely destroyed by fire.(Photo credit: P. Stolk, <strong>Farm</strong> Mutual Reinsurance Plan)While <str<strong>on</strong>g>the</str<strong>on</strong>g> sources <str<strong>on</strong>g>of</str<strong>on</strong>g> many fires are undetermined due to significant fire damage, <str<strong>on</strong>g>the</str<strong>on</strong>g>re are three leadingcauses <str<strong>on</strong>g>of</str<strong>on</strong>g> identifiable farm fires, as reported by fire services.Mechanical/electrical failure• short circuit or ground fault in electrical equipment• failure <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> built-in automatic c<strong>on</strong>trols in mechanical equipment or systemMisuse <str<strong>on</strong>g>of</str<strong>on</strong>g> igniti<strong>on</strong> source or igniting equipment• improperly discarded smoker’s material• igniti<strong>on</strong> source left unattended• smoking where flammable vapours are present• improper use <str<strong>on</strong>g>of</str<strong>on</strong>g> extensi<strong>on</strong> cords (e.g. overloaded circuit, multiple strings in sequence)Design, c<strong>on</strong>structi<strong>on</strong> or maintenance deficiency• improperly c<strong>on</strong>structed building feature or system• improperly installed object such as a heating appliance that is too close to combustible building features• improper maintenance such as failure to remove accumulati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> combustible dust or debris, which is <str<strong>on</strong>g>the</str<strong>on</strong>g>nignited by heating appliances, process equipment or electrical equipment• faulty product design causes a fire even when <str<strong>on</strong>g>the</str<strong>on</strong>g> product is installed and used correctly1

REDUCING THE RISK OF FIRE ON YOUR FARMMechanical/Electrical FailureThe insurance industry, in associati<strong>on</strong> with <str<strong>on</strong>g>the</str<strong>on</strong>g> Electrical Safety Authority (ESA), reviewed additi<strong>on</strong>alinformati<strong>on</strong> <strong>on</strong> mechanical and electrical failures leading to barn fires. They identified <str<strong>on</strong>g>the</str<strong>on</strong>g> corrosiveenvir<strong>on</strong>ment found inside c<strong>on</strong>fined livestock barns as <str<strong>on</strong>g>the</str<strong>on</strong>g> leading cause <str<strong>on</strong>g>of</str<strong>on</strong>g> degradati<strong>on</strong> or failure <str<strong>on</strong>g>of</str<strong>on</strong>g> electricalequipment. The degradati<strong>on</strong> is typically corrosi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> exposed metal comp<strong>on</strong>ents (e.g. wires, c<strong>on</strong>necti<strong>on</strong>s,etc.). The corrosi<strong>on</strong> increases <str<strong>on</strong>g>the</str<strong>on</strong>g> resistance at <str<strong>on</strong>g>the</str<strong>on</strong>g>se points causing a reducti<strong>on</strong> in <str<strong>on</strong>g>the</str<strong>on</strong>g> flow <str<strong>on</strong>g>of</str<strong>on</strong>g> electricity through<str<strong>on</strong>g>the</str<strong>on</strong>g> circuit. The increased resistance results in more <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> electrical energy being c<strong>on</strong>verted to heat (Figures 1.1and 1.2). As <str<strong>on</strong>g>the</str<strong>on</strong>g> corrosi<strong>on</strong> levels c<strong>on</strong>tinue to increase, <str<strong>on</strong>g>the</str<strong>on</strong>g> heat generated rises to <str<strong>on</strong>g>the</str<strong>on</strong>g> igniti<strong>on</strong> temperature <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>materials surrounding <str<strong>on</strong>g>the</str<strong>on</strong>g> equipment. The decay can occur over a short period <str<strong>on</strong>g>of</str<strong>on</strong>g> time. Evidence <str<strong>on</strong>g>of</str<strong>on</strong>g> corrosi<strong>on</strong>has been observed in barns less than five years after c<strong>on</strong>structi<strong>on</strong>.Figure 1.1. Thermographic picture <str<strong>on</strong>g>of</str<strong>on</strong>g> an electrical receptacle in a livestock barn.(Photo credit: R. Drysdale, <strong>Farm</strong> Mutual Reinsurance Plan)Figure 1.2. Thermographic picture <str<strong>on</strong>g>of</str<strong>on</strong>g> an electrical panel in a livestock barn.(Photo credit: R. Drysdale, <strong>Farm</strong> Mutual Reinsurance Plan)2

1.0 Leading Causes <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>Farm</strong> Building <str<strong>on</strong>g>Fire</str<strong>on</strong>g>sMisuse <str<strong>on</strong>g>of</str<strong>on</strong>g> Igniti<strong>on</strong> Source or Igniting EquipmentA comm<strong>on</strong>ly reported cause <str<strong>on</strong>g>of</str<strong>on</strong>g> fires in farm buildings is <str<strong>on</strong>g>the</str<strong>on</strong>g> misuse <str<strong>on</strong>g>of</str<strong>on</strong>g> equipment (i.e. arc welders, cuttingtorches or grinders) in <str<strong>on</strong>g>the</str<strong>on</strong>g> presence <str<strong>on</strong>g>of</str<strong>on</strong>g> combustible materials or gases without <str<strong>on</strong>g>the</str<strong>on</strong>g> proper safeguards. The carelessuse <str<strong>on</strong>g>of</str<strong>on</strong>g> smoker’s materials (i.e. cigarettes, matches, pipes) c<strong>on</strong>tinues to be a comm<strong>on</strong> cause <str<strong>on</strong>g>of</str<strong>on</strong>g> fires. <str<strong>on</strong>g>Fire</str<strong>on</strong>g>s reportedin this group reflect human error and are preventable with best practice operating procedures (Figure 1.3).Figure 1.3. Grinding operati<strong>on</strong> taking place in <str<strong>on</strong>g>the</str<strong>on</strong>g>presence <str<strong>on</strong>g>of</str<strong>on</strong>g> combustible materials. Use this type <str<strong>on</strong>g>of</str<strong>on</strong>g>equipment outside <str<strong>on</strong>g>the</str<strong>on</strong>g> barn and away fromcombustibles, or put safeguards in place to reduce<str<strong>on</strong>g>the</str<strong>on</strong>g> risk <str<strong>on</strong>g>of</str<strong>on</strong>g> accidental igniti<strong>on</strong>.Design, C<strong>on</strong>structi<strong>on</strong> or Maintenance DeficiencyImproperly designed, installed or maintained building systems are ano<str<strong>on</strong>g>the</str<strong>on</strong>g>r comm<strong>on</strong> cause <str<strong>on</strong>g>of</str<strong>on</strong>g> farm building fires.This includes heating equipment, lighting systems, process equipment and electrical distributi<strong>on</strong>. For example,heat shields for a suspended radiant tube heater may become displaced with <str<strong>on</strong>g>the</str<strong>on</strong>g> use <str<strong>on</strong>g>of</str<strong>on</strong>g> a high pressure washer.Without <str<strong>on</strong>g>the</str<strong>on</strong>g> shields properly in place, <str<strong>on</strong>g>the</str<strong>on</strong>g> underside <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> ceiling becomes too hot and increases <str<strong>on</strong>g>the</str<strong>on</strong>g> potentialfor igniti<strong>on</strong> and fire (Figures 1.4 and 1.5). Although <str<strong>on</strong>g>the</str<strong>on</strong>g> design and installati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> equipment is correct,a maintenance deficiency would be identified as <str<strong>on</strong>g>the</str<strong>on</strong>g> cause <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> fire.Figure 1.4. Radiant tube heater with heat shield displaced. Note charring<strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> ceiling.(Photo credit: R. Drysdale, <strong>Farm</strong> Mutual Reinsurance Plan)3

REDUCING THE RISK OF FIRE ON YOUR FARMFigure 1.5. Radiant tube heater lacking heat shield. Note close proximityto combustibles (wood ceiling and c<strong>on</strong>duit).(Photo credit: R. Drysdale, <strong>Farm</strong> Mutual Reinsurance Plan)O<str<strong>on</strong>g>the</str<strong>on</strong>g>r Factors that C<strong>on</strong>tribute to <str<strong>on</strong>g>the</str<strong>on</strong>g> Impact <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g>sIn additi<strong>on</strong> to looking at <str<strong>on</strong>g>the</str<strong>on</strong>g> causes <str<strong>on</strong>g>of</str<strong>on</strong>g> fire, it is important to review o<str<strong>on</strong>g>the</str<strong>on</strong>g>r factors that c<strong>on</strong>tribute to fire growthand <str<strong>on</strong>g>the</str<strong>on</strong>g> magnitude <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> losses. An igniti<strong>on</strong> source must be close to combustible materials for fire to start.Combustible materials cannot be totally avoided <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> farm, but reducing <str<strong>on</strong>g>the</str<strong>on</strong>g>ir use in c<strong>on</strong>structi<strong>on</strong> andestablishing good housekeeping practices goes a l<strong>on</strong>g way in reducing fire growth. The use <str<strong>on</strong>g>of</str<strong>on</strong>g> fire compartmentsis an effective design strategy to c<strong>on</strong>tain a fire and prevent total building destructi<strong>on</strong>. To be effective, keep firecompartments in good c<strong>on</strong>diti<strong>on</strong>, including <str<strong>on</strong>g>the</str<strong>on</strong>g> proper operati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> fire doors. Early detecti<strong>on</strong> and fire resp<strong>on</strong>seare key to reducing <str<strong>on</strong>g>the</str<strong>on</strong>g> magnitude <str<strong>on</strong>g>of</str<strong>on</strong>g> farm fires. Many <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>se c<strong>on</strong>cepts and recommended c<strong>on</strong>siderati<strong>on</strong>s arecovered in this guide.4

2.0 Preventative Maintenance to Reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>Risk</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g>2.0 Preventative Maintenance to Reduce<str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>Risk</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g>There are several operati<strong>on</strong>al and maintenance practices that farm operators can use to reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> risk<str<strong>on</strong>g>of</str<strong>on</strong>g> fires <strong>on</strong> farm.General Operating Practices• Do not allow smoking in farm buildings. Restricting access to farm buildings keeps people out who d<strong>on</strong>’tknow or respect <str<strong>on</strong>g>the</str<strong>on</strong>g>se rules.• When repairing fixed or stati<strong>on</strong>ary equipment inside a farm building (livestock penning, stabling, etc.) withigniti<strong>on</strong> source equipment (welders, cutting torches or grinders), ensure that:• fire extinguishers are located in <str<strong>on</strong>g>the</str<strong>on</strong>g> work area• all combustible materials are removed from <str<strong>on</strong>g>the</str<strong>on</strong>g> work area• <str<strong>on</strong>g>the</str<strong>on</strong>g> site is well ventilated to reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>centrati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> combustible gases presentEstablish a fire watch during <str<strong>on</strong>g>the</str<strong>on</strong>g> work and for a period <str<strong>on</strong>g>of</str<strong>on</strong>g> time following completi<strong>on</strong>. Gas detecti<strong>on</strong> devicesare available if accurate gas c<strong>on</strong>centrati<strong>on</strong> levels are required.• Establish good housekeeping practices. Eliminate clutter inside and outside <str<strong>on</strong>g>the</str<strong>on</strong>g> buildings. Keep grass andweeds mowed around buildings. These measures reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> risk <str<strong>on</strong>g>of</str<strong>on</strong>g> fire spread and improve <str<strong>on</strong>g>the</str<strong>on</strong>g> effectiveness<str<strong>on</strong>g>of</str<strong>on</strong>g> suppressi<strong>on</strong> activities.• Be careful when pressure washing inside a farm building. The high pressure water can physically damageequipment and allow deep water penetrati<strong>on</strong> into unwanted areas such as electrical panels, heater c<strong>on</strong>trols, etc.• Grain handling and feed preparati<strong>on</strong> activities generate dust which presents an explosi<strong>on</strong> and/or fire hazard.Vent <str<strong>on</strong>g>the</str<strong>on</strong>g>se areas and provide a fresh air supply. Properly protect electrical fixtures and use totally enclosed,fan-cooled motors. Good housekeeping practices are critical to limit combustible materials from this area.• Ensure all liquid fuel and propane storage areas are located according to applicable Codes (adequateseparati<strong>on</strong> distance from fixed igniti<strong>on</strong> sources, etc.). If <str<strong>on</strong>g>the</str<strong>on</strong>g> storage tanks are exposed to vehicle traffic,install protecti<strong>on</strong> (i.e. bollards or equivalent) around <str<strong>on</strong>g>the</str<strong>on</strong>g> storage tanks to reduce risk <str<strong>on</strong>g>of</str<strong>on</strong>g> damage from vehiclecollisi<strong>on</strong>s (Figure 2.1).5

REDUCING THE RISK OF FIRE ON YOUR FARMFigure 2.1. On-farm fuel storage with vehicle protecti<strong>on</strong> (bollards).(Photo credit: FS Partners)• Install all electrical equipment associated with fuel storage (i.e. electric fuel pump) according to <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Ontario</strong>Electrical Safety Code.Electrical SystemsThe combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a humid (wet) and corrosive envir<strong>on</strong>ment is harmful to exposed electrical equipment(plug ends, unsealed juncti<strong>on</strong> points, etc.). Excessive corrosi<strong>on</strong> increases <str<strong>on</strong>g>the</str<strong>on</strong>g> equipment’s electricalresistance and results in increased heat producti<strong>on</strong>, <str<strong>on</strong>g>the</str<strong>on</strong>g> suspected igniti<strong>on</strong> source in a number <str<strong>on</strong>g>of</str<strong>on</strong>g> barn fires.Thermographic imaging exposes <str<strong>on</strong>g>the</str<strong>on</strong>g> problem, primarily in swine buildings, however <str<strong>on</strong>g>the</str<strong>on</strong>g> issue is also seenin poultry and o<str<strong>on</strong>g>the</str<strong>on</strong>g>r livestock facilities. Review and follow <str<strong>on</strong>g>the</str<strong>on</strong>g>se best practices relating to <str<strong>on</strong>g>the</str<strong>on</strong>g> use andmaintenance <str<strong>on</strong>g>of</str<strong>on</strong>g> electrical equipment.• On a yearly basis, have a licensed electrical c<strong>on</strong>tractor inspect all electrical equipment within <str<strong>on</strong>g>the</str<strong>on</strong>g> barn. Focusparticular attenti<strong>on</strong> <strong>on</strong> cord caps (ends), ceiling mounted outlets, light fixtures (Figure 2.2) and electricalpanels located within <str<strong>on</strong>g>the</str<strong>on</strong>g> animal areas.Figure 2.2. Light fixture in a dairy barn that caught fire due to <str<strong>on</strong>g>the</str<strong>on</strong>g> presence<str<strong>on</strong>g>of</str<strong>on</strong>g> a bird’s nest (proximity <str<strong>on</strong>g>of</str<strong>on</strong>g> combustibles).(Photo credit: R. Drysdale, <strong>Farm</strong> Mutual Reinsurance Plan)6

2.0 Preventative Maintenance to Reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>Risk</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g>• Complete a yearly <str<strong>on</strong>g>the</str<strong>on</strong>g>rmographic inspecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> entire electrical system when <str<strong>on</strong>g>the</str<strong>on</strong>g> barn is at its peakelectrical demand (e.g. summer for swine and poultry). Many insurance companies now <str<strong>on</strong>g>of</str<strong>on</strong>g>fer this value addedservice for <str<strong>on</strong>g>the</str<strong>on</strong>g>ir policyholders. Make any necessary repairs to eliminate identified hot spots (Figure 2.3).Figure 2.3. Thermographic image <str<strong>on</strong>g>of</str<strong>on</strong>g> an electricaloutlet in a barn discovered during an annualinspecti<strong>on</strong>. Note <str<strong>on</strong>g>the</str<strong>on</strong>g> hotspots (red) at greaterthan 100 ºC (212 ºF).(Photo credit: R. Drysdale, <strong>Farm</strong> Mutual Reinsurance Plan)• The <strong>Ontario</strong> Electrical Safety Code permits <str<strong>on</strong>g>the</str<strong>on</strong>g> use <str<strong>on</strong>g>of</str<strong>on</strong>g> wiring for damp locati<strong>on</strong>s in farm buildings housinglivestock or poultry when <str<strong>on</strong>g>the</str<strong>on</strong>g> area has adequate ventilati<strong>on</strong>. For more informati<strong>on</strong> <strong>on</strong> ventilating livestockbuildings, see OMAFRA Publicati<strong>on</strong> 833, Ventilati<strong>on</strong> for Livestock and Poultry Facilities, www.service<strong>Ontario</strong>.ca• Replace older wiring that passes through <str<strong>on</strong>g>the</str<strong>on</strong>g> walls or o<str<strong>on</strong>g>the</str<strong>on</strong>g>r c<strong>on</strong>cealed building spaces with wiring installedin c<strong>on</strong>duit.• Have a licensed electrical c<strong>on</strong>tractor perform all electrical work within <str<strong>on</strong>g>the</str<strong>on</strong>g> building to ensure it is d<strong>on</strong>esafely and meets <str<strong>on</strong>g>the</str<strong>on</strong>g> requirements <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Ontario</strong> Electrical Safety Code. All electrical installati<strong>on</strong>s mustbe inspected by <str<strong>on</strong>g>the</str<strong>on</strong>g> Electrical Safety Authority (ESA).• Properly secure wiring enclosure covers to minimize <str<strong>on</strong>g>the</str<strong>on</strong>g> entry <str<strong>on</strong>g>of</str<strong>on</strong>g> corrosive gases and moisture.Replace damaged or deteriorated parts.• Do not store flammable and/or combustible material underneath or around <str<strong>on</strong>g>the</str<strong>on</strong>g> electrical panels.• Ensure a minimum <str<strong>on</strong>g>of</str<strong>on</strong>g> 1 m (3 ft) <str<strong>on</strong>g>of</str<strong>on</strong>g> clear access space in fr<strong>on</strong>t <str<strong>on</strong>g>of</str<strong>on</strong>g> each electrical panel.• Repair all damaged or malfuncti<strong>on</strong>ing fixtures or equipment as so<strong>on</strong> as practical.• Completely remove or physically disable all aband<strong>on</strong>ed or malfuncti<strong>on</strong>ing wiring within <str<strong>on</strong>g>the</str<strong>on</strong>g> barn. Removing<str<strong>on</strong>g>the</str<strong>on</strong>g> fuse or turning <str<strong>on</strong>g>of</str<strong>on</strong>g>f <str<strong>on</strong>g>the</str<strong>on</strong>g> breaker is not a good practice, or l<strong>on</strong>g-term soluti<strong>on</strong>, and can lead to dangeroussituati<strong>on</strong>s if <str<strong>on</strong>g>the</str<strong>on</strong>g> circuit is reactivated by accident.• Heat lamps are a comm<strong>on</strong> source <str<strong>on</strong>g>of</str<strong>on</strong>g> fire. When heat lamps are required, protect <str<strong>on</strong>g>the</str<strong>on</strong>g> immediate area withn<strong>on</strong>-combustible sheathing (c<strong>on</strong>crete board, c<strong>on</strong>crete, steel, tile, etc.). Keep <str<strong>on</strong>g>the</str<strong>on</strong>g> area around <str<strong>on</strong>g>the</str<strong>on</strong>g> heat lampclear <str<strong>on</strong>g>of</str<strong>on</strong>g> clutter or bedding materials that could catch fire. Only use heat lamps with <str<strong>on</strong>g>the</str<strong>on</strong>g> CSA or ULC label.Figures 2.4a and 2.4b show examples <str<strong>on</strong>g>of</str<strong>on</strong>g> incorrect and correct uses <str<strong>on</strong>g>of</str<strong>on</strong>g> heat lamps.7

REDUCING THE RISK OF FIRE ON YOUR FARMFigure 2.4a. Example <str<strong>on</strong>g>of</str<strong>on</strong>g> incorrect use <str<strong>on</strong>g>of</str<strong>on</strong>g> a heat lamp.The following situati<strong>on</strong>s are incorrect uses for a heat lamp:• lamp suspended using baler twine (combustible material)• incorrect wiring, electrical cords are knotted toge<str<strong>on</strong>g>the</str<strong>on</strong>g>r• lamp suspended too close to bedding (combustible)• animals have access to lampFigure 2.4b. Example <str<strong>on</strong>g>of</str<strong>on</strong>g> improved use <str<strong>on</strong>g>of</str<strong>on</strong>g> a heat lamp.These situati<strong>on</strong>s are correct ways to use a heat lamp:• lamp suspended using chain (n<strong>on</strong>-combustible material)• plug c<strong>on</strong>necti<strong>on</strong> is not knotted allowing for easy separati<strong>on</strong>• lamp suspended at a correct height to bedding• limit large animal access to lamp8

2.0 Preventative Maintenance to Reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>Risk</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g>Mechanical SystemsMechanical systems such as ventilati<strong>on</strong> fans, feed auger motors, milk cooling equipment and generators breakdown or wear out with time. Regular maintenance reduces <str<strong>on</strong>g>the</str<strong>on</strong>g> risk <str<strong>on</strong>g>of</str<strong>on</strong>g> overheating and decreases <str<strong>on</strong>g>the</str<strong>on</strong>g> risk <str<strong>on</strong>g>of</str<strong>on</strong>g> fire.• Inspect all motors and mechanical equipment according to <str<strong>on</strong>g>the</str<strong>on</strong>g> manufacturer’s maintenance schedule(minimum, yearly) for evidence <str<strong>on</strong>g>of</str<strong>on</strong>g> wear, overheating, etc. Repair or replace equipment as required.• Ventilate mechanical rooms to reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> risk <str<strong>on</strong>g>of</str<strong>on</strong>g> motors (standby generators, refrigerati<strong>on</strong> compressors,milk vacuum pumps, etc.) overheating during normal operati<strong>on</strong>.• Properly shield exhaust pipes from standby generators or vacuum pumps, that pass through a wall or ceiling,to reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> risk <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> building overheating and possibly igniting (Figure 2.5). Figure 2.6 shows <str<strong>on</strong>g>the</str<strong>on</strong>g>potential risk for fire due to <str<strong>on</strong>g>the</str<strong>on</strong>g> lack <str<strong>on</strong>g>of</str<strong>on</strong>g> a heat shield ring.Figure 2.5. Proper installati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> exhaust pipe through <str<strong>on</strong>g>the</str<strong>on</strong>g> wall. Note <str<strong>on</strong>g>the</str<strong>on</strong>g> heat shield ring around <str<strong>on</strong>g>the</str<strong>on</strong>g> exhaust pipe.Figure 2.6. Thermographic image <str<strong>on</strong>g>of</str<strong>on</strong>g> an exhaust pipe. Note <str<strong>on</strong>g>the</str<strong>on</strong>g> lack <str<strong>on</strong>g>of</str<strong>on</strong>g> heat shieldingwhere <str<strong>on</strong>g>the</str<strong>on</strong>g> pipe passes through <str<strong>on</strong>g>the</str<strong>on</strong>g> wall.(Photo credit: R. Drysdale, <strong>Farm</strong> Mutual Reinsurance Plan)9

REDUCING THE RISK OF FIRE ON YOUR FARM• For belt-driven fans, regularly inspect <str<strong>on</strong>g>the</str<strong>on</strong>g> belts to ensure <str<strong>on</strong>g>the</str<strong>on</strong>g>y are not damaged or missing. Also ensure <str<strong>on</strong>g>the</str<strong>on</strong>g>fan blade assembly spins freely and does not hit <str<strong>on</strong>g>the</str<strong>on</strong>g> fan housing.• Dust and debris build up over time and can cause fan blades to stop turning, resulting in overheating <str<strong>on</strong>g>of</str<strong>on</strong>g><str<strong>on</strong>g>the</str<strong>on</strong>g> fan motor. Remove dust and debris from fan motors and blades to reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> risk <str<strong>on</strong>g>of</str<strong>on</strong>g> a fire starting(Figure 2.7). This maintenance is especially important in feed rooms and barns housing livestock and poultry.Figure 2.7. Example <str<strong>on</strong>g>of</str<strong>on</strong>g> a dirty fan in need <str<strong>on</strong>g>of</str<strong>on</strong>g> cleaning.• Have all repairs completed by a qualified individual and ensure all applicable Codes are met.Heating Appliance SystemsHeating systems are particularly important as <str<strong>on</strong>g>the</str<strong>on</strong>g>y c<strong>on</strong>tain an igniti<strong>on</strong> source (i.e. pilot light, igniters)and open flames.• Complete annual maintenance <str<strong>on</strong>g>of</str<strong>on</strong>g> all heating devices within <str<strong>on</strong>g>the</str<strong>on</strong>g> farm buildings. C<strong>on</strong>sult a qualified heatingtechnician for this maintenance. Figures 2.8a and 2.8b show how heating equipment can corrode in a barnwith high humidity and corrosive air properties.Figure 2.8a. Rear view <str<strong>on</strong>g>of</str<strong>on</strong>g> a radiant tube heater insidea broiler barn.10

2.0 Preventative Maintenance to Reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>Risk</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Fire</str<strong>on</strong>g>Figure 2.8b. Fr<strong>on</strong>t view <str<strong>on</strong>g>of</str<strong>on</strong>g> a radiant tube heater inside<str<strong>on</strong>g>the</str<strong>on</strong>g> same broiler barn. Corrosi<strong>on</strong> is present.• Ensure all heat shields are in place for any heating device that requires <str<strong>on</strong>g>the</str<strong>on</strong>g>m. This is especially importantfor radiant tube heaters (Figure 2.9).Figure 2.9. Radiant tube heater lacking heat shield. Note close proximityto combustibles (wood ceiling and c<strong>on</strong>duit).(Photo credit: R. Drysdale, <strong>Farm</strong> Mutual Reinsurance Plan)11

12REDUCING THE RISK OF FIRE ON YOUR FARM

3.0 Preventing <str<strong>on</strong>g>Fire</str<strong>on</strong>g> Spread3.0 Preventing <str<strong>on</strong>g>Fire</str<strong>on</strong>g> SpreadDesign Codes and/or standards are minimum requirements established to protect <str<strong>on</strong>g>the</str<strong>on</strong>g> lives <str<strong>on</strong>g>of</str<strong>on</strong>g> people and <str<strong>on</strong>g>the</str<strong>on</strong>g>c<strong>on</strong>tents in farm buildings. Codes describe correct farm building materials to use to reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> number <str<strong>on</strong>g>of</str<strong>on</strong>g>igniti<strong>on</strong> sources, reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> rate fire spreads within buildings and establish separati<strong>on</strong> distances for fire spreadto o<str<strong>on</strong>g>the</str<strong>on</strong>g>r buildings. These Codes are in place because barn layout and c<strong>on</strong>structi<strong>on</strong> materials greatly influence<str<strong>on</strong>g>the</str<strong>on</strong>g> fire risk associated with a given site.When discussing fire safety, preventi<strong>on</strong>, precauti<strong>on</strong>s and procedures are <str<strong>on</strong>g>of</str<strong>on</strong>g>ten included. Preventi<strong>on</strong>,as highlighted in this secti<strong>on</strong>, deals with ways to prevent <str<strong>on</strong>g>the</str<strong>on</strong>g> initial source <str<strong>on</strong>g>of</str<strong>on</strong>g> igniti<strong>on</strong> from spreadingand prevent fire from starting in adjacent areas.<str<strong>on</strong>g>Fire</str<strong>on</strong>g> Separati<strong>on</strong>One <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> key c<strong>on</strong>cepts <str<strong>on</strong>g>of</str<strong>on</strong>g> fire safety in all buildings, including farm buildings, is to limit <str<strong>on</strong>g>the</str<strong>on</strong>g> spread <str<strong>on</strong>g>of</str<strong>on</strong>g> firethroughout a building with a physical barrier, known as a fire separati<strong>on</strong>. A fire separati<strong>on</strong> can be a wall, ceilingor floor <str<strong>on</strong>g>of</str<strong>on</strong>g> a building (Figure 3.1). Several fire separati<strong>on</strong>s are <str<strong>on</strong>g>of</str<strong>on</strong>g>ten used in combinati<strong>on</strong> to surround a givenspace and c<strong>on</strong>tain fire within it; this space is termed a fire compartment.Figure 3.1. Example <str<strong>on</strong>g>of</str<strong>on</strong>g> a fire separati<strong>on</strong> that served its purposein a swine complex, preventing <str<strong>on</strong>g>the</str<strong>on</strong>g> fire from spreading to <str<strong>on</strong>g>the</str<strong>on</strong>g>rest <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> barn.(Photo credit: R. Drysdale, <strong>Farm</strong> Mutual Reinsurance Plan)A wall, when put toge<str<strong>on</strong>g>the</str<strong>on</strong>g>r or c<strong>on</strong>structed in a building, is known as a wall assembly. Similarly, ceilings andfloors, <strong>on</strong>ce built, are referred to as ceiling and floor assemblies.Wall, floor and ceiling assemblies <str<strong>on</strong>g>of</str<strong>on</strong>g> buildings are built in different ways using a variety <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>structi<strong>on</strong>materials. The way <str<strong>on</strong>g>the</str<strong>on</strong>g>se assemblies are c<strong>on</strong>structed determines how l<strong>on</strong>g it will take a fire to burn through<str<strong>on</strong>g>the</str<strong>on</strong>g> assembly and penetrate from <strong>on</strong>e fire compartment to ano<str<strong>on</strong>g>the</str<strong>on</strong>g>r. Wall, floor and ceiling assemblies builtas required fire separati<strong>on</strong>s are usually given a specific fire-resistance rating to meet.A fire-resistance rating is a measure <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> length <str<strong>on</strong>g>of</str<strong>on</strong>g> time a properly c<strong>on</strong>structed and maintained assembly canwithstand fire c<strong>on</strong>diti<strong>on</strong>s. In <str<strong>on</strong>g>the</str<strong>on</strong>g> case <str<strong>on</strong>g>of</str<strong>on</strong>g> a fire separati<strong>on</strong>, a fire-resistance rating identifies <str<strong>on</strong>g>the</str<strong>on</strong>g> time for a fire toburn through from <strong>on</strong>e compartment to ano<str<strong>on</strong>g>the</str<strong>on</strong>g>r (30 minutes, 1 hour, 2 hours, etc.).13

REDUCING THE RISK OF FIRE ON YOUR FARMExamples <str<strong>on</strong>g>of</str<strong>on</strong>g> comm<strong>on</strong> wall assemblies used as fire separati<strong>on</strong>s in farm buildings are shown in Table 3.1. It isimportant to note that <str<strong>on</strong>g>the</str<strong>on</strong>g> fire-resistance rating <str<strong>on</strong>g>of</str<strong>on</strong>g> a c<strong>on</strong>structi<strong>on</strong> assembly is for a specific c<strong>on</strong>figurati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g>structural elements. A similar wall comp<strong>on</strong>ent may behave differently if it is located in a ceiling.Table 3.1. Estimated <str<strong>on</strong>g>Fire</str<strong>on</strong>g>-Resistance Ratings for Assemblies 1, 2Structure Membranes <str<strong>on</strong>g>Fire</str<strong>on</strong>g>-resistance(minutes)38 mm x 89 mm (2 in. x 4 in.)wood studs, 400 mm (16 in.) <strong>on</strong>centres (o.c.)38 mm x 89 mm (2 in. x 4 in.)wood studs, 600 mm (24 in.) o.c.38 mm x 89 mm (2 in. x 4 in.)wood studs, 400 mm (16 in.) or600 mm (24 in.) o.c.140 mm (5 1 ⁄2 in.) hollow c<strong>on</strong>creteblocks (normal weight aggregate)190 mm (7 1 ⁄2 in.) hollow c<strong>on</strong>creteblocks (normal weight aggregate)11.0 mm ( 7 ⁄16 in.) Douglas fir plywood, OSB or waferboard (both faces)14.5 mm ( 9 ⁄16 in.) Douglas fir plywood, OSB or15.5 mm ( 5 ⁄8 in.±) wafer board (both faces)11.0 mm ( 7 ⁄16 in.) Douglas fir plywood, OSB or wafer30board (both faces) with <str<strong>on</strong>g>the</str<strong>on</strong>g> stud spaces filled withmineral wool12.7 mm ( 1 ⁄2 in.) gypsum wallboard (both faces) 3 351 layer <str<strong>on</strong>g>of</str<strong>on</strong>g> 15.9 mm ( 5 ⁄8 in.) Type X gypsum board<strong>on</strong> each side*Block is <str<strong>on</strong>g>the</str<strong>on</strong>g> membrane 601Additi<strong>on</strong>al informati<strong>on</strong> <strong>on</strong> fire-resistance ratings for assemblies is given in <strong>Ontario</strong>’s Building Code.2Interior walls are rated from both sides, whereas floors and ro<str<strong>on</strong>g>of</str<strong>on</strong>g>s are rated from below.3Use gypsum wallboard in farm buildings <strong>on</strong>ly in specific locati<strong>on</strong>s.Source: Nati<strong>on</strong>al <strong>Farm</strong> Building Code <str<strong>on</strong>g>of</str<strong>on</strong>g> Canada, 1995.*2006 Building Code – Supplementary Standards SB-3, page 2.30356090<str<strong>on</strong>g>Fire</str<strong>on</strong>g> separati<strong>on</strong>s must be c<strong>on</strong>tinuous. Except for openings in <str<strong>on</strong>g>the</str<strong>on</strong>g> outside face <str<strong>on</strong>g>of</str<strong>on</strong>g> a building, provide openings infire separati<strong>on</strong>s around a fire compartment with properly rated closures. Use appropriate c<strong>on</strong>structi<strong>on</strong> materialsto ensure all gaps are fire stopped. In a number <str<strong>on</strong>g>of</str<strong>on</strong>g> situati<strong>on</strong>s where it is not practical to avoid openings, specialmeasures are taken to limit <str<strong>on</strong>g>the</str<strong>on</strong>g> spread <str<strong>on</strong>g>of</str<strong>on</strong>g> fire through <str<strong>on</strong>g>the</str<strong>on</strong>g>se openings. See <str<strong>on</strong>g>the</str<strong>on</strong>g> secti<strong>on</strong> <strong>on</strong> Protecti<strong>on</strong> or Closure<str<strong>on</strong>g>of</str<strong>on</strong>g> Openings in <str<strong>on</strong>g>Fire</str<strong>on</strong>g> Separati<strong>on</strong>s.14

3.0 Preventing <str<strong>on</strong>g>Fire</str<strong>on</strong>g> SpreadFigure 3.2. Example <str<strong>on</strong>g>of</str<strong>on</strong>g> a comm<strong>on</strong> <strong>on</strong>e hour fire separati<strong>on</strong>. Where drywall is used in highmoisture areas, provide a vapour barrier in an appropriate locati<strong>on</strong> that protects <str<strong>on</strong>g>the</str<strong>on</strong>g> drywall.C<strong>on</strong>taining <str<strong>on</strong>g>the</str<strong>on</strong>g> electrical/mechanical room in farm buildings is an example <str<strong>on</strong>g>of</str<strong>on</strong>g> a fire separati<strong>on</strong> that providesa valuable compartment to prevent <str<strong>on</strong>g>the</str<strong>on</strong>g> spread <str<strong>on</strong>g>of</str<strong>on</strong>g> fire. Equipment such as standby generators or compressorsfor refrigerati<strong>on</strong> units can overheat and start a fire. Having a c<strong>on</strong>tinuous fire separati<strong>on</strong> around this equipment<str<strong>on</strong>g>of</str<strong>on</strong>g>ten provides enough time to extinguish <str<strong>on</strong>g>the</str<strong>on</strong>g> fire before it spreads to <str<strong>on</strong>g>the</str<strong>on</strong>g> rest <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> building causing a totalloss <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> structure.With <str<strong>on</strong>g>the</str<strong>on</strong>g> excepti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> specific heating and cooling equipment, <str<strong>on</strong>g>the</str<strong>on</strong>g> NFBCC fur<str<strong>on</strong>g>the</str<strong>on</strong>g>r requires a fire separati<strong>on</strong>with a minimum rating <str<strong>on</strong>g>of</str<strong>on</strong>g> 30 minutes between fuel-fired appliances, crop drying and equipment repair rooms,and <str<strong>on</strong>g>the</str<strong>on</strong>g> remainder <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> building. The TechnicalAdvisory Committee <strong>on</strong> <strong>Farm</strong> <str<strong>on</strong>g>Fire</str<strong>on</strong>g>s (TACFF)recommends increasing <str<strong>on</strong>g>the</str<strong>on</strong>g>se fire separati<strong>on</strong>s to <strong>on</strong>ehour for buildings c<strong>on</strong>taining liquid fuel storage orhighly combustible materials such as hay or straw.To reduce fire losses and as a best managementpractice, TACFF recommends paying increasedattenti<strong>on</strong> to <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>structi<strong>on</strong> and maintenance<str<strong>on</strong>g>of</str<strong>on</strong>g> fire separati<strong>on</strong>s.15

REDUCING THE RISK OF FIRE ON YOUR FARM<str<strong>on</strong>g>Fire</str<strong>on</strong>g> CompartmentsA fire compartment is a usable, enclosed space in a building that is separated from all o<str<strong>on</strong>g>the</str<strong>on</strong>g>r parts <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>building. Many Codes specify maximum compartment sizes, to c<strong>on</strong>tain a specific fire risk within an area andprotect people in <str<strong>on</strong>g>the</str<strong>on</strong>g> rest <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> building. For <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>cept to work, compartment boundaries must have anadequate level <str<strong>on</strong>g>of</str<strong>on</strong>g> fire-resistance. All openings and penetrati<strong>on</strong>s through <str<strong>on</strong>g>the</str<strong>on</strong>g>se boundaries require protecti<strong>on</strong>with rated closures or fire stops. The level <str<strong>on</strong>g>of</str<strong>on</strong>g> fire-resistance required depends <strong>on</strong> many things including <str<strong>on</strong>g>the</str<strong>on</strong>g>building size and type <str<strong>on</strong>g>of</str<strong>on</strong>g> occupancy.The NFBCC does not limit <str<strong>on</strong>g>the</str<strong>on</strong>g> building size <str<strong>on</strong>g>of</str<strong>on</strong>g> farm buildings, but specifies that where <str<strong>on</strong>g>the</str<strong>on</strong>g> floor area exceeds<str<strong>on</strong>g>the</str<strong>on</strong>g> maximum size (Table 3.2), <str<strong>on</strong>g>the</str<strong>on</strong>g> building be separated into fire compartments.Table 3.2. Maximum Floor Areas for <strong>Farm</strong> Buildings <str<strong>on</strong>g>of</str<strong>on</strong>g> Low Human OccupancyNumber <str<strong>on</strong>g>of</str<strong>on</strong>g> StoreysMaximum Floor Area/Storey1 4,800 m 2 (51,600 ft 2 )2 2,400 m 2 (25,800 ft 2 )3 1,200 m 2 (12,900 ft 2 )Source: Nati<strong>on</strong>al <strong>Farm</strong> Building Code <str<strong>on</strong>g>of</str<strong>on</strong>g> Canada, 1995.Review existing farm buildings to assess <str<strong>on</strong>g>the</str<strong>on</strong>g> practicality <str<strong>on</strong>g>of</str<strong>on</strong>g> reducing fire compartment sizes to c<strong>on</strong>form withbuilding area limits established in Table 3.2.C<strong>on</strong>sider <str<strong>on</strong>g>the</str<strong>on</strong>g>se sizes when designing new buildings. For a <strong>on</strong>e storey barn, <str<strong>on</strong>g>the</str<strong>on</strong>g> NFBCC allows a maximumcompartment size <str<strong>on</strong>g>of</str<strong>on</strong>g> 4,800 m 2 (51,600 ft 2 ). If <str<strong>on</strong>g>the</str<strong>on</strong>g> building footprint is larger than 4,800 m 2 , <str<strong>on</strong>g>the</str<strong>on</strong>g> designer’s challengeis to maximize <str<strong>on</strong>g>the</str<strong>on</strong>g> overall efficiency <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> layout and achieve all <str<strong>on</strong>g>the</str<strong>on</strong>g> safety objectives for compartmentalizati<strong>on</strong>.For example, dividing a large free stall dairy barn, 33 m (110 ft) wide x 198 m (650 ft) l<strong>on</strong>g, into two compartmentsto meet <str<strong>on</strong>g>the</str<strong>on</strong>g> compartment size requirement would involve erecting a fire separati<strong>on</strong> wall near <str<strong>on</strong>g>the</str<strong>on</strong>g> midpoint <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>198 m (650 ft) length. Since <str<strong>on</strong>g>the</str<strong>on</strong>g> cow alleyways and <str<strong>on</strong>g>the</str<strong>on</strong>g> central feed alleyway run <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> l<strong>on</strong>g axis <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> building,this would result in five large door openings in <str<strong>on</strong>g>the</str<strong>on</strong>g> fire separati<strong>on</strong> equipped with closure devices (fire doors). Thislayout could negatively impact equipment and cow traffic, and air movement in <str<strong>on</strong>g>the</str<strong>on</strong>g> barn (Figure 3.3).16

3.0 Preventing <str<strong>on</strong>g>Fire</str<strong>on</strong>g> SpreadFigure 3.3. A large free stall dairy barn with fire separati<strong>on</strong> wall at <str<strong>on</strong>g>the</str<strong>on</strong>g> midpoint.From a fire separati<strong>on</strong> stand point, it is more effective to erect several free stall barns that each measure less than4,800 m 2 (51,600 ft 2 ). These barns could be spaced at least 30 m (100 ft) apart and interc<strong>on</strong>nected with hallwaysto house <str<strong>on</strong>g>the</str<strong>on</strong>g> animals. One closure device (fire door) located in <str<strong>on</strong>g>the</str<strong>on</strong>g> middle <str<strong>on</strong>g>of</str<strong>on</strong>g> each c<strong>on</strong>necting hallway enables<str<strong>on</strong>g>the</str<strong>on</strong>g> design to meet <str<strong>on</strong>g>the</str<strong>on</strong>g> fire compartment size requirements, and minimize flow issues associated with cow andequipment traffic, and air movement (Figure 3.4).17

REDUCING THE RISK OF FIRE ON YOUR FARMFigure 3.4. The fire compartments formed by several fire separati<strong>on</strong>s will slow <str<strong>on</strong>g>the</str<strong>on</strong>g> spread <str<strong>on</strong>g>of</str<strong>on</strong>g> fire andprovide a better opportunity to fight a fire in this large building complex.<str<strong>on</strong>g>Fire</str<strong>on</strong>g> Stopping<str<strong>on</strong>g>Fire</str<strong>on</strong>g> stopping is ano<str<strong>on</strong>g>the</str<strong>on</strong>g>r key c<strong>on</strong>cept for fire safety in all buildings, including farm buildings. <str<strong>on</strong>g>Fire</str<strong>on</strong>g> stops areused to limit <str<strong>on</strong>g>the</str<strong>on</strong>g> spread <str<strong>on</strong>g>of</str<strong>on</strong>g> fire throughout a building with a physical barrier in c<strong>on</strong>cealed spaces.<str<strong>on</strong>g>Fire</str<strong>on</strong>g> stops are usually located within walls, floors, ceilings and in attic spaces. <str<strong>on</strong>g>Fire</str<strong>on</strong>g> stops are comm<strong>on</strong>lyc<strong>on</strong>structed with solid lumber not less than 38 mm thick (1 1 ⁄2 in.). <str<strong>on</strong>g>Fire</str<strong>on</strong>g> stops in c<strong>on</strong>cealed spaces shouldc<strong>on</strong>form to <str<strong>on</strong>g>the</str<strong>on</strong>g> provisi<strong>on</strong>s in <str<strong>on</strong>g>the</str<strong>on</strong>g> NFBCC. As noted in <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Ontario</strong> C<strong>on</strong>structi<strong>on</strong> Guide for <strong>Farm</strong> Buildings2003 at www.orderline.com, fire stops in farm buildings reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> spread <str<strong>on</strong>g>of</str<strong>on</strong>g> smoke and flames within c<strong>on</strong>cealedspaces, giving people time to escape in <str<strong>on</strong>g>the</str<strong>on</strong>g> event <str<strong>on</strong>g>of</str<strong>on</strong>g>fire. Properly installed fire stops also prevent rodentsand birds from easy access throughout <str<strong>on</strong>g>the</str<strong>on</strong>g> samec<strong>on</strong>cealed spaces, making <str<strong>on</strong>g>the</str<strong>on</strong>g> buildings more durablewhile increasing fire safety. Figure 3.5 shows a typicaltwo storey barn cross-secti<strong>on</strong>.To reduce fire losses, and as a best managementpractice, TACFF recommends using smallercompartment sizes in farm buildings with properlyc<strong>on</strong>structed fire walls and separati<strong>on</strong> distances.18

3.0 Preventing <str<strong>on</strong>g>Fire</str<strong>on</strong>g> SpreadFigure 3.5. A two storey barn cross-secti<strong>on</strong> showing fire stopping locati<strong>on</strong>s.19

REDUCING THE RISK OF FIRE ON YOUR FARMAttic fire stops limit fire from moving quickly through <str<strong>on</strong>g>the</str<strong>on</strong>g> attic space <str<strong>on</strong>g>of</str<strong>on</strong>g> a building. The NFBCC requires firestops in attic spaces be c<strong>on</strong>structed at intervals no greater than 30 m (100 ft) in ei<str<strong>on</strong>g>the</str<strong>on</strong>g>r directi<strong>on</strong>. C<strong>on</strong>struct firestops to ensure <str<strong>on</strong>g>the</str<strong>on</strong>g>re are no openings to allow fire to move quickly to <str<strong>on</strong>g>the</str<strong>on</strong>g> next space. <str<strong>on</strong>g>Fire</str<strong>on</strong>g> stops are comm<strong>on</strong>lyc<strong>on</strong>structed using <str<strong>on</strong>g>the</str<strong>on</strong>g> following sheathing materials:• cement board• 0.38 mm (28 U.S. gauge) sheet steel• 12.7 mm ( 1 ⁄2 in.) gypsum board• 12.5 mm ( 1 ⁄2 in.) plywood, Oriented Strand Board (OSB) or wafer board with joints backed withsimilar materialThe sheathing materials are <str<strong>on</strong>g>of</str<strong>on</strong>g>ten mounted <strong>on</strong> <strong>on</strong>e side <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> ro<str<strong>on</strong>g>of</str<strong>on</strong>g> trusses in <str<strong>on</strong>g>the</str<strong>on</strong>g> attic space (Figure 3.6). Thetruss manufacturer can provide specific guidance if required. In all cases, <str<strong>on</strong>g>the</str<strong>on</strong>g> joints must be backed with similarmaterial and sealed to create a draft-tight barrier to restrict <str<strong>on</strong>g>the</str<strong>on</strong>g> passage <str<strong>on</strong>g>of</str<strong>on</strong>g> smoke and flame.Figure 3.6. Example <str<strong>on</strong>g>of</str<strong>on</strong>g> an attic fire stop under c<strong>on</strong>structi<strong>on</strong> ina new calf barn.Attic fire stops are <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> most neglected c<strong>on</strong>structi<strong>on</strong> details in farm buildings. Pay particular attenti<strong>on</strong> to<str<strong>on</strong>g>the</str<strong>on</strong>g> tightness <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>structi<strong>on</strong> since it provides <str<strong>on</strong>g>the</str<strong>on</strong>g> critical functi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> reducing <str<strong>on</strong>g>the</str<strong>on</strong>g> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> fire spread. If <str<strong>on</strong>g>the</str<strong>on</strong>g>fire stop is pierced with wiring, plumbing or ductwork, <str<strong>on</strong>g>the</str<strong>on</strong>g> space between <str<strong>on</strong>g>the</str<strong>on</strong>g> stopping material and <str<strong>on</strong>g>the</str<strong>on</strong>g> objectpiercing must be sealed and caulked with fire-rated material. A fire stop is expected to slow <str<strong>on</strong>g>the</str<strong>on</strong>g> progress <str<strong>on</strong>g>of</str<strong>on</strong>g> a fireby at least 15 minutes.Unfortunately, <str<strong>on</strong>g>the</str<strong>on</strong>g> lack <str<strong>on</strong>g>of</str<strong>on</strong>g> proper attic fire stops, or breached fire stops in <str<strong>on</strong>g>the</str<strong>on</strong>g> attic, has c<strong>on</strong>tributed to <str<strong>on</strong>g>the</str<strong>on</strong>g> rapidprogressi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> fires in several <strong>Ontario</strong> swine barns. Figure 3.7 shows a fire stop that has been breached by anopening, and would allow a fire to jump into <str<strong>on</strong>g>the</str<strong>on</strong>g> next attic compartment without slowing down.20

REDUCING THE RISK OF FIRE ON YOUR FARMVentilati<strong>on</strong> openings in naturally ventilated farm buildings present a challenge for designers looking tomaximize a building’s fire safety characteristics. These buildings have large openings in <str<strong>on</strong>g>the</str<strong>on</strong>g> sidewalls to allow<str<strong>on</strong>g>the</str<strong>on</strong>g> required air flow into <str<strong>on</strong>g>the</str<strong>on</strong>g> barn, providing a comfortable envir<strong>on</strong>ment for livestock during warm wea<str<strong>on</strong>g>the</str<strong>on</strong>g>rc<strong>on</strong>diti<strong>on</strong>s. During a fire, <str<strong>on</strong>g>the</str<strong>on</strong>g>se large openings perform <str<strong>on</strong>g>the</str<strong>on</strong>g> same functi<strong>on</strong>, allowing large volumes <str<strong>on</strong>g>of</str<strong>on</strong>g> air to enter<str<strong>on</strong>g>the</str<strong>on</strong>g> building and provide oxygen to feed <str<strong>on</strong>g>the</str<strong>on</strong>g> fire. These unrestricted wall openings also present challenges wheretwo buildings meet, providing a locati<strong>on</strong> for a fire to “jump” from <strong>on</strong>e building to <str<strong>on</strong>g>the</str<strong>on</strong>g> o<str<strong>on</strong>g>the</str<strong>on</strong>g>r.Proper locati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> fire separati<strong>on</strong>s in <str<strong>on</strong>g>the</str<strong>on</strong>g>se buildings is critical to prevent fire spread. C<strong>on</strong>struct <str<strong>on</strong>g>the</str<strong>on</strong>g> wallimmediately adjacent to <str<strong>on</strong>g>the</str<strong>on</strong>g> fire separati<strong>on</strong> as a solid wall without ventilati<strong>on</strong> openings, to help stop a fire fromjumping <str<strong>on</strong>g>the</str<strong>on</strong>g> fire separati<strong>on</strong>. Ano<str<strong>on</strong>g>the</str<strong>on</strong>g>r way to avoid this problem is to locate fire separati<strong>on</strong>s in hallways betweenbuildings at a sufficient distance from o<str<strong>on</strong>g>the</str<strong>on</strong>g>r openings (Figures 3.9 and 3.10).Figure 3.9. Unacceptable locati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> fire separati<strong>on</strong> doors. This door locati<strong>on</strong> is unacceptablesince a fire can easily jump past it.22

3.0 Preventing <str<strong>on</strong>g>Fire</str<strong>on</strong>g> SpreadFigure 3.11. Melted vinyl sheathing <strong>on</strong> ceiling. Note <str<strong>on</strong>g>the</str<strong>on</strong>g> lack <str<strong>on</strong>g>of</str<strong>on</strong>g> backingbehind <str<strong>on</strong>g>the</str<strong>on</strong>g> vinyl leaving <str<strong>on</strong>g>the</str<strong>on</strong>g> attic space exposed.(Photo credit: R. Drysdale, <strong>Farm</strong> Mutual Reinsurance Plan)Specific sheathing materials c<strong>on</strong>tribute to <str<strong>on</strong>g>the</str<strong>on</strong>g> spread <str<strong>on</strong>g>of</str<strong>on</strong>g> flames at varying rates. Materials give <str<strong>on</strong>g>of</str<strong>on</strong>g>f varyingamounts <str<strong>on</strong>g>of</str<strong>on</strong>g> smoke as <str<strong>on</strong>g>the</str<strong>on</strong>g>y burn. Table 3.4 provides a guide to <str<strong>on</strong>g>the</str<strong>on</strong>g> characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g> some comm<strong>on</strong> interiorsheathing materials.Table 3.4. Flame Spread Rating and Smoke Developed Classificati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g>Comm<strong>on</strong> Building Material SystemsType <str<strong>on</strong>g>of</str<strong>on</strong>g> C<strong>on</strong>structi<strong>on</strong>C<strong>on</strong>crete sandwich wall,c<strong>on</strong>crete blockFlame SpreadRating (FSR) 1Smoke DevelopedClassificati<strong>on</strong>(SDC) 2Comment– – Does not support combusti<strong>on</strong>Walls – insulated stud or post-frame wall c<strong>on</strong>structi<strong>on</strong> with <str<strong>on</strong>g>the</str<strong>on</strong>g> following materials appliedto <str<strong>on</strong>g>the</str<strong>on</strong>g> interior surface:Curtain sidewall High High Some proprietary products are treatedto reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> FSR and SDC – checkwith manufacturer.Vinyl sheathing Low High Some proprietary products are treatedto reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> FSR and SDC – checkwith manufacturer.Fiberglass over plywood Low Low Some proprietary products are treatedto reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> FSR and SDC – checkwith manufacturer.Polyethylene board(puckboard)Low High Some proprietary products are treatedto reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> FSR and SDC – checkwith manufacturer.25