Temperature and Altitude Affect Fan Selection - New York Blower

Temperature and Altitude Affect Fan Selection - New York Blower

Temperature and Altitude Affect Fan Selection - New York Blower

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

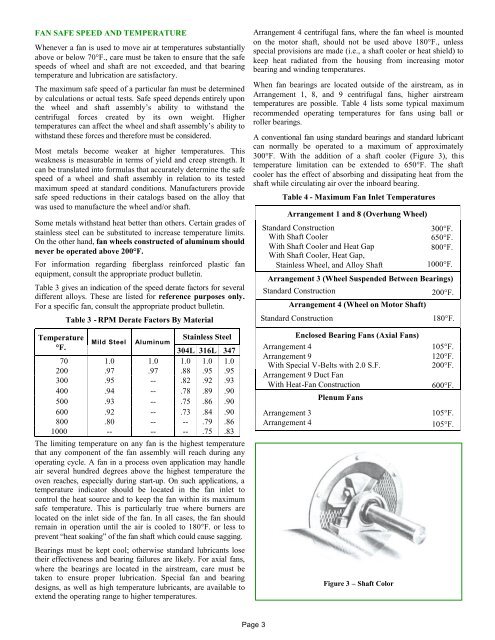

FAN SAFE SPEED AND TEMPERATUREWhenever a fan is used to move air at temperatures substantiallyabove or below 70°F., care must be taken to ensure that the safespeeds of wheel <strong>and</strong> shaft are not exceeded, <strong>and</strong> that bearingtemperature <strong>and</strong> lubrication are satisfactory.The maximum safe speed of a particular fan must be determinedby calculations or actual tests. Safe speed depends entirely uponthe wheel <strong>and</strong> shaft assembly’s ability to withst<strong>and</strong> thecentrifugal forces created by its own weight. Highertemperatures can affect the wheel <strong>and</strong> shaft assembly’s ability towithst<strong>and</strong> these forces <strong>and</strong> therefore must be considered.Most metals become weaker at higher temperatures. Thisweakness is measurable in terms of yield <strong>and</strong> creep strength. Itcan be translated into formulas that accurately determine the safespeed of a wheel <strong>and</strong> shaft assembly in relation to its testedmaximum speed at st<strong>and</strong>ard conditions. Manufacturers providesafe speed reductions in their catalogs based on the alloy thatwas used to manufacture the wheel <strong>and</strong>/or shaft.Some metals withst<strong>and</strong> heat better than others. Certain grades ofstainless steel can be substituted to increase temperature limits.On the other h<strong>and</strong>, fan wheels constructed of aluminum shouldnever be operated above 200°F.For information regarding fiberglass reinforced plastic fanequipment, consult the appropriate product bulletin.Table 3 gives an indication of the speed derate factors for severaldifferent alloys. These are listed for reference purposes only.For a specific fan, consult the appropriate product bulletin.Table 3 - RPM Derate Factors By Material<strong>Temperature</strong>Stainless SteelMild Steel Aluminum°F.304L 316L 34770 1.0 1.0 1.0 1.0 1.0200 .97 .97 .88 .95 .95300 .95 -- .82 .92 .93400 .94 -- .78 .89 .90500 .93 -- .75 .86 .90600 .92 -- .73 .84 .90800 .80 -- -- .79 .861000 -- -- -- .75 .83The limiting temperature on any fan is the highest temperaturethat any component of the fan assembly will reach during anyoperating cycle. A fan in a process oven application may h<strong>and</strong>leair several hundred degrees above the highest temperature theoven reaches, especially during start-up. On such applications, atemperature indicator should be located in the fan inlet tocontrol the heat source <strong>and</strong> to keep the fan within its maximumsafe temperature. This is particularly true where burners arelocated on the inlet side of the fan. In all cases, the fan shouldremain in operation until the air is cooled to 180°F. or less toprevent “heat soaking” of the fan shaft which could cause sagging.Bearings must be kept cool; otherwise st<strong>and</strong>ard lubricants losetheir effectiveness <strong>and</strong> bearing failures are likely. For axial fans,where the bearings are located in the airstream, care must betaken to ensure proper lubrication. Special fan <strong>and</strong> bearingdesigns, as well as high temperature lubricants, are available toextend the operating range to higher temperatures.Arrangement 4 centrifugal fans, where the fan wheel is mountedon the motor shaft, should not be used above 180°F., unlessspecial provisions are made (i.e., a shaft cooler or heat shield) tokeep heat radiated from the housing from increasing motorbearing <strong>and</strong> winding temperatures.When fan bearings are located outside of the airstream, as inArrangement 1, 8, <strong>and</strong> 9 centrifugal fans, higher airstreamtemperatures are possible. Table 4 lists some typical maximumrecommended operating temperatures for fans using ball orroller bearings.A conventional fan using st<strong>and</strong>ard bearings <strong>and</strong> st<strong>and</strong>ard lubricantcan normally be operated to a maximum of approximately300°F. With the addition of a shaft cooler (Figure 3), thistemperature limitation can be extended to 650°F. The shaftcooler has the effect of absorbing <strong>and</strong> dissipating heat from theshaft while circulating air over the inboard bearing.Table 4 - Maximum <strong>Fan</strong> Inlet <strong>Temperature</strong>sArrangement 1 <strong>and</strong> 8 (Overhung Wheel)St<strong>and</strong>ard ConstructionWith Shaft CoolerWith Shaft Cooler <strong>and</strong> Heat GapWith Shaft Cooler, Heat Gap,Stainless Wheel, <strong>and</strong> Alloy Shaft300°F.650°F.800°F.1000°F.Arrangement 3 (Wheel Suspended Between Bearings)St<strong>and</strong>ard ConstructionArrangement 4 (Wheel on Motor Shaft)St<strong>and</strong>ard ConstructionEnclosed Bearing <strong>Fan</strong>s (Axial <strong>Fan</strong>s)Arrangement 4Arrangement 9With Special V-Belts with 2.0 S.F.Arrangement 9 Duct <strong>Fan</strong>With Heat-<strong>Fan</strong> ConstructionArrangement 3Arrangement 4Plenum <strong>Fan</strong>sFigure 3 – Shaft Color200°F.180°F.105°F.120°F.200°F.600°F.105°F.105°F.Page 3