National Occupational Standards Manufacturing Textile ... - Skillset

National Occupational Standards Manufacturing Textile ... - Skillset

National Occupational Standards Manufacturing Textile ... - Skillset

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

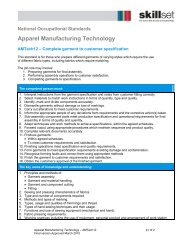

SKSTEX16 – Produce textile productsOverview:This standard is for those who produce textile products using different machinery, equipment andconstruction methods.The job role may involve:1. Assembling components to specification2. Maintaining and controlling the work pattern3. Maximising production4. Maintaining quality requirementsPerformance Criteria:P1 Receive and interpret work instructions and specificationsP2 Carry out handover procedureP3 Check materials and components against specificationP4 Identify faulty components or components that do not match specification and takeactionP5 Maintain a clean, safe work areaP6 Ensure equipment meets specifications and is ready for useP7 Organise work area to optimise production flowP8 Use approved methods of assembly to assemble componentsP9 Follow work instructions and specifications accuratelyP10 Identify assembly problems and take appropriate prompt actionP11 Monitor the supply of materials and components to meet production requirementsP12 Manage own work pattern to ensure maximum operating efficiencyP13 Make adjustments to work pattern to maintain the required flow of productionP14 Meet and maintain productivity levelsP15 Protect the output from dirt and damageP16 Handle materials and components safely and carefullyP17 Forward manufactured goods using agreed proceduresP18 Complete and store accurate records and documentationP19 Carry out daily upkeep of machinery and equipmentKnowledge and Understanding:K1 How to receive work instructions and specifications and interpret them accuratelyK2 How to make use of the information detailed in specifications and instructionsK3 Hand over procedures and information required at changeover pointsK4 Ways of planning work activities to maintain continuity of operationsK5 Characteristics of materials and components to be assembledK6 Capabilities of machinery and equipment to be used and action to be taken when itdoes not conform to specificationK7 Reasons why materials and components do not conform and corrective actionneededK8 Importance of keeping the work area clean and free from obstructionsK9 Types of preparation activitiesK10 Types of faults and irregularities in components and appropriate action to takeK11 Types of problems in manufacturing and appropriate action to takeK12 Methods of protecting materials and manufactured goodsK13 Importance of maintaining product qualityK14 How the supply of materials and components is maintainedK15 Types of adjustment to work patterns that can be madeK16 Forwarding procedures<strong>Manufacturing</strong> <strong>Textile</strong> ProductsJanuary 2013 Page number 32