National Occupational Standards Manufacturing Textile ... - Skillset

National Occupational Standards Manufacturing Textile ... - Skillset

National Occupational Standards Manufacturing Textile ... - Skillset

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

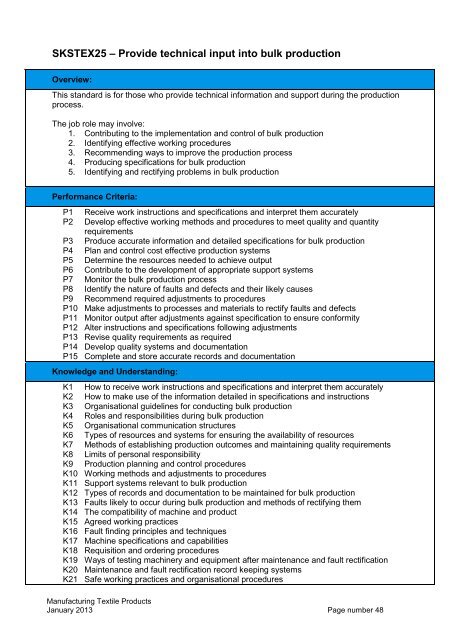

SKSTEX25 – Provide technical input into bulk productionOverview:This standard is for those who provide technical information and support during the productionprocess.The job role may involve:1. Contributing to the implementation and control of bulk production2. Identifying effective working procedures3. Recommending ways to improve the production process4. Producing specifications for bulk production5. Identifying and rectifying problems in bulk productionPerformance Criteria:P1 Receive work instructions and specifications and interpret them accuratelyP2 Develop effective working methods and procedures to meet quality and quantityrequirementsP3 Produce accurate information and detailed specifications for bulk productionP4 Plan and control cost effective production systemsP5 Determine the resources needed to achieve outputP6 Contribute to the development of appropriate support systemsP7 Monitor the bulk production processP8 Identify the nature of faults and defects and their likely causesP9 Recommend required adjustments to proceduresP10 Make adjustments to processes and materials to rectify faults and defectsP11 Monitor output after adjustments against specification to ensure conformityP12 Alter instructions and specifications following adjustmentsP13 Revise quality requirements as requiredP14 Develop quality systems and documentationP15 Complete and store accurate records and documentationKnowledge and Understanding:K1 How to receive work instructions and specifications and interpret them accuratelyK2 How to make use of the information detailed in specifications and instructionsK3 Organisational guidelines for conducting bulk productionK4 Roles and responsibilities during bulk productionK5 Organisational communication structuresK6 Types of resources and systems for ensuring the availability of resourcesK7 Methods of establishing production outcomes and maintaining quality requirementsK8 Limits of personal responsibilityK9 Production planning and control proceduresK10 Working methods and adjustments to proceduresK11 Support systems relevant to bulk productionK12 Types of records and documentation to be maintained for bulk productionK13 Faults likely to occur during bulk production and methods of rectifying themK14 The compatibility of machine and productK15 Agreed working practicesK16 Fault finding principles and techniquesK17 Machine specifications and capabilitiesK18 Requisition and ordering proceduresK19 Ways of testing machinery and equipment after maintenance and fault rectificationK20 Maintenance and fault rectification record keeping systemsK21 Safe working practices and organisational procedures<strong>Manufacturing</strong> <strong>Textile</strong> ProductsJanuary 2013 Page number 48