Designing and operating safe chemical reaction processes HSG143

Designing and operating safe chemical reaction processes HSG143

Designing and operating safe chemical reaction processes HSG143

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

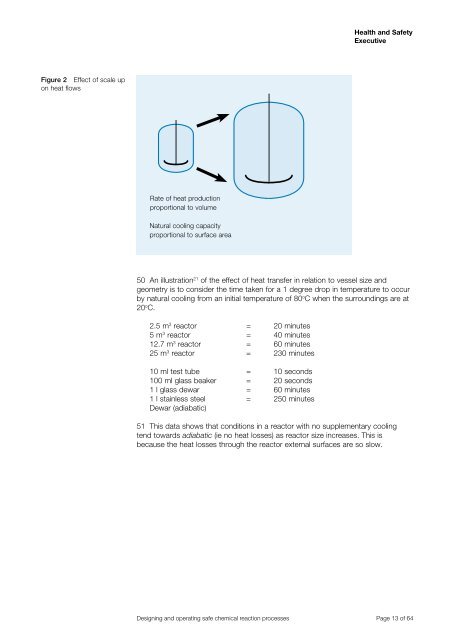

Health <strong>and</strong> SafetyExecutiveFigure 2 Effect of scale upon heat flowsRate of heat productionproportional to volumeNatural cooling capacityproportional to surface area50 An illustration 21 of the effect of heat transfer in relation to vessel size <strong>and</strong>geometry is to consider the time taken for a 1 degree drop in temperature to occurby natural cooling from an initial temperature of 80 o C when the surroundings are at20 o C.2.5 m 3 reactor = 20 minutes5 m 3 reactor = 40 minutes12.7 m 3 reactor = 60 minutes25 m 3 reactor = 230 minutes10 ml test tube = 10 seconds100 ml glass beaker = 20 seconds1 l glass dewar = 60 minutes1 l stainless steel = 250 minutesDewar (adiabatic)51 This data shows that conditions in a reactor with no supplementary coolingtend towards adiabatic (ie no heat losses) as reactor size increases. This isbecause the heat losses through the reactor external surfaces are so slow.<strong>Designing</strong> <strong>and</strong> <strong>operating</strong> <strong>safe</strong> <strong>chemical</strong> <strong>reaction</strong> <strong>processes</strong> Page 13 of 64