SARM 69 - Mintek

SARM 69 - Mintek

SARM 69 - Mintek

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

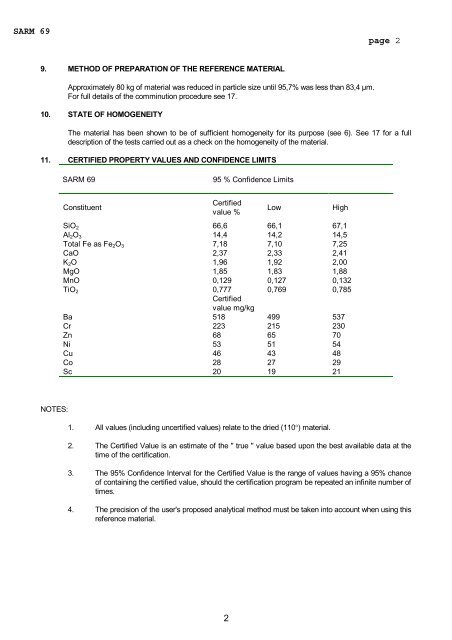

<strong>SARM</strong> <strong>69</strong>page 29. METHOD OF PREPARATION OF THE REFERENCE MATERIALApproximately 80 kg of material was reduced in particle size until 95,7% was less than 83,4 µm.For full details of the comminution procedure see 17.10. STATE OF HOMOGENEITYThe material has been shown to be of sufficient homogeneity for its purpose (see 6). See 17 for a fulldescription of the tests carried out as a check on the homogeneity of the material.11. CERTIFIED PROPERTY VALUES AND CONFIDENCE LIMITS<strong>SARM</strong> <strong>69</strong>95 % Confidence LimitsConstituentCertifiedvalue %LowHighSiO 2 66,6 66,1 67,1Al 2 O 3 14,4 14,2 14,5Total Fe as Fe 2 O 3 7,18 7,10 7,25CaO 2,37 2,33 2,41K 2 O 1,96 1,92 2,00MgO 1,85 1,83 1,88MnO 0,129 0,127 0,132TiO 2 0,777 0,7<strong>69</strong> 0,785Certifiedvalue mg/kgBa 518 499 537Cr 223 215 230Zn 68 65 70Ni 53 51 54Cu 46 43 48Co 28 27 29Sc 20 19 21NOTES:1. All values (including uncertified values) relate to the dried (110°) material.2. The Certified Value is an estimate of the " true " value based upon the best available data at thetime of the certification.3. The 95% Confidence Interval for the Certified Value is the range of values having a 95% chanceof containing the certified value, should the certification program be repeated an infinite number oftimes.4. The precision of the user's proposed analytical method must be taken into account when using thisreference material.2