Model: PURY-P144 TKMU-A - Mitsubishi Electric Sales Canada Inc.

Model: PURY-P144 TKMU-A - Mitsubishi Electric Sales Canada Inc.

Model: PURY-P144 TKMU-A - Mitsubishi Electric Sales Canada Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

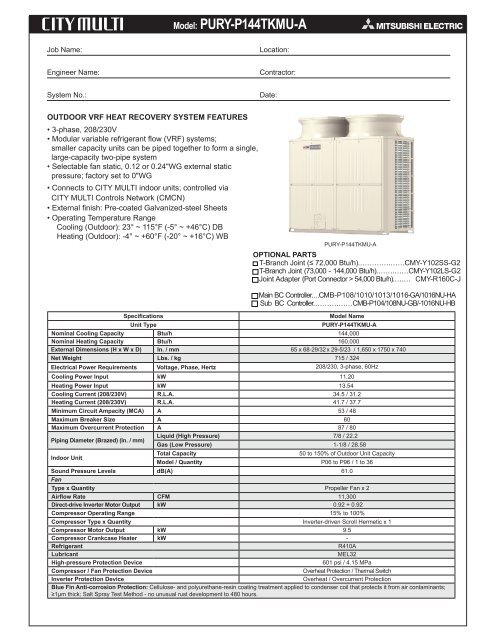

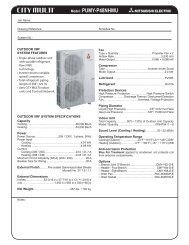

<strong>Model</strong>: <strong>PURY</strong>-<strong>P144</strong><strong>TKMU</strong>-AJob Name:Location:Engineer Name: Contractor:System No.:Date:OUTDOOR VRF HEAT RECOVERY SYSTEM FEATURES• 3-phase, 208/230V• Modular variable refrigerant flow (VRF) systems;smaller capacity units can be piped together to form a single,large-capacity two-pipe system• Selectable fan static, 0.12 or 0.24"WG external staticpressure; factory set to 0"WG• Connects to CITY MULTI indoor units; controlled viaCITY MULTI Controls Network (CMCN)• External finish: Pre-coated Galvanized-steel Sheets• Operating Temperature RangeCooling (Outdoor): 23° ~ 115°F (-5° ~ +46°C) DBHeating (Outdoor): -4° ~ +60°F (-20° ~ +16°C) WBSpecifications<strong>PURY</strong>-<strong>P144</strong><strong>TKMU</strong>-AOPTIONAL PARTS□ T-Branch Joint (≤ 72,000 Btu/h).………….……CMY-Y102SS-G2□ T-Branch Joint (73,000 - 144,000 Btu/h).…….……CMY-Y102LS-G2□ Joint Adapter (Port Connector > 54,000 Btu/h).….… CMY-R160C-J<strong>Model</strong> NameUnit Type<strong>PURY</strong>-<strong>P144</strong><strong>TKMU</strong>-ANominal Cooling Capacity Btu/h 144,000Nominal Heating Capacity Btu/h 160,000External Dimensions (H x W x D) In. / mm 65 x 68-29/32 x 29-5/23 / 1,650 x 1750 x 740Net Weight Lbs. / kg 715 / 324<strong>Electric</strong>al Power Requirements Voltage, Phase, Hertz 208/230, 3-phase, 60HzCooling Power Input kW 11.20Heating Power Input kW 13.54Cooling Current (208/230V) R.L.A. 34.5 / 31.2Heating Current (208/230V) R.L.A. 41.7 / 37.7Minimum Circuit Ampacity (MCA) A 53 / 48Maximum Breaker Size A 60Maximum Overcurrent Protection A 87 / 80Piping Diameter (Brazed) (In. / mm)Liquid (High Pressure) 7/8 / 22.2Gas (Low Pressure) 1-1/8 / 28.58Indoor UnitTotal Capacity□ Main BC Controller....CMB-P108/1010/1013/1016-GA/1016NU-HA□ Sub BC Controller.……….……CMB-P104/108NU-GB/-1016NU-HB50 to 150% of Outdoor Unit Capacity<strong>Model</strong> / Quantity P06 to P96 / 1 to 36Sound Pressure Levels dB(A) 61.0FanType x Quantity Propeller Fan x 2Airflow Rate CFM 11,300Direct-drive Inverter Motor Output kW 0.92 + 0.92Compressor Operating Range 15% to 100%Compressor Type x Quantity Inverter-driven Scroll Hermetic x 1Compressor Motor Output kW 9.5Compressor Crankcase Heater kW -RefrigerantR410ALubricantMEL32High-pressure Protection Device601 psi / 4.15 MPaCompressor / Fan Protection DeviceOverheat Protection / Thermal SwitchInverter Protection DeviceOverheat / Overcurrent ProtectionBlue Fin Anti-corrosion Protection: Cellulose- and polyurethane-resin coating treatment applied to condenser coil that protects it from air contaminants;≥1μm thick; Salt Spray Test Method - no unusual rust development to 480 hours.

Module: <strong>PURY</strong>-<strong>P144</strong><strong>TKMU</strong>-A - Dimensions<strong>PURY</strong>-P120,144<strong>TKMU</strong>-A(-BS)Note 1.Please refer to the next page for informationregarding necessary spacing around theunit and foundation work.2.At brazing of pipes,wrap the refrigerant service valvewith wet cloth and keep the temperature ofrefrigerant service valve under 120°C(248°F).740(29-5/32)(23-5/8)=(5-29/32)X4600=150X4Connecting pipe specificationsDiameter(2-25/32)70Service valveRefrigerant pipe19.5(25/32)49(1-15/16)831(32-23/32)831(32-23/32)<strong>Model</strong>19.5(25/32)2X7-ø4.6(3/16) Hole(Make hole at the plastic fan guardfor snow hood attachment)LowpressureHighpressureLowpressureHighpressure1750(68-29/32)Top viewDischarge airø19.05 Brazed ø28.58 Brazed ø25.4 ø28.58(3/4) *2 (1-1/8) *1 (1) (1-1/8)ø22.2 Brazed ø28.58 Brazed ø25.4 ø28.58(7/8) *2 (1-1/8) *1 (1) (1-1/8)<strong>PURY</strong>-P120<strong>TKMU</strong><strong>PURY</strong>-<strong>P144</strong><strong>TKMU</strong>303(11-15/16)Control box*1 Expand the on-site piping and connect to the refrigerant service valve piping.*2 Use the pipe joint(field supply) and connect to the refrigerant service valve piping.IntakeairIntakeair1650(64-31/32)Intakeair1347(53-1/16)ServicepanelService panel5Refrigerant service valveSpecifications140 × 77 Knockout hole(5-17/32)(3-1/16)NO. UsageFan boxø45 Knockout hole(1-25/32)89 77(3-17/32) (3-1/16)184Refrigerant service valveFront through hole12Front through hole(Uses when twinningkit (optional parts)is mounted.)For pipes145217(10-11/32)26254(2-5/32)2150 × 94 Knockout hole(5-29/32)(3-23/32)ø62.7 or ø34.5 Knockout hole(2-15/32) (1-3/8)ø43.7 or ø22.2 Knockout hole(1-3/4) (7/8)ø65 Knockout hole(2-9/16)ø52 Knockout hole(2-1/16)ø34 Knockout hole(1-11/32)Bottom through hole32X2-80(3-5/32)X35(1-13/32) Oval hole(5-23/32)(8-9/16)Front through hole2X3-14(9/16)X20(13/16) Oval hole2020(13/16) (13/16)57 586(23-3/32) 57(2-1/4) (2-1/4)Left side viewFor wires(26-13/16)29.5 681(678~684) 29.5(1-3/16) (26-23/32~26-15/16) (1-3/16)(Mounting pitch)(740)(29-5/32)145(5-23/32)84(3-5/16)526(20-23/32) 75(2-31/32)541(21-5/16) 58(2-5/16)562(22-5/32) 140(5-17/32)Front view561(22-3/32) 150(5-29/32)590(23-1/4) 83516(20-11/32) (3-9/32)Front through holeBottom through holeBottom through holeFront through hole(7-23/32)(5-3/4)(4-25/32)196146121For transmission cables4567894(3-23/32)6 73Unit : mm(in.)Refrigerant service valveRefrigerant service valve80 795(31-5/16) 795(31-5/16) 80(3-5/32) (Mounting pitch)(Mounting pitch) (3-5/32)Bottom view<strong>Mitsubishi</strong> <strong>Electric</strong> Air Conditioning & Refrigeration Systems Wo rks acquired ISObased on a review of quality warranties for the production of refrigeration and airconditioning equipment.ISO Authorization SystemThe ISO 9000 series is a plant authorization system relating to quality warranties asdevelopment, production, installation and auxiliary services" for products built atan authorized plant.<strong>Mitsubishi</strong> <strong>Electric</strong> <strong>Sales</strong> <strong>Canada</strong> <strong>Inc</strong>.www.<strong>Mitsubishi</strong><strong>Electric</strong>.ca<strong>Mitsubishi</strong> <strong>Electric</strong> Air Conditioning & Refrigeration Systems Works acquired environmentalThe ISO 14000 series is a set of standards applying to environmental protection set by theInternational Standard Organization (ISO).Specifications are subject to change without notice.SB_<strong>PURY</strong>-<strong>P144</strong><strong>TKMU</strong>-A_201301