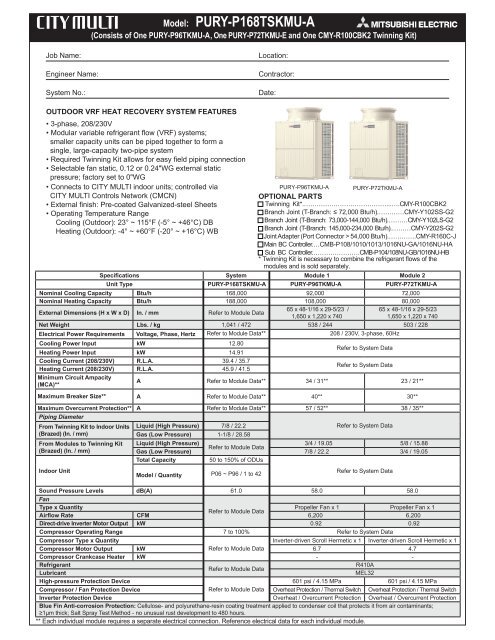

Model: PURY-P168TSKMU-A - Mitsubishi Electric Sales Canada Inc.

Model: PURY-P168TSKMU-A - Mitsubishi Electric Sales Canada Inc.

Model: PURY-P168TSKMU-A - Mitsubishi Electric Sales Canada Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

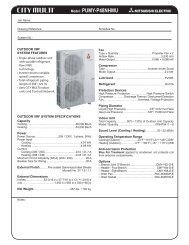

Module :<strong>PURY</strong>-<strong>P168TSKMU</strong>-A – DIMENSIONSDischarge air1220(48-1/16) 30(1-3/16)1220(48-1/16)Outdoor unit 1Outdoor unit 2IntakeairIntakeairTwinning pipe(Low pressure)dTwinning pipe connection sizePackage unit nameOutdoor unit 1Component unit nameOutdoor unit 2Outdoor Twinning Kit(optional parts) CMY-R100CBK2BC controller~Twinning pipeLeft viewHigh pressureLow pressureab<strong>PURY</strong>-<strong>P168TSKMU</strong>-A(-BS) <strong>PURY</strong>-P192TSKMU-A(-BS)<strong>PURY</strong>-P96TKMU-A(-BS) <strong>PURY</strong>-P96TKMU-A(-BS)<strong>PURY</strong>-P72TKMU-A(-BS) <strong>PURY</strong>-P96TKMU-A(-BS)ø22.2(7/8)ø28.58(1-1/8)~Outdoor unitTwinning KitNote 1.Connect the pipes as shown in the figure above. Refer to the table above for the pipe size.2.Twinning pipe (High pressure) should not be tilted more than 15 degrees from the horizontal plane.Be sure to see the Installation Manual for details of Twinning pipe installation.3.The pipe section before the Twinning pipe (section "a" in the figure) must have at least 500mm(19-11/16) of straight section(*including the straight pipe that is supplied with the Twinning pipe).4.Only use the Twinning pipe by <strong>Mitsubishi</strong> (optional parts).5.Connect the outdoor unit 1 with the Twinning pipe (Low pressure) (section "d" in the figure).Unit modelComponentunit modelHigh pressureLow pressurecFront viewP168 P192P96 P72 P96P96c ø19.05(3/4) e ø15.88(5/8) c ø19.05(3/4) ed - (Note 5) f ø19.05(3/4) d (Note 5) feø19.05(3/4)ø22.2(7/8)abTo BC controllerTwinning pipe(High pressure)To BC controllerf-<strong>PURY</strong>-P168,192TSKMU-A(-BS)IntakeairUnit : mm(in.)740(29-5/32)1650(64-31/32)

Module :<strong>PURY</strong>-P96TKMU-A – DIMENSIONS<strong>PURY</strong>-P72,96TKMU-A(-BS)Note 1.Please refer to the next page for informationregarding necessary spacing around theunit and foundation work.2.At brazing of pipes,wrap the refrigerant service valvewith wet cloth and keep the temperature ofrefrigerant service valve under 120°C(248°F).Connecting pipe specificationsDiameterService valveRefrigerant pipe<strong>Model</strong>LowpressureHighpressureLowpressureHighpressure<strong>PURY</strong>-P72TKMU ø15.88 Brazed ø19.05 Brazed ø25.4 ø25.4(5/8) *1 (3/4) *1 (1)(1)<strong>PURY</strong>-P96TKMU ø19.05 Brazed ø22.2 Brazed ø25.4 ø25.4(3/4) *1 (7/8) *1 (1)(1)*1 Use the pipe joint(field supply) and connect to the refrigerant service valve piping.SpecificationsUsageNO.140 × 77 Knockout hole(5-17/32) (3-1/16)Front through holeFront through hole1ø45 Knockout hole(1-25/32)(Uses when twinningkit (optionalparts) is mounted.)For pipesBottom through hole150 × 94 Knockout hole(5-29/32) (3-23/32)Front through hole ø62.7 or ø34.5 Knockout hole(2-15/32) (1-3/8)Front through hole ø43.7 or ø22.2 Knockout hole(1-3/4) (7/8)For wiresBottom through hole ø65 Knockout (2-9/16)holeBottom through hole ø52 Knockout (2-1/16)holeFor transmission cables Front through hole ø34 Knockout (1-11/32)hole29.5(1-3/16)(26-13/16)681(678~684)(26-23/32~26-15/16)(Mounting pitch)(7-23/32)(5-3/4)(4-25/32)146(5-3/4)94 84(3-23/32) (3-5/16)29.5(1-3/16)(8-9/16)(5-23/32)(10-11/32)2020(9-5/16) 236 75(2-31/32)(13/16) (13/16)586(23-3/32) 57(9-29/32) 251 58(2-5/16)(2-1/4)(10-23/32) 272 140(5-17/32)Left side view Front view(10-23/32) (11-7/8) (8-15/16) 272 301 227150(5-29/32)83(3-9/32)2(3-5/32) (Mounting pitch) (3-5/32)34Unit : mm(in.)(2-5/32)89 77(3-17/32) (3-1/16)303(11-15/16)(23-5/8)(2-25/32) =(5-29/32)X4600=150×4Intakeair57(2-1/4)Discharge air19.5(25/32)19.5(25/32)1181(46-1/2)1220(48-1/16)Top view54(740)(29-5/32)1961461212171452621347(53-1/16)1650(64-31/32)70150(5-29/32)740(29-5/32)4X5-ø4.6(3/16) Hole(Make hole at the plastic fan guardfor snow hood attachment)Control boxRefrigerant service valveRefrigerant service valveIntakeair4 5267Refrigerant servicevalve 381Refrigerant servicevalve IntakeairServicepanel2X2-80(3-5/32)X35(1-13/32) Oval hole2X2-14(9/16)X20(13/16) Oval hole80 1060(41-3/4)Bottom view805678

Module :<strong>PURY</strong>-P72TKMU-A – DIMENSIONS<strong>PURY</strong>-P72,96TKMU-A(-BS)Note 1.Please refer to the next page for informationregarding necessary spacing around theunit and foundation work.2.At brazing of pipes,wrap the refrigerant service valvewith wet cloth and keep the temperature ofrefrigerant service valve under 120°C(248°F).Connecting pipe specificationsDiameterService valveRefrigerant pipe<strong>Model</strong>LowpressureHighpressureLowpressureHighpressure<strong>PURY</strong>-P72TKMU ø15.88 Brazed ø19.05 Brazed ø25.4 ø25.4(5/8) *1 (3/4) *1 (1)(1)<strong>PURY</strong>-P96TKMU ø19.05 Brazed ø22.2 Brazed ø25.4 ø25.4(3/4) *1 (7/8) *1 (1)(1)*1 Use the pipe joint(field supply) and connect to the refrigerant service valve piping.SpecificationsUsageNO.140 × 77 Knockout hole(5-17/32) (3-1/16)Front through holeFront through hole1ø45 Knockout hole(1-25/32)(Uses when twinningkit (optionalparts) is mounted.)For pipesBottom through hole150 × 94 Knockout hole(5-29/32) (3-23/32)Front through hole ø62.7 or ø34.5 Knockout hole(2-15/32) (1-3/8)Front through hole ø43.7 or ø22.2 Knockout hole(1-3/4) (7/8)For wiresBottom through hole ø65 Knockout (2-9/16)holeBottom through hole ø52 Knockout (2-1/16)holeFor transmission cables Front through hole ø34 Knockout (1-11/32)hole29.5(1-3/16)(26-13/16)681(678~684)(26-23/32~26-15/16)(Mounting pitch)(7-23/32)(5-3/4)(4-25/32)146(5-3/4)94 84(3-23/32) (3-5/16)29.5(1-3/16)(8-9/16)(5-23/32)(10-11/32)2020(9-5/16) 236 75(2-31/32)(13/16) (13/16)586(23-3/32) 57(9-29/32) 251 58(2-5/16)(2-1/4)(10-23/32) 272 140(5-17/32)Left side view Front view(10-23/32) (11-7/8) (8-15/16) 272 301 227150(5-29/32)83(3-9/32)2(3-5/32) (Mounting pitch) (3-5/32)34Unit : mm(in.)(2-5/32)89 77(3-17/32) (3-1/16)303(11-15/16)(23-5/8)(2-25/32) =(5-29/32)X4600=150×4Intakeair57(2-1/4)Discharge air19.5(25/32)19.5(25/32)1181(46-1/2)1220(48-1/16)Top view54(740)(29-5/32)1961461212171452621347(53-1/16)1650(64-31/32)70150(5-29/32)740(29-5/32)4X5-ø4.6(3/16) Hole(Make hole at the plastic fan guardfor snow hood attachment)Control boxRefrigerant service valveRefrigerant service valveIntakeair4 5267Refrigerant servicevalve 381Refrigerant servicevalve IntakeairServicepanel2X2-80(3-5/32)X35(1-13/32) Oval hole2X2-14(9/16)X20(13/16) Oval hole80 1060(41-3/4)Bottom view805678

Twinning Kit:CMY-R100CBK2CMY-R100CBK2Low-pressure pipe twinning kit1”(Outside diameter)1-5/32"1-5/32"1-31/32"1”1-3/32”5-1/4”17-1/32”4-5/32”1-5/32”(Outside diameter)3-17/32” 1-1/4”7/8”21/32” (Outside diameter)6-15/16”1-7/16”1-31/32"1-7/16”7/8"7/8"1”1”2-3/8”7/8" 3/4”(Outside diameter)2-15/32"3-5/32"High-pressure twinning pipe3/4"7/8"1-13/32”3/4"(Outside diameter)1"1"3/4"2-5/16"3-5/32"3/4"21/32"8-7/16” 4-17/32"7-17/32"3/4”(Outside diameter)5/8”2-15/32"(3Pcs.)Ref: CMY_R100VBK_EXD_EUDB_SINote 1. Reference the attitude angle of the branch pipe below the fig.Distributer15Notes:The angle of the branch pipe for hign pressure is within 15 against the horizontal plane.2. Use the attached pipe to braze the port-opening of the distributer.3. Pipe diameter is indicated by inside diameter.4. Only use the Twinning pipe by <strong>Mitsubishi</strong> (optional parts) .<strong>Mitsubishi</strong> <strong>Electric</strong> Air Conditioning & Refrigeration Systems Wo rks acquired ISObased on a review of quality warranties for the production of refrigeration and airconditioning equipment.ISO Authorization SystemThe ISO 9000 series is a plant authorization system relating to quality warranties asdevelopment, production, installation and auxiliary services" for products built atan authorized plant.<strong>Mitsubishi</strong> <strong>Electric</strong> <strong>Sales</strong> <strong>Canada</strong> <strong>Inc</strong>.www.<strong>Mitsubishi</strong><strong>Electric</strong>.ca<strong>Mitsubishi</strong> <strong>Electric</strong> Air Conditioning & Refrigeration Systems Works acquired environmentalThe ISO 14000 series is a set of standards applying to environmental protection set by theInternational Standard Organization (ISO).Specifications are subject to change without notice.SB_<strong>PURY</strong>-<strong>P168TSKMU</strong>-A_201206