Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.ministry<strong>of</strong>textiles.gov.in

Annual Report(2010-11)<strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong>Government <strong>of</strong> India

CONTENTSSl.No. Chapter PageI Highlights 1II Functions & Organisational Set-up 19III The Organised <strong>Textiles</strong> Mill Industry 29IV Exports 43V The Cotton and Man-made Fibre and Filament Yarn Industry 65VI The Jute and Jute <strong>Textiles</strong> Industry 75VII Sericulture and Silk Industry 97VIII The Wool and Woollen <strong>Textiles</strong> Industry 117IX Decentralised Powerloom Sector 125X Handlooms 133XI Handicrafts 153XII Public Sector Undertakings 175XIII <strong>Textiles</strong> Research Associations 203XIV Citizen's / Client's Charter 239XV Welfare <strong>of</strong> Scheduled Castes, Scheduled Tribes and Women 249XVI <strong>Textiles</strong> in North Eastern Region 253XVII Gender Justice 259XVIII Information and Communication Technology in <strong>Textiles</strong> 263XIX Vigilance Activities 269XX Observations <strong>of</strong> the Comptroller and Auditor General <strong>of</strong> India 273XXI Persons with Disabilities 281

annual report 2010-11CHAPTER IHIGHLIGHTS1

2ministry <strong>of</strong> textiles

annual report 2010-11CHAPTER IHIGHLIGHTSThe Union Minister for <strong>Textiles</strong>, Thiru. Dayanidhi Maran at the 16th National Institute <strong>of</strong>Fashion Technology (NIFT) Convocation, in New Delhi on November 02, 2010The Indian <strong>Textiles</strong> Industry has anoverwhelming presence in theeconomic life <strong>of</strong> the country. Apartfrom providing one <strong>of</strong> the basic necessities<strong>of</strong> life, the textiles industry also plays apivotal role through its contribution toindustrial output, employment generation,and the export earnings <strong>of</strong> the country.Currently, it contributes about 14 percentto industrial production, 4 percent to theGDP, and 17 percent to the country'sexport earnings. It provides directemployment to over 35 million people,which includes a substantial number <strong>of</strong>SC/ST, and women. The <strong>Textiles</strong> sectoris the second largest provider <strong>of</strong>employment after agriculture. Thus, thegrowth and all round development <strong>of</strong> thisindustry has a direct bearing on theimprovement <strong>of</strong> the economy <strong>of</strong> the nation.The Indian textiles industry is extremelyvaried, with the hand-spun and handwovensector at one end <strong>of</strong> the spectrum,and the capital intensive, sophisticatedmill sector at the other. The decentralizedpowerlooms / hosiery and knitting sectorfrom the largest section <strong>of</strong> the <strong>Textiles</strong>Sector. The close linkage <strong>of</strong> the Industryto agriculture and the ancient culture, and3

annual report 2010-11(2002-07), Rs. 1,270 crore had beenearmarked for the scheme. However, thenet utilization <strong>of</strong> funds under this Schemewas Rs. 2044.17 crore.The modified techno-financial parameters<strong>of</strong> the Scheme will infuse capitalinvestment into the textiles sector, andhelp it capitalize on the vibrant andexpanding global and domestic markets,through technology up gradation, costeffectiveness, quality production, efficiencyand global competitiveness. It is estimatedthat this will ensure a growth rate <strong>of</strong> 16%in the sector. The modified structure <strong>of</strong>TUFS focuses on additional capacitybuilding, better adoption <strong>of</strong> technology,and provides for a higher level <strong>of</strong>assistance to segments that have a largerpotential for growth, like garmenting,technical textiles, and processing.The Scheme covers spinning, cottonginning & pressing, silk, reeling & twistingwool, scouring & combing, syntheticfilament yarn texturising, crimping andtwisting, manufacturing <strong>of</strong> viscose filamentyarn (VFY) / viscose staple fibre (VSF),weaving/knitting including non-wovens andtechnical textiles, garments, made-upmanufacturing, processing <strong>of</strong> fibres, yarns,fabrics, garments and made-ups, and thejute sector.PROGRESSThe progress <strong>of</strong> TUFS is steadily goingup which is evident from the data givenat table 1.1.TEXTILE WORKERS' REHABILITATIONFUND SCHEME (TWRFS)The Textile Workers' Rehabilitation FundScheme came into force with effect from15.09.1986 with the objective to provideinterim relief to textile workers renderedunemployed as a consequence <strong>of</strong>permanent closure <strong>of</strong> any particular portionTable 1.1(Rs. in crore)Period Received Sanctioned DisbursedNo. <strong>of</strong> Project No. <strong>of</strong> Project Amount No. <strong>of</strong> Amount Subsidyapplications Cost applications Cost applications1999-2000 407 5771 309 5074 2421 179 746 12000-2001 719 6296 616 4380 2090 494 1863 702001-2002 472 1900 444 1320 630 401 804 198.892002-2003 494 1835 456 1438 839 411 931 202.592003-2004 867 3356 884 3289 1341 814 856 249.062004-2005 986 7941 986 7349 2990 801 1757 283.602005-2006 1086 16194 1078 15032 6776 993 3962 4852006-2007 12336 61063 12589 66233 29073 13168 26605 823.922007-2008 2408 21254 2260 19917 8058 2207 6854 1143.372008-2009 (P) 6113 56542 6072 55707 24007 6111 21826 2632.002009-2010 2384 28005 2352 27611 6612 2361 8140 28862010-11 (UptoJune 2010) (P) 256 397 256 397 254 240 282As on30.06.2010(P) 28528 210554 28302 207747 85091 28180 74627 8665.435

ministry <strong>of</strong> textilesor entire textile unit. Assistance under theScheme is payable to eligible workersonly for the purpose <strong>of</strong> enabling them tosettle in another employment. Suchassistance is not heritable, transferable orcapable <strong>of</strong> being attached on account <strong>of</strong>any other liabilities <strong>of</strong> the worker. Theworker's eligibility shall cease if he takesup employment in another registered orlicensed undertaking. The rehabilitationassistance will not be curtailed if theworker fixes himself in a self-employmentventure.ProgressTill 30.9.2010, 82 mills were found eligibleunder the scheme. A total <strong>of</strong> 111634workers out <strong>of</strong> 143157 workers on therolls <strong>of</strong> these mills had been disbursedrelief <strong>of</strong> Rs. 296.77 crore. The State-wisecumulative position is given at table 1.2.EXPORTSIndia's textiles and clothing industry is one<strong>of</strong> the mainstays <strong>of</strong> the national economy.It is also one <strong>of</strong> the largest contributingsectors <strong>of</strong> India's exports worldwide. TheVision Statement for the textiles industryfor the 11th Five Year Plan (2007-12),inter-alia, envisages India securing a 7%share in the global textiles trade by 2012.At current prices the Indian textiles industryis pegged at US$ 55 billion, 64% <strong>of</strong> whichservices domestic demand. The textilesindustry accounts for 14% <strong>of</strong> industrialproduction, which is 4% <strong>of</strong> GDP; employs35 million people and accounts for nearly12% share <strong>of</strong> the country's total exportsbasket.MILESTONESi) Exports <strong>of</strong> textiles and clothingproducts from India have increasedsteadily over the last few years,particularly after 2004 when textilesexports quota were discontinued.ii)India's <strong>Textiles</strong> & Clothing (T&C)export registered robust growth <strong>of</strong>25% in 2005-06, recording a growth<strong>of</strong> US$ 3.5 billion over 2004-05 inTable 1.2S. State No. <strong>of</strong> mills No. <strong>of</strong> No. <strong>of</strong> workers benefited Disbursed amountNo. identified workers (as on 30.9.2010) (Rs. in crores)on rollNo. <strong>of</strong> Workersmills received relief1 Gujarat 43 80749 43 63608 159.502 Maharashtra 6 9958 6 7646 22.643. Madhya Pradesh 5 19800 5 18596 52.034. Tamil Nadu 6 5685 6 4761 7.455. Kerala 1 500 1 437 2.476. Karnataka 9 10020 9 5818 21.347. Andhra Pradesh 4 2501 4 1298 5.318. Delhi 1 5187 1 5170 11.939 West Bengal 3 2072 3 2042 5.3310. Punjab 4 6685 4 2258 8.77Total 82 143157 82 111634 296.776

annual report 2010-11iii)iv)value terms thereby reaching a level<strong>of</strong> US$ 17.52 billion and the growthcontinued in 2006-07 with T&Cexports <strong>of</strong> US$19.15 billion recordinga increase <strong>of</strong> 9.28% over previousyear and reached USD22.15 billionin 2007-08 denoting an increase <strong>of</strong>15.7% but declined by over 5% in2008-09 with exports <strong>of</strong> USD 20.94billion. During 2009-10, the exports<strong>of</strong> T&C increased by over 5.60% andreached the level <strong>of</strong> USD 22.42billion. Thus exports <strong>of</strong> T&C havedenoted an increase <strong>of</strong> 60.14% inthe last five years (2004-05 to 2009-10). Indian T&C exports is facingvarious constraints <strong>of</strong> infrastructure,high power and transaction cost,incidence <strong>of</strong> state level cess andduties, lack <strong>of</strong> state-<strong>of</strong>-the-arttechnology etc.Readymade Garments account foralmost 45% <strong>of</strong> the total textilesexports. Apparel and cotton textilesproducts together contribute nearly70% <strong>of</strong> the total textiles exports.The exports basket consists <strong>of</strong> awide range <strong>of</strong> items comprisingreadymade garments, cotton textiles,handloom textiles, man-made fibretextiles, wool and woolen goods, silk,jute and handicrafts including carpets.v) India's textiles products, includinghandlooms and handicrafts, areexported to more than a hundredcountries. However, the USA and theEU, account for about two-third <strong>of</strong>India's textiles exports. The othermajor export destinations areCanada, U.A.E., Japan, Saudi Arabia,Republic <strong>of</strong> Korea, Bangladesh,Turkey, etc.September'10, exports <strong>of</strong> T&C havebeen achieved at USD 11.26 billion.SCHEME FOR INTEGRATED TEXTILEPARKS (SITP)The 'Scheme for Integrated Textile Parks(SITP)' is being implemented to facilitatesetting up <strong>of</strong> textile units with appropriatesupport infrastructure. IndustryAssociations / Group <strong>of</strong> Entrepreneursare the main promoters <strong>of</strong> the Integrated<strong>Textiles</strong> Park (ITP).Scope <strong>of</strong> the SchemeThe scheme targets industrial clusters/locations with high growth potential, whichrequire strategic interventions by way <strong>of</strong>providing world-class infrastructuresupport. The project cost covers commoninfrastructure and buildings for production/support activities, depending on the needs<strong>of</strong> the ITP. The components <strong>of</strong> an ITPare:(a)(b)(c)(d)Group A - Land.Group B - Common Infrastructurelike compound wall, roads, drainage,water supply, electricity supplyincluding captive power plant, effluenttreatment, telecommunication linesetc.Group C - Buildings for commonfacilities like testing laboratory, designcenter, training center, trade center/display center, ware housing facility/raw material depot, crèche, canteen,workers hostel, <strong>of</strong>fices <strong>of</strong> serviceproviders, labour rest and recreationfacilities etc.Group D - Factory buildings forproduction purposes.vi)The export <strong>of</strong> textiles and clothingaggregated to US$ 22.42 billion in2009-10. The Government fixed thetarget for 2010-11 at US$ 25.48billion. So far during the period April-(e)Group E - Plant & machinery.The total Project Cost for the purpose <strong>of</strong>this Scheme includes the cost on account<strong>of</strong> components <strong>of</strong> ITP, as listed under7

ministry <strong>of</strong> textilesGroups A, B, C and D above, provided theownership <strong>of</strong> the factory buildings vestswith the SPV. The SPV has, however,have the option <strong>of</strong> seeking financial supportfrom Government <strong>of</strong> India for componentsunder Groups B and C only, if factorybuildings are individually owned.Funding PatternThe total project cost, as indicated above,is funded through a mix <strong>of</strong> Equity/Grant -from the <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong>, StateGovernment, State Industrial DevelopmentCorporation, Industry & ProjectManagement Consultant and Loan - fromBanks / Financial Institutions. TheGovernment <strong>of</strong> India's (GOI) support underthe Scheme by way <strong>of</strong> Grant or Equity islimited to 40% <strong>of</strong> the project cost subjectto a ceiling <strong>of</strong> Rs. 40 crore. However, GOIsupport will be provided @90% <strong>of</strong> theproject cost subject to a ceiling <strong>of</strong> Rs. 40crore for first two projects in the States <strong>of</strong>Arunachal Pradesh, Assam, Manipur,Meghalaya, Mizoram, Nagaland, Tripura,Sikkim and Jammu & Kashmir.Progress <strong>of</strong> implementationForty (40) textiles park projects havebeen Snactioned by the <strong>Ministry</strong> <strong>of</strong><strong>Textiles</strong>. State-wise sanction <strong>of</strong> project is- Andhra Pradesh (5), Gujarat (7),Karnataka (1), Madhya Pradesh (1),Maharashtra (9), Punjab (3) Rajasthan(5), Tamil Nadu (8), West Bengal (1) and.These Parks would have facilities forspinning, sizing, texturising, weaving,processing, apparels etc. The estimatedproject cost (for common infrastructureand common facilities) is Rs. 4193.65Crore, <strong>of</strong> which Government <strong>of</strong> Indiaassistance under the scheme would beRs. 1419.69 Crore. 2292 entrepreneurswill put up their units in these parkscovering an area <strong>of</strong> 4307.97 Acre. Theprojected investment in these parks is Rs.19,456.90 Crore and estimated annualproduction is Rs 33568.50 Crore. Afterthese parks are fully operational therewould be employment available for 7.50lakh persons (3 lakh direct & 4.50 indirect).So far assistance <strong>of</strong> Rs. 882.60 Crore hasbeen provided for execution <strong>of</strong> theseprojects. The promoters <strong>of</strong> these textilespark projects have brought in Rs.1000Crore (approx.) as their contribution. Fourprojects have been completed - Brandix& Pochampally Handloom Park Ltd.-Andhra Pradesh, Gujarat Eco Textile Park-Gujarat and Palladam Hi-Tech WeavingPark - Tamil Nadu and production hasbeen started in 24 out <strong>of</strong> 40 projects.DECENTRALIZEDSECTORPOWERLOOMThe decentralized Powerloom Sector playsa pivotal role in meeting the clothingneeds <strong>of</strong> the country. The powerloomindustry produces a wide variety <strong>of</strong> cloth,both grey as well as processed. Production<strong>of</strong> cloth as well as generation <strong>of</strong>employment has been rapidly increasingin the powerloom sector. There are 22.69lakh powerlooms in the country as on31.10.2010 distributed over approximately5.11 lakh units. The powerloom sectorcontributes about 61% <strong>of</strong> the total clothproduction <strong>of</strong> the country, and providesemployment to about 56.64 lakh persons.More than 60% <strong>of</strong> the cloth meant forexport comes from the powerloom sector.Growth in the Powerloom SectorThe estimated number <strong>of</strong> powerlooms inthe decentralized sector in the country till31st October 2010 were 22,69,469.Product Pr<strong>of</strong>ileThe Powerloom Sector produces a variety<strong>of</strong> fabrics for domestic as well as exportmarkets, such as shirting, suitings, dressmaterial, saree, dhoti, sheetings, towels,chaddar, furnishing, shawls, blankets,tweeds etc. made out <strong>of</strong> cotton, blended,synthetic, silk, wool etc.8

annual report 2010-11Technology LevelAs on 31st October 2010 there are 22.69lakh looms installed in the country. Most<strong>of</strong> these looms are conventional, plain /ordinary looms <strong>of</strong> old vintage, withoutdated technology, very low speed,marked by low productivity andmanufacturing by and large defect proneand low value fabrics.COTTONCotton is one <strong>of</strong> the principal crops <strong>of</strong> thecountry and is the major raw material fordomestic textile industry. It providessustenance to million <strong>of</strong> farmers as alsothe workers involved in cotton industry,right from processing to trading <strong>of</strong> cotton.The Indian textile industry consumes adiverse range <strong>of</strong> fibres and yarn, but ispredominantly cotton based. The ratio <strong>of</strong>the use <strong>of</strong> cotton to man-made fibres andfilament yarns by the domestic industry isabout 56:94. Indian Textile Industry has anoverwhelming presence in the economiclife <strong>of</strong> the country. Apart from providing one<strong>of</strong> the basic necessities <strong>of</strong> life, the textileindustry also plays a pivotal role throughits contribution to industrial output,employment generation and the exportearnings <strong>of</strong> the country. It contributes about14% to the industrial production, 4% to theGDP and 14.42% to the country's exportearnings. The textile sector is the secondlargest provider <strong>of</strong> employment afteragriculture. Hence, growth and all arounddevelopment <strong>of</strong> cotton and cotton industryhas a vital bearing on the overalldevelopment <strong>of</strong> the Indian economy.ACREAGE UNDER COTTONCULTIVATIONAcreage under cotton in India had beencontinuously increasing. The cottonacreage in 2009-10 (October-September)had reached a record level <strong>of</strong> 103.29 lakhhectares as against 94.06 lakh hectaresin previous year.Approximately 65% <strong>of</strong> Indian's cotton isproduced on rainfed areas and 35% onirrigated lands. Cotton farmers in Indiahave been showing increasing inclinationin bringing more and more areas under Btcultivation, which has helped them inincreasing their net earning through higheryields and lower cost on pesticidesconsumption. Acreage under Bt. Cotton inthe country is continuously increasingyear by year. During cotton season 2009-10, the acreage under Bt cultivation hadbeen around 81 lakh hectares as against68 lakh hectares in the previous year. Theshare <strong>of</strong> Bt. Cultivation in 2009-10constitute around 79% <strong>of</strong> the total acreageas against 73% during last year.INDIAN COTTON VARIETIESIndia is the only country to grow all fourspecies <strong>of</strong> cultivated cotton Gossypiumarboreum and herbaceum (Asian cotton),G.barbadense (Egyptian cotton) and G.hirsutum (American Upland cotton).Gossypium hirsutum represents 90% <strong>of</strong>the hybrid cotton production in India andall the current Bt cotton hybrids areG.hirsutuim. India produces large number<strong>of</strong> cotton varieties and hybrids. Thoughthe number <strong>of</strong> varieties in cultivationexceeds seventy-five, 98% <strong>of</strong> theproduction is contributed by about 25varieties only.COTTON PRODUCTION ANDPRODUCTIVITYCotton is produced in India in three zonesviz., Northern zone comprising the States<strong>of</strong> Punjab, Haryana and Rajasthan, Centralzone comprising the States <strong>of</strong>Maharashtra, Madhya Pradesh andGujarat and Southern zone comprisingthe States <strong>of</strong> Andhra Pradesh, Karnatakaand Tamil Nadu. Besides these nineStates, cotton cultivation has gainedmomentum in the eastern State <strong>of</strong> Orissa.With increased acreage and advent <strong>of</strong> Bt9

ministry <strong>of</strong> textilescultivation, the country has achieved cottonproduction <strong>of</strong> 5.02 million tons in cottonseason 2009-10 as against 4.93 milliontons in the previous year. The country hasonce again retained the position as thesecond largest cotton producing countryin the world, after China.The adverse agro-climatic conditions,insufficient rains in certain parts hadaffected the cotton yield during the year2009-10 and the same had been at 488kgs per hectare as against 524 kgs perhectare during cotton year 2008-09.The higher cotton production in the countryfor the fifth consecutive year has beendue to significant increase in acreageunder Bt cultivation.TECHNOLOGY MISSION ON COTTONThe Government <strong>of</strong> India commissionedthe Technology Mission on Cotton (TMC)on February 21, 2000. The Mission aimsto address the issues <strong>of</strong> raisingproductivity, improving quality and reducingthe cost <strong>of</strong> production and thus providethe much-needed competitive advantageto the textile industry along with ensuringattractive returns to the farmers. The XPlan scheme was operational upto31.03.2007. However, the Scheme MM IIIand IV <strong>of</strong> TMC has been further extendedin the 11th Five Year Plan for two yearsi.e. upto 31.3.2009 to accomplish targetand completion <strong>of</strong> the projects.The Mission comprises <strong>of</strong> four MiniMissions, which are jointly beingimplemented by the Ministries <strong>of</strong>Agriculture and <strong>Textiles</strong>. MM-I relates toResearch and Development on Cottonand MM-II is Dissemination <strong>of</strong> technologyto farmers are being undertaken by the<strong>Ministry</strong> <strong>of</strong> Agriculture.<strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong> is the Nodal Agencyfor Mini Missions III & IV <strong>of</strong> TMC. MiniMission III aims to improve the quality <strong>of</strong>cotton, particularly in respect <strong>of</strong> trash,contamination etc. by improving themarketing infrastructure in the marketyards for cotton by providing better facilities<strong>of</strong> cotton producing facilities by upgrading/modernizing the existing Ginning andPressing factories resulting in cottonprocessing with minimum or nocontamination to achieve better valueproducts like yarn, cloth, garments madeupsetc. Target as well as achievementmade under MM-III and MM-IV <strong>of</strong> TMC isgiven at table 1.3.Table 1.3Objectives Target Achievement(MM-III)Market Yards 250 242(MM-IV)Ginning & Pressingfactories 1011 885With the intervention <strong>of</strong> MM III and MM IV,the trash content and contamination hasreduced substantially which in turn hasenhanced the export <strong>of</strong> clean andcontamination free cotton bales to variouscountries branding the Indian Cotton inglobal arena and also benefiting the textilesmills in producing good quality cottontextile. The TMC has been a valuablevehicle to bring the ultimate stakeholders<strong>of</strong> cotton textile industry in touch with therelevant advancement so as to increasefarm productively and in turn for themultiplier effect to work on the cottoneconomy as whole. The Mission is aneffort towards the collective cause for theentire cotton economy and cotton textileIndustry.Mini Mission III & IV <strong>of</strong> TMC havecompleted its tenure.SERICULTURE AND SILK INDUSTRYIndia continues to be the second largestproducer <strong>of</strong> silk in the World after China.10

annual report 2010-11Garmenting UnitIndia also has the unique distinction <strong>of</strong>producing all four commercially producedvarieties <strong>of</strong> silk in the world, i.e. Mulberry,Eri, Muga and Tassar. In 2009-10,Mulberry accounted for 82.9% (16322MT), Eri 12.5% (2460 MT), Tasar 4.1%(803 MT) and Muga 0.5% (105MT) <strong>of</strong> thetotal raw silk production in the country. In2009-10 production <strong>of</strong> mulberry raw silkincreased by about 4.6% after a declinein production in 2008-09. Production <strong>of</strong>non-mulberry raw silk, on the other hand,has been on a growth trajectory, recordingdouble-digit growth between 2005-06 and2009-10. Silk fabrics production alsoshowed a growth <strong>of</strong> over 4% in 2009-10compared to 2008-09.Sericulture continues to be an importantlabour-intensive and agro-based cottageindustry, providing gainful occupation toaround 6.8 million persons in rural andsemi-urban areas in India. Of these, asizeable number <strong>of</strong> workers belong to theeconomically weaker sections <strong>of</strong> societyand women. Post cocoon activities,including reeling, weaving and garmentingalso provide significant opportunity forinclusive growth for large segment <strong>of</strong>population in number <strong>of</strong> States.During the year 2008-09, total production<strong>of</strong> all varieties <strong>of</strong> raw silk was 18,370 tonscompared to the production <strong>of</strong> 18,320tons by the end <strong>of</strong> 2007-08, indicating anincrease <strong>of</strong> 0.3%. However, during theyear 2009-10, total production <strong>of</strong> allvarieties <strong>of</strong> raw silk increased to 19,690tons registering an increase <strong>of</strong> 7.2%.In the first year <strong>of</strong> the XI Plan i.e., 2007-08, production <strong>of</strong> Mulberry raw silkdecreased by 1.7% (16245 MT) comparedto the previous year 2006-07 (16525 MT).Production <strong>of</strong> mulberry raw silk during2008-09 declined by 3.9% to 15,610 tonsmainly due to decline in the Mulberryplantation and production <strong>of</strong> Mulberry rawsilk in Karnataka and Andhra PradeshStates. Production <strong>of</strong> mulberry raw silk11

ministry <strong>of</strong> textilesregistered an increase <strong>of</strong> 4.6% during2009-10 to 16,322 tons compared to theyear 2008-09, indicating recovery inmulberry plantation.However, Vanya Raw Silk (Tasar, Eri andMuga raw silk) Production continues toshow better performance in the Xi planperiod. Vany Silk Production increased by6.4% (2075 MT) during the year 2007-08as compared to the production <strong>of</strong> 1950MT during the previous year 2006-07.Production <strong>of</strong> Tasar, Eri and Muga during2008-09, were 603 MT, 2038 MT & 119MT, respectively, corresponding to 428MT, 1530 MT & 117 MT produced duringthe year 2007-08, indicating an increase<strong>of</strong> 40.9%, 33.2% & 1.7%, respectively.Production <strong>of</strong> Vanya silk (Tasar, Eri andMuga raw silk) during 2009-10, were 803MT, 2460 MT & 105 MT, respectively,corresponding to 603 MT, 2038 MT & 119MT produced during the year 2008-09,indicating an increase <strong>of</strong> 33.2% in Tasar,20.7% in Eri and a decrease <strong>of</strong> 11.8% inMuga.THE JUTE AND JUTE TEXTILESINDUSTRYThe Jute industry occupies an importantplace in the national economy <strong>of</strong> India. Itis one <strong>of</strong> the major industries in theeastern region, particularly in West Bengal.Jute, the golden fibre, meets all thestandards for 'safe' packaging in view <strong>of</strong>being a natural, renewable, biodegradableand eco-friendly product. It is estimatedthat that the jute industry provides directemployment to 0.37 million workers inorganized mills and in diversified unitsincluding tertiary sector and allied activitiesand supports the livelihood <strong>of</strong> around 4.0million farm families. In addition there area large number <strong>of</strong> persons engaged in thetrade <strong>of</strong> jute.In the world perspective, India is themajor producer <strong>of</strong> both raw jute and juteproducts. Out <strong>of</strong> the total world production<strong>of</strong> Jute, Kenaf and allied fibre <strong>of</strong> 3.0million tonnes in 2007-08, India produced1.8 million tonnes. In percentage termsIndia accounted for 60% <strong>of</strong> worldproduction in 2007-08. Global production<strong>of</strong> jute and allied fibres is estimated tohave increased by 25% to 3.0 milliontonnes in 2007-08 compared to 2004-05season. Production in India has alsoincreased by 28% to 1.8 million tonnes in2007-08 over 2004-05.There are 79 composite jute mills in India.Out <strong>of</strong> the total 79 jute mills, 62 jute millsare located in West Bengal, 3 each inBihar and U.P., 7 in Andhra Pradesh and1 each in Assam, Orissa, Tripura andChattisgarh. Ownership- wise division is:-6 mills are under Government <strong>of</strong> India'sP.S.U., 1 mill (Tripura) is under StateGovernment, 2 mills (Assam & NewCentral) are in the co-operative sectorand 70 are privately owned mills.As on 01-01-2010 total number <strong>of</strong> loomsinstalled in the jute industry stood at48,260 consisting <strong>of</strong> 22,038 Hessianlooms, 24,093 sacking looms, 1,068 C.B.Clooms and others at 1,061. The installedspindles in jute mills other than 100%export oriented units were 731,408comprising 622,324 fine spindles and109,084 coarse spindles. As on 01-01-2010, installed spindles in 100% exportoriented units stood at 9,482 with finespindles at 6,974 and coarse spindles at2,508. The maximum installed capacity injute mills other than 100% export orientedunits (on the basis <strong>of</strong> 305 working daysper year) is estimated to be <strong>of</strong> 2.51 milliontonnes per annum.In exercise <strong>of</strong> the power conferred bySub-section(I) <strong>of</strong> section 3 <strong>of</strong> the JutePackaging Materials (Compulsory Use inPacking Commodities) Act, 1987, <strong>Ministry</strong><strong>of</strong> <strong>Textiles</strong> issued Notification dated 27-08-2010 stipulating that 100% food grainand sugar to be compulsorily packed injute packaging material. The Notification12

annual report 2010-11came into effect from the date <strong>of</strong> itspublication and would remain valid upto30-06-2011.NATIONAL JUTE POLICYGovernment <strong>of</strong> India recognized thesignificance <strong>of</strong> jute in India's economywhich provides sustenance to more than4 million people including jute farmers,workmen, labourers and self employedartisans and weavers, especially in Easternand North-Eastern part <strong>of</strong> the country,where it is the mainstay <strong>of</strong> agro basedindustries. World over it has beenrecognized that jute and allied fibresoccupy a unique position as eco-friendly,bio-degradable, renewable natural fibreswith substantial value addition at eachstage <strong>of</strong> processing. Taking note <strong>of</strong> thenew opportunities presented by thechanging global environment <strong>of</strong> integrationin the development <strong>of</strong> natural fibres, thestrength and weaknesses <strong>of</strong> the jutesector in India and acknowledging thegrowing demand for diversified andinnovative jute product in the world market,GOI announced the "National Jute Policy- 2005" to redefine the goals andobjectives, focus on thrust areas andsharpen strategy in tune with the timeswith a view to give the jute industry inIndia a fresh impetus in all respect.The main objective <strong>of</strong> the policy is t<strong>of</strong>acilitate the jute sector in India to attainand sustain a pre-eminent global standingin the manufacture and export <strong>of</strong> juteproducts by enabling the jute industry tobuild world-class state-<strong>of</strong>-the artmanufacturing capabilities in conformitywith environmental standards. The policyseeks to strengthen R&D activities inagricultural practices with public-privatepartnership with a vision to ensureremunerative prices to millions <strong>of</strong> jutefarmers by enabling them to producebetter quality jute fibre for value addeddiversified jute products and enhance perhectare yield <strong>of</strong> raw jute.HANDLOOMSHandloom constitutes a timeless facet <strong>of</strong>the rich cultural heritage <strong>of</strong> India. As aneconomic activity and in terms <strong>of</strong>employment generation, the handloomsector occupies a place second only toagriculture. This sector is, however, isconfronted with various problems, suchas, obsolete technology, unorganizedproduction system, low productivity,inadequate working capital, conventionalproduct range, weak marketing linksleading to accumulation <strong>of</strong> stocks atvarious levels etc. The Government <strong>of</strong>India has, therefore, been initiating variousdevelopmental and welfare measures tohelp the handloom sector to tide overthese problems to a great extent.PRODUCTION IN THE HANDLOOMSECTOR INCREASEDResultant to the developmental and welfaremeasures initiated by the Government <strong>of</strong>India, the declining trend in production inthe handloom sector had been reusedand from the year 2004-05 there, in fact,has been a considerable growth inproduction in the sector. Production in thehandloom sector recorded a figure <strong>of</strong>6769 million sq. meters in the year 2009-10, which is about 23.23% over theproduction figure <strong>of</strong> 5493 million sqr.Meters recorded in the year 2003-04.475 HANDLOOM CLUSTERS, EACHCOVERING 300-500 HANDLOOM,TAKEN UP FOR DEVELOPMENTThe Integrated Handlooms DevelopmentScheme (IHDS) has been launched witha view to develop holistically andcomprehensively the weavers' clustersthroughout the country. Under this scheme,475 Handloom clusters have been takenup upto December, 2010 and financialassistance <strong>of</strong> Rs 101.59 crore has beenreleased to various Implementing agenciesfor various components like skill13

ministry <strong>of</strong> textilesupgradation, awareness programme,formation <strong>of</strong> consortium etc.16 LAKH WEAVERS COVERED UNDERTHE HEALTH INSURANCE SCHEMEThe Health Insurance Scheme provideshealth care facilities to the handloomweavers and their families. 16.11 lakhweavers are covered under the scheme.80% <strong>of</strong> the premium is paid by theGovernment <strong>of</strong> India while only 20% ispaid by the Weavers/State Government.During the Policy period (2010-11) thepremium has been drastically reduced by14% on an average throughout thecountry. 4.12 lakh weavers covered underthe Mahatma Gandhi Bunkar Bima Yojanaupto December, 2010. The scheme isimplemented through LIC <strong>of</strong> India.Scholarships91168 children <strong>of</strong> weavers have beengiven worth 8.27 crores (upto December,2010).SUPPLY OF YARN UNDER THE MILLGATE PRICE SCHEME715 yarn depots, covering all the handloomclusters, have been set up by the NationalHandloom Development Corporation(NHDC) to ensure steady and timelysupply <strong>of</strong> requisite yarn at Mill Gate Priceto the handloom weavers. NationalHandloom Development Corporation(NHDC) under the Mill Gate Price Schemesupplied 1081.21 lakh kgs. yarn valued atRs.987.23 core in the year 2009-10 ascompared to the figure <strong>of</strong> 855.10 lakh kgsvaluing Rs.793.77 core in the year 2008-09.SANT KABIR AWARDSANT KABIR AWARD for handloomweavers is being conferred every year,beginning from the year 2009. This awardis being given to such outstanding weaverswho have made valuable contribution inkeeping alive the handloom heritage andalso for their dedication in building uplinkages between the past, present andthe future through dissemination <strong>of</strong>knowledge on traditional skills and designs.Each award consists <strong>of</strong> one mounted goldcoin, one shawl and a citation. In addition,financial assistance to the extent <strong>of</strong> Rs.6.00 lakh also is being given to each <strong>of</strong>the Sant Kabir Awardee to innovate andcreate 10 new products <strong>of</strong> high level <strong>of</strong>excellence, <strong>of</strong> high aesthetic value and <strong>of</strong>high quality. 10 handloom weavers havebeen selected for Sant Kabir Award forthe year 2009.BRAND BUILDING THROUGHHANDLOOM MARKEmphasis has been laid on BrandDevelopment through Handloom Markduring the XI Five Year Plan. TheHandloom Mark was launched by theHon'ble Prime Minister <strong>of</strong> India on 28thJune, 2006. The Handloom Mark servesas a guarantee to the buyer that thehandloom product being purchased is agenuine handwoven product and notpowerloom or mill made. Handloom Markis being promoted and popularized throughadvertisements in newspapers andmagazines, electronic media, syndicatedarticles, fashion shows, films etc.The <strong>Textiles</strong> Committee is theImplementing agency for promotion <strong>of</strong>Handloom Mark. As on 30th Nov. 2010,1.77 crore handloom mark labels havebeen sold to 7328 stakeholders. 747retails outlets are selling handloom goodswith handloom mark label.The new beneficiaries now included in theHandloom Mark scheme to get the benefitsare: Self Help Groups, Joint LiabilityGroups, Consortia, Producer companies,Handloom Weavers Groups or any otherlegal entity organization involved in14

annual report 2010-11Handloom activities and approved byDevelopment Commissioner forHandlooms with a one time registrationfee <strong>of</strong> Rs.500.Sale price <strong>of</strong> one label was brought downfrom Rs. 1.25 (at the time <strong>of</strong> launch) to60 paise. Application forms are nowavailable free <strong>of</strong> cost. The Registrationfee for individual weavers is reduced toRs. 25 (from Rs. 100) while for Masterweavers Rs. 500 (from Rs. 2000).HANDLOOM WEEKHandlooms constitute a living heritage <strong>of</strong>our country reflecting the ethos <strong>of</strong> the artand craft traditions <strong>of</strong> our country whichgives employment to about 43 lakh people.It is the only environmental friendly fabricrequires continuous promotion, adoptionand protection. "Handloom Week" wascelebrated for the first time in the countryfrom 21st December to 27th December.During the Handloom week a number <strong>of</strong>promotional and awareness programmes,organisation <strong>of</strong> domestic marketing throughhandloom expos, fashion shows, publicitythrough newspapers, magazines, outdoorpublicity, through electronic media wereundertaken.During the current financial year 2010-11,Handloom Week was celebratedthroughout the country from 21st to 27thDecember, 2010. A series <strong>of</strong> fashion shows<strong>of</strong> handlooms designed by famousdesigners were held at Chennai, Delhi andRanchi. During the handloom week, anexhibition <strong>of</strong> handloom products on silkenthem (TANTAVI) and Buyer Seller Meetwas organized at Shilpi Haat, Rajiv GandhiHandicrafts Bhawan. Third NationalHandloom Census Report was releasedon 23rd December, 2010 and Photo IdentityCards were also issued to some handloomweavers by the Hon'ble Minister <strong>of</strong> Statefor <strong>Textiles</strong>. An exhibition-cum-sale <strong>of</strong>Handloom Mark and Silk Mark products incollaboration with Silk Mark Organisationwas held at Indian Islamic Centre from24th to 26th Dec, 2010. For the first timeEssay Writing competition and Handloomapparel design competition was alsoconducted and winners were given cashaward and certificates.Increase in the number <strong>of</strong> marketingeventsThe target <strong>of</strong> marketing events for theyear 2010-11 has been increased to 650from 561 during the year 2009-10 to giveadequate opportunity for the weavers tomarket their products directly to theconsumers without the intervention <strong>of</strong> themiddlemen. As on December, 2010, 667marketing events have been sanctionedto various State Governments,Corporations, ACASH, NHDC and othereligible agencies.HANDICRAFTSThe Handicrafts Sector plays a significant& important role in the country's economy.It provides employment to a vast segment<strong>of</strong> craft persons in rural & semi urban areasand generates substantial foreign exchangefor the country, while preserving its culturalheritage. Handicrafts have great potential,as they hold the key for sustaining not onlythe existing set <strong>of</strong> millions <strong>of</strong> artisansspread over length and breadth <strong>of</strong> thecountry, but also for the increasingly largenumber <strong>of</strong> new entrants in the crafts activity.Presently, handicrafts contributesubstantially to employment generation andexports. The Handicraft sector has,however, suffered due to its beingunorganized, with the additional constraints<strong>of</strong> lack <strong>of</strong> education, low capital, poorexposure to new technologies, absence <strong>of</strong>market intelligence, and a poor institutionalframework. In spite <strong>of</strong> these constraints,sector has witnessed a significant growth<strong>of</strong> 3% annually, and efforts are beingaugmented during the 11th Five Year planon the core issues for the development <strong>of</strong>the sector.15

ministry <strong>of</strong> textiles●Providing Infrastructural support forproduction & Exports.● Improve quality & productdiversification with more awarenessfor both stakeholders & consumer.● A greater role for NGO asimplementing partners andparticipation <strong>of</strong> private resources -both human and financial.In view <strong>of</strong> the 3% growth annually inHandicrafts sector, it is presumed that thetotal employment in the sector as at theend <strong>of</strong> 10th plan is 67.70 lakhs, which atthe beginning <strong>of</strong> the 10th plan was 60.16lakhs, showing an annual growth rate <strong>of</strong>about 3%, on the basis <strong>of</strong> this growth inthe sector it is expected this employmentto reach 80 lakhs by the end <strong>of</strong> 11th Plan.The plan expenditure during the periodalso witnessed a steady growth increasingfrom Rs.71.65 crores in 2002-03 toRs.286.00 crores in 2010-11. Theproduction during the period 2002-03 hasincreased from Rs.19,564.52 crores toRs.20221.58 crores during the year 2009-10. The exports during the periodincreased from Rs.10933.67 crores in theyear 2002-03 to Rs.11224.27 crores atthe end <strong>of</strong> the year 2009-10 registering acumulative increased 2.65%, The budgetoutlay for the year 2011-12 has beenproposed for Rs. 316.27 crores.Handicrafts activity being a State subject,its development and promotion are theprimary responsibility <strong>of</strong> every StateGovernment. However, the CentralGovernment is supplementing their effortsby implementing various developmentalschemes.SARDAR VALLABHBHAI PATELINTERNATIONAL SCHOOL OFTEXTILES AND MANAGEMENTSardar Vallabhbhai Patel InternationalSchool <strong>of</strong> <strong>Textiles</strong> and Management,Coimbatore, Tamil Nadu, was set upinitially as Sardar Vallabhbhai PatelInstitute <strong>of</strong> <strong>Textiles</strong> Management onDecember 24, 2002 as a national levelinstitute for Textile Management to preparethe Indian Textile Industry to face thechallenges <strong>of</strong> Post-MFA era and enable itto establish itself as a leader in the globaltextiles trade. Recognising the emergingareas in textiles, especially technicaltextiles, and the greater role the Institutehas to play for the benefit <strong>of</strong> the textilessector, the Institute was upgraded asSardar Vallabhbhai Patel InternationalSchool <strong>of</strong> <strong>Textiles</strong> and Management(SPVISTM) by the Hon'ble Minister <strong>of</strong><strong>Textiles</strong>, Shri Dayanidhi Maran on July 7,2010. (Upgradation <strong>of</strong> SVPITM toSVPISTM and Signing <strong>of</strong> MOU withIGNOU on July 7, 2010).SVIPSTM is a National Level AutonomousInstitution providing comprehensiveeducation, training, consultancy andresearch in textiles management. TheSchool has been set up by the Government<strong>of</strong> India, <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong> and the <strong>Textiles</strong>Industry, registered under the Tamil NaduSocieties Registration Act, 1975 to cater tothe long-felt need for management coursesspecialising in textiles, including researchin textiles management.NATIONAL INSTITUTE OF FASHIONTECHNOLOGY (NIFT)The National Institute <strong>of</strong> FashionTechnology was set up in 1986 as anautonomous Society in collaboration withthe Fashion Technology (FIT), New York,to train pr<strong>of</strong>essionals to meet therequirements <strong>of</strong> the textiles industry. Theinstitute has pioneered the evolution <strong>of</strong>fashion business education across thecountry through its network <strong>of</strong> fifteencentres at New Delhi, Bengaluru, Chennai,Gandhinagar, Hyderabad, Kolkata,Mumbai, Rae Bareli, Patna, Bhopal,Shillong, Kangra, Kannur, Jodhpur andBhubaneswar.16

annual report 2010-11NIFT besides conducting regularpr<strong>of</strong>essional undergraduate andpostgraduate programmes in Design,Management and Technology, also <strong>of</strong>fersshort duration part-time courses under itsContinuing Education (CE) Programmes.A Specialty Centre will be opened atCoimbatore very shortly.The National Institute <strong>of</strong> FashionTechnology Act, 2006 came into force onJuly 14, 2006 and came into effect from1st April, 2007. The Act provides statutorystatus to the Institute and formallyrecognizes its leadership in fashiontechnology sector, and empowers NIFT toaward degrees to its students. NIFT is thefirst Institute in the world to award degreesin fashion education.ACTIVITIES RELATED TOPROGRESSIVE USE OF OFFICIALLANGUAGEHindi is the Official Language <strong>of</strong> the Union<strong>of</strong> India and the policy <strong>of</strong> the Governmentaims at progressive use <strong>of</strong> Hindi in <strong>of</strong>ficialwork. Effective steps have been takenduring the year in the M/o <strong>Textiles</strong> toensure compliance with the OfficialLanguage Policy <strong>of</strong> the Government;implementation <strong>of</strong> the annual programmeand compliance with the various orders <strong>of</strong>the Government <strong>of</strong> India on therecommendations <strong>of</strong> the Committee <strong>of</strong>Parliament on Official Language.Compliance with the provisions <strong>of</strong> theOfficial Language Act, 1963All documents such as resolutions, generalorders, rules etc., under Section 3(3) <strong>of</strong> theOfficial Language Act and all papers laid onthe Table <strong>of</strong> both the Houses <strong>of</strong> Parliamentwere issued bilingually, i.e. in Hindi and<strong>English</strong>. General orders meant fordepartmental use were issued in Hindi only.Replies to letters in HindiAll letters received in Hindi were repliedto in Hindi.Sections specified for working in HindiThe 12 Sections <strong>of</strong> the <strong>Ministry</strong> whichhave been specified for doing hundredper cent work in Hindi, are workingsatisfactorily.Monitoring and inspectionsIn order to ensure compliance with theOfficial Language Policy, monitoring isdone through reviewing the quarterlyprogress reports. During the year, apartfrom the Sections <strong>of</strong> the <strong>Ministry</strong>, fivehead <strong>of</strong>fices and three sub-<strong>of</strong>fices <strong>of</strong>organizations under the control <strong>of</strong> the<strong>Ministry</strong> were inspected to ensureprogressive use <strong>of</strong> Hindi and compliancewith the Official Language policy.Training <strong>of</strong> OfficialsAll the clerks / stenographers in the<strong>Ministry</strong> have already been trained inHindi typing and Hindi stenography.Use <strong>of</strong> Mechanical aidsAs per the provisions <strong>of</strong> the OfficialLanguage Act, facilities have beenprovided on all the computers in the<strong>Ministry</strong>, to work in Hindi.CommitteesThe Hindi Salahar Samitee has beenconstituted in the <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong>under the Chairmanship <strong>of</strong> Minister <strong>of</strong><strong>Textiles</strong>. The first meeting <strong>of</strong> the committeewas held on 9th November, 2010.The Departmental Official LanguageImplementation Committee in the M/o<strong>Textiles</strong> has been constituted under theChairmanship <strong>of</strong> the Joint Secretary (In-Charge Hindi). The Quarterly meetings <strong>of</strong>the Committee were organized andimportant decisions were taken forprogressive use <strong>of</strong> Hindi in <strong>of</strong>ficial work.Necessary follow-up action was taken forcompliance <strong>of</strong> these decisions.17

ministry <strong>of</strong> textilesHindi FortnightHindi Fortnight was celebrated during 1-14 September, 2010 in the <strong>Ministry</strong>.Various competitions like Hindi Essay,Hindi Noting & Drafting, Hindi Questionsand Answers, Story Writing, Hindi Debate,Hindi Poetry Recitation, Dictation, HindiGyan and Hindi Typing were organized toencourage and motivate the employeesfor doing <strong>of</strong>ficial work in Hindi. A largenumber <strong>of</strong> <strong>of</strong>ficers and staff participated inthese events with enthusiasm. Appealsfrom the Hon'ble Home Minister, Minister<strong>of</strong> <strong>Textiles</strong>, Minister <strong>of</strong> State for <strong>Textiles</strong>and Secretary (<strong>Textiles</strong>) were circulatedon the occasion <strong>of</strong> Hindi Diwas in theM/o <strong>Textiles</strong> as well as in its Attached /Subordinate <strong>of</strong>fices and PSUs etc. forinformation and compliance.18

annual report 2010-11CHAPTER IIFUNCTIONS &ORGANISATIONAL SET-UP19

20ministry <strong>of</strong> textiles

annual report 2010-11CHAPTER IIFUNCTIONS & ORGANISATIONAL SET-UPThe <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong> is responsiblefor policy formulation, planning,development, export promotion andtrade regulation <strong>of</strong> the <strong>Textiles</strong> Industry.This includes all natural and manmadecellulosic fibres that go into the making <strong>of</strong>textiles, clothing, and handicrafts. Thematters relating to non-cellulosic syntheticfibres and filament yarns, such as nylon,polyster acrylic, and poly-propylene areunder the administrative control <strong>of</strong> <strong>Ministry</strong><strong>of</strong> Chemicals and Petrochemicals.The<strong>Ministry</strong> maintains an interactive website:www.texmin.nic.in. The <strong>Ministry</strong> is headedby a Secretary, who is assisted in thedischarge <strong>of</strong> her duties by four JointSecretaries, an Economic Advisor, andthe Development Commissioners forHandlooms and Handicrafts, the <strong>Textiles</strong>Commissioner and the Jute Commissioner.VISIONTo build state <strong>of</strong> the art productioncapacities and achieve a pre-eminentglobal standing in manufacture and export<strong>of</strong> all types <strong>of</strong> textiles including technicaltextiles, jute, silk and wool and develop avibrant handloom and handicraft sectorfor sustainable economic developmentand promoting and preserving the age oldcultural heritage in these sectors.MISSION●To promote planned and harmoniousgrowth <strong>of</strong> textiles by making availableadequate fibres to all sectors.● To promote technologicalupgradation for all types <strong>of</strong> textilesincluding technical textiles, jute, silkand wool.●To promote skills <strong>of</strong> all textile workers,handloom weavers and handicraftsartisans, creation <strong>of</strong> new employmentopportunities and development <strong>of</strong> newdesigns to make these sectorseconomically sustainable.● To ensure proper workingenvironment and easy access tohealth care facilities and insurancecover to weavers and artisans toachieve better quality <strong>of</strong> life.●To promote exports <strong>of</strong> all types <strong>of</strong>textiles and handicrafts and increaseIndia's share <strong>of</strong> world exports inthese sectors.OBJECTIVES●●●●To make available adequate rawmaterial to all sectors <strong>of</strong> <strong>Textiles</strong>Industry.To augment the production <strong>of</strong> fabricsat reasonable prices from theorganised and decentralised sectors.To lay down guidelines for a plannedand harmonious growth <strong>of</strong> varioussectors with special emphasis on thedevelopment <strong>of</strong> the handlooms sectordue to its large employment potential.To monitor the techno-economicstatus <strong>of</strong> the industry and to providethe requisite policy framework formoderisation and rehabilitation.FUNCTIONAL AREAS●●The <strong>Textiles</strong> Policy & CoordinationThe Man-made Fibre/Filament YarnIndustry21

ministry <strong>of</strong> textiles●●●●●●●●●●●The Cotton <strong>Textiles</strong> IndustryThe Jute IndustryThe Sericulture and Silk <strong>Textiles</strong>,IndustryThe Wool & Woollen <strong>Textiles</strong> IndustryThe Decentralized PowerloomsSectorThe Export PromotionHandicraftsHandloomsThe Planning & Economic AnalysisThe Integrated Finance MattersThe Information Technology.1. ATTACHED OFFICES(i)The Office <strong>of</strong> the DevelopmentCommissioner for Handlooms,New DelhiThe Office is headed by theDevelopment Commissioner forHandlooms. It administers variousschemes for the promotion anddevelopment <strong>of</strong> the handlooms sectorand supplements to the efforts <strong>of</strong>State Governments, Societies, NGOs,etc. Its subordinate organisationsinclude Weavers' Services Centres(WSCs), the Indian Institues <strong>of</strong>Handloom Technology (IIHT) and theEnforcement Machinery for theimplementation <strong>of</strong> the Handlooms(Reservation <strong>of</strong> Articles forProduction) Act, 1985.(ii) The Office <strong>of</strong> the DevelopmentCommissioner for Handicrafts,New DelhiThe <strong>of</strong>fice is headed by theDevelopment Commissioner forHandicrafts. It administers variousschemes and functions to promotethe development and export <strong>of</strong>handicrafts, and supplements theefforts <strong>of</strong> State Governments byimplementing various developmentalschemes. It has six regional <strong>of</strong>ficesat Mumbai, Kolkata, Lucknow,Chennai, Guwahati, and New Delhi.2. SUBORDINATE OFFICES(i) Office <strong>of</strong> the <strong>Textiles</strong>Commissioner, MumbaiThe <strong>of</strong>fice <strong>of</strong> the TextileCommissioner (TXC) has itsheadquarters at Mumbai and eightregional <strong>of</strong>fices at Amritsar, Noida,Kanpur, Kolkata, Bengluru,Coimbatore, Navi Mumbai andAhmedabad. The <strong>Textiles</strong>Commissioner acts as the principaltechnical advisor to the <strong>Ministry</strong>. TheOffice <strong>of</strong> <strong>Textiles</strong> Commissionercarries out techno-economic surveysand advises the government on thegeneral economic health <strong>of</strong> thetextiles industry. The developmentalactivities <strong>of</strong> the Office <strong>of</strong> the <strong>Textiles</strong>Commissioner centre around planningfor the growth and development <strong>of</strong>the textiles sector. Of the forty fourPowerloom Service Centres (PSCs)functioning throughtout the country,fourteen are functioning under theadministrative control <strong>of</strong> the <strong>Textiles</strong>Commissioner. The <strong>of</strong>fice <strong>of</strong> TXCalso coordinates and providesguidance to the remaining thirtyPowerloom Service Centres, beingrun by the various <strong>Textiles</strong> ResearchAssociations and State GovernmentAgencies. The Office also implementsand monitors various developmentaland promotional schemes like theTechnology Upgradation FundScheme (TUFS) for the modernization<strong>of</strong> the <strong>Textiles</strong> and Jute industry,20% and 15% Margin Money SubsidySchemes for decentralizedPowerloom Sectors, the <strong>Textiles</strong>Workers' Rehabilitation Fund Scheme22

annual report 2010-11(ii)(TWRFS), and the TechnologyMission on Cotton (TMC), etc.Office <strong>of</strong> the Jute Commissioner,KolkataThis <strong>of</strong>fice is headed by the JuteCommissioner and is entrusted withthe responsibility <strong>of</strong> implementing thepolicies <strong>of</strong> the Government in theJute sector. The Jute Commissioneracts as the principal technical adviserto the Government <strong>of</strong> India, andgives technical advice to the <strong>Ministry</strong>on matters relating to the jute industry,including the jute machinery industry.3. ADVISORY BOARDS(i)(ii)All India Handicrafts BoardThe All India Handicrafts Board is anadvisory body under the chairmanship<strong>of</strong> the Minister <strong>of</strong> <strong>Textiles</strong>, with theDevelopment Commissioner(Handicrafts) as the MemberSecretary. It gives its advice to theGovernment on matters pertaining tothe development <strong>of</strong> thehandicrafts sector.All India Powerlooms BoardThe All India Powerlooms Board isan advisory body under thechairmanship <strong>of</strong> the Minister <strong>of</strong><strong>Textiles</strong>, with the <strong>Textiles</strong>Commissioner as the Member-Secretary. It has representatives <strong>of</strong>the Central and State Governments,and powerlooms federations/associations as its members. Thefunctions <strong>of</strong> the Board includeadvising the Government on mattersconcerning growth and development<strong>of</strong> the decentralized powerloomssector.(iii) All India Handlooms BoardThe Board is an advisory body underthe chairmanship <strong>of</strong> Minister <strong>of</strong><strong>Textiles</strong>, with the developmentCommissioner (Handlooms) as theMember-Secretary. The main functionis to advise the Government onvarious aspects <strong>of</strong> development <strong>of</strong>the handlooms sector.(iv) The Cotton Advisory Board(v)The Cotton Advisory Board is headedby the <strong>Textiles</strong> Commissioner and isa representative body <strong>of</strong> variousinterest groups like GovernmentAgencies, Cotton Growers, <strong>Textiles</strong>Industry and Trade. It advises theGovernment generally on matterspertaining to production, consumptionand marketing <strong>of</strong> cotton and alsoprovides a forum for liaison. TheBoard was reconstituted on 5th May,2010 for a period <strong>of</strong> two years. Atpresent the Board has sixty ninemembers, including <strong>of</strong>ficial and non<strong>of</strong>ficialmembers.The Cotton Yarn Advisory BoardThe Cotton Yarn Advisory Board,headed by the <strong>Textiles</strong> Commissionerwas constituted on 13th September,2010 up to 31st March, 2012 untilfurther orders or whichever is earlier.It is a representative body <strong>of</strong> variousinterest groups like governmentagencies, textiles industry and trade.Its main functions are to monitordomestic and international prices <strong>of</strong>cotton yarn, suggest measures forincreasing the availability <strong>of</strong> cottonyarn, monitor import and export <strong>of</strong>yarn and prepare the Cotton YarnBalance Sheet.(vi) Jute Advisory BoardThe Jute Advisory Board headed bythe Jute Commissioner advises theGovernment on matters pertaining tojute falling within the purview <strong>of</strong> Jute23

ministry <strong>of</strong> textilesand Jute <strong>Textiles</strong> Control Order 2002,including production estimates <strong>of</strong> juteand mesta. New Board has beenreconstituted on 23.04.2010.(vii) Coordination Council <strong>of</strong> TRAsThe Coordination Council for the<strong>Textiles</strong> Research Associations hasbeen constituted under thechairmanship <strong>of</strong> Secretary (<strong>Textiles</strong>)to coordinate the activities <strong>of</strong> all the<strong>Textiles</strong> Research Associations(TRAs), with a view to promotelinkages for the development <strong>of</strong> the<strong>Textiles</strong> industry and for achievement<strong>of</strong> national priorities. The functions <strong>of</strong>the Councils are to assess theongoing programmes <strong>of</strong> researchassociations, identify programmesand priorities keeping in view theoverall needs <strong>of</strong> the industry,including the decentralized sector. Itensures appropriate coordinationamongst different researchassociations, conduct periodicalevaluation <strong>of</strong> the work carried out incooperative research, and considerssystemizing research programmesand funding arrangements so thatfunding is in conformity with planpriorities, and all other mattersconnected with the effectivefunctioning <strong>of</strong> these ResearchAssociations.4. REGISTERED SOCIETIES(i)Central Wool Development Board(CWDB), JodhpurThe Central Wool Development Board(CWDB), Jodhpur was constituted bythe Government <strong>of</strong> India, <strong>Ministry</strong> <strong>of</strong><strong>Textiles</strong> in 1987 under the RajasthanSocieties Registration Act, 1958 topromote the growth and overalldevelopment <strong>of</strong> wool and the woolentextiles industry in the Country. TheBoard administers various projects(ii)and programmes through the StateGovernments and Non GovernmentOrganisations (NGOs). The Boardwas reconstituted on November 16,2010 for a period <strong>of</strong> two years.Sardar Vallabhbhai Patel Institute<strong>of</strong> <strong>Textiles</strong> Management (SVPITM),CoimbatoreSVPITM was set-up on December24, 2002, as a premier National levelInstitute for <strong>Textiles</strong> Management atCoimbatore, Tamil Nadu, to preparethe Indian <strong>Textiles</strong> Industry to facethe challenges <strong>of</strong> post-MFA era andestablish it as a leader in the globaltextiles trade. The Board <strong>of</strong> theinstitute was reconstituted on April12,2010, for a period <strong>of</strong> three years.5. STATUTORY BODIES(i)National Jute BoardThe National Jute Board is a newbody under <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong>, whichis the apex organisation forcoordinating and synergising thefunctions <strong>of</strong> all the Organisations anda centre point for all jute relatedactivities. The National Jute Board isalso responsible for implementation<strong>of</strong> the Jute Technology Mission in acentralized and coordinated mannerand helps in speedily resolving theills <strong>of</strong> Jute Industry in the matters <strong>of</strong>diversification and marketing <strong>of</strong> JuteProducts as well as modernisation <strong>of</strong>Jute Mills. National Jute Board havea membership <strong>of</strong> 34 persons, <strong>of</strong>which 15 will be Governmentrepresentatives from CentralGovernment and State Governmentshaving stake in production andpromotion <strong>of</strong> Jute Products and 19Members from private jute relatedsector i.e. jute farmers, growers,research association, small andmedium enterprises as well as there24

annual report 2010-11(ii)Members <strong>of</strong> Parliament. TheHeadquarters <strong>of</strong> the National JuteBoard is in Kolkatta, with regionalrepresentations in Jute growing areasand in other areas for marketing <strong>of</strong>the Jute Products.The Central Silk Board (CSB),BangaloreThe Central Silk Board is a statutorybody, and it was constituted by anAct <strong>of</strong> Parliament (LXI <strong>of</strong> 1948), withthe objective <strong>of</strong> promoting the growthand development <strong>of</strong> Sericulture inthe country. These programmes areprimarily formulated and implementedby the State Sericulture/<strong>Textiles</strong>Departments. However, the CentralSilk Board supplements the efforts <strong>of</strong>the States by providing necessarysupport by way <strong>of</strong>research anddevelopment, and extension andtraining through its countrywidenetwork <strong>of</strong> R&D and extensioncentres. Besides, the Central SilkBoard organises the development,production and supply <strong>of</strong> qualitysilkworm seedsetc., and developmentand propagation <strong>of</strong> feed plants.Central Silk Board also implementsvarious Sericulture projects directly,as well as, jointly with the Statesericulture Departments and otherexternal agencies.(iv) <strong>Textiles</strong> Committee, MumbaiThe <strong>Textiles</strong> Committee wasestablished on July, 1964 under the<strong>Textiles</strong> Committee Act, 1963, withthe objective <strong>of</strong> ensuring the quality<strong>of</strong> textiles from both the internal andexport markets. Its functions includethe promotion <strong>of</strong> textiles, textilesexports, research in technical andeconomic fields, establishingstandards for textiles and textilesmachinery, setting up <strong>of</strong> laboratories,and data collection located throughout(v)the country. The <strong>Textiles</strong> Committee,in addition to it's headquarters atMumbai, has thirty Offices to assistthe industry and trade in testing theirproducts. The Committee has thefollowing functional divisions at itsHeadquarters in Mumbai : (1) <strong>Textiles</strong>Inspectorate Wing (2) <strong>Textiles</strong>Laboratory Wing (3) Market ResearchWing (4) ISO Wing (5) Vigilance Cell(6) Accounts Wing, and (7)Administration and CoordinationWing. The Committee has beenreconstituted on October 14, 2009,for a period <strong>of</strong> two years. It consists<strong>of</strong> twenty five members, including<strong>of</strong>ficial and non-<strong>of</strong>ficial members.Commissioner <strong>of</strong> Payments (COP),New DelhiThe Office <strong>of</strong> Commissioner <strong>of</strong>Payments with its headquarters atDelhi, is a statutory authority, set upunder Section 17(1) <strong>of</strong> the Sick<strong>Textiles</strong>Undertakings(Nationalisation) Act, 1974, Section15(1) <strong>of</strong> the Swadeshi Cotton MillsCompany Ltd. (Acquisition andTransfer <strong>of</strong> Undertakings) Act, 1986,and also under Section 17(1) <strong>of</strong> the<strong>Textiles</strong>Undertakings(Nationalisation) Act, 1995. TheCommissioner <strong>of</strong> Payments disbursesthe amount placed at his disposal tothe owners <strong>of</strong> each textilesundertaking nationalized by theaforesaid three Acts.(vi) The National Institute <strong>of</strong> FashionTechnology (NIFT), New DelhiThe National Institute <strong>of</strong> FashionTechnology was set up in 1986 asan autonomous Society incollaboration with the Fashion Institute<strong>of</strong> Technology (FIT), New York, toprepare and train pr<strong>of</strong>essionals tomeet the requirements <strong>of</strong> the textilesindustry. The Government brought25

ministry <strong>of</strong> textilesinto force the National Institute <strong>of</strong>Fashion Technology Act, 2006 onJuly 14, 2006. This Act providesstatutory status to the Institute, andformally recognizes its leadership inthe fashion technology sector. TheAct empowers NIFT to award degreesto its students from 2007 onwards.The President <strong>of</strong> India is the Visitor<strong>of</strong> the Institute. The Institute haspioneered the evolution <strong>of</strong> the fashionbusiness education across thecountry through centres at New Delhi,Bangalore, Chennai, Gandhinagar,Hyderabad, Kolkata, Mumbai,Kannur, Patna, Shillong, Kangra,Bhopal, Rae Bareli, Jodhpur andBhuvneshwar.6. THE RIGHT TO INFORMATIONACT, 2005To promote openness, transparency andaccountability in administration and providethe right to every citizen to secure accessto information under the control <strong>of</strong> PublicAuthorities, the Right to Information Acthas come into effect for implementationw.e.f. October 12, 2005. The Act marksthe beginning <strong>of</strong> a new era in the approach<strong>of</strong> the Government where openness shallnow be the rule and secrecy an exception.Every Citizen can obtain the informationthey desire by submission <strong>of</strong> an applicationand by paying a nominal charge as anapplication fee, to the Central PublicInformation Officer designated by thepublic authority for the purpose under theAct. This <strong>Ministry</strong> has designated <strong>of</strong>ficersas Central Public Information Officers(CPIOs) and Appellate Authorities. The<strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong>, as well as, its Attached& Subordinate Offices, Autonomous &Statutory Bodies and Public SectorUndertakings have completed the actionfor setting up <strong>of</strong> the necessaryinfrastructure for implementation <strong>of</strong> theAct. <strong>Ministry</strong> monitors the implementation<strong>of</strong> the Act by the organizations under the<strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong>.7. PUBLIC GRIEVANCE REDRESSALMACHINERY IN THE MINISTRYThe Department <strong>of</strong> Administrative Reformsand Public Grievances issues instructionsand guidelines to establish, activate, andstrengthen the Centralized PublicGrievances Redressal and monitoringsystem (CPGRM) in the Ministries,Departments, and other Organisations <strong>of</strong>the Government <strong>of</strong> India. In pursuance <strong>of</strong>these instructions/guidelines, onlineCPGRAMS has been introduced in the<strong>Ministry</strong>. Similar arrangements are alsobeing made in each <strong>of</strong> the attached/subordinate <strong>of</strong>fices <strong>of</strong> the <strong>Ministry</strong> <strong>of</strong><strong>Textiles</strong>. A Grievance Committee underthe Chairmanship <strong>of</strong> a Joint Secretary hasbeen formed to monitor the functioning <strong>of</strong>CPGRM in the <strong>Ministry</strong>, as well as inattached and subordinate organizations. Ifneed be, the files relating to pendinggrievances are called or and cases aresettled by the Committee in its meetings.The <strong>Ministry</strong> have taken, the followingsteps to strengthen the CPGRMS:●●●●●Time Norms for the disposal <strong>of</strong>grievance cases have been fixed,and the same have been circulatedand displayed at prominent places <strong>of</strong>the building:✓ Acknowledgement <strong>of</strong> thecomplainant within seven days;✓Final disposal within two months.Publicity about the CPGRM in themedia.The Citizens' Charter has beenformulated and hosted on theWebsite.Details about the CPGRM have alsobeen placed on the Website <strong>of</strong> the<strong>Ministry</strong> (texmin.nic.in).An Information & Facilitation Counterhas been established at Gate No.14Udyog Bhawan, New Delhi, to make26

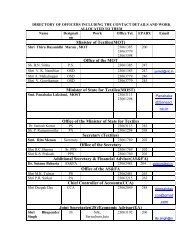

annual report 2010-11●information readily available tocustomers/consumers.A complaint box has been kept at theInformation & Facilitation Counter.The list <strong>of</strong> Officers handling Public/StaffGrievances in the <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong> andits attached/Subordinate Offices is givenat table 2.1 and is also available at thewebsite <strong>of</strong> the <strong>Ministry</strong>.The list <strong>of</strong> organisations under the <strong>Ministry</strong><strong>of</strong> <strong>Textiles</strong> is at table 2.2.Table 2.1List <strong>of</strong> Officers handling public/staff grievance in the <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong> and itsAttached/Subordinate OfficerS.No. OfficesPublic/Staff Grievances Officer1. <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong> Shri Sujit GulatiJoint Secretary/Director (PG)Room No. 232, Udyog BhawanNew Delhi-110011Phone: 230631922. Office <strong>of</strong> the Development Smt. Alka AroraCommissioner (Handicraft) Addl. Development Commissioner (Handicrafts)West Block-7, R.K. Puram, New DelhiPhone: 011-26191569Email: dchejs@nic.in3. Office <strong>of</strong> the Development Shri Sohan Kumar JhaCommissioner (Handloom) Addl. Development Commissioner (Handloom)Office <strong>of</strong> DC (Handloom)Udyog Bhawan, New Delhi-110011Phone: 011-230622384. Office <strong>of</strong> the Textile Shri S. BalarajuCommissionerJoint Textile CommissionerNew CGO Building, 48 Marine Line, Mumbai-400020Phone: 022-220010505. Office <strong>of</strong> the Jute Shri Binod KispottaCommissionerJute CommissionerC.G.O. Complex, 3rd MSO Building4th Floor, DF Block, Salt Lake CityKolkata-700064Phone: 033-23376973/7527

ministry <strong>of</strong> textilesTable 2.2LIST OF ORGANISATIONS UNDER THE MINISTRY OF TEXTILES(EXCEPT ATTACHED/SUBORDINATE OFFICES)Public sector <strong>Textiles</strong> Export Advisory Registered StatutoryUndertakings Research Promotion Body Society BodiesAssociations Councils1. Birds Jute 1. Ahmedabad 1. Apparel Export All India 1. Central Wool 1. Central SilkExport Ltd. <strong>Textiles</strong> Industry's Promotion Council Handloom Development Board(BJEL), Research (AEPC), New Delhi Board Board (CWDC), (CSB),Kolkata Association (ATIRA), Jodhpur BangaloreAhmedabad2. British India 2. Bombay <strong>Textiles</strong> 2. Carpet Export All India 2. Sardar Vallabhai 2.CommissionserCorporation Research Promotion Council Handicrafts Patel Institute <strong>of</strong> <strong>of</strong> Payments(BIC) along with Association (BTRA), (CEPC), Board <strong>Textiles</strong> (COP),its subsidiaries Mumbai New Delhi Management New Delhi(SVPITM),Coimbatore3. The Central 3. Indian Jute 3. Cotton <strong>Textiles</strong> Export All India 3. NationalCottage Industries Industries Research Promotion Council Powerloom Jute Board,Corporation <strong>of</strong> Association (TEXPROCIL), Board KolkataIndia Ltd. (CCIC) (IJIRA), Kolkata MumbaiNew Delhi4. The Cotton 4. Man-made <strong>Textiles</strong> 4. Export Promotion Coordination 4. <strong>Textiles</strong>Corporation <strong>of</strong> Research Association Council for Handicrafts Council for Committee,India Ltd. (CCI), (MANTRA), (EPCH), <strong>Textiles</strong> MumbaiMumbai Surat New Delhi ResearchAssociations5. The Handicrafts 5. Northern India 5. Handlooms Export Cotton Advisory 5. Nationaland Handlooms <strong>Textiles</strong> Research Promotion Council Board Institute <strong>of</strong>Exports Association (HEPC), Chennai FashionCorporation <strong>of</strong> (NITRA), TechnologyIndia Ltd. Gaziabad (NIFT),(HHEC),New DelhiNew Delhi6. The Jute 6. South India <strong>Textiles</strong> 6. Indian Silk Export Jute AdvisoryCorporation <strong>of</strong> Research Association Promotion Council BoardIndia Ltd. (JCI), (SITRA), Coimbatore (ISEPC), MumbaiKolkata7. National 7. Synthetic and Art Silk 7. Powerloom Cotton YarnHandlooms Mills Research Development & Advisory BoardDevelopment Association Export PromotionCorporation Ltd. (SASMIRA), Council (PEDEXCIL),(NHDC), Mumbai MumbaiLucknow8. National Jute 8. Wool Research 8. Synthetic and RayonManufactures Association <strong>Textiles</strong> ExportCorporation (WRA), Thane Promotion Council(NJMC),(SRTEDC),KolkataMumbai9. National 9. Wool and Woolen<strong>Textiles</strong>Export PromotionCorporationCouncil (WWEPC),Ltd. (NTC),New DelhiNew Delhi10. Wool IndustryExport PromotionCouncil (WOOLTEXPRO), Mumbai28

annual report 2010-11CHAPTER IIITHE ORGANISED TEXTILESMILL INDUSTRY29

30ministry <strong>of</strong> textiles

annual report 2010-11CHAPTER IIITHE ORGANISED TEXTILES MILL INDUSTRYThe Cotton / Man-made fibre textileindustry is the largest organizedindustry in the country in terms <strong>of</strong>employment (nearly 1 million workers)and number <strong>of</strong> units. Besides, there area large number <strong>of</strong> subsidiary industriesdependent on this sector, such as thosemanufacturing machinery, accessories,stores, ancillaries, dyes & chemicals. Ason 30.9.2010, there were 1896 cotton/man-made fibre textile mills (non-SSI) inthe country with an installed capacity <strong>of</strong>38.53 million spindles 5,18,000 rotors and57,000 looms.Textile production covering man-madefibre, filament yarn and spun yarn isshowing increasing trend. Man-made fibreproduction recorded a marginal fall andfilament yarn production recorded a slightincrease <strong>of</strong> about 1.89% during 2010-11(April - October 2010). The production <strong>of</strong>spun yarn during April-Oct (2010-11) isshowing an increasing trend by 9.17%.The production <strong>of</strong> cotton yarn during2010-11 April-Oct (2010-11) recorded anincrease <strong>of</strong> 11% (Provisional). Blendedand 100% Non-cotton yarn productionrecorded an increase <strong>of</strong> about 4% during2010-11.Cloth production by mill sector showedmarginal increase <strong>of</strong> 3% during April-Oct.(2010-11) (provisional). During the sameperiod cloth production by power loomand hosiery sector showed an increase <strong>of</strong>1.7% and 5.30% respectively. Howeverthe cloth production in handloom sectorshowed a decrease <strong>of</strong> 4.7%.CAPACITYThere were 1896 cotton/man-made fibretextile mills (non-SSI) in the country withan installed capacity <strong>of</strong> 38.53 millionspindles 5,18,000 rotors and 57,000 loomsas on 30.9.2010.CAPACITY UTILISATION IN THE MILLSECTORThe capacity utilization in the spinningsector <strong>of</strong> the organized textile mill industryranged between 80 to 90% while thecapacity utilization in the weaving sector<strong>of</strong> the organized textile mill industry rangedbetween 41 to 62%.PRODUCTION OF SPUN YARNIt would be relevant to mention that thecontribution from the SSI sector has beenabout 10% in the total spun yarn production.A statement showing the production <strong>of</strong>spun yarn (including SSI units) during thelast few years is given at table 3.1.SICKNESS/CLOSURE OF TEXTILEMILLSThe incidence <strong>of</strong> sickness and closure inthe organized textiles industry is a matter<strong>of</strong> concern. <strong>Textiles</strong> being the oldest andthe largest industry <strong>of</strong> the country, it is butnatural that at any given point <strong>of</strong> timesome textiles units could be lying sick /closed. One main reason <strong>of</strong> sickness isstructural transformation resulting in thecomposite units in the organized sectorlosing ground to power looms in thedecentralised sector, on account <strong>of</strong> thelatter's greater cost effectiveness. Othercauses <strong>of</strong> sickness/ closure <strong>of</strong> the industryinclude low productivity due to lack <strong>of</strong>modernisation, stagnation in demand andinability <strong>of</strong> some units to expand in theexport market, increase in the cost <strong>of</strong>inputs, difficulties in getting timely and31