download pdf version - Contractors World

download pdf version - Contractors World

download pdf version - Contractors World

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

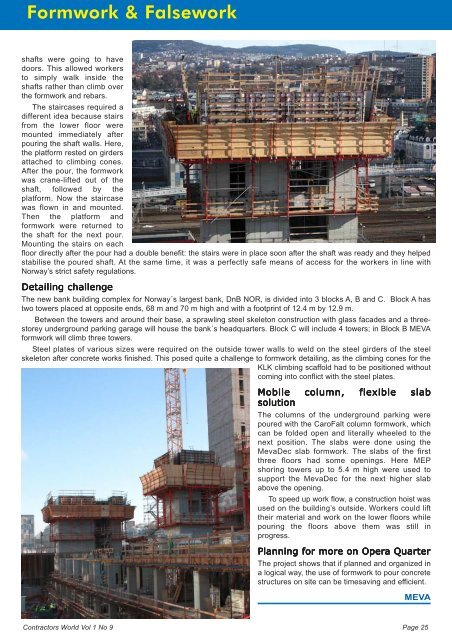

Formwork & Falseworkshafts were going to havedoors. This allowed workersto simply walk inside theshafts rather than climb overthe formwork and rebars.The staircases required adifferent idea because stairsfrom the lower floor weremounted immediately afterpouring the shaft walls. Here,the platform rested on girdersattached to climbing cones.After the pour, the formworkwas crane-lifted out of theshaft, followed by theplatform. Now the staircasewas flown in and mounted.Then the platform andformwork were returned tothe shaft for the next pour.Mounting the stairs on eachfloor directly after the pour had a double benefit: the stairs were in place soon after the shaft was ready and they helpedstabilise the poured shaft. At the same time, it was a perfectly safe means of access for the workers in line withNorway’s strict safety regulations.Detailing challengeThe new bank building complex for Norway´s largest bank, DnB NOR, is divided into 3 blocks A, B and C. Block A hastwo towers placed at opposite ends, 68 m and 70 m high and with a footprint of 12.4 m by 12.9 m.Between the towers and around their base, a sprawling steel skeleton construction with glass facades and a threestoreyunderground parking garage will house the bank´s headquarters. Block C will include 4 towers; in Block B MEVAformwork will climb three towers.Steel plates of various sizes were required on the outside tower walls to weld on the steel girders of the steelskeleton after concrete works finished. This posed quite a challenge to formwork detailing, as the climbing cones for theKLK climbing scaffold had to be positioned withoutcoming into conflict with the steel plates.Mobile column, flexible slabsolutionThe columns of the underground parking werepoured with the CaroFalt column formwork, whichcan be folded open and literally wheeled to thenext position. The slabs were done using theMevaDec slab formwork. The slabs of the firstthree floors had some openings. Here MEPshoring towers up to 5.4 m high were used tosupport the MevaDec for the next higher slababove the opening.To speed up work flow, a construction hoist wasused on the building’s outside. Workers could lifttheir material and work on the lower floors whilepouring the floors above them was still inprogress.Planning for more on Opera QuarterThe project shows that if planned and organized ina logical way, the use of formwork to pour concretestructures on site can be timesaving and efficient.MEVA<strong>Contractors</strong> <strong>World</strong> Vol 1 No 9Page 25