Product Data Sheet FILARC 56S - Eurocardis

Product Data Sheet FILARC 56S - Eurocardis

Product Data Sheet FILARC 56S - Eurocardis

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

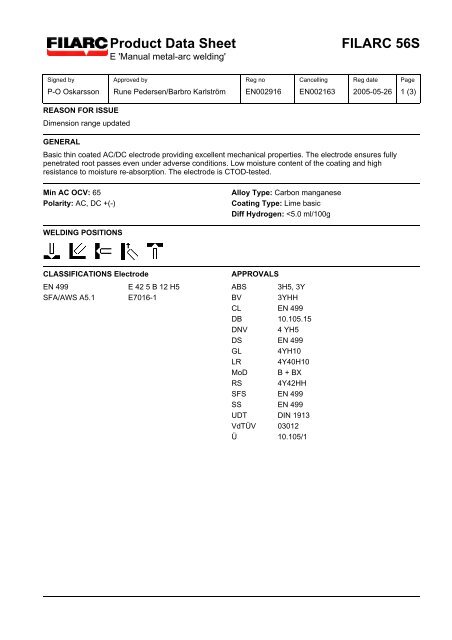

<strong>Product</strong> <strong>Data</strong> <strong>Sheet</strong>E 'Manual metal-arc welding'<strong>FILARC</strong> <strong>56S</strong>Signed by Approved by Reg no Cancelling Reg date PageP-O Oskarsson Rune Pedersen/Barbro Karlström EN002916 EN002163 2005-05-26 1 (3)REASON FOR ISSUEDimension range updatedGENERALBasic thin coated AC/DC electrode providing excellent mechanical properties. The electrode ensures fullypenetrated root passes even under adverse conditions. Low moisture content of the coating and highresistance to moisture re-absorption. The electrode is CTOD-tested.Min AC OCV: 65Polarity: AC, DC +(-)Alloy Type: Carbon manganeseCoating Type: Lime basicDiff Hydrogen:

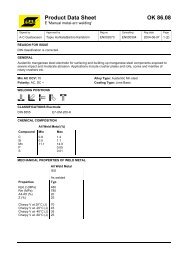

<strong>Product</strong> <strong>Data</strong> <strong>Sheet</strong>E 'Manual metal-arc welding'<strong>FILARC</strong> <strong>56S</strong>Signed by Approved by Reg no Cancelling Reg date PageP-O Oskarsson Rune Pedersen/Barbro Karlström EN002916 EN002163 2005-05-26 2 (3)CHEMICAL COMPOSITIONCSiMnPSCrNiMoVNbCuAlSnTiPbAsAll Weld Metal (%)MinMax0.04 0.090.20 0.601.10 1.500.0250.0150.050.070.020.010.010.050.010.010.040.010.05MECHANICAL PROPERTIES OF WELD METALPropertiesReL (MPa)Rm (MPa)A4-A5 (%)Charpy V at -20°C (J)Charpy V at -40°C (J)Charpy V at -50°C (J)All Weld MetalISOAs weldedMinMax420510 640221508047ISOStress relievedMin320490221508047

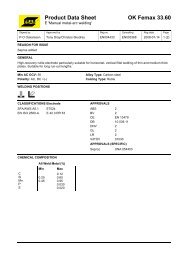

<strong>Product</strong> <strong>Data</strong> <strong>Sheet</strong>E 'Manual metal-arc welding'<strong>FILARC</strong> <strong>56S</strong>Signed by Approved by Reg no Cancelling Reg date PageP-O Oskarsson Rune Pedersen/Barbro Karlström EN002916 EN002163 2005-05-26 3 (3)ECONOMICS & CURRENT DATA--Dimension (mm) Current (A) W η N B H T UØ x Length Min Max2.0 x 300 35 60 1.3 114 0.58 135 0.46 57 222.5 x 350 55 85 1.9 100 0.58 90.0 0.80 50 223.2 x 350 80 140 3.1 100 0.61 52.0 1.30 53 223.2 x 450 80 130 4.0 100 0.61 41.0 1.20 73 224.0 x 350 110 180 4.6 100 0.64 34.0 1.70 62 224.0 x 450 110 170 5.9 100 0.65 26.0 1.70 83 225.0 x 450 180 230 8.9 100 0.66 17.0 2.40 90 22WηNBHTU= Weight (kg / 100 electrodes)= Efficiency (g weld metal x 100 / g core wire)= Effective value (kg weld metal / kg electrodes)= Changes (number of electrodes / kg weld metal)= Deposit rate at 90% of max current (kg weld metal / hour arc time)= Fusion time at 90% of max current (s / electrode)= Arc voltage (V)OTHER DATA1) Diams 2.0-2.5 mm: min 72VDiffusible hydrogen in the weld metal according to the mercury method. Rebaking instructions:For max 5 ml H2/100 g weld metal: 1 h/400°C + 20°CFor max 10 ml H2/100 g weld metal: 1 h/350°C + 20°CCore wire: P