Product Data Sheet OK 86.08 - Eurocardis

Product Data Sheet OK 86.08 - Eurocardis

Product Data Sheet OK 86.08 - Eurocardis

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

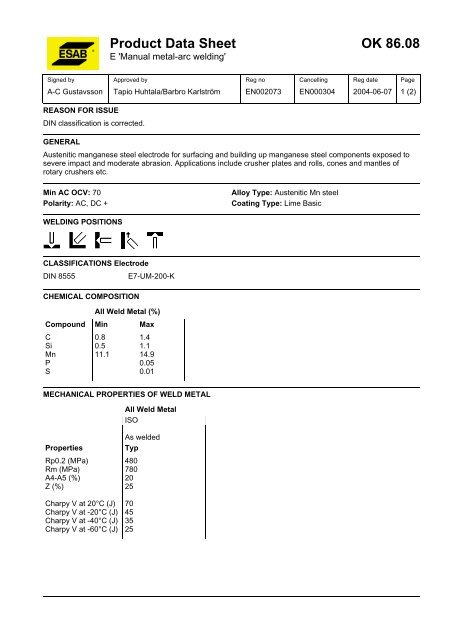

<strong>Product</strong> <strong>Data</strong> <strong>Sheet</strong> <strong>OK</strong> <strong>86.08</strong>E 'Manual metal-arc welding'Signed by Approved by Reg no Cancelling Reg date PageA-C Gustavsson Tapio Huhtala/Barbro Karlström EN002073 EN000304 2004-06-07 1 (2)REASON FOR ISSUEDIN classification is corrected.GENERALAustenitic manganese steel electrode for surfacing and building up manganese steel components exposed tosevere impact and moderate abrasion. Applications include crusher plates and rolls, cones and mantles ofrotary crushers etc.Min AC OCV: 70Polarity: AC, DC +Alloy Type: Austenitic Mn steelCoating Type: Lime BasicWELDING POSITIONSCLASSIFICATIONS ElectrodeDIN 8555E7-UM-200-KCHEMICAL COMPOSITIONAll Weld Metal (%)CompoundMinMaxCSiMnPS0.8 1.40.5 1.111.1 14.90.050.01MECHANICAL PROPERTIES OF WELD METALAll Weld MetalISOPropertiesRp0.2 (MPa)Rm (MPa)A4-A5 (%)Z (%)Charpy V at 20°C (J)Charpy V at -20°C (J)Charpy V at -40°C (J)Charpy V at -60°C (J)As weldedTyp480780202570453525

<strong>Product</strong> <strong>Data</strong> <strong>Sheet</strong> <strong>OK</strong> <strong>86.08</strong>E 'Manual metal-arc welding'Signed by Approved by Reg no Cancelling Reg date PageA-C Gustavsson Tapio Huhtala/Barbro Karlström EN002073 EN000304 2004-06-07 2 (2)ECONOMICS & CURRENT DATA--Dimension (mm) Current (A) W η N B H T UØ x Length Min Max3.2 x 450 95 135 4.7 105 0.60 35.5 1.10 95 234.0 x 450 130 180 7.1 105 0.60 24.0 1.40 109 235.0 x 450 170 230 11.0 105 0.60 15.0 1.80 132 25WηNBHTU= Weight (kg / 100 electrodes)= Efficiency (g weld metal x 100 / g core wire)= Effective value (kg weld metal / kg electrodes)= Changes (number of electrodes / kg weld metal)= Deposit rate at 90% of max current (kg weld metal / hour arc time)= Fusion time at 90% of max current (s / electrode)= Arc voltage (V)OTHER DATARecommendations for welding:Austenitic manganese steels, in as cast condition or as weld metal, are sensitive to hot shortness and maycrack if subjected to excessive heat.Under normal conditions the base material should not be preheated and interpass temperatures above 200 °Cshould be avoided.Welding outdoor in very cold weather, the base material should be warmed up to 50-100 °C.Weld metal hardness, (all weld metal):As welded.....180-200 HB. (no preheat, interpass temperature 100-150 °C.)Workhardened..44-48 HRC. (About 25 % degree of reduction.)Machinability: Grinding is normally applied. Overheating must be avoided.Redrying the electrodes: 200 °C, 2 h.