Design principles of reconfigurable machines

Design principles of reconfigurable machines

Design principles of reconfigurable machines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

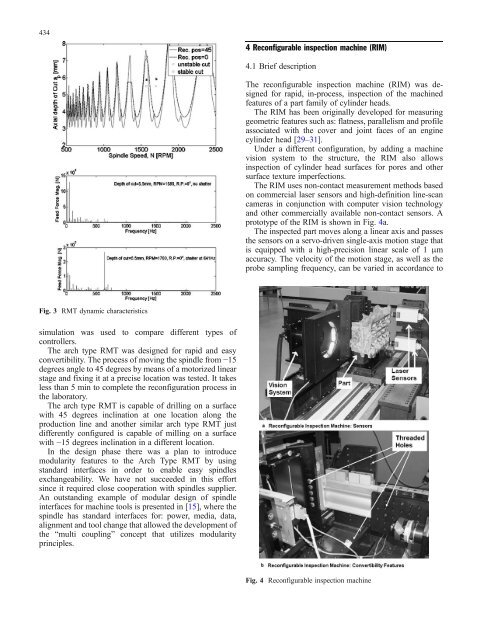

4344 Reconfigurable inspection machine (RIM)4.1 Brief descriptionThe <strong>reconfigurable</strong> inspection machine (RIM) was designedfor rapid, in-process, inspection <strong>of</strong> the machinedfeatures <strong>of</strong> a part family <strong>of</strong> cylinder heads.The RIM has been originally developed for measuringgeometric features such as: flatness, parallelism and pr<strong>of</strong>ileassociated with the cover and joint faces <strong>of</strong> an enginecylinder head [29–31].Under a different configuration, by adding a machinevision system to the structure, the RIM also allowsinspection <strong>of</strong> cylinder head surfaces for pores and othersurface texture imperfections.The RIM uses non-contact measurement methods basedon commercial laser sensors and high-definition line-scancameras in conjunction with computer vision technologyand other commercially available non-contact sensors. Aprototype <strong>of</strong> the RIM is shown in Fig. 4a.The inspected part moves along a linear axis and passesthe sensors on a servo-driven single-axis motion stage thatis equipped with a high-precision linear scale <strong>of</strong> 1 μmaccuracy. The velocity <strong>of</strong> the motion stage, as well as theprobe sampling frequency, can be varied in accordance toFig. 3 RMT dynamic characteristicssimulation was used to compare different types <strong>of</strong>controllers.The arch type RMT was designed for rapid and easyconvertibility. The process <strong>of</strong> moving the spindle from −15degrees angle to 45 degrees by means <strong>of</strong> a motorized linearstage and fixing it at a precise location was tested. It takesless than 5 min to complete the reconfiguration process inthe laboratory.The arch type RMT is capable <strong>of</strong> drilling on a surfacewith 45 degrees inclination at one location along theproduction line and another similar arch type RMT justdifferently configured is capable <strong>of</strong> milling on a surfacewith −15 degrees inclination in a different location.In the design phase there was a plan to introducemodularity features to the Arch Type RMT by usingstandard interfaces in order to enable easy spindlesexchangeability. We have not succeeded in this effortsince it required close cooperation with spindles supplier.An outstanding example <strong>of</strong> modular design <strong>of</strong> spindleinterfaces for machine tools is presented in [15], where thespindle has standard interfaces for: power, media, data,alignment and tool change that allowed the development <strong>of</strong>the “multi coupling” concept that utilizes modularity<strong>principles</strong>.Fig. 4 Reconfigurable inspection machine