- Page 1 and 2:

Electronics Product Listeffective a

- Page 3 and 4:

ContentTweezers, Cutters, Pliers, E

- Page 5 and 6:

Content EremTweezers 6 - 17Pointed

- Page 7 and 8:

Tweezers for highprecisionTweezers

- Page 9 and 10:

TweezersPointed Tips StraightPointe

- Page 11 and 12:

TweezersPointed Tips Straight Relie

- Page 13 and 14:

TweezersFlat Round Tips Straight /P

- Page 15 and 16:

TweezersSMD TweezersSMD TweezersMod

- Page 17 and 18:

TweezersCutting Tweezers / Strippin

- Page 19 and 20:

Erem will impress youInduction hard

- Page 21 and 22:

Erem SeriesErem offers the right he

- Page 23 and 24:

Tip Cutter Side Cutter Side CutterA

- Page 25 and 26:

CuttersSide- and Tip CuttersTip Cut

- Page 27 and 28:

CuttersSide- and Tip CuttersTip Cut

- Page 29 and 30:

CuttersSide- and Tip CuttersSide Cu

- Page 31 and 32:

CuttersSide- and Tip CuttersTip Cut

- Page 33 and 34:

CuttersSide- and Tip CuttersSide Cu

- Page 35 and 36:

CuttersSide- and Tip CuttersSide Cu

- Page 37 and 38:

CuttersPneumatic Side + Tip Cutters

- Page 39 and 40:

CuttersDistance CuttersDistance Cut

- Page 41 and 42:

PliersPliers Series 2400 MagicSense

- Page 43 and 44:

EROPCutters and PliersPliersModel/O

- Page 45 and 46:

Pre-Forming ToolsFor Passive Compon

- Page 47 and 48:

IC + SMD ToolsInserting and Extract

- Page 49 and 50:

Vacuum ManipulatorHandleModel/Order

- Page 51 and 52:

Tool KitsErem Toolset UniversalMode

- Page 53 and 54:

Dispensers, Syringes Adapters, Need

- Page 55 and 56:

Dispensers & SystemsKDS824AOrder No

- Page 57 and 58:

NeedlesStainless Steel Plastic Hub

- Page 59 and 60:

Soldering, Desoldering, Hot Air

- Page 61 and 62:

SurveyFunction of Soldering, Hot Ai

- Page 63 and 64:

WD 2000M WD 3M WSD 81 WSD 151 WAD 1

- Page 65 and 66:

Survey Reflow NozzlesDX CSF DS F R

- Page 67 and 68:

WPH 80 KHE KHE/P KHP WDH 10 WDH 10T

- Page 69 and 70:

New Soldering stationsRechargeable

- Page 71 and 72:

New Electric screwdriverControl uni

- Page 73 and 74:

The New Highlight:WD 2000M Power Un

- Page 75 and 76:

Soldering StationsElectronically Co

- Page 77 and 78:

Soldering StationsElectronically Co

- Page 79 and 80:

Soldering StationsElectronically Co

- Page 81 and 82:

Soldering StationsElectronically Co

- Page 83 and 84:

Soldering StationsElectronically Co

- Page 85 and 86:

Soldering StationsSoldering Station

- Page 87 and 88:

High precision and avery fast heat

- Page 89 and 90:

Soldering Irons and TipsElectronica

- Page 91 and 92:

Soldering Irons and TipsElectronica

- Page 93 and 94:

Soldering Irons and TipsElectronica

- Page 95 and 96: Soldering Irons and TipsElectronica

- Page 97 and 98: Soldering Irons and TipsElectronica

- Page 99 and 100: Soldering Irons and TipsElectronica

- Page 101 and 102: Soldering Irons and TipsElectronica

- Page 103 and 104: Soldering Irons and TipsElectronica

- Page 105 and 106: Soldering Irons and TipsMagnastat C

- Page 107 and 108: Soldering Irons and TipsMagnastat C

- Page 109 and 110: Soldering Irons and TipsMagnastat C

- Page 111 and 112: Soldering Irons and TipsUnregulated

- Page 113 and 114: Soldering Irons and TipsButane Gas

- Page 115 and 116: Soldering Irons and TipsButane Gas

- Page 117 and 118: WR 3M - Desolderingand Rework on hi

- Page 119 and 120: Desoldering StationsElectronically

- Page 121 and 122: Desoldering StationsElectronically

- Page 123 and 124: Desoldering StationsElectronically

- Page 125 and 126: DSX 80 - Desolderingiron with excen

- Page 127 and 128: Desoldering Irons, Nozzles & HeadsE

- Page 129 and 130: Desoldering Irons, Nozzles & HeadsC

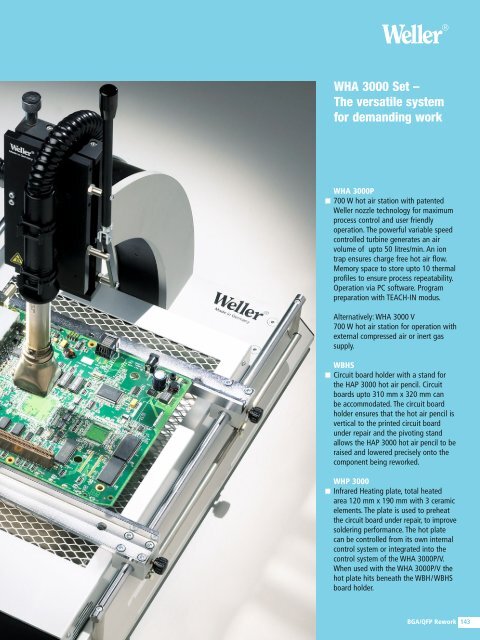

- Page 131 and 132: Patented WellerNozzle Technology700

- Page 133 and 134: Hot Air Stations200 W Hot Air Stati

- Page 135 and 136: Hot Air Stations700 W Hot Air Stati

- Page 137 and 138: Hot Air Stations700 W Hot Air Stati

- Page 139 and 140: WRK SetThe newly developed, innovat

- Page 141 and 142: Hot Air Irons and NozzlesHot Air No

- Page 143 and 144: Hot Air Irons and NozzlesHot Air No

- Page 145: Hot Air Irons and NozzlesHot Air No

- Page 149 and 150: BGA/QFP ReworkOrder No. Model Descr

- Page 151 and 152: BGA/QFP ReworkAccessory for WQB 400

- Page 153 and 154: BGA/QFP ReworkPositioning Templates

- Page 155 and 156: 100 % Air cleaningZero-SmogThe Well

- Page 157 and 158: Fume ExtractionTip Extraction Units

- Page 159 and 160: Fume ExtractionTip Extraction Units

- Page 161 and 162: Fume ExtractionTip Extraction Units

- Page 163 and 164: Fume ExtractionVolume Extraction Un

- Page 165 and 166: Fume ExtractionVolume Extraction Un

- Page 167 and 168: Fume ExtractionVolume Extraction Un

- Page 169 and 170: Fume ExtractionVolume Extraction Un

- Page 171 and 172: Fume ExtractionVolume Extraction Un

- Page 173 and 174: Fume ExtractionAccessory for Tip an

- Page 175 and 176: Installation OptionsInstallation op

- Page 177 and 178: Risk Reduce ofThermal DamageWHP 300

- Page 179 and 180: AccessoryTemperature Measuring and

- Page 181 and 182: AccessoryHeating PlatesOrder No. Mo

- Page 183 and 184: AccessorySoldering BathesSoldering

- Page 185 and 186: AccessoryMiscellaneousDesoldering P

- Page 187 and 188: AccessoryMiscellaneousOrder No. Mod

- Page 189 and 190: AccessorySafety RestsSafety rests f

- Page 191 and 192: Index Exploded DrawingsModelPageMod

- Page 193 and 194: DXV 80FE 25Exploded Drawings 189

- Page 195 and 196: FE 75 FE 80Exploded Drawings 191

- Page 197 and 198:

PUD 81R Pyropen + Pyropen PiezoExpl

- Page 199 and 200:

WAD 100 WAD 101Exploded Drawings 19

- Page 201 and 202:

WD 1M / WD 1000M WD 2MExploded Draw

- Page 203 and 204:

WDD 161V WFEExploded Drawings 199

- Page 205 and 206:

WFE P WFE P(2)Exploded Drawings 201

- Page 207 and 208:

WHA 900 WHA 2000Exploded Drawings 2

- Page 209 and 210:

WHP 300 WHP 30005 87 577 83 (230V)5

- Page 211 and 212:

WMD 1SWMD 3 / WMD 3K2Exploded Drawi

- Page 213 and 214:

WS 50 WS 51Exploded Drawings 209

- Page 215 and 216:

WS 81(valid until year of manufactu

- Page 217 and 218:

WSD 130 WSD 150Exploded Drawings 21

- Page 219 and 220:

1WSF 80D5 87 328 825 87 328 81 P55

- Page 221 and 222:

WT 50WTCP 51Exploded Drawings 217

- Page 223 and 224:

WP 120 WFE 2ESExploded Drawings 219

- Page 225 and 226:

WP 200 WHP 1000Exploded Drawings 22

- Page 227 and 228:

Spare PartsOrder No. Description Or

- Page 229 and 230:

Spare PartsOrder No. Description Or

- Page 231 and 232:

Wrap/Unwrap Tools, Bits, Stripping

- Page 233 and 234:

Wrap/Unwrap ToolsElectronic Powered

- Page 235 and 236:

Bits for Standard andModified Conne

- Page 237 and 238:

Sleevesbare wirebitsleeve• Use ou

- Page 239 and 240:

Stripping toolsStripping tools• S

- Page 241 and 242:

14YB314G1Exploded Drawing 237

- Page 243 and 244:

Knives, Shearcutters, Screwdriver,

- Page 245 and 246:

Knives & BladesKnivesOrder No. Desc

- Page 247 and 248:

Screwdriver & Nutdriver SetsMini Sc

- Page 249 and 250:

Screwdriver &Nutdriver SetsNutdrive

- Page 251 and 252:

Series 99 Service Kits & SetsOrder

- Page 253 and 254:

Series 99 Service Kits & SetsOrder

- Page 255 and 256:

Tool CasesOrder No.TC100STDescripti

- Page 257 and 258:

SpecialsOffset Ratchet Screwdriver