BENCHTOP CSTR IN SERIES - Solution Engineering

BENCHTOP CSTR IN SERIES - Solution Engineering

BENCHTOP CSTR IN SERIES - Solution Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

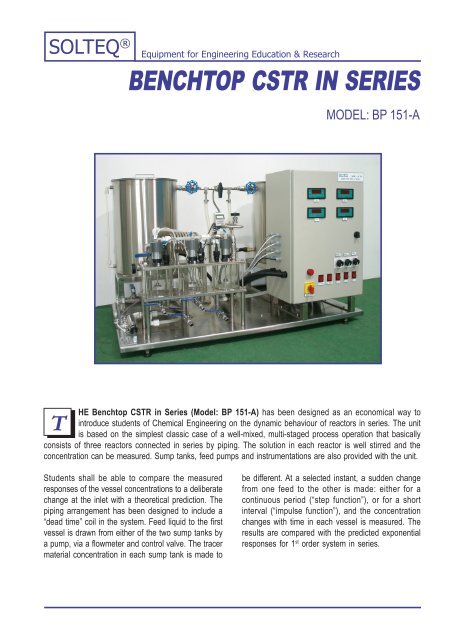

SOLTEQ ®Equipment for <strong>Engineering</strong> Education & Research<strong>BENCHTOP</strong> <strong>CSTR</strong> <strong>IN</strong> <strong>SERIES</strong>MODEL: BP 151-ATHE Benchtop <strong>CSTR</strong> in Series (Model: BP 151-A) has been designed as an economical way tointroduce students of Chemical <strong>Engineering</strong> on the dynamic behaviour of reactors in series. The unitis based on the simplest classic case of a well-mixed, multi-staged process operation that basicallyconsists of three reactors connected in series by piping. The solution in each reactor is well stirred and theconcentration can be measured. Sump tanks, feed pumps and instrumentations are also provided with the unit.Students shall be able to compare the measuredresponses of the vessel concentrations to a deliberatechange at the inlet with a theoretical prediction. Thepiping arrangement has been designed to include a“dead time” coil in the system. Feed liquid to the firstvessel is drawn from either of the two sump tanks bya pump, via a flowmeter and control valve. The tracermaterial concentration in each sump tank is made tobe different. At a selected instant, a sudden changefrom one feed to the other is made: either for acontinuous period (“step function”), or for a shortinterval (“impulse function”), and the concentrationchanges with time in each vessel is measured. Theresults are compared with the predicted exponentialresponses for 1 st order system in series.

SOLTEQ ®Equipment for <strong>Engineering</strong> Education & ResearchEXPERIMENTAL CAPABILITIES♦ Mass balance♦ Dynamic behaviour of <strong>CSTR</strong> in Series♦ Effect of “step change”♦ Effect of “pulse input”♦ Investigation on “dead time” coil♦ Computerised operation and data analysis(optional)SPECIFICATIONSa) BenchA space saving bench constructed fromchemically resistant worktop.b) Reactors3 units of 1-L vessels made of borosilicate glass.Each vessel comes with stirrer system. Flowbetween each vessel is by gravity. Conductivitysensors are also provided for each vessel.c) Stirrer SystemVariable speed motor; with speed controller andindicator; stainless steel impeller.d) Feed Tanks35-L cylindrical tanks; material: stainless steelf) Feed PumpsCapacity: max. 15 LPM @ 1.5m headHead: max. 6.0mg) Liquid FlowmeterRange: 0 to 500 ml/minh) ConductivityRange: 0 to 200 mS/cmi) Dead Time SectorVolume: approx. 20 mlOPTIONAL ITEMS- EIDIGITAL <strong>IN</strong>STRUMENTATIONSi) 1 unit of electronic flowmeter with indicatorii) 4 units of conductivity sensors with monitors-DASSOLDAS DATA ACQUISITION SYSTEMSOLTEQi) A PC with latest Pentium Processorii) An electronic signal conditioning systemiii) Stand alone data acquisition modulesiv) Windows based software♦ Data Logging♦ Signal Analysis♦ Process Control♦ Real-Time Display♦ Tabulated Results♦ Graph of Experimental Results- CALSOLCAL COMPUTER AIDED LEARN<strong>IN</strong>GSOFTWAREi) Interactive multimedia featuresii) Graphical simulationiii) Experiment results samplesiv) Full experiment manualsREQUIREMENTSPotassium or sodium ChlorideDistilled or deionised waterDrain pointsElectricity supply: 240VAC/1-phase/50HzOVERALL DIMENSIONSHeight : 0.70 mWidth : 1.20 mDepth : 0.70 mMANUALThe unit is supplied with Operating and ExperimentManuals in English giving full descriptions of the unit,sumary of theory, experimental procedures andtypical experiment results.

SOLTEQ ®Equipment for <strong>Engineering</strong> Education & ResearchTYPICAL EXPERIMENT RESULTS:Conductivity [mS/cm]Conductivity [mS/cm]1.000.900.800.700.600.500.400.300.200.10Experiment A: The Effect of Step ChangeExperiment B: The Effect of Pulse InputSOLTEQ3.002.802.602.402.202.001.801.601.401.20zReactor 11.00Reactor 20.80Reactor 30.600.400.200.000.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0 24.0 26.0 28.0 30.0Time, t [min]Reactor 1Reactor 2Reactor 30.000.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0 24.0 26.0 28.0 30.0Time, t [min]

SOLTEQ ®Equipment for <strong>Engineering</strong> Education & ResearchSOFTWARE & E - LEARN<strong>IN</strong>GOur range of teaching equipment can be complemented with ourSOLDAS and SOLCAL software.®SOLDAS - Supervisory Control & Data Acquisition- Data Logging- Signal Analysis- Process Control- Real-Time Display- Tabulated Results- Graph of Experimental Results®SOLCAL - Computer Aided Learning- Multimedia Features- Interactive- Graphic Simulation- Experiment Result Samples- Full Experiment ManualsContact us for a catalog CDSOLUTION ENG<strong>IN</strong>EER<strong>IN</strong>G SDN. BHD.(Co. No. 174876-M)AGENT:Sales Office :No.3, Jalan TPK 2/4, Taman Perindustrian Kinrara,47100 Puchong, Selangor Darul Ehsan, Malaysia.Tel. No. : +(603) 80758000Fax. No. : +(603) 80755784R&D Office :G-2A, Incubator 3, Technology Park Malaysia,Bukit Jalil, 57000 Kuala Lumpur, Malaysia.Tel. No. : +(603) 8996 0023EmailWeb site: solution@solution.com.my: http//www.solution.com.my/BUATAN MALAYSIAMSC- StatusCompany