Reduction in Interaction between Coarse Aggregate and Mortar in ...

Reduction in Interaction between Coarse Aggregate and Mortar in ...

Reduction in Interaction between Coarse Aggregate and Mortar in ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

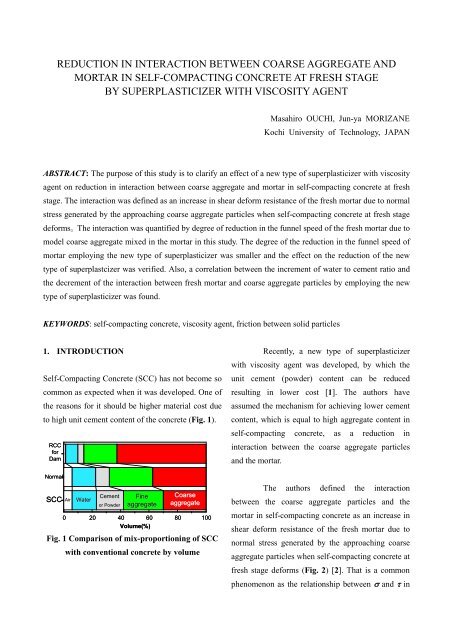

REDUCTION IN INTERACTION BETWEEN COARSE AGGREGATE ANDMORTAR IN SELF-COMPACTING CONCRETE AT FRESH STAGEBY SUPERPLASTICIZER WITH VISCOSITY AGENTMasahiro OUCHI, Jun-ya MORIZANEKochi University of Technology, JAPANABSTRACT: The purpose of this study is to clarify an effect of a new type of superplasticizer with viscosityagent on reduction <strong>in</strong> <strong>in</strong>teraction <strong>between</strong> coarse aggregate <strong>and</strong> mortar <strong>in</strong> self-compact<strong>in</strong>g concrete at freshstage. The <strong>in</strong>teraction was def<strong>in</strong>ed as an <strong>in</strong>crease <strong>in</strong> shear deform resistance of the fresh mortar due to normalstress generated by the approach<strong>in</strong>g coarse aggregate particles when self-compact<strong>in</strong>g concrete at fresh stagedeforms。The <strong>in</strong>teraction was quantified by degree of reduction <strong>in</strong> the funnel speed of the fresh mortar due tomodel coarse aggregate mixed <strong>in</strong> the mortar <strong>in</strong> this study. The degree of the reduction <strong>in</strong> the funnel speed ofmortar employ<strong>in</strong>g the new type of superplasticizer was smaller <strong>and</strong> the effect on the reduction of the newtype of superplastcizer was verified. Also, a correlation <strong>between</strong> the <strong>in</strong>crement of water to cement ratio <strong>and</strong>the decrement of the <strong>in</strong>teraction <strong>between</strong> fresh mortar <strong>and</strong> coarse aggregate particles by employ<strong>in</strong>g the newtype of superplasticizer was found.KEYWORDS: self-compact<strong>in</strong>g concrete, viscosity agent, friction <strong>between</strong> solid particles1. INTRODUCTIONSelf-Compact<strong>in</strong>g Concrete (SCC) has not become socommon as expected when it was developed. One ofthe reasons for it should be higher material cost dueto high unit cement content of the concrete (Fig. 1).RCCforDamNormalSCCAirCementWateror PowderF<strong>in</strong>e<strong>Coarse</strong>aggregateaggregate0 20 40 60 80 100Volume(%)Fig. 1 Comparison of mix-proportion<strong>in</strong>g of SCCwith conventional concrete by volumeRecently, a new type of superplasticizerwith viscosity agent was developed, by which theunit cement (powder) content can be reducedresult<strong>in</strong>g <strong>in</strong> lower cost [1]. The authors haveassumed the mechanism for achiev<strong>in</strong>g lower cementcontent, which is equal to high aggregate content <strong>in</strong>self-compact<strong>in</strong>g concrete, as a reduction <strong>in</strong><strong>in</strong>teraction <strong>between</strong> the coarse aggregate particles<strong>and</strong> the mortar.The authors def<strong>in</strong>ed the <strong>in</strong>teraction<strong>between</strong> the coarse aggregate particles <strong>and</strong> themortar <strong>in</strong> self-compact<strong>in</strong>g concrete as an <strong>in</strong>crease <strong>in</strong>shear deform resistance of the fresh mortar due tonormal stress generated by the approach<strong>in</strong>g coarseaggregate particles when self-compact<strong>in</strong>g concrete atfresh stage deforms (Fig. 2) [2]. That is a commonphenomenon as the relationship <strong>between</strong> σ <strong>and</strong> τ <strong>in</strong>

Funnel speed of concrete R cFig. 4 Larger reduction <strong>in</strong> flowability due to10.80.60.4F<strong>in</strong>e aggregate content <strong>in</strong> mortar: 40%<strong>Interaction</strong>50%Smaller0.2<strong>Coarse</strong> aggregateLargercontent : fixed00 0.5 1 1.5 2Funnel speed of mortar R mlarger <strong>in</strong>teraction by higher f<strong>in</strong>e aggregatecontent <strong>in</strong> mortar [Ozawa & Nagamoto]Fig. 5 <strong>Reduction</strong> <strong>in</strong> funnel speed due to<strong>Reduction</strong> <strong>in</strong> funnelspeed due to <strong>in</strong>teractionR mR mb<strong>in</strong>teraction <strong>between</strong> mortar <strong>and</strong> glass beads asmodel coarse aggregateConcrete for the funnel test was obta<strong>in</strong>edby mix<strong>in</strong>g glass beads as model coarse aggregate <strong>and</strong>mortar. The volumetric ratio of the coarse aggregatewas 20% of the concrete accord<strong>in</strong>g to Ouchi et. al’sexperimental result suitable for quantify<strong>in</strong>g thedegree of <strong>in</strong>teraction <strong>in</strong> self-compact<strong>in</strong>g concrete.The specific gravity of the glass beads was 2.55g/cm 3 , which was almost the same as commoncoarse aggregate. The diameter of the glass beadswas uniformly 10 mm.The funnel speed of fresh mortar R m wasdefned as 10/t, <strong>in</strong> which t was the duration ofmortar’s discharg<strong>in</strong>g through the funnel (Fig. 3). Thefunnel speed of fresh concrete (mortar <strong>and</strong> glassbeads as model coarse aggregate) was def<strong>in</strong>ed asR mb . The funnel for R m <strong>and</strong> R mb was common.If the <strong>in</strong>teraction was zero, the value of R mbwas equal to that of R m . The degree of the<strong>in</strong>teraction <strong>between</strong> fresh mortar <strong>and</strong> coarseaggregate particles was def<strong>in</strong>ed as (1-R mb /R m ).Larger <strong>in</strong>teraction resulted <strong>in</strong> larger (1-R mb /R m ) (Fig.5).3. EFFECT OF NEW TYPE OFSUPERPLASTICIZER WITH VISCOSITYAGENT ON REDUCING ITERACTIONBETWEEN MORTAR AND COARSEAGGREGATE PARTICLESThe degree of the <strong>in</strong>teraction <strong>in</strong> fresh SCC mortar<strong>and</strong> coarse aggregate (1-R mb /R m ) was obta<strong>in</strong>ed forfour types of mix-proportion<strong>in</strong>g (Table 1). The f<strong>in</strong>eaggregate content <strong>in</strong> the mortar by volume (s/m) was45%, recommended value for SCC or 50%, a littlebit higher than recommended. The materials <strong>in</strong> useare shown <strong>in</strong> Table 2. The mix<strong>in</strong>g <strong>and</strong> test<strong>in</strong>gprocedures are shown <strong>in</strong> Fig. 6. <strong>and</strong> Fig. 7. Thetemperature was kept constant at 20 degreecentigrade.Table 1 Mix-proportion<strong>in</strong>g of mortarSP s/m W/C Sp/C (%)SP10.35 1.200.45SP20.33 1.20SP10.40 0.700.45SP20.40 0.65SP10.35 1.200.50SP20.34 1.00

SP10.45 0.700.50SP20.40 1.00Table 2 Materials <strong>in</strong> useCement (C) Ord<strong>in</strong>ary portl<strong>and</strong> cement(3.15 g/cm 3 )F<strong>in</strong>e aggregate Crushed limestone s<strong>and</strong> (2.68(S)g/cm 3 , F.M.: 2.72)Model coarse Glass beads (2.55 g/cm 3 ,aggregate uniform diameter of 10 mm)New type of BASF Pozzolythsuperplasticizer Grenium 6550 (1.058 g/cm 3 )(SP1)Conventional BASF Pozzolythtype of Rhoebuild SP-8RV(1.095superplasticizer g/cm 3 )(SP2)C+SW+SPFor each mix-proportion<strong>in</strong>g, both R m <strong>and</strong>R mb were obta<strong>in</strong>ed. Each mix-proportion<strong>in</strong>g wasmixed <strong>and</strong> tested three times <strong>and</strong> the average value<strong>and</strong> st<strong>and</strong>ard deviation (m ± σ) were obta<strong>in</strong>ed. Boththe dosage of superpasticizer <strong>and</strong> water to cementratio were adjusted so that R m may be almost thesame <strong>between</strong> the conventional <strong>and</strong> the new types ofsuperplasticizers. That is because the difference <strong>in</strong>the degree of <strong>in</strong>teraction can be compared <strong>between</strong>conventional <strong>and</strong> new types of superplasticizer byus<strong>in</strong>g R mb clearly.The experimental results of R m <strong>and</strong> R mb areshown <strong>in</strong> Fig. 8. Also, the degree of the <strong>in</strong>teraction(1 – R mb /R m ) was compared <strong>in</strong> Fig. 9 (left). In all thecases except of one, it is evident that the new type ofsuperplasticizer (SP1) reduced the degree of the<strong>in</strong>teraction compared with the conventional type ofsuperplasticizer (SP2).Mix<strong>in</strong>g 30 secMix<strong>in</strong>g 120 secFig. 6 Mix<strong>in</strong>g procedure of mortarSP1Mix<strong>in</strong>g of mortarSP220 m<strong>in</strong>.Funnel test forR m & R mbFig. 8 R m <strong>and</strong> R mb with each type ofsuperplasticizer <strong>and</strong> mix-proportion<strong>in</strong>g-LargerR mb with SP1 compared with almost same R mb(SP1: new type; SP2: conventional type)Fig. 7 Mix<strong>in</strong>g procedure of mortar

However, there was a case <strong>in</strong> which thedecrement of the <strong>in</strong>teraction was not zero <strong>in</strong> spite ofthe <strong>in</strong>crement of water to cement ratio of zero. Thatmay be due to another effect of the new type ofsuperplasticizer <strong>in</strong> which the polymer itself canreduce the <strong>in</strong>teraction. Further research on it isnecessary.superplasticizer was found. It can be a factor formechanism of the effect of the new type ofsuperplasticizer.Further <strong>in</strong>vestigation is necessary forclarify<strong>in</strong>g the mechanism for reduc<strong>in</strong>g the<strong>in</strong>teraction.5. CONCLUSIONSThe purpose of this study is to clarify an effect of anew type of superplasticizer with viscosity agent onreduction <strong>in</strong> <strong>in</strong>teraction <strong>between</strong> mortar <strong>and</strong> coarseaggregate particles <strong>in</strong> self-compact<strong>in</strong>g concrete atfresh stage. The <strong>in</strong>teraction was def<strong>in</strong>ed as an<strong>in</strong>crease <strong>in</strong> shear deform resistance of the freshmortar due to normal stress generated by theapproach<strong>in</strong>g coarse aggregate particles whenself-compact<strong>in</strong>g concrete at fresh stage deforms. The<strong>in</strong>teraction was quantified by degree of reduction <strong>in</strong>the funnel speed of the fresh mortar due to modelcoarse aggregate mixed <strong>in</strong> the mortar <strong>in</strong> this study.The follow<strong>in</strong>g items were clarified <strong>in</strong> thisstudy:REFERENCES[1]http://www.pozzolith.basf.co.jp/ja/products/Documents/SDC.pdf[2] Ouchi, M., Edamatsu, Y., Ozawa, K. <strong>and</strong>Okamura, H.: "A simple evaluation method for<strong>in</strong>teraction <strong>between</strong> coarse aggregate <strong>and</strong> mortarparticles <strong>in</strong> self-compact<strong>in</strong>g concrete," Transactionsof the Japan Concrete Institute, pp.1-6, Vol.21,February 2000.[3] Okamura, H., Ozawa, K. <strong>and</strong> Ouchi, M."Self-compact<strong>in</strong>g concrete," fib Journal "StructuralConcrete," pp.3-17, March 2000.[4] Nagamoto, N., Ozawa, K.: Mixture properties ofself-compact<strong>in</strong>g high performance concrete, HighPerformance Concrete: Design, Materials <strong>and</strong>Advances <strong>in</strong> Concrete Technology, ACI Sp-172,pp.623-636, 1997.(1) The degree of the reduction <strong>in</strong> the<strong>in</strong>teraction <strong>between</strong> fresh mortar <strong>and</strong> coarseaggregate particles employ<strong>in</strong>g the new type ofsuperplasticizer was smaller. It is possible that theeffect on the reduction <strong>in</strong> friction <strong>between</strong> solidparticles by the new type of superplastcizer wasverified.(2) A correlation <strong>between</strong> the <strong>in</strong>crement ofwater to cement ratio <strong>and</strong> the decrement of the<strong>in</strong>teraction <strong>between</strong> fresh mortar <strong>and</strong> coarseaggregate particles by employ<strong>in</strong>g the new type of