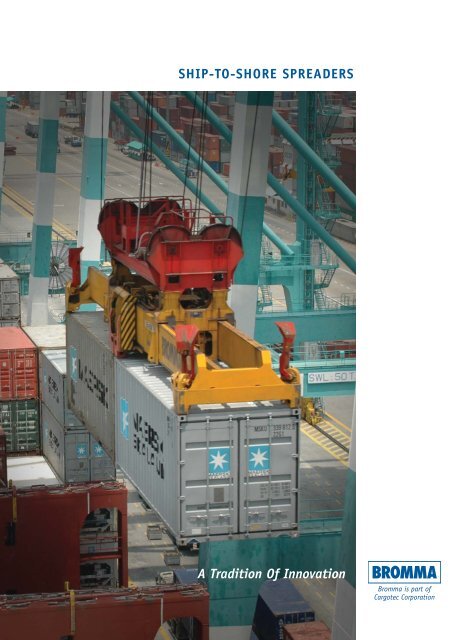

A Tradition Of Innovation SHIP-TO-SHORE SPREADERS

A Tradition Of Innovation SHIP-TO-SHORE SPREADERS

A Tradition Of Innovation SHIP-TO-SHORE SPREADERS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SHIP</strong>-<strong>TO</strong>-<strong>SHORE</strong> <strong>SPREADERS</strong>A <strong>Tradition</strong> <strong>Of</strong> <strong>Innovation</strong>Bromma is part ofCargotec Corporation

The First Name In SpreadersFrom an overall capital investment standpoint, theship-to-shore spreader is of small importance. Yet whileits cost is little more than 2% of a container crane, itsperformance is a critical factor in the economics ofcontainer handling. Terminals which “turn” ships fastergain a marketing advantage over peers, which can meanhigher market share, better berth utilization, and greaterpricing power. Spreader fleets that under-perform costterminals – in repairs, downtime expense, and highercapital investment for spares. Yet the greatest “cost” ofunder-performance is how a less reliable spreader canweaken a terminal’s relationships with its customers,and slow its growth.For more than thirty years Bromma has been at theforefront of our containerized global economy. Fromits headquarters in Sweden, Bromma has for decadesbeen the first name in crane spreaders, selling morethan 900 telescopic crane spreaders each year – morethan all of its competitors combined. Including spreadersfor FLTs, Reach Stackers, and Straddle Carriers,2Bromma sells more than 2,000 spreaders a year.Bromma is the market leader in every segment of thecrane spreader marketplace – ship-to-shore, mobileharbour, and yard. When you partner with Bromma,you are working with the most experienced, mostreliable spreader firm in the industry.The New Frontier<strong>Innovation</strong> is a Scandinavian tradition, and is embeddedin everything Bromma does. Bromma has made a habitof finding the new frontier – with the first telescopicspreader, first twin-lift spreader, first all-electric cranespreader, first true lightweight spreader, first advancedspreader communications and control system, calledSCS, first advanced safety technology, such as TTDSTwin-Twenty Detection, and the first twin-40 and twin-45 spreader, called Bromma Tandem. On the frontierwhere the future is created, Bromma Research &Development has made a habit of giving terminals thetools needed to take performance to a higher level.

Value-Driven Product DevelopmentBromma understands the familiar terrain of containerhandling – the tough physical environment in whichterminals operate. High heat and humidity, driving rain,sleet or snow, blowing sand, wind-borne salt – suchconditions would test any equipment, but in addition tothis, spreaders are beat up constantly. Yet Brommaspreaders understand the terrain of the terminal, andremain productive, reliable and durable under conditionsthat are never ideal. Marketing language, such as“design simplicity, quality control, manufacturingintegrity, or leading technology” is often viewed asslogans and nothing more. Yet, these core productdevelopment values lie at the heart of minimizingspreader downtime, and helping terminals achievefaster ship turns and the fullest possible utilization ofterminal berth capacity. In addition, Bromma has theresources to invest for production success. Brommadevelops its own testing systems, and its own productionrigs, because Bromma understands that few physicalenvironments are as challenging as container handling.Thinking Strategically About SpreadersOperational performance determines which terminalscompete and win, and which flatten or decline. This iswhy spreader fleet planning must be based on the fullspectrum of value – cost to purchase, but also cost tooperate – lifetime energy and maintenance costs, fleetdurability, and spreader productivity. Indeed, theBromma Return On Investment calculator demonstratesclearly how different spreader performance indicatorscan have a vast impact on terminal return on investment.Growing terminals need business partners whounderstand the metrics of performance and the necessityof achieving high capital return on investment.Bromma supports the success and growth of our terminalpartners, through our equipment, our organizationaldepth, our intellectual capital, and the enterprise valuesat Bromma which are consistent with success.Bromma is the strongest company in spreaders.3

Bromma Hydraulic Spreaders:A Higher Level <strong>Of</strong> ReliabilityBromma is the world leader in ship-to-shore cranespreaders, with more than 60% of the global market.Bromma has a dominant position for a simple reason:Bromma spreaders show up for work every day andperform at a high level of productivity. When reliabilityis crucial, as it especially is in ship-to-shore operations,Bromma is the obvious choice. Bromma’s family ofhydraulic ship-to-shore spreaders includes single-liftspreaders, twin-lift spreaders, and the innovative,high-productivity Bromma Tandem product family,capable of twin-40' and twin-45' container handling.Reduce DowntimeOne of the most important technical developments inship-to-shore spreaders in recent years has beenBromma SCS technology. In service on thousands ofspreaders around the globe, Bromma SCS monitorsspreader performance, reduces downtime events(through simplified wiring and fewer connections) andshortens downtime duration (through faster fault diagnosis)when faults occur. The latest generation of this technology,SCS 3 , is easy to use and simpler to understand, due toan on-board touch-screen display. It also features theindustry’s first generation of spreader prognostics, an“early warning system” for future spreader faults.Spreader prognostics means that terminals can now notonly fix problems faster, but prevent faults (and downtime)from occurring. Bromma Services believes that theinformation made possible by SCS 3 can reduce downtimeduration by an average of 20% or more.A Higher Level <strong>Of</strong> ProductivityBromma ship-to-shore spreaders are known for theirexceptional productivity. Bromma’s top-selling STS45separating twin-lift spreader in particular has exceptionalperformance characteristics. Higher productivityboosts the terminal bottom line. Bromma calculatesthat a spreader at a busy container terminal that averages4

one more box per hour (26,0 versus 25,0) can generate afurther $50,000 USD in terminal profit over its lifetime.Bromma’s vast global experience (Bromma spreadersare in use today at 96 out of the top 100 containerports) is also a major factor in the dependability ofBromma equipment. Bromma knows what terminalsneed, what can go wrong, and how to deliver equipmentthat performs in the “real world” scenarios that terminalsface every day.Weight & EnergyResearch and Development pays serious attention tospreader weight throughout its entire product line.A Spreader That Shows Up For WorkEvery DayBromma ship-to-shore spreaders are also known forexceptional durability – often remaining in active servicefor 12 or more years at high-throughput terminals.Bromma hydraulic ship-to-shore spreaders show up forwork every day, produce more while they’re on thejob, and keep performing for a long time.Spreader weight directly impacts crane energyconsumption, an area of growing concern for terminalsfacing fuel cost increases. Bromma Research andDevelopment models indicate that a 1,5 tonne reductionin ship-to-shore spreader weight can produce morethan $2,500 USD in annual energy savings. Bromma5

SSX40TECHNICAL SPECIFICATIONSSSX40/SSX45LIFTING CAPACITY41 tonne ± 10% eccentric loading41 tonne evenly loadedLIFTING LUGS4 x 10 tonne in end beamWEIGHT (w/o extra equipment) SSX40: 8,7 tonne / SSX45: 9,6 tonneTELESCOPIC MOTION SSX40: 20’ - 40’ in approx. 28 secondsSSX45: 20’ - 45’ in approx. 30 secondsFLIPPER ARM SPEED180° in 3 to 5 secondsTWISTLOCK ROTATION 90° in approx. 1 secondHYDRAULICSSystem pressure 100 barPOWER SUPPLY400/230 V AC 50 Hz or as agreed<strong>TO</strong>TAL POWER CONSUMPTION 7,5 kWHEIGHT1368 mmMINIMUM LENGTH6060 mmWIDTH2440 mmTWINLIFT UNIT UP/DOWN –TWIN SEPARATING SPEED –SSX45TECHNICAL SPECIFICATIONSSSX40/SSX45LIFTING CAPACITY41 tonne ± 10% eccentric loading41 tonne evenly loadedLIFTING LUGS4 x 10 tonne in end beamWEIGHT (w/o extra equipment) SSX40: 8,7 tonne / SSX45: 9,6 tonnesTELESCOPIC MOTION SSX40: 20’ - 40’ in approx. 28 secondsSSX45: 20’ - 45’ in approx. 30 secondsFLIPPER ARM SPEED180° in 3 to 5 secondsTWISTLOCK ROTATION 90° in approx. 1 secondHYDRAULICSSystem pressure 100 barPOWER SUPPLY400/230 V AC 50 Hz or as agreed<strong>TO</strong>TAL POWER CONSUMPTION 7,5 kWHEIGHT1368 mmMINIMUM LENGTH6060 mmWIDTH1466 mmTWINLIFT UNIT UP/DOWN –TWIN SEPARATING SPEED –SSX40LWTECHNICAL SPECIFICATIONSLIFTING CAPACITYLIFTING LUGSWEIGHTTELESCOPIC MOTIONFLIPPER ARM SPEEDTWISTLOCK ROTATIONHYDRAULICSPOWER SUPPLY<strong>TO</strong>TAL POWER CONSUMPTIONMINIMUM LENGTHWIDTHTWINLIFT UNIT UP/DOWN –TWIN SEPARATING SPEED –SSX40LW30,5 tonne ± 10% eccentric loading35 tonne evenly loaded4 x 8,5 tonne in end beam5,8 tonne (w/o extra equipment)20’ - 40’ in approx. 30 seconds180° in 5 seconds90° in approx. 1,5 secondSystem pressure 100 bar400/230 V AC 50 Hz or as agreed5,5 kW6060 mm2440 mm7

BENEFITS• Twin-lift ship-to-shore hydraulic spreaders are the most popular products in theBromma product line, due to their higher productivity and versatility• With the STS45 separating twin-lift spreader, a larger percentage of above-deckcontainers can be moved in twin-lift mode.• The separating STS45 has excellent operational flexibility. It can move two 20' containersfrom 0 mm to 1600 mm apart under full load.• The STS45LW has the same basic functionality as the Bromm STS45, but with 1,6tonnes less weight.Twin-Lift Hydraulic SpreadersBromma twin-lift hydraulic spreaders are feature-rich. Bromma advanced performancetechnology, such as SCS, 3 is standard on these spreaders. Bromma’s optional MPS memorypositioning system, available on the STS45, makes the crane operator’s task easier, andincreases productivity. The Bromma Twin-Twenty Detection System adds safety and theHIS Height Indication System is ideal for use on high-speed cranes.On the STS45 and STS45LW, separating twin movement can be done at any time in thecrane cycle, which means there is no stopping time to change the container spacing. Thisresults in higher flexibility in container ship loading and unloading. Bromma’s 30-persondesign engineering team ensures high structural integrity through strategic engineering,such as finite element modeling, which analyzes stress points on the spreader and projectsthe likely effect of accumulated stress over time. Bromma design studies, includingbuckling, vibration, and stress-related stiffening analyses, enable Bromma Research andDevelopment to evaluate the long-time impact of design changes, and develop optimumdesign solutions.Bromma uses premium Swedish steel for spreader frame structures on the STR40/45,STS45, and STS45LW, steel selected on the basis of its strength, weldability, and formability. ISO twistlocks allow for 6mm of float in all lateral directions, providing efficientlocating in the container corner castings. These spreaders can retract to the 19'6" positionin the event the spreader becomes jammed in the ship’s twenty foot cell. Positioning tothe 19'6" position can be controlled by the operator if appropriate controls are furnishedin the crane cab.Bromma’s STS45 spreader is the industry standard for ship-to-shore container handling,and a constant presence in the most demanding terminals in the world. Bromma understandswhat ship-to-shore container handling requires, and the twin-lift hydraulic STSspreaders from Bromma deliver it.8

Bromma Tandem:A Higher Level <strong>Of</strong> ProductivityThe Bromma Tandem spreader is a new productivitytool for an industry that’s hungry for productivity. Atcontainer terminals around the world, there are moreand more 40' containers, and fewer 20' containers.The type of spreader used to handle these containers,and the brand of spreader selected, can have a majorimpact on operating efficiency. Bromma Tandem isone tool in the effort to boost productivity, as it offersthe opportunity to greatly expand the productivity ofeach lift cycle.Chances are that whatever your terminal’s containermix is today, it will be somewhat different tomorrow,and that whatever your terminal’s container volumeis today, it will be somewhat greater tomorrow.Bromma Tandem is a spreader advance in bothareas – providing both a productivity boost and anextremely versatile lifting tool.Bromma Tandem will increase productivity whenloading and unloading those sections of containerships stacked with 40' containers. It is also ideal forterminals with a high volume of empty containersand cranes with limited lifting capacity. BrommaTandem has the ability to simultaneously lift four20' containers (Tandem T45 or Tandem Quattro),or two 40' containers, or two 45' containers, or manyother combinations, including hatch covers. It caneasily handle container height differences of up to700mm, and has productivity of up to 60 40' or 45'containers per hour.10

A Proven DesignMoreover, except for lifting capacity, there is no needfor a special crane design. With Bromma’s pioneeringSCS 3 spreader technology, terminals can swap spreadersbetween different cranes, and install new spreader models,such as Tandem, without any concern about the interfacewith other spreader models.While Bromma Tandem is innovative, it is alsoimportant to note that it is based on a simple technicalapproach that features spreader design and technologywith proven reliability. The fixed-length Tandem wasfirst put into field tests in 2003. It is also not acomplicated design solution. The type of Tandemspreader selected depends on the crane lift capacity.Except for sufficient lifting capacity, there is no needfor a special crane design.The inherent versatility of the Bromma Tandem familymakes it an ideal choice for terminals looking to thehorizon and operating with a long-term perspectivewhen making spreader fleet planning decisions.11

BENEFITS• The Tandem T45 spreader offers terminals the highest level of productivity andversatility, with the capacity and flexibility to handle all possible combinations of20', 40', and 45' containers quickly and efficiently. It can also handle four 20' containerssimultaneously and separate the 20' containers longitudinally between 0 and 1,6 meters.• The Tandem 40/45 spreader is able to twin-lift two 20', 40', or 45' containers withoutthe need, as in the Tandem fixed-length version, for change-out.• This is a proven spreader design field-tested in high-throughput European and Asianterminals.• Customers with a high number of empty 40' containers may want to give specialconsideration to the productivity advantages of the Tandem.• The Tandem headblock is necessary for the efficient handling of the Tandemspreader line.The Separating T45 spreader offers the highest level of productivity and versatility, butrequires a higher-capacity container crane. Tandem T45 spreader weight is an estimated31 tonnes. To fully utilize the lift capacity of the spreader requires a high crane capacity,but most customers will rate 20 foot containers to a maximum of 20-25 tonne, therebyresulting in a required crane capacity of 115-135 tonne in the ropes.Tandem ProductivityThe Tandem 40/45 spreader is based on proven Bromma spreader design, as it uses theSSX40/45 spreader as its standard base. A terminal planning to utilize the full 70 tonnecapacity under the spreader will need crane capacity of approximately 100 tonne in theropes. As such, the Tandem 40/45 can be used without restriction on many last-generationcontainer cranes already in service today. Customers who handle very few 45' containersmay wish to consider the 40' version of the Tandem 40/45. This will save approximately2 tonne in spreader weight.Bromma Tandem spreaders are feature-rich. The adjustable pusher with memory functionkeeps a pre-set space between the spreaders, reducing the swinging of the two spreadersand simplifying the entering of ship cell guides. Long side flippers mounted on an inclinedbase, and rounded end beams, avoid jamming in cell guides. The four wagons can be movedindividually to allow skewing and gravity point adjustment, should this be needed. A memorysystem allows a pre-set positioning distance between the spreaders. Chain suspension allowsTandem to handle containers of different height. Eight powerful flippers with large scoopsin optimal configuration allow Tandem to handle different combinations efficiently.The Bromma Tandem Headblock with adjustable pulley wheel distance keeps the gravitypoint of the two containers between the pulley wheels center in Tandem mode. Whenoperating with a standard spreader, the pulley wheels will retract to normal headblockwidth. Pulley wheels move from standard (750-1000 mm) up to 2,6 metres. Bromma canalso provide a fully automatic electrical plug/socket interface and will offer to modify theexisting crane electrical interface and communication system to enable the handling ofTandem spreaders.12

Separating T45TECHNICAL SPECIFICATIONSLIFTING CAPACITYWEIGHTFLIPPER ARM SPEEDTWISTLOCK ROTATIONHYDRAULICS<strong>TO</strong>TAL POWER CONSUMPTIONSPREADER HEIGHTT452 x 51 tonne31 tonne180° in 3 to 5 seconds90° in approx. 1 secondSystem pressure 100/160 bar15 kW2900 mmCONTAINER HEIGHT DIFFERENCELOADING/UNLOADING 2' 660 mm (standard)SKEWING±20 degreesSKEWING SPEED1 degree in 20 secondsTANDEM SEPARATING SPEED 100 mm in 10 secondsTWINLIFT UNIT UP/DOWN Approx. 8 secondsTWIN SEPARATING SPEED Approx. 16 secondsTandem 40/45TECHNICAL SPECIFICATIONS TANDEM 40/TANDEM 45LIFTING CAPACITY2 x 41 tonneWEIGHTTANDEM 40: 23,2 tonneTANDEM 45: 25 tonneFLIPPER ARM SPEED180° in 3 to 5 secondsTWISTLOCK ROTATION 90° in approx. 1 secondHYDRAULICSSystem pressure 140 bar<strong>TO</strong>TAL POWER CONSUMPTION 15 kWSPREADER HEIGHTTandem 40: 2800 mm Tandem 45: 2900 mmCONTAINER HEIGHT DIFFERENCELOADING/UNLOADING 2' 660 mm (standard)SKEWING±20 degreesSKEWING SPEED1 degree in 20 secondsTANDEM SEPARATING SPEED 100 mm in 10 secondsHeadblockTECHNICAL SPECIFICATIONSHEADBLOCKLOAD CAPACITY UNDER HEADBLOCK 71 tonne (for Tandem 45)HEADBLOCK TARE WEIGHT 5 tonne (for Tandem 45)HEIGHT5500 mmLENGTH3800 mmWIDTH2100 mmWIDTH IN TWIN-LIFT MODE 3700 mmCONNECTION <strong>TO</strong> SPREADER TwistlockPULLEY WHEEL DISTANCE Approx. 5 min. (manual)Approx. 1 min. (fully automatic)13

BENEFITS• The Tandem Fix 40 is an ideal choice for customers interested in gaining the addedproductivity of twin-40 container handling, but who are somewhat restricted in theirchoices due to cranes with limited lifting capacity.• A container terminal with a high percentage of 40 foot containers will gain an immediateboost to its lift cycle productivity, since the Tandem Fix 40 spreader can lift two40' containers at a time, not one.• The Tandem Quattro offers the same capacity and nearly the same flexibility as theTandem T45, including the ability to handle four 20 foot containers at a time – two20 foot containers under each spreader – but it does so with a lower spreader weight.• The Tandem Quattro spreader also offers another advantage: the capability to doside shift on individual spreaders, which is useful when the chassis or container onthe ground is not fully lined up in the longitudinal direction.The Tandem Fix 40 is, from a design standpoint, the simplest Tandem model availabletoday. It uses Bromma spreader design and technology that has been proven to be reliableover many years and many millions of lift cycles. Customers should keep in mind that theoperating limitation of the Tandem Fix 40 is that it is for 40' containers only. This iswhy the Tandem Fix 40 is best-suited for terminals where ships tend to be stacked witha high percentage of 40’ containers, or when the crane has a limited lift capacity.The Tandem Quattro is a high-productivity, lower weight Tandem solution. The limitationTandem Versatilityon Tandem Quattro is that it is not designed to lift a single 20' container. The TandemQuattro is especially well-suited for container terminals that have a high percentage of 40'and 45' containers, and a low percentage of 20' containers that are located in such a waythat they need to be loaded/unloaded in single lift mode.14

Tandem Fix 40TECHNICAL SPECIFICATIONS TANDEM FIX 40LIFTING CAPACITY2 x 35 tonneWEIGHT16 tonneFLIPPER ARM SPEED180° in 3 to 5 secondsTWISTLOCK ROTATION 90° in approx. 1 secondHYDRAULICSSystem pressure 140 bar<strong>TO</strong>TAL POWER CONSUMPTION 7,5 kWSPREADER HEIGHT2400 mmCONTAINER HEIGHT DIFFERENCELOADING/UNLOADING 2' 660 mm (standard)SKEWING±20 degreesSKEWING SPEED1 degree in 20 secondsTANDEM SEPARATING SPEED 100 mm in 10 secondsTandem QuattroTANDEM QUATTROTECHNICAL SPECIFICATIONSLIFTING CAPACITY2 x 51 tonne4 x 32,5 tonneWEIGHT24 tonneFLIPPER ARM SPEED180° in 3 to 5 secondsFLIPPER ARM <strong>TO</strong>RQUE approx. 1,650 NmHYDRAULICSSystem pressure 140 bar<strong>TO</strong>TAL POWER CONSUMPTION 15 kWSPREADER HEIGHT2900 mmCONTAINER HEIGHT DIFFERENCELOADING/UNLOADING 2' 660 mm (standard)SKEWING±20 degreesSKEWING SPEED1 degree in 20 secondsTANDEM SEPARATING SPEED 100 mm in 10 seconds15

The New E-Series: Less Service,Lower Weight, More UptimeThe operational centre of any great container terminalis a highly productive and reliable ship-to-shorespreader operation. Bromma Group’s new E-Series ofall-electric ship-to-shore spreaders are loaded withadvantages designed to create lifecycle cost savingswhile boosting fleet uptime.Easier To MaintainHydraulics is history on the E-Series spreader family,which makes them easier to maintain. Many servicepoints have been taken away. There’s no hydraulicpowerpack and no hoses. There are no fluids, or oil filter,to replace.This elimination of hydraulics means reduced servicetime and reduced service materials cost (for oil, hoses,and filters). It will also eliminate many of the “nuisance”downtime events that occur due to spreader hydraulics(bad hose connections, etc.) Making hydraulics historyreduces both scheduled and unscheduled spreaderdowntime.Lighter, For Less Energy CostBromma all-electric spreaders, particularly the STS45Eseparating twin-lift, are also lighter, with the STS45Efeaturing a best-in-class weight of only 11,7 tonnes.There is a direct correlation between spreader weightand energy cost. The heavier the spreader, the higherthe energy costs. For example, a 1,5 tonne weight savingsmeans some $40,000 USD in energy savings over itslifetime. So spreader weight is a very significant factorwhen spreader fleet planning takes place.The elimination of the idling hydraulic pump on theseall-electric spreaders also adds to the energy savings.Bromma Research & Development estimates that the16

idling action of a hydraulic pump results in energyconsumption of approximately 3 kWh. Eliminating thisidling hydraulic motor thus should mean an approximate$13,500 USD in lifetime energy savings. (Actual costsavings should trend higher due to expected inflation inenergy costs.)New, But Not UnprovenThese ship-to-shore all-electric spreaders are new, butnot unproven, since they are based on the same framestructure used by Bromma customers throughout theworld. Everything on this spreader that has to do withlifting containers, landing, and shocks, is proven, sinceit’s the same spreader that has been performing thesefunctions for years.Smart & Easy To UseE-Series all-electrics equipped with Bromma SCS 3 ,such as the STS45E, are both smart and easy to use,due to their simple-to-understand touchscreen display,fast fault diagnostics, and the industry’s first spreaderprognostics. SCS 3 can dramatically reduce wired terminalpoints and I/O relays for greater simplicity, while givingterminals advanced functionality, such as on-line sensoradjustments, and communications capabilities such astransmission of spreader events, logs, alarms, andMMBF statistics to terminal headquarters for analysis.QuieterE-Series spreaders are also quieter. The sound youdon’t hear is your spreader beam telescoping. Plus,there’s no continuously running hydraulic powerpack.So if you are concerned about how terminal noise levelsimpact the surrounding community, Bromma all-electricsare another step in the right direction.Durable ConstructionBromma all-electric spreaders also benefit from theconsistency of Bromma manufacturing processes.Bromma pursues higher quality at every level – inmaterials, in components, and in the Bromma spreadermanufacturing process. The result is the durableconstruction and long life that Bromma spreaders areknown for throughout the terminal world.The Bromma all-electric E-Series family: less service,lower weight, more uptime, and they are only fromBromma.17

BENEFITS• Proven design: the Bromma SSX40E and SSX45E structure is based on the reliablehydraulic versions of this spreader• Designed for lower or higher throughput environments and for service on high-speed cranes• Reduced routine maintenance due to all-electric design• Reduced energy consumption due to elimination of the hydraulic power-packBromma single-lift SSX40/45E spreaders offer strength, reliability, and durability, plusthe advantage of lower lifecycle costs. On these all-electric spreaders, many service pointshave been taken away. There’s no hydraulic powerpack and no hoses. There are no fluids,or oil filter, to replace. This elimination of hydraulics means reduced service time andreduced service materials cost (for oil, hoses, and filters). It will also eliminate many ofthe “nuisance” downtime events that occur due to spreader hydraulics (bad hose connections,etc.). Making hydraulics history reduces both scheduled and unscheduled spreader downtime.Strategic Engineering For A Longer LifeSingle-Lift All-ElectricIn the design of these spreaders, Bromma achieves superior structural strength throughstrategic engineering tools, such as finite element modeling, which analyzes stress pointson the spreader and projects the likely effect of accumulated stress over time. The benefitsof a more robust design, a higher grade of materials, and a more rugged construction, areoften not visible until a spreader has been in service for several years. Yet, the “invisible”advantages of exceptional design and construction are obvious in the traditionally longerlifetime of Bromma spreaders.These spreaders have the ability to retract to the 19'6" position in the event the spreaderbecomes jammed in the ship’s twenty foot cell. Positioning to the 19'6" position can becontrolled by the operator if appropriate controls are furnished in the crane cab. Thesespreaders fulfill the most demanding design criteria among DIN, FEM and BritishStandard. Bromma advanced performance technology, such as SCS 3 , the TTDS Twin-Twenty Detection System (an excellent safety feature), and the HIS Height IndicationSystem are installed or available for installation on all Bromma spreaders.18

SSX40ETECHNICAL SPECIFICATIONSLIFTING CAPACITYLIFTING LUGSWEIGHTTELESCOPIC MOTIONFLIPPER ARM SPEEDTWISTLOCK ROTATIONHYDRAULICSHEIGHTMINIMUM LENGTHWIDTHSSX40E41 tonne ± 10% eccentric loading41 tonne evenly loaded4 x 10 tonne in end beam8,7 tonne (w/o extra equipment)20’ - 40’ in approx. 28 seconds180° in 3 to 5 seconds90° in approx. 1 secondNone1366 mm6060 mm2440 mmSSX45ETECHNICAL SPECIFICATIONSLIFTING CAPACITYLIFTING LUGSWEIGHTTELESCOPIC MOTIONFLIPPER ARM SPEEDTWISTLOCK ROTATIONHYDRAULICSHEIGHTMINIMUM LENGTHWIDTHSSX45E41 tonne ± 10% eccentric loading41 tonne evenly loaded4 x 10 tonne in end beam9,6 tonne (w/o extra equipment)20’ - 45’ in approx. 30 seconds180° in 3 to 5 seconds90° in approx. 1 secondNone1466 mm6060 mm2440 mm19

BENEFITS• Proven design: the Bromma STR40E/45E and STS45E are based on Brommaspreaders in service throughout the world• Lower energy consumption• Reduced spreader maintenance requirements, due to the elimination of hydraulics• Simpler – less settings and fewer sensors• Twin-lift ship-to-shore spreaders are the most popular products in the Bromma productline, due to their higher productivity and versatility• With the STS45E separating twin-lift spreader, a larger percentage of above-deckcontainers can be transported in twin-lift mode.Higher productivity translates into higher potential revenue. The STS45E separating twin-lift hasexceptional performance characteristics. At a busy container terminal, even a one box per hourimprovement in container handling (26,0 versus 25,0) can generate a further $50,000 USD interminal profit over a spreader lifetime.Twin-Lift All-Electrric All-ElectricBromma’s optional MPS memory positioning system makes the crane operator’s task easier, andincreases productivity. The Twin-Twenty Detection System adds safety and the HIS HeightIndication System is ideal for use on high-speed cranes. Bromma all-electric twin-lift spreadersalso have maintenance and energy consumption advantages. At only 11,7 tonnes, the STS45E willsave energy compared to competing brands. For example, a 1,5 tonne weight savings means some$40,000 USD in energy savings over its lifetime. The elimination of the idling hydraulic pump onthese all-electric spreaders also adds to the energy savings. The idling action of a hydraulic pumpresults in energy consumption of approximately 3 kWh. Eliminating this idling hydraulic motorthus should mean an approximate $13,500 USD in lifetime energy savings.Bromma has been able to make the STS45E lighter through more intelligent design – an improvementin technique. Mechanical functions that perform the separating twin motion have been replaced by anew electrical concept, which allows weight reduction. The separating twin motion doesn’t requireany mechanical connection – hooks or lashes – which lowers weight. This spreader features the best ofthe old … and the new. The new on the STS45E includes a completely re-designed all electric flipper, anall-electric synchronized separating system, and a faster up/down motion for twinlift boxes. Yet, muchis the same, including Bromma’s proven twistlock system and Bromma’s extremely durable spreaderconstruction.The control and communications capabilities of Bromma all-electric twins are unsurpassed.Bromma SCS 3 – with its user-friendly touchscreen display and advanced diagnostics and prognosticsfunctionality, is standard on these spreaders. Easy to use, simple to understand, and intelligentlyadvanced, SCS 3 dramatically reduces wired terminal points and I/O relays for greater simplicity,while giving terminals advanced functionality, such as on-line sensor adjustments, and communicationscapability, such as transmission of spreader events, logs, alarms, and MMBF statistics toterminal headquarters for analysis.Operational flexibility is a hallmark of these spreaders. Separating twin movement can be done atany time in the crane cycle, which means there is no stopping time to change the container spacing.This results in superior container ship loading and unloading flexibility. Plus, these spreaders canretract to the 19'6" position in the event the spreader becomes jammed in the ship’s twenty footcell. Positioning to the 19'6" position can be controlled by the operator if appropriate controls arefurnished in the crane cab.Finally, Bromma is uncompromising in its selection of materials and components, using premiumSwedish steel for all spreader frame structures, steel selected on the basis of its strength, weldabilityand formability.20

STR40E/45ETECHNICAL SPECIFICATIONSLIFTING CAPACITYLIFTING LUGSWEIGHTTELESCOPIC MOTIONFLIPPER ARM SPEEDTWISTLOCK ROTATIONHYDRAULICSTWINLIFT UNIT UP/DOWNLENGTHSTR40E/45E51 tonne ± 10% eccentric loading51 tonne evenly loaded4 x 32,5 tonne (2x20’ ISO)11,2 tonneSTR40E: 20’ - 40’ in 28 secondsSTR45E: 20’ - 45’ in 30 seconds180° in 5 seconds90° in approx. 1 secondNoneApprox. 6 seconds6060 mmSTS45ETECHNICAL SPECIFICATIONSLIFTING CAPACITYLIFTING LUGSWEIGHTTELESCOPIC MOTIONFLIPPER ARM SPEEDTWISTLOCK ROTATIONHYDRAULICSTWINLIFT UNIT UP/DOWNTWIN SEPARATING SPEEDLENGTHSTS45E51 tonne ± 10% eccentric loading51 tonne evenly loaded2 x 32,5 tonnes (2x20’ ISO)2 x 32,5 tonne (2x20’ ISO)11,7 tonne (w/o extra equipment)20’ - 45’ in approx. 30 seconds180° in 5 seconds90° in approx. 1 secondNoneApprox. 6 secondsApprox. 18 seconds6060 mm21

Technical SpecificationsHYDRAULICTANDEME-SERIESBrommaSpreaderSSX40SSX45SSX40LWSTR40STR45STS45STS45LWTANDEM T45TANDEM 40TANDEM 45TANDEM FIX 40TANDEM QUATTROHEADBLOCKSSX40ESSX45ESTR40E/45ESTS45EPageCORROSION PROTECTION FOR STS <strong>SPREADERS</strong>:Blast cleaning to SA2,5 - ISO 8501:1Interzinc 72: 50 myIntercure 429: 70 myInterfine 629 HS: 2 x 40 myMin. coating thickness: total 200 my666888812121214141218182020STANDARD TECHNICAL SPECIFICATIONSLiftingCapacity41 tonne ± 10% eccentric loading41 tonnes evenly loaded41 tonne ± 10% eccentric loading41 tonnes evenly loaded30,5 tonne ± 10% eccentric loading35 tonnes evenly loaded51 tonne ± 10% eccentric loading51 tonnes evenly loaded2 x 32,5 tonnes (2x20” ISO)51 tonne ± 10% eccentric loading51 tonnes evenly loaded2 x 32,5 tonnes (2x20” ISO)51 tonne ± 10% eccentric loading51 tonnes evenly loaded2 x 32,5 tonnes (2x20” ISO)41 tonne ± 10% eccentric loading41 tonnes evenly loaded2 x 32,5 tonnes (2x20” ISO)51 tonne ± 10% eccentric loading4 x 32,5 tonnes2 x 41 tonnes2 x 41 tonnes2 x 35 tonnes51 tonne ± 10% eccentric loading4 x 32,5 tonnes71 tonne (for Tandem 45)41 tonne ± 10% eccentric loading41 tonnes evenly loaded41 tonne ± 10% eccentric loading41 tonnes evenly loaded51 tonne ± 10% eccentric loading51 tonnes evenly loaded2 x 32,5 tonnes (2x20” ISO)51 tonne ± 10% eccentric loading51 tonnes evenly loaded2 x 32,5 tonnes (2x20” ISO)TWISTLOCK ROTATION:90° in approx 1 secondWARRANTY:One yearWeight8,7 tonne9,6 tonne5,8 tonne9,9 tonne11 tonne12,7 tonne11,2 tonne31 tonne23,2 tonne25 tonne16 tonne24 tonne5 tonne8,7 tonne9,6 tonne11,2 tonne11,7 tonne22

HydraulicsOperating DetailsSystem pressure 100 barSystem pressure 100 barSystem pressure 100 barSystem pressure 100 barTwinlift unit up/down approx. 8 secondsSystem pressure 100 barTwinlift unit up/down approx. 8 secondsSystem pressure 100/160 barSystem pressure 120 barSystem pressure 100/160 barSystem pressure 140 barSystem pressure 140 barSystem pressure 140 barSystem pressure 140 barNoneTwinlift unit up/down approx. 8 secondsTwin separating speed approx. 20 secondsTwinlift unit up/down approx. 8 secondsTwin separating speed approx. 20 secondsLoading/unloading: 2’ 660mm (standard); Skewing: ±20°;Skewing speed: 1° in 20 sec.; Separating speed: 100mm in 10 sec.Loading/unloading: 2’ 660mm (standard); Skewing: ±20°;Skewing speed: 1° in 20 sec.; Separating speed: 100mm in 10 sec.Loading/unloading: 2’ 660mm (standard); Skewing: ±20°;Skewing speed: 1° in 20 sec.; Separating speed: 100mm in 10 sec.Loading/unloading: 2’ 660mm (standard); Skewing: ±20°;Skewing speed: 1° in 20 sec.; Separating speed: 100mm in 10 sec.Loading/unloading: 2’ 660mm (standard); Skewing: ±20°;Skewing speed: 1° in 20 sec.; Separating speed: 100mm in 10 sec.Pulley wheel distance: 5 minutes (manual), 1 minute (fully automatic)NoneNoneNoneTwinlift unit up/down approx. 6 secondsNoneTwinlift unit up/down approx. 6 secondsTwin separating speed approx. 18 secondsMANUALS:Full service and repair manualDESIGN CRITERIA:DIN 15018 H2B4; FEM 1.001;British Standard BS 2573All technical specifications may be changed and are subject to notice.Contact your Bromma representative orHYPERLINK "http://www.bromma.com/" www.bromma.com forcurrent technical specifications.23

A <strong>Tradition</strong> <strong>Of</strong> <strong>Innovation</strong>Bromma is part ofCargotec CorporationBROMMA CONQUIP ABMalaxgatan 7164 74 Kista, SwedenPHONE: +46 8 620 0900FAX: +46 8 739 3786E-MAIL: sales@bromma.comBROMMA INC.4400 Ben Franklin Blvd.Suite 200Durham, NC 27704 USAPHONE: +1 919 471 4000FAX: +1 919 471 4343E-MAIL: brommaus.sales@bromma.comBROMMA FAR EASTBlk. 102E Pasir Panjang Road#08-07, Citilink Warehouse ComplexSingapore 118529PHONE: +65 6272 0400FAX: +65 6272 0411E-MAIL: bfe@bromma.comBROMMA SHANGHAIShanghai, China Representation <strong>Of</strong>ficeB, 20 Fir, Liang Feng MansionNo. 8 Dong Fang Road, PudongShanghai 200120, ChinaPHONE: +86 21 588 871 64PHONE: +86 21 588 874 09FAX: +86 21 588 874 08E-MAIL: jeff_jiefu@bromma.com.cnBROMMA Sdn. Bhd.Lot 19, Jalan Kelebang 1/6Kinta Free Industrial ZonePoskod 31200 ChemorPerak, MalaysiaPHONE: +60 529 388 90FAX: +60 529 140 99E-MAIL: malaysia@bromma.comBROMMA UKThe Loughton Seedbed Centre D11Langston RoadLoughtonEssex, IG10 3TQUKPHONE: +44 (0)20 8787 7031FAX: +44 (0)20 8787 7086E-MAIL: carl.kesselmark@bromma.comBROMMA GmbHIm Klint 12D-30938 BurgwedelGermanyPHONE: +49 513 980 6630FAX: +49 513 980 6644E-MAIL: spreader.sales@bromma-gmbh.deBROMMA MIDDLE EASTBROMMA M.E. FZCOP.O. Box 17909 Dubai,United Arab EmiratesPHONE OFFICE: +971 488 725 20PHONE MOBILE: +971 505 518 255FAX: +971 488 725 25E-MAIL: graham.boxall@bromma.comwww.bromma.comPRINTED MAY 2007