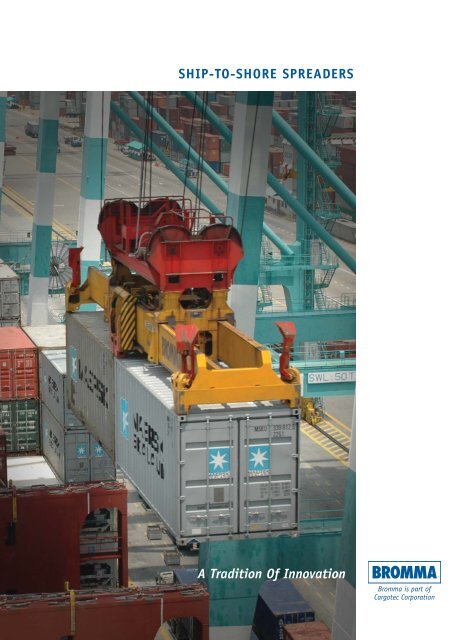

A Tradition Of Innovation SHIP-TO-SHORE SPREADERS

A Tradition Of Innovation SHIP-TO-SHORE SPREADERS

A Tradition Of Innovation SHIP-TO-SHORE SPREADERS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SHIP</strong>-<strong>TO</strong>-<strong>SHORE</strong> <strong>SPREADERS</strong><br />

A <strong>Tradition</strong> <strong>Of</strong> <strong>Innovation</strong><br />

Bromma is part of<br />

Cargotec Corporation

The First Name In Spreaders<br />

From an overall capital investment standpoint, the<br />

ship-to-shore spreader is of small importance. Yet while<br />

its cost is little more than 2% of a container crane, its<br />

performance is a critical factor in the economics of<br />

container handling. Terminals which “turn” ships faster<br />

gain a marketing advantage over peers, which can mean<br />

higher market share, better berth utilization, and greater<br />

pricing power. Spreader fleets that under-perform cost<br />

terminals – in repairs, downtime expense, and higher<br />

capital investment for spares. Yet the greatest “cost” of<br />

under-performance is how a less reliable spreader can<br />

weaken a terminal’s relationships with its customers,<br />

and slow its growth.<br />

For more than thirty years Bromma has been at the<br />

forefront of our containerized global economy. From<br />

its headquarters in Sweden, Bromma has for decades<br />

been the first name in crane spreaders, selling more<br />

than 900 telescopic crane spreaders each year – more<br />

than all of its competitors combined. Including spreaders<br />

for FLTs, Reach Stackers, and Straddle Carriers,<br />

2<br />

Bromma sells more than 2,000 spreaders a year.<br />

Bromma is the market leader in every segment of the<br />

crane spreader marketplace – ship-to-shore, mobile<br />

harbour, and yard. When you partner with Bromma,<br />

you are working with the most experienced, most<br />

reliable spreader firm in the industry.<br />

The New Frontier<br />

<strong>Innovation</strong> is a Scandinavian tradition, and is embedded<br />

in everything Bromma does. Bromma has made a habit<br />

of finding the new frontier – with the first telescopic<br />

spreader, first twin-lift spreader, first all-electric crane<br />

spreader, first true lightweight spreader, first advanced<br />

spreader communications and control system, called<br />

SCS, first advanced safety technology, such as TTDS<br />

Twin-Twenty Detection, and the first twin-40 and twin-<br />

45 spreader, called Bromma Tandem. On the frontier<br />

where the future is created, Bromma Research &<br />

Development has made a habit of giving terminals the<br />

tools needed to take performance to a higher level.

Value-Driven Product Development<br />

Bromma understands the familiar terrain of container<br />

handling – the tough physical environment in which<br />

terminals operate. High heat and humidity, driving rain,<br />

sleet or snow, blowing sand, wind-borne salt – such<br />

conditions would test any equipment, but in addition to<br />

this, spreaders are beat up constantly. Yet Bromma<br />

spreaders understand the terrain of the terminal, and<br />

remain productive, reliable and durable under conditions<br />

that are never ideal. Marketing language, such as<br />

“design simplicity, quality control, manufacturing<br />

integrity, or leading technology” is often viewed as<br />

slogans and nothing more. Yet, these core product<br />

development values lie at the heart of minimizing<br />

spreader downtime, and helping terminals achieve<br />

faster ship turns and the fullest possible utilization of<br />

terminal berth capacity. In addition, Bromma has the<br />

resources to invest for production success. Bromma<br />

develops its own testing systems, and its own production<br />

rigs, because Bromma understands that few physical<br />

environments are as challenging as container handling.<br />

3<br />

Thinking Strategically About Spreaders<br />

Operational performance determines which terminals<br />

compete and win, and which flatten or decline. This is<br />

why spreader fleet planning must be based on the full<br />

spectrum of value – cost to purchase, but also cost to<br />

operate – lifetime energy and maintenance costs, fleet<br />

durability, and spreader productivity. Indeed, the<br />

Bromma Return On Investment calculator demonstrates<br />

clearly how different spreader performance indicators<br />

can have a vast impact on terminal return on investment.<br />

Growing terminals need business partners who<br />

understand the metrics of performance and the necessity<br />

of achieving high capital return on investment.<br />

Bromma supports the success and growth of our terminal<br />

partners, through our equipment, our organizational<br />

depth, our intellectual capital, and the enterprise values<br />

at Bromma which are consistent with success.<br />

Bromma is the strongest company in spreaders.

Bromma Hydraulic Spreaders:<br />

A Higher Level <strong>Of</strong> Reliability<br />

Bromma is the world leader in ship-to-shore crane<br />

spreaders, with more than 60% of the global market.<br />

Bromma has a dominant position for a simple reason:<br />

Bromma spreaders show up for work every day and<br />

perform at a high level of productivity. When reliability<br />

is crucial, as it especially is in ship-to-shore operations,<br />

Bromma is the obvious choice. Bromma’s family of<br />

hydraulic ship-to-shore spreaders includes single-lift<br />

spreaders, twin-lift spreaders, and the innovative,<br />

high-productivity Bromma Tandem product family,<br />

capable of twin-40' and twin-45' container handling.<br />

Reduce Downtime<br />

One of the most important technical developments in<br />

ship-to-shore spreaders in recent years has been<br />

Bromma SCS technology. In service on thousands of<br />

spreaders around the globe, Bromma SCS monitors<br />

spreader performance, reduces downtime events<br />

(through simplified wiring and fewer connections) and<br />

4<br />

shortens downtime duration (through faster fault diagnosis)<br />

when faults occur. The latest generation of this technology,<br />

SCS 3 , is easy to use and simpler to understand, due to<br />

an on-board touch-screen display. It also features the<br />

industry’s first generation of spreader prognostics, an<br />

“early warning system” for future spreader faults.<br />

Spreader prognostics means that terminals can now not<br />

only fix problems faster, but prevent faults (and downtime)<br />

from occurring. Bromma Services believes that the<br />

information made possible by SCS 3 can reduce downtime<br />

duration by an average of 20% or more.<br />

A Higher Level <strong>Of</strong> Productivity<br />

Bromma ship-to-shore spreaders are known for their<br />

exceptional productivity. Bromma’s top-selling STS45<br />

separating twin-lift spreader in particular has exceptional<br />

performance characteristics. Higher productivity<br />

boosts the terminal bottom line. Bromma calculates<br />

that a spreader at a busy container terminal that averages

one more box per hour (26,0 versus 25,0) can generate a<br />

further $50,000 USD in terminal profit over its lifetime.<br />

Bromma’s vast global experience (Bromma spreaders<br />

are in use today at 96 out of the top 100 container<br />

ports) is also a major factor in the dependability of<br />

Bromma equipment. Bromma knows what terminals<br />

need, what can go wrong, and how to deliver equipment<br />

that performs in the “real world” scenarios that terminals<br />

face every day.<br />

Weight & Energy<br />

Spreader weight directly impacts crane energy<br />

consumption, an area of growing concern for terminals<br />

facing fuel cost increases. Bromma Research and<br />

Development models indicate that a 1,5 tonne reduction<br />

in ship-to-shore spreader weight can produce more<br />

than $2,500 USD in annual energy savings. Bromma<br />

5<br />

Research and Development pays serious attention to<br />

spreader weight throughout its entire product line.<br />

A Spreader That Shows Up For Work<br />

Every Day<br />

Bromma ship-to-shore spreaders are also known for<br />

exceptional durability – often remaining in active service<br />

for 12 or more years at high-throughput terminals.<br />

Bromma hydraulic ship-to-shore spreaders show up for<br />

work every day, produce more while they’re on the<br />

job, and keep performing for a long time.

Single-Lift Hydraulic Spreaders<br />

BENEFITS<br />

• Unmatched experience: Bromma designed the first telescopic single-lift spreader and<br />

has sold thousands of them around the world<br />

• Experience means low downtime: at some terminals Bromma spreader availability<br />

exceeds 99%<br />

• Designed for higher throughput environments and for service on high-speed cranes<br />

• Lightweight SSX40LW is ideal for use on cranes rated to lift less weight<br />

• High reliability allows for a lower spreader spare ratio in the terminal fleet<br />

Bromma single-lift SSX40/45 spreaders are known throughout the world for exceptional<br />

strength, reliability, and long life. Bromma achieves superior structural strength through<br />

strategic engineering tools, such as finite element modeling, which analyzes stress points<br />

on the spreader and projects the likely effect of accumulated stress over time. Spreaders<br />

like the new SSX40LW in particular benefit from design studies, including buckling,<br />

vibration, and stress-related stiffening analyses, which enable Bromma to evaluate the<br />

long-time impact of design changes, and develop optimum design solutions.<br />

Floating ISO twistlocks allow for 6mm of float in all lateral directions, providing efficient<br />

locating in the container corner castings. The contact surfaces between the main frame<br />

and the telescoping beams consist of grease-lubricated low-friction plates. These spreaders<br />

have the ability to retract to the 19'6" position in the event the spreader becomes jammed<br />

in the ship’s twenty foot cell. Positioning to the 19'6" position can be controlled by the<br />

operator if appropriate controls are furnished in the crane cab. Bromma advanced performance<br />

technology, such as SCS3 , TTDS Twin-Twenty Detection System (an excellent safety feature),<br />

and the HIS Height Indication System is installed or available for installation on all<br />

Bromma spreaders.<br />

6

SSX40<br />

TECHNICAL SPECIFICATIONS SSX40/SSX45<br />

LIFTING CAPACITY 41 tonne ± 10% eccentric loading<br />

41 tonne evenly loaded<br />

LIFTING LUGS 4 x 10 tonne in end beam<br />

WEIGHT (w/o extra equipment) SSX40: 8,7 tonne / SSX45: 9,6 tonne<br />

TELESCOPIC MOTION SSX40: 20’ - 40’ in approx. 28 seconds<br />

SSX45: 20’ - 45’ in approx. 30 seconds<br />

FLIPPER ARM SPEED 180° in 3 to 5 seconds<br />

TWISTLOCK ROTATION 90° in approx. 1 second<br />

HYDRAULICS System pressure 100 bar<br />

POWER SUPPLY 400/230 V AC 50 Hz or as agreed<br />

<strong>TO</strong>TAL POWER CONSUMPTION 7,5 kW<br />

HEIGHT 1368 mm<br />

MINIMUM LENGTH 6060 mm<br />

WIDTH 2440 mm<br />

TWINLIFT UNIT UP/DOWN –<br />

TWIN SEPARATING SPEED –<br />

SSX45<br />

TECHNICAL SPECIFICATIONS SSX40/SSX45<br />

LIFTING CAPACITY 41 tonne ± 10% eccentric loading<br />

41 tonne evenly loaded<br />

LIFTING LUGS 4 x 10 tonne in end beam<br />

WEIGHT (w/o extra equipment) SSX40: 8,7 tonne / SSX45: 9,6 tonnes<br />

TELESCOPIC MOTION SSX40: 20’ - 40’ in approx. 28 seconds<br />

SSX45: 20’ - 45’ in approx. 30 seconds<br />

FLIPPER ARM SPEED 180° in 3 to 5 seconds<br />

TWISTLOCK ROTATION 90° in approx. 1 second<br />

HYDRAULICS System pressure 100 bar<br />

POWER SUPPLY 400/230 V AC 50 Hz or as agreed<br />

<strong>TO</strong>TAL POWER CONSUMPTION 7,5 kW<br />

HEIGHT 1368 mm<br />

MINIMUM LENGTH 6060 mm<br />

WIDTH 1466 mm<br />

TWINLIFT UNIT UP/DOWN –<br />

TWIN SEPARATING SPEED –<br />

SSX40LW<br />

TECHNICAL SPECIFICATIONS SSX40LW<br />

LIFTING CAPACITY 30,5 tonne ± 10% eccentric loading<br />

35 tonne evenly loaded<br />

LIFTING LUGS 4 x 8,5 tonne in end beam<br />

WEIGHT 5,8 tonne (w/o extra equipment)<br />

TELESCOPIC MOTION 20’ - 40’ in approx. 30 seconds<br />

FLIPPER ARM SPEED 180° in 5 seconds<br />

TWISTLOCK ROTATION 90° in approx. 1,5 second<br />

HYDRAULICS System pressure 100 bar<br />

POWER SUPPLY 400/230 V AC 50 Hz or as agreed<br />

<strong>TO</strong>TAL POWER CONSUMPTION 5,5 kW<br />

MINIMUM LENGTH 6060 mm<br />

WIDTH 2440 mm<br />

TWINLIFT UNIT UP/DOWN –<br />

TWIN SEPARATING SPEED –<br />

7

Twin-Lift Twin-Lift Hydraulic Hydraulic Spreaders<br />

Spreaders<br />

BENEFITS<br />

• Twin-lift ship-to-shore hydraulic spreaders are the most popular products in the<br />

Bromma product line, due to their higher productivity and versatility<br />

• With the STS45 separating twin-lift spreader, a larger percentage of above-deck<br />

containers can be moved in twin-lift mode.<br />

• The separating STS45 has excellent operational flexibility. It can move two 20' containers<br />

from 0 mm to 1600 mm apart under full load.<br />

• The STS45LW has the same basic functionality as the Bromm STS45, but with 1,6<br />

tonnes less weight.<br />

Bromma twin-lift hydraulic spreaders are feature-rich. Bromma advanced performance<br />

technology, such as SCS, 3 is standard on these spreaders. Bromma’s optional MPS memory<br />

positioning system, available on the STS45, makes the crane operator’s task easier, and<br />

increases productivity. The Bromma Twin-Twenty Detection System adds safety and the<br />

HIS Height Indication System is ideal for use on high-speed cranes.<br />

On the STS45 and STS45LW, separating twin movement can be done at any time in the<br />

crane cycle, which means there is no stopping time to change the container spacing. This<br />

results in higher flexibility in container ship loading and unloading. Bromma’s 30-person<br />

design engineering team ensures high structural integrity through strategic engineering,<br />

such as finite element modeling, which analyzes stress points on the spreader and projects<br />

the likely effect of accumulated stress over time. Bromma design studies, including<br />

buckling, vibration, and stress-related stiffening analyses, enable Bromma Research and<br />

Development to evaluate the long-time impact of design changes, and develop optimum<br />

design solutions.<br />

Bromma uses premium Swedish steel for spreader frame structures on the STR40/45,<br />

STS45, and STS45LW, steel selected on the basis of its strength, weldability, and form<br />

ability. ISO twistlocks allow for 6mm of float in all lateral directions, providing efficient<br />

locating in the container corner castings. These spreaders can retract to the 19'6" position<br />

in the event the spreader becomes jammed in the ship’s twenty foot cell. Positioning to<br />

the 19'6" position can be controlled by the operator if appropriate controls are furnished<br />

in the crane cab.<br />

Bromma’s STS45 spreader is the industry standard for ship-to-shore container handling,<br />

and a constant presence in the most demanding terminals in the world. Bromma understands<br />

what ship-to-shore container handling requires, and the twin-lift hydraulic STS<br />

spreaders from Bromma deliver it.<br />

8

STS45<br />

TECHNICAL SPECIFICATIONS STS45<br />

LIFTING CAPACITY 51 tonne ± 10% eccentric loading<br />

51 tonne evenly loaded<br />

2 x 32,5 tonne (2 x 20’ ISO)<br />

LIFTING LUGS 4 x 10 tonne in end beam<br />

WEIGHT 12,7 tonne (w/o extra equipment)<br />

TELESCOPIC MOTION 20’ - 45’ in approx. 30 seconds<br />

FLIPPER ARM SPEED 180° in 3 to 5 seconds<br />

TWISTLOCK ROTATION 90° in approx. 1 second<br />

HYDRAULICS System pressure 100/160 bar<br />

POWER SUPPLY 400/230 V AC 50 Hz or as agreed<br />

<strong>TO</strong>TAL POWER CONSUMPTION 7,5 kW<br />

HEIGHT 1466 mm<br />

MINIMUM LENGTH 6060 mm<br />

WIDTH 2440 mm<br />

TWINLIFT UNIT UP/DOWN Approx. 8 seconds<br />

TWIN SEPARATING SPEED Approx. 20 seconds<br />

STS45LW<br />

TECHNICAL SPECIFICATIONS STS45LW<br />

LIFTING CAPACITY 41 tonne ± 10% eccentric loading<br />

41 tonne evenly loaded<br />

2 x 25 tonne (2 x 20’ ISO)<br />

LIFTING LUGS 4 x 10 tonne in end beam<br />

WEIGHT 11,2 tonne (w/o extra equipment)<br />

TELESCOPIC MOTION 20’ - 45’ in approx. 30 seconds<br />

FLIPPER ARM SPEED 180° in 3 to 5 seconds<br />

TWISTLOCK ROTATION 90° in approx. 1 second<br />

HYDRAULICS System pressure 120 bar<br />

POWER SUPPLY 400/230 V AC 50 Hz or as agreed<br />

<strong>TO</strong>TAL POWER CONSUMPTION 7,5 kW<br />

HEIGHT 1466 mm<br />

MINIMUM LENGTH 6060 mm<br />

WIDTH 2440 mm<br />

TWINLIFT UNIT UP/DOWN Approx. 8 seconds<br />

TWIN SEPARATING SPEED Approx. 20 seconds<br />

STR40/45<br />

TECHNICAL SPECIFICATIONS STR40/STR45<br />

LIFTING CAPACITY 51 tonne ± 10% eccentric loading<br />

51 tonne evenly loaded<br />

2 x 32,5 tonne (2 x 20’ ISO)<br />

LIFTING LUGS 4 x 10 tonne in end beam<br />

WEIGHT (w/o extra equipment) STR40: 9,9 tonne / STR45: 11 tonnes<br />

TELESCOPIC MOTION SSX40: 20’ - 40’ in approx. 28 seconds<br />

SSX45: 20’ - 45’ in approx. 30 seconds<br />

FLIPPER ARM SPEED 180° in 3 to 5 seconds<br />

TWISTLOCK ROTATION 90° in approx. 1 second<br />

HYDRAULICS System pressure 100 bar<br />

POWER SUPPLY 400/230 V AC 50 Hz or as agr.<br />

<strong>TO</strong>TAL POWER CONSUMPTION 7,5 kW<br />

HEIGHT STR40: 1366 mm STR45: 1466 mm<br />

MINIMUM LENGTH 6060 mm (both)<br />

WIDTH 1466 mm (both)<br />

TWINLIFT UNIT UP/DOWN Approx. 8 seconds<br />

TWIN SEPARATING SPEED –<br />

9

Bromma Tandem:<br />

A Higher Level <strong>Of</strong> Productivity<br />

The Bromma Tandem spreader is a new productivity<br />

tool for an industry that’s hungry for productivity. At<br />

container terminals around the world, there are more<br />

and more 40' containers, and fewer 20' containers.<br />

The type of spreader used to handle these containers,<br />

and the brand of spreader selected, can have a major<br />

impact on operating efficiency. Bromma Tandem is<br />

one tool in the effort to boost productivity, as it offers<br />

the opportunity to greatly expand the productivity of<br />

each lift cycle.<br />

Chances are that whatever your terminal’s container<br />

mix is today, it will be somewhat different tomorrow,<br />

and that whatever your terminal’s container volume<br />

is today, it will be somewhat greater tomorrow.<br />

Bromma Tandem is a spreader advance in both<br />

areas – providing both a productivity boost and an<br />

extremely versatile lifting tool.<br />

10<br />

Bromma Tandem will increase productivity when<br />

loading and unloading those sections of container<br />

ships stacked with 40' containers. It is also ideal for<br />

terminals with a high volume of empty containers<br />

and cranes with limited lifting capacity. Bromma<br />

Tandem has the ability to simultaneously lift four<br />

20' containers (Tandem T45 or Tandem Quattro),<br />

or two 40' containers, or two 45' containers, or many<br />

other combinations, including hatch covers. It can<br />

easily handle container height differences of up to<br />

700mm, and has productivity of up to 60 40' or 45'<br />

containers per hour.

A Proven Design<br />

Moreover, except for lifting capacity, there is no need<br />

for a special crane design. With Bromma’s pioneering<br />

SCS 3 spreader technology, terminals can swap spreaders<br />

between different cranes, and install new spreader models,<br />

such as Tandem, without any concern about the interface<br />

with other spreader models.<br />

While Bromma Tandem is innovative, it is also<br />

important to note that it is based on a simple technical<br />

approach that features spreader design and technology<br />

with proven reliability. The fixed-length Tandem was<br />

first put into field tests in 2003. It is also not a<br />

complicated design solution. The type of Tandem<br />

spreader selected depends on the crane lift capacity.<br />

11<br />

Except for sufficient lifting capacity, there is no need<br />

for a special crane design.<br />

The inherent versatility of the Bromma Tandem family<br />

makes it an ideal choice for terminals looking to the<br />

horizon and operating with a long-term perspective<br />

when making spreader fleet planning decisions.

Tandem Productivity<br />

BENEFITS<br />

• The Tandem T45 spreader offers terminals the highest level of productivity and<br />

versatility, with the capacity and flexibility to handle all possible combinations of<br />

20', 40', and 45' containers quickly and efficiently. It can also handle four 20' containers<br />

simultaneously and separate the 20' containers longitudinally between 0 and 1,6 meters.<br />

• The Tandem 40/45 spreader is able to twin-lift two 20', 40', or 45' containers without<br />

the need, as in the Tandem fixed-length version, for change-out.<br />

• This is a proven spreader design field-tested in high-throughput European and Asian<br />

terminals.<br />

• Customers with a high number of empty 40' containers may want to give special<br />

consideration to the productivity advantages of the Tandem.<br />

• The Tandem headblock is necessary for the efficient handling of the Tandem<br />

spreader line.<br />

The Separating T45 spreader offers the highest level of productivity and versatility, but<br />

requires a higher-capacity container crane. Tandem T45 spreader weight is an estimated<br />

31 tonnes. To fully utilize the lift capacity of the spreader requires a high crane capacity,<br />

but most customers will rate 20 foot containers to a maximum of 20-25 tonne, thereby<br />

resulting in a required crane capacity of 115-135 tonne in the ropes.<br />

The Tandem 40/45 spreader is based on proven Bromma spreader design, as it uses the<br />

SSX40/45 spreader as its standard base. A terminal planning to utilize the full 70 tonne<br />

capacity under the spreader will need crane capacity of approximately 100 tonne in the<br />

ropes. As such, the Tandem 40/45 can be used without restriction on many last-generation<br />

container cranes already in service today. Customers who handle very few 45' containers<br />

may wish to consider the 40' version of the Tandem 40/45. This will save approximately<br />

2 tonne in spreader weight.<br />

Bromma Tandem spreaders are feature-rich. The adjustable pusher with memory function<br />

keeps a pre-set space between the spreaders, reducing the swinging of the two spreaders<br />

and simplifying the entering of ship cell guides. Long side flippers mounted on an inclined<br />

base, and rounded end beams, avoid jamming in cell guides. The four wagons can be moved<br />

individually to allow skewing and gravity point adjustment, should this be needed. A memory<br />

system allows a pre-set positioning distance between the spreaders. Chain suspension allows<br />

Tandem to handle containers of different height. Eight powerful flippers with large scoops<br />

in optimal configuration allow Tandem to handle different combinations efficiently.<br />

The Bromma Tandem Headblock with adjustable pulley wheel distance keeps the gravity<br />

point of the two containers between the pulley wheels center in Tandem mode. When<br />

operating with a standard spreader, the pulley wheels will retract to normal headblock<br />

width. Pulley wheels move from standard (750-1000 mm) up to 2,6 metres. Bromma can<br />

also provide a fully automatic electrical plug/socket interface and will offer to modify the<br />

existing crane electrical interface and communication system to enable the handling of<br />

Tandem spreaders.<br />

12

Separating T45<br />

TECHNICAL SPECIFICATIONS T45<br />

LIFTING CAPACITY 2 x 51 tonne<br />

WEIGHT 31 tonne<br />

FLIPPER ARM SPEED 180° in 3 to 5 seconds<br />

TWISTLOCK ROTATION 90° in approx. 1 second<br />

HYDRAULICS System pressure 100/160 bar<br />

<strong>TO</strong>TAL POWER CONSUMPTION 15 kW<br />

SPREADER HEIGHT 2900 mm<br />

CONTAINER HEIGHT DIFFERENCE<br />

LOADING/UNLOADING 2' 660 mm (standard)<br />

SKEWING ±20 degrees<br />

SKEWING SPEED 1 degree in 20 seconds<br />

TANDEM SEPARATING SPEED 100 mm in 10 seconds<br />

TWINLIFT UNIT UP/DOWN Approx. 8 seconds<br />

TWIN SEPARATING SPEED Approx. 16 seconds<br />

Tandem 40/45<br />

TECHNICAL SPECIFICATIONS TANDEM 40/TANDEM 45<br />

LIFTING CAPACITY 2 x 41 tonne<br />

WEIGHT TANDEM 40: 23,2 tonne<br />

TANDEM 45: 25 tonne<br />

FLIPPER ARM SPEED 180° in 3 to 5 seconds<br />

TWISTLOCK ROTATION 90° in approx. 1 second<br />

HYDRAULICS System pressure 140 bar<br />

<strong>TO</strong>TAL POWER CONSUMPTION 15 kW<br />

SPREADER HEIGHT Tandem 40: 2800 mm Tandem 45: 2900 mm<br />

CONTAINER HEIGHT DIFFERENCE<br />

LOADING/UNLOADING 2' 660 mm (standard)<br />

SKEWING ±20 degrees<br />

SKEWING SPEED 1 degree in 20 seconds<br />

TANDEM SEPARATING SPEED 100 mm in 10 seconds<br />

Headblock<br />

TECHNICAL SPECIFICATIONS HEADBLOCK<br />

LOAD CAPACITY UNDER HEADBLOCK 71 tonne (for Tandem 45)<br />

HEADBLOCK TARE WEIGHT 5 tonne (for Tandem 45)<br />

HEIGHT 5500 mm<br />

LENGTH 3800 mm<br />

WIDTH 2100 mm<br />

WIDTH IN TWIN-LIFT MODE 3700 mm<br />

CONNECTION <strong>TO</strong> SPREADER Twistlock<br />

PULLEY WHEEL DISTANCE Approx. 5 min. (manual)<br />

Approx. 1 min. (fully automatic)<br />

13

Tandem Versatility<br />

BENEFITS<br />

• The Tandem Fix 40 is an ideal choice for customers interested in gaining the added<br />

productivity of twin-40 container handling, but who are somewhat restricted in their<br />

choices due to cranes with limited lifting capacity.<br />

• A container terminal with a high percentage of 40 foot containers will gain an immediate<br />

boost to its lift cycle productivity, since the Tandem Fix 40 spreader can lift two<br />

40' containers at a time, not one.<br />

• The Tandem Quattro offers the same capacity and nearly the same flexibility as the<br />

Tandem T45, including the ability to handle four 20 foot containers at a time – two<br />

20 foot containers under each spreader – but it does so with a lower spreader weight.<br />

• The Tandem Quattro spreader also offers another advantage: the capability to do<br />

side shift on individual spreaders, which is useful when the chassis or container on<br />

the ground is not fully lined up in the longitudinal direction.<br />

The Tandem Fix 40 is, from a design standpoint, the simplest Tandem model available<br />

today. It uses Bromma spreader design and technology that has been proven to be reliable<br />

over many years and many millions of lift cycles. Customers should keep in mind that the<br />

operating limitation of the Tandem Fix 40 is that it is for 40' containers only. This is<br />

why the Tandem Fix 40 is best-suited for terminals where ships tend to be stacked with<br />

a high percentage of 40’ containers, or when the crane has a limited lift capacity.<br />

The Tandem Quattro is a high-productivity, lower weight Tandem solution. The limitation<br />

on Tandem Quattro is that it is not designed to lift a single 20' container. The Tandem<br />

Quattro is especially well-suited for container terminals that have a high percentage of 40'<br />

and 45' containers, and a low percentage of 20' containers that are located in such a way<br />

that they need to be loaded/unloaded in single lift mode.<br />

14

Tandem Fix 40<br />

TECHNICAL SPECIFICATIONS TANDEM FIX 40<br />

LIFTING CAPACITY 2 x 35 tonne<br />

WEIGHT 16 tonne<br />

FLIPPER ARM SPEED 180° in 3 to 5 seconds<br />

TWISTLOCK ROTATION 90° in approx. 1 second<br />

HYDRAULICS System pressure 140 bar<br />

<strong>TO</strong>TAL POWER CONSUMPTION 7,5 kW<br />

SPREADER HEIGHT 2400 mm<br />

CONTAINER HEIGHT DIFFERENCE<br />

LOADING/UNLOADING 2' 660 mm (standard)<br />

SKEWING ±20 degrees<br />

SKEWING SPEED 1 degree in 20 seconds<br />

TANDEM SEPARATING SPEED 100 mm in 10 seconds<br />

Tandem Quattro<br />

TECHNICAL SPECIFICATIONS TANDEM QUATTRO<br />

LIFTING CAPACITY 2 x 51 tonne<br />

4 x 32,5 tonne<br />

WEIGHT 24 tonne<br />

FLIPPER ARM SPEED 180° in 3 to 5 seconds<br />

FLIPPER ARM <strong>TO</strong>RQUE approx. 1,650 Nm<br />

HYDRAULICS System pressure 140 bar<br />

<strong>TO</strong>TAL POWER CONSUMPTION 15 kW<br />

SPREADER HEIGHT 2900 mm<br />

CONTAINER HEIGHT DIFFERENCE<br />

LOADING/UNLOADING 2' 660 mm (standard)<br />

SKEWING ±20 degrees<br />

SKEWING SPEED 1 degree in 20 seconds<br />

TANDEM SEPARATING SPEED 100 mm in 10 seconds<br />

15

The New E-Series: Less Service,<br />

Lower Weight, More Uptime<br />

The operational centre of any great container terminal<br />

is a highly productive and reliable ship-to-shore<br />

spreader operation. Bromma Group’s new E-Series of<br />

all-electric ship-to-shore spreaders are loaded with<br />

advantages designed to create lifecycle cost savings<br />

while boosting fleet uptime.<br />

Easier To Maintain<br />

Hydraulics is history on the E-Series spreader family,<br />

which makes them easier to maintain. Many service<br />

points have been taken away. There’s no hydraulic<br />

powerpack and no hoses. There are no fluids, or oil filter,<br />

to replace.<br />

This elimination of hydraulics means reduced service<br />

time and reduced service materials cost (for oil, hoses,<br />

and filters). It will also eliminate many of the “nuisance”<br />

downtime events that occur due to spreader hydraulics<br />

16<br />

(bad hose connections, etc.) Making hydraulics history<br />

reduces both scheduled and unscheduled spreader<br />

downtime.<br />

Lighter, For Less Energy Cost<br />

Bromma all-electric spreaders, particularly the STS45E<br />

separating twin-lift, are also lighter, with the STS45E<br />

featuring a best-in-class weight of only 11,7 tonnes.<br />

There is a direct correlation between spreader weight<br />

and energy cost. The heavier the spreader, the higher<br />

the energy costs. For example, a 1,5 tonne weight savings<br />

means some $40,000 USD in energy savings over its<br />

lifetime. So spreader weight is a very significant factor<br />

when spreader fleet planning takes place.<br />

The elimination of the idling hydraulic pump on these<br />

all-electric spreaders also adds to the energy savings.<br />

Bromma Research & Development estimates that the

idling action of a hydraulic pump results in energy<br />

consumption of approximately 3 kWh. Eliminating this<br />

idling hydraulic motor thus should mean an approximate<br />

$13,500 USD in lifetime energy savings. (Actual cost<br />

savings should trend higher due to expected inflation in<br />

energy costs.)<br />

New, But Not Unproven<br />

These ship-to-shore all-electric spreaders are new, but<br />

not unproven, since they are based on the same frame<br />

structure used by Bromma customers throughout the<br />

world. Everything on this spreader that has to do with<br />

lifting containers, landing, and shocks, is proven, since<br />

it’s the same spreader that has been performing these<br />

functions for years.<br />

Smart & Easy To Use<br />

E-Series all-electrics equipped with Bromma SCS 3 ,<br />

such as the STS45E, are both smart and easy to use,<br />

due to their simple-to-understand touchscreen display,<br />

fast fault diagnostics, and the industry’s first spreader<br />

prognostics. SCS 3 can dramatically reduce wired terminal<br />

points and I/O relays for greater simplicity, while giving<br />

terminals advanced functionality, such as on-line sensor<br />

17<br />

adjustments, and communications capabilities such as<br />

transmission of spreader events, logs, alarms, and<br />

MMBF statistics to terminal headquarters for analysis.<br />

Quieter<br />

E-Series spreaders are also quieter. The sound you<br />

don’t hear is your spreader beam telescoping. Plus,<br />

there’s no continuously running hydraulic powerpack.<br />

So if you are concerned about how terminal noise levels<br />

impact the surrounding community, Bromma all-electrics<br />

are another step in the right direction.<br />

Durable Construction<br />

Bromma all-electric spreaders also benefit from the<br />

consistency of Bromma manufacturing processes.<br />

Bromma pursues higher quality at every level – in<br />

materials, in components, and in the Bromma spreader<br />

manufacturing process. The result is the durable<br />

construction and long life that Bromma spreaders are<br />

known for throughout the terminal world.<br />

The Bromma all-electric E-Series family: less service,<br />

lower weight, more uptime, and they are only from<br />

Bromma.

Single-Lift All-Electric<br />

BENEFITS<br />

• Proven design: the Bromma SSX40E and SSX45E structure is based on the reliable<br />

hydraulic versions of this spreader<br />

• Designed for lower or higher throughput environments and for service on high-speed cranes<br />

• Reduced routine maintenance due to all-electric design<br />

• Reduced energy consumption due to elimination of the hydraulic power-pack<br />

Bromma single-lift SSX40/45E spreaders offer strength, reliability, and durability, plus<br />

the advantage of lower lifecycle costs. On these all-electric spreaders, many service points<br />

have been taken away. There’s no hydraulic powerpack and no hoses. There are no fluids,<br />

or oil filter, to replace. This elimination of hydraulics means reduced service time and<br />

reduced service materials cost (for oil, hoses, and filters). It will also eliminate many of<br />

the “nuisance” downtime events that occur due to spreader hydraulics (bad hose connections,<br />

etc.). Making hydraulics history reduces both scheduled and unscheduled spreader downtime.<br />

Strategic Engineering For A Longer Life<br />

In the design of these spreaders, Bromma achieves superior structural strength through<br />

strategic engineering tools, such as finite element modeling, which analyzes stress points<br />

on the spreader and projects the likely effect of accumulated stress over time. The benefits<br />

of a more robust design, a higher grade of materials, and a more rugged construction, are<br />

often not visible until a spreader has been in service for several years. Yet, the “invisible”<br />

advantages of exceptional design and construction are obvious in the traditionally longer<br />

lifetime of Bromma spreaders.<br />

These spreaders have the ability to retract to the 19'6" position in the event the spreader<br />

becomes jammed in the ship’s twenty foot cell. Positioning to the 19'6" position can be<br />

controlled by the operator if appropriate controls are furnished in the crane cab. These<br />

spreaders fulfill the most demanding design criteria among DIN, FEM and British<br />

Standard. Bromma advanced performance technology, such as SCS3 , the TTDS Twin-<br />

Twenty Detection System (an excellent safety feature), and the HIS Height Indication<br />

System are installed or available for installation on all Bromma spreaders.<br />

18

SSX40E<br />

TECHNICAL SPECIFICATIONS SSX40E<br />

LIFTING CAPACITY 41 tonne ± 10% eccentric loading<br />

41 tonne evenly loaded<br />

LIFTING LUGS 4 x 10 tonne in end beam<br />

WEIGHT 8,7 tonne (w/o extra equipment)<br />

TELESCOPIC MOTION 20’ - 40’ in approx. 28 seconds<br />

FLIPPER ARM SPEED 180° in 3 to 5 seconds<br />

TWISTLOCK ROTATION 90° in approx. 1 second<br />

HYDRAULICS None<br />

HEIGHT 1366 mm<br />

MINIMUM LENGTH 6060 mm<br />

WIDTH 2440 mm<br />

SSX45E<br />

TECHNICAL SPECIFICATIONS SSX45E<br />

LIFTING CAPACITY 41 tonne ± 10% eccentric loading<br />

41 tonne evenly loaded<br />

LIFTING LUGS 4 x 10 tonne in end beam<br />

WEIGHT 9,6 tonne (w/o extra equipment)<br />

TELESCOPIC MOTION 20’ - 45’ in approx. 30 seconds<br />

FLIPPER ARM SPEED 180° in 3 to 5 seconds<br />

TWISTLOCK ROTATION 90° in approx. 1 second<br />

HYDRAULICS None<br />

HEIGHT 1466 mm<br />

MINIMUM LENGTH 6060 mm<br />

WIDTH 2440 mm<br />

19

Twin-Lift All-Electrric All-Electric<br />

BENEFITS<br />

• Proven design: the Bromma STR40E/45E and STS45E are based on Bromma<br />

spreaders in service throughout the world<br />

• Lower energy consumption<br />

• Reduced spreader maintenance requirements, due to the elimination of hydraulics<br />

• Simpler – less settings and fewer sensors<br />

• Twin-lift ship-to-shore spreaders are the most popular products in the Bromma product<br />

line, due to their higher productivity and versatility<br />

• With the STS45E separating twin-lift spreader, a larger percentage of above-deck<br />

containers can be transported in twin-lift mode.<br />

Higher productivity translates into higher potential revenue. The STS45E separating twin-lift has<br />

exceptional performance characteristics. At a busy container terminal, even a one box per hour<br />

improvement in container handling (26,0 versus 25,0) can generate a further $50,000 USD in<br />

terminal profit over a spreader lifetime.<br />

Bromma’s optional MPS memory positioning system makes the crane operator’s task easier, and<br />

increases productivity. The Twin-Twenty Detection System adds safety and the HIS Height<br />

Indication System is ideal for use on high-speed cranes. Bromma all-electric twin-lift spreaders<br />

also have maintenance and energy consumption advantages. At only 11,7 tonnes, the STS45E will<br />

save energy compared to competing brands. For example, a 1,5 tonne weight savings means some<br />

$40,000 USD in energy savings over its lifetime. The elimination of the idling hydraulic pump on<br />

these all-electric spreaders also adds to the energy savings. The idling action of a hydraulic pump<br />

results in energy consumption of approximately 3 kWh. Eliminating this idling hydraulic motor<br />

thus should mean an approximate $13,500 USD in lifetime energy savings.<br />

Bromma has been able to make the STS45E lighter through more intelligent design – an improvement<br />

in technique. Mechanical functions that perform the separating twin motion have been replaced by a<br />

new electrical concept, which allows weight reduction. The separating twin motion doesn’t require<br />

any mechanical connection – hooks or lashes – which lowers weight. This spreader features the best of<br />

the old … and the new. The new on the STS45E includes a completely re-designed all electric flipper, an<br />

all-electric synchronized separating system, and a faster up/down motion for twinlift boxes. Yet, much<br />

is the same, including Bromma’s proven twistlock system and Bromma’s extremely durable spreader<br />

construction.<br />

The control and communications capabilities of Bromma all-electric twins are unsurpassed.<br />

Bromma SCS 3 – with its user-friendly touchscreen display and advanced diagnostics and prognostics<br />

functionality, is standard on these spreaders. Easy to use, simple to understand, and intelligently<br />

advanced, SCS 3 dramatically reduces wired terminal points and I/O relays for greater simplicity,<br />

while giving terminals advanced functionality, such as on-line sensor adjustments, and communications<br />

capability, such as transmission of spreader events, logs, alarms, and MMBF statistics to<br />

terminal headquarters for analysis.<br />

Operational flexibility is a hallmark of these spreaders. Separating twin movement can be done at<br />

any time in the crane cycle, which means there is no stopping time to change the container spacing.<br />

This results in superior container ship loading and unloading flexibility. Plus, these spreaders can<br />

retract to the 19'6" position in the event the spreader becomes jammed in the ship’s twenty foot<br />

cell. Positioning to the 19'6" position can be controlled by the operator if appropriate controls are<br />

furnished in the crane cab.<br />

Finally, Bromma is uncompromising in its selection of materials and components, using premium<br />

Swedish steel for all spreader frame structures, steel selected on the basis of its strength, weldability<br />

and formability.<br />

20

STR40E/45E<br />

TECHNICAL SPECIFICATIONS STR40E/45E<br />

LIFTING CAPACITY 51 tonne ± 10% eccentric loading<br />

51 tonne evenly loaded<br />

LIFTING LUGS 4 x 32,5 tonne (2x20’ ISO)<br />

WEIGHT 11,2 tonne<br />

TELESCOPIC MOTION STR40E: 20’ - 40’ in 28 seconds<br />

STR45E: 20’ - 45’ in 30 seconds<br />

FLIPPER ARM SPEED 180° in 5 seconds<br />

TWISTLOCK ROTATION 90° in approx. 1 second<br />

HYDRAULICS None<br />

TWINLIFT UNIT UP/DOWN Approx. 6 seconds<br />

LENGTH 6060 mm<br />

STS45E<br />

TECHNICAL SPECIFICATIONS STS45E<br />

LIFTING CAPACITY 51 tonne ± 10% eccentric loading<br />

51 tonne evenly loaded<br />

2 x 32,5 tonnes (2x20’ ISO)<br />

LIFTING LUGS 2 x 32,5 tonne (2x20’ ISO)<br />

WEIGHT 11,7 tonne (w/o extra equipment)<br />

TELESCOPIC MOTION 20’ - 45’ in approx. 30 seconds<br />

FLIPPER ARM SPEED 180° in 5 seconds<br />

TWISTLOCK ROTATION 90° in approx. 1 second<br />

HYDRAULICS None<br />

TWINLIFT UNIT UP/DOWN Approx. 6 seconds<br />

TWIN SEPARATING SPEED Approx. 18 seconds<br />

LENGTH 6060 mm<br />

21

Technical Specifications<br />

HYDRAULIC<br />

TANDEM<br />

E-SERIES<br />

Bromma<br />

Spreader<br />

SSX40<br />

SSX45<br />

SSX40LW<br />

STR40<br />

STR45<br />

STS45<br />

STS45LW<br />

TANDEM T45<br />

TANDEM 40<br />

TANDEM 45<br />

TANDEM FIX 40<br />

TANDEM QUATTRO<br />

HEADBLOCK<br />

SSX40E<br />

SSX45E<br />

STR40E/45E<br />

STS45E<br />

Page<br />

CORROSION PROTECTION FOR STS <strong>SPREADERS</strong>:<br />

Blast cleaning to SA2,5 - ISO 8501:1<br />

Interzinc 72: 50 my<br />

Intercure 429: 70 my<br />

Interfine 629 HS: 2 x 40 my<br />

Min. coating thickness: total 200 my<br />

6<br />

6<br />

6<br />

8<br />

8<br />

8<br />

8<br />

12<br />

12<br />

12<br />

14<br />

14<br />

12<br />

18<br />

18<br />

20<br />

20<br />

STANDARD TECHNICAL SPECIFICATIONS<br />

22<br />

Lifting<br />

Capacity<br />

41 tonne ± 10% eccentric loading<br />

41 tonnes evenly loaded<br />

41 tonne ± 10% eccentric loading<br />

41 tonnes evenly loaded<br />

30,5 tonne ± 10% eccentric loading<br />

35 tonnes evenly loaded<br />

51 tonne ± 10% eccentric loading<br />

51 tonnes evenly loaded<br />

2 x 32,5 tonnes (2x20” ISO)<br />

51 tonne ± 10% eccentric loading<br />

51 tonnes evenly loaded<br />

2 x 32,5 tonnes (2x20” ISO)<br />

51 tonne ± 10% eccentric loading<br />

51 tonnes evenly loaded<br />

2 x 32,5 tonnes (2x20” ISO)<br />

41 tonne ± 10% eccentric loading<br />

41 tonnes evenly loaded<br />

2 x 32,5 tonnes (2x20” ISO)<br />

51 tonne ± 10% eccentric loading<br />

4 x 32,5 tonnes<br />

2 x 41 tonnes<br />

2 x 41 tonnes<br />

2 x 35 tonnes<br />

51 tonne ± 10% eccentric loading<br />

4 x 32,5 tonnes<br />

71 tonne (for Tandem 45)<br />

41 tonne ± 10% eccentric loading<br />

41 tonnes evenly loaded<br />

41 tonne ± 10% eccentric loading<br />

41 tonnes evenly loaded<br />

51 tonne ± 10% eccentric loading<br />

51 tonnes evenly loaded<br />

2 x 32,5 tonnes (2x20” ISO)<br />

51 tonne ± 10% eccentric loading<br />

51 tonnes evenly loaded<br />

2 x 32,5 tonnes (2x20” ISO)<br />

TWISTLOCK ROTATION:<br />

90° in approx 1 second<br />

WARRANTY:<br />

One year<br />

Weight<br />

8,7 tonne<br />

9,6 tonne<br />

5,8 tonne<br />

9,9 tonne<br />

11 tonne<br />

12,7 tonne<br />

11,2 tonne<br />

31 tonne<br />

23,2 tonne<br />

25 tonne<br />

16 tonne<br />

24 tonne<br />

5 tonne<br />

8,7 tonne<br />

9,6 tonne<br />

11,2 tonne<br />

11,7 tonne

Hydraulics<br />

System pressure 100 bar<br />

System pressure 100 bar<br />

System pressure 100 bar<br />

System pressure 100 bar<br />

System pressure 100 bar<br />

System pressure 100/160 bar<br />

System pressure 120 bar<br />

System pressure 100/160 bar<br />

System pressure 140 bar<br />

System pressure 140 bar<br />

System pressure 140 bar<br />

System pressure 140 bar<br />

None<br />

None<br />

None<br />

None<br />

None<br />

MANUALS:<br />

Full service and repair manual<br />

DESIGN CRITERIA:<br />

DIN 15018 H2B4; FEM 1.001;<br />

British Standard BS 2573<br />

All technical specifications may be changed and are subject to notice.<br />

Contact your Bromma representative or<br />

HYPERLINK "http://www.bromma.com/" www.bromma.com for<br />

current technical specifications.<br />

23<br />

Operating Details<br />

Twinlift unit up/down approx. 8 seconds<br />

Twinlift unit up/down approx. 8 seconds<br />

Twinlift unit up/down approx. 8 seconds<br />

Twin separating speed approx. 20 seconds<br />

Twinlift unit up/down approx. 8 seconds<br />

Twin separating speed approx. 20 seconds<br />

Loading/unloading: 2’ 660mm (standard); Skewing: ±20°;<br />

Skewing speed: 1° in 20 sec.; Separating speed: 100mm in 10 sec.<br />

Loading/unloading: 2’ 660mm (standard); Skewing: ±20°;<br />

Skewing speed: 1° in 20 sec.; Separating speed: 100mm in 10 sec.<br />

Loading/unloading: 2’ 660mm (standard); Skewing: ±20°;<br />

Skewing speed: 1° in 20 sec.; Separating speed: 100mm in 10 sec.<br />

Loading/unloading: 2’ 660mm (standard); Skewing: ±20°;<br />

Skewing speed: 1° in 20 sec.; Separating speed: 100mm in 10 sec.<br />

Loading/unloading: 2’ 660mm (standard); Skewing: ±20°;<br />

Skewing speed: 1° in 20 sec.; Separating speed: 100mm in 10 sec.<br />

Pulley wheel distance: 5 minutes (manual), 1 minute (fully automatic)<br />

Twinlift unit up/down approx. 6 seconds<br />

Twinlift unit up/down approx. 6 seconds<br />

Twin separating speed approx. 18 seconds

A <strong>Tradition</strong> <strong>Of</strong> <strong>Innovation</strong><br />

BROMMA CONQUIP AB<br />

Malaxgatan 7<br />

164 74 Kista, Sweden<br />

PHONE: +46 8 620 0900<br />

FAX: +46 8 739 3786<br />

E-MAIL: sales@bromma.com<br />

BROMMA INC.<br />

4400 Ben Franklin Blvd.<br />

Suite 200<br />

Durham, NC 27704 USA<br />

PHONE: +1 919 471 4000<br />

FAX: +1 919 471 4343<br />

E-MAIL: brommaus.sales@bromma.com<br />

BROMMA FAR EAST<br />

Blk. 102E Pasir Panjang Road<br />

#08-07, Citilink Warehouse Complex<br />

Singapore 118529<br />

PHONE: +65 6272 0400<br />

FAX: +65 6272 0411<br />

E-MAIL: bfe@bromma.com<br />

BROMMA SHANGHAI<br />

Shanghai, China Representation <strong>Of</strong>fice<br />

B, 20 Fir, Liang Feng Mansion<br />

No. 8 Dong Fang Road, Pudong<br />

Shanghai 200120, China<br />

PHONE: +86 21 588 871 64<br />

PHONE: +86 21 588 874 09<br />

FAX: +86 21 588 874 08<br />

E-MAIL: jeff_jiefu@bromma.com.cn<br />

BROMMA Sdn. Bhd.<br />

Lot 19, Jalan Kelebang 1/6<br />

Kinta Free Industrial Zone<br />

Poskod 31200 Chemor<br />

Perak, Malaysia<br />

PHONE: +60 529 388 90<br />

FAX: +60 529 140 99<br />

E-MAIL: malaysia@bromma.com<br />

BROMMA UK<br />

The Loughton Seedbed Centre D11<br />

Langston Road<br />

Loughton<br />

Essex, IG10 3TQ<br />

UK<br />

PHONE: +44 (0)20 8787 7031<br />

FAX: +44 (0)20 8787 7086<br />

E-MAIL: carl.kesselmark@bromma.com<br />

BROMMA GmbH<br />

Im Klint 12<br />

D-30938 Burgwedel<br />

Germany<br />

PHONE: +49 513 980 6630<br />

FAX: +49 513 980 6644<br />

E-MAIL: spreader.sales@bromma-gmbh.de<br />

BROMMA MIDDLE EAST<br />

BROMMA M.E. FZCO<br />

P.O. Box 17909 Dubai,<br />

United Arab Emirates<br />

PHONE OFFICE: +971 488 725 20<br />

PHONE MOBILE: +971 505 518 255<br />

FAX: +971 488 725 25<br />

E-MAIL: graham.boxall@bromma.com<br />

www.bromma.com<br />

PRINTED MAY 2007<br />

Bromma is part of<br />

Cargotec Corporation