Aerzen Rotary Piston Gas Meters

Aerzen Rotary Piston Gas Meters

Aerzen Rotary Piston Gas Meters

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

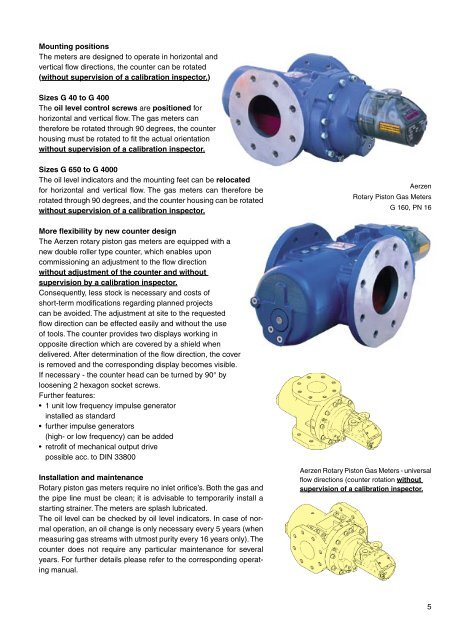

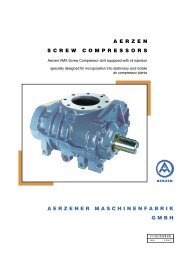

Mounting positionsThe meters are designed to operate in horizontal andvertical flow directions, the counter can be rotated(without supervision of a calibration inspector.)Sizes G 40 to G 400The oil level control screws are positioned forhorizontal and vertical flow. The gas meters cantherefore be rotated through 90 degrees, the counterhousing must be rotated to fit the actual orientationwithout supervision of a calibration inspector.Sizes G 650 to G 4000The oil level indicators and the mounting feet can be relocatedfor horizontal and vertical flow. The gas meters can therefore berotated through 90 degrees, and the counter housing can be rotatedwithout supervision of a calibration inspector.<strong>Aerzen</strong><strong>Rotary</strong> <strong>Piston</strong> <strong>Gas</strong> <strong>Meters</strong>G 160, PN 16More flexibility by new counter designThe <strong>Aerzen</strong> rotary piston gas meters are equipped with anew double roller type counter, which enables uponcommissioning an adjustment to the flow directionwithout adjustment of the counter and withoutsupervision by a calibration inspector.Consequently, less stock is necessary and costs ofshort-term modifications regarding planned projectscan be avoided. The adjustment at site to the requestedflow direction can be effected easily and without the useof tools. The counter provides two displays working inopposite direction which are covered by a shield whendelivered. After determination of the flow direction, the coveris removed and the corresponding display becomes visible.If necessary - the counter head can be turned by 90° byloosening 2 hexagon socket screws.Further features:• 1 unit low frequency impulse generatorinstalled as standard• further impulse generators(high- or low frequency) can be added• retrofit of mechanical output drivepossible acc. to DIN 33800Installation and maintenance<strong>Rotary</strong> piston gas meters require no inlet orifice’s. Both the gas andthe pipe line must be clean; it is advisable to temporarily install astarting strainer. The meters are splash lubricated.The oil level can be checked by oil level indicators. In case of normaloperation, an oil change is only necessary every 5 years (whenmeasuring gas streams with utmost purity every 16 years only). Thecounter does not require any particular maintenance for severalyears. For further details please refer to the corresponding operatingmanual.<strong>Aerzen</strong> <strong>Rotary</strong> <strong>Piston</strong> <strong>Gas</strong> <strong>Meters</strong> - universalflow directions (counter rotation withoutsupervision of a calibration inspector.5