Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

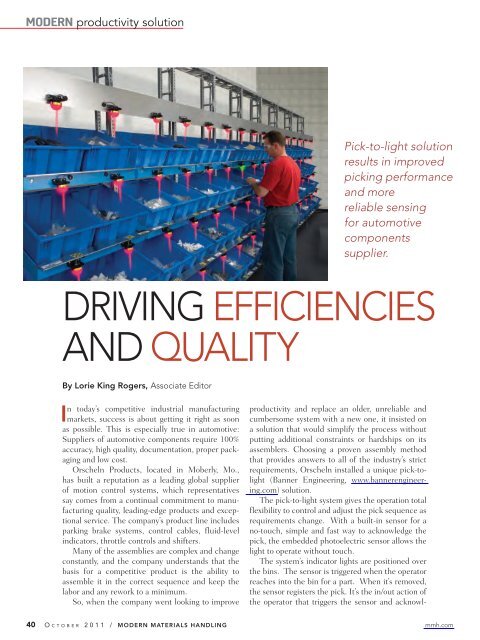

modern productivity solutionPick-to-light solutionresults in improvedpicking performanceand morereliable sensingfor automotivecomponentssupplier.Driving efficienciesand qualityBy Lorie King Rogers, Associate EditorIn today’s competitive industrial manufacturingmarkets, success is about getting it right as soonas possible. This is especially true in automotive:Suppliers of automotive components require 100%accuracy, high quality, documentation, proper packagingand low cost.Orscheln Products, located in Moberly, Mo.,has built a reputation as a leading global supplierof motion control systems, which representativessay comes from a continual commitment to manufacturingquality, leading-edge products and exceptionalservice. The company’s product line includesparking brake systems, control cables, fluid-levelindicators, throttle controls and shifters.Many of the assemblies are complex and changeconstantly, and the company understands that thebasis for a competitive product is the ability toassemble it in the correct sequence and keep thelabor and any rework to a minimum.So, when the company went looking to improveproductivity and replace an older, unreliable andcumbersome system with a new one, it insisted ona solution that would simplify the process withoutputting additional constraints or hardships on itsassemblers. Choosing a proven assembly methodthat provides answers to all of the industry’s strictrequirements, Orscheln installed a unique pick-tolight(Banner Engineering, www.bannerengineering.com)solution.The pick-to-light system gives the operation totalflexibility to control and adjust the pick sequence asrequirements change. With a built-in sensor for ano-touch, simple and fast way to acknowledge thepick, the embedded photoelectric sensor allows thelight to operate without touch.The system’s indicator lights are positioned overthe bins. The sensor is triggered when the operatorreaches into the bin for a part. When it’s removed,the sensor registers the pick. It’s the in/out action ofthe operator that triggers the sensor and acknowl-40 O c t o b e r 2 0 1 1 / <strong>Modern</strong> <strong>Materials</strong> <strong>Handling</strong> mmh.com