Solartron density transducers - Measurement Resources

Solartron density transducers - Measurement Resources

Solartron density transducers - Measurement Resources

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

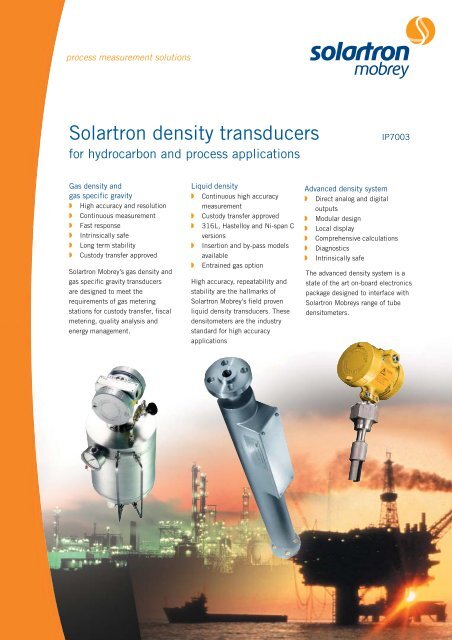

process measurement solutions1234<strong>Solartron</strong> <strong>density</strong> <strong>transducers</strong>for hydrocarbon and process applicationsIP7003Gas <strong>density</strong> andgas specific gravity High accuracy and resolution Continuous measurement Fast response Intrinsically safe Long term stability Custody transfer approved<strong>Solartron</strong> Mobrey’s gas <strong>density</strong> andgas specific gravity <strong>transducers</strong>are designed to meet therequirements of gas meteringstations for custody transfer, fiscalmetering, quality analysis andenergy management.Liquid <strong>density</strong> Continuous high accuracymeasurement Custody transfer approved 316L, Hastelloy and Ni-span Cversions Insertion and by-pass modelsavailable Entrained gas optionHigh accuracy, repeatability andstability are the hallmarks of<strong>Solartron</strong> Mobrey’s field provenliquid <strong>density</strong> <strong>transducers</strong>. Thesedensitometers are the industrystandard for high accuracyapplicationsAdvanced <strong>density</strong> system Direct analog and digitaloutputs Modular design Local display Comprehensive calculations Diagnostics Intrinsically safeThe advanced <strong>density</strong> system is astate of the art on-board electronicspackage designed to interface with<strong>Solartron</strong> Mobreys range of tubedensitometers.

On-line liquid <strong>density</strong> measurement solutions...The <strong>Solartron</strong> Mobrey’s field proven range of densitometers have been designed to meetthe most demanding applications found in modern processing plants. These metershave long been recognised as the industry standard.Where the high accuracy of the 7835 series is not required the 7826/8 InsertionDensitometer provides the ideal solution. This unit can be mounted either in a statictank or in a pipeline.All <strong>Solartron</strong> densitometers are available with a choice of flange and material ofconstruction. This allows them to be used in a broad range of process liquids ensuringthat <strong>Solartron</strong> has the answer to your metering and control requirements.Corrosive ApplicationsFor corrosive applications where AISI316L stainless steel is not suitable, the7846 offers wetted parts in HastelloyC22.Hygienic Applications<strong>Solartron</strong> densitometers are widely used inthe food industry for the monitoring andcontrol of foodstuffs, for example, milkand yogurt. The 3A-authorised, allstainless steel 7847 with special bellowsmake it an ideal solution. Various sanitaryfittings are available for the transducer.Insertion DensitometerThe 7826/8 Insertion Densitometer hasbeen developed for applications requiringliquid <strong>density</strong> measurement in pipelinesor static tanks.The 7826/8 consists of a tuning forkarrangement with the tines mounted froma flange, which in turn supports theelectronics housing. The transducer isavailable in a range of flange options,including a 3A authorised unit. Anintegral 4-20mA version, the 7828 isavailable.Fiscal MeteringThe 7835 is designed for fiscal meteringof crude and refined hydrocarbons andnon-corrosive process liquids. Thistransducer offers the highest accuracywith excellent repeatability under pipelineoperating conditions. The vibratingelement is manufactured from Ni-Span-Cfor excellent long term and temperaturestability.General ProcessSuitable for most general processapplications, the 7845 is manufacturedwith all wetted parts in AISI 316Lstainless steel. typical applications are: Percentage mass, percentagevolume and specific gravity offluids or fluid/fluid fluid/solidmixes. Caustic soda blending.Concentrated product delivered byroad tanker is diluted with waterfor on-sitestorage. Enerygy conservation in whiskydistilling. Used to monitor thealcohol content and shut off heatsource when the value of thealcohol falls near the cost of theenergy consumed. In the sugar industry forcontrolling degress Brix. Interface detection. Blending control.

Principles of operationAll <strong>Solartron</strong> Mobrey liquid <strong>density</strong><strong>transducers</strong> operate on the same generalprinciple and can be likened to that of aspring mass system. As the product<strong>density</strong> changes it in turn changes thevibrating mass, which is then detected bya change n the resonant frequency.When a mass on a spring is displaced andreleased it will oscillate at a naturalfrequency until it comes to a rest due toviscous damping. An oscillation at thenatural frequency may be maintained bysupplying a driving force to overcome theeffects of damping.The resonant frequency can be derived as:Where: K is the stiffness. M is the massof the element (M 1) plus the mass of thefluid (M 2).If K and M 1are all constant then:HenceThe equation is further enhanced by theaddition of a K1 term to improve linearityand therefore the final equation becomes:The transfer standard <strong>transducers</strong> arecalibrated in an in-house United KingdomAccreditation Service (UKAS) approvedlabratory on three fluids. The <strong>density</strong> ofeach calibration liquid is determined bydisplacement methods to an uncertainty of50ppm. A number of meters from eachbatch are overchecked in this laboratory toverify the accuracy of the calibration.The factory calibration datum is 20ºC and 1bar absolute. When operating at otherconditions it is necessary to increase theuncertainty of measurement. The overallaccuracy is the RMS error of the below errorsources. For example at 40ºC and 30 bar,7835 accuracy = +/-0.25 Kg/m 3 , 7845 = +/-1.07Kg/m 3 .Error sources7835Primary standardTransfer standardInstrument accuracy(at calibration conditions)Temperature coefficientPressure effect0.05Kg/m 30.1Kg/m 30.15Kg/m 3+/-0.005Kg/m 3 /ºC+/-0.006Kg/m 3 /bar78450.05Kg/m30.1Kg/m30.35Kg/m3+/-0.05+/-0.006Calibration<strong>Solartron</strong> <strong>transducers</strong> undergo rigorousfactory calibration on three fluids: air, oiland a high <strong>density</strong> fluid (non CFC).Initially the units are pressure tested to1.5 times the operating pressure. Withoil the rig is first varied in temperature todetermine the temperature coefficient ofthe transducer and then varied inpressure to determine the pressurecoefficient.To ensure that the production units areaccurately calibrated to a high integritythe calibration rigs have two integraltransfer standards. The <strong>density</strong> readingsfrom these standards must agree withincertain limits, thus ensuring that the righas stabilised. Once stabilisation isachieved readings of periodic time fromeach of the production units can be takenon oil and the high <strong>density</strong> fluid. Fromthese results and with results from an aircalibration, the final calibration of thetransducer is calculated.

Advanced <strong>density</strong> systemThe Advanced Density System (ADS) is a state of the art electronics package designed tointerface with the <strong>Solartron</strong> Mobrey 7835/45/46/47 range of tube densitometers.Located in the head of the transducer the ADS has been designed as a modular systemwhich allows additional functionality to be added as required. The transducer can beinterfaced DIRECTLY to a DCS, PID controller or other plant processing equipment viathe digital communications link or via the 4-20mA outputs. In the majority of casesthere is no need for additional electronics, since most standard calculations areperformed within the unit thus providing a very cost effective solution.The transducer leaves the factory with all calibration factors and initial configuationstored in EPROM on the meter. This means that from initial power up the transducerprovides an accurate output of line <strong>density</strong> and temperature, without the need forextensive programming. The only additional configuration which may be required is theoptimisation of the outputs to suit the particular application.<strong>Measurement</strong> and calculated dataAll <strong>Solartron</strong> Mobrey liquid <strong>density</strong><strong>transducers</strong> measure two primeparameters, line <strong>density</strong> and temperature.From these two prime measurements theADS can perform a number ofcalculations, for example: Referred <strong>density</strong> (matrix & API) ºAPI % Mass % Volume ºBrix ºBaume Specific gravityOutputsThe base board provides four separateoutputs: Two 4-20mA outputs, which canbe configured to output anymeasured or calculated data. One pulse output which provideseither tube resonant frequency oran alarm status. One RS485 digitalcommunications link normally foruse with the remote display.The RS232/RS485 and the HART boardprovide additional digitalcommunications capabilities. If desiredthe HART board can be used purely as athird 4-20mA output.BaseboardThe baseboard is the heart of the system,utilising a high performance low powermicrocontroller to: Perform the complex calculationspreviously performed in a separateflow computer or signal converter. Store all the transducer’scalibration data, significantlyreducing the level of customerprogramming. Ensure that the transducer isoperating correctly, providingseveral diagnostic facilities for theservice engineer. Facilitate digital communicationswith the remote display or othercomputer systems (e.g. PC, PLC orDCS). Provide two direct analog outputs.The baseboard along with the liquid <strong>density</strong>transducer provides a complete system formeasuring liquid <strong>density</strong> and temperature.However, if outputs need to be configured inthe field or if additional functionality isrequird then a remote display or option boardmay be used.Remote display/keypadThis unit is intended for either hand held orwall mounted use. It provides a convenientmeans for displaying calculated data and forconfiguring or analysing the system setup.The display can be operated up to 100 metersaway from the transducer and communicateswith the baseboard via an RS485 digitalcommunications link. The display is of anintrinsically safe design and can therefore bemounted in the hazardous area.Option boardsThree option boards are available for fitting tothe baseboard: Switch board - Providing a low cost meansof configuring the system, and offers someflexibility on system functionality. HART board - Providing full HARTcommunications and an additional 4-20mA output and full systemsfunctionality. RS232/RS485 board - Providingadditional serial communicationcapabilities and full system functionality.

Gas <strong>density</strong> and SG measurement<strong>Solartron</strong> gas <strong>density</strong> meters have beenserving the hydrocarbon industry incustody transfer of natural gas for overtwo decades. The 7812 gas densitometeris the latest in the range and replacesboth the 7810 an 7811 meters.7812 DensitometerThe <strong>Solartron</strong> 7812 gas <strong>density</strong>transducer is designed to meet therequirements of custody transfer meteringstations by combining high performancewith safety. The sensor is designed forinsertion mounting into the gas flow path,either directly or in a thermowell pocket,but with the gas sample brought to theinstrument via a sample loop. Thisinstrument satisfies the requirements ofon-line <strong>density</strong> measurement as in ISO5167 and AGA 3.The pressure retaining parts of the 7812gas <strong>density</strong> transducer are manufacturedfor NACE compatible materials. Thetransducer is approved by CENELEC foruse in all catagories of hazardous area.3098 Principle of operationThe 3098 consists of a vibrating elementgas <strong>density</strong> transducer surrounded by aconstant volume reference chamberretaining a fixed quantity of gas known asthe reference gas.The reference gas pressure acts through aseparator diaphragm on the pressurecontrol valve chamber so that the gaspressure on both sides of the diaphragmis equal. Temperature equalisation isachieved by temperature stabiliser coilsand a thermal insulation cover.The basic theoryThe specific gravity (G) of a gas is theration of its molecular weight (M) to thatof standard air. However, under settemperature (T) and pressure (P)conditions, with the super-compressibilityfactors (Z) taken into consideration,specific gravity and relaive <strong>density</strong> aresynonymous. The <strong>density</strong> of the samplegas (p) by definition is:Principle of operationThe transducer sensing element consistsof a thin-walled metal cylinder, resonatingat its natural frequency. The gas flowsover both surfaces of the cylinder and themass of gas in contact with the cylinderdepends on the gas <strong>density</strong>. Sinceincreasing the mass decreases the naturalfrequency of vibration, the gas <strong>density</strong>can be determined by measuring theresonant frequency.And since a fixed quantity of referencegas is contained in a constant volume,then:Under equalised pressure andtemperature:3098 Specific gravity transducerThe <strong>Solartron</strong> 3098 Gas Specific Gravitytransducer provides a direct on-linemeasurement of gas specific gravity ornormal <strong>density</strong> for custody transfer,standard volume flow determination,quality analysis and energy management.The 3098 is most frequently applied inderiving standard volume and energy flowmeasurements of natural gas, where theexceptional accuracy and repeatability areof direct benfit.Thus the output signal from the <strong>density</strong>transducer is a measurement of themolecular weight or specific gravity of thesample gas.

Technical specificationLiquid Density78267835784578467847Wetted parts materialDensity accuracyDensity repeatabilityDensity rangeCalibrated <strong>density</strong> rangeOperating pressure (max)Pressure coefficientTemperature rangeDensity temp. coefficientSafety approvalPower supplySS 316L NiSpan CHastelloy C220.001 g/cc 0.00015* g/cc0.0001 g/cc 0.00002 g/cc0-3 g/cc 0-3 g/cc0.3-1.1 g/cc 0.3-1.1 g/cc207 bar 150 bar(3000 psi) (2175 psi)negligible-50ºC to 160ºC(-58ºF to 320ºF)+/- 0.0001 g/cc/ºC +/- 0.000005g/cc/ºCEExd IICT4. CSA24-27VDC, 50mASS 316L0.00035* g/cc0.0001 g/cc0-3 g/cc0.6-1.6 g/cc100 bar(1450)psiHastelloy C220.00035* g/cc0.0001 g/cc0-3 g/cc0.6-1.6 g/cc50 bar(725 psi)* 0.0001 available with additional calibrationSS 316L0.00035* g/cc0.0001 g/cc0-3 g/cc0.6-1.6 g/cc20bar(290 psi)+/- 0.000006 g/cc/bar-50ºC to +110ºC (-58ºF to +230ºF)-50ºC to +160ºC (-58ºF to +320ºF) high temp kit+/- 0.00005 g/cc/ºCEEx ia IIC T6, CSA16 to 28 VDC at 25mA maxLiquid DensityTransducer performanceAnalog outputsNumberAccuracyRepeatabilityOut of range capabilityPulse outputCommunication optionsConfiguration optionsCalculationsSafety approvalEMC approvalAdvanced Density SystemAs above2 (+1 with HART option board+/- 0.1% of reading plus 0.05% of full scale+/- 0.025%2-22mA on 4-20mA (programmable alarm scale)Open collector output, alarm status or frequencyHART, RS232, RS422, RS485, ModbusRemote display/keyboard, switchboard, via communications protocolLine <strong>density</strong>, line temperature, Base <strong>density</strong>, ºAPI, ºBrix, ºBaume, % solids, % mass,% volume, specific gravityEEx ia IIC T4. Class 1, Division 1, Groups B, C, DEmissions: BS EN 50081-2: 1994 Heavy industrial environmentImmunity: BS EN 50082-2: 1995 Heavy industrial environmentGas Density/Specific Gravity78123098Density accuracyDensity repeatabilityDensity rangeSpecific gravity rangeOperating pressure (max)Temperature rangeProcess connection+/- 0.1% reading (Nitrogen)+/- 0.15% reading (Natural Gas)+/- 0.01% reading0-0.4 g/ccN/A250 bar (2625 psi)-20ºC to +85ºC (-4ºF to +185ºF)1/4” NPT (API) female+/- 0.1%+/- 0.02%N/AunlimitedRegulator used to set input pressure-30ºC to +50ºC (-22ºF to +122ºF)1/4” compression fitting (6mm) pipe

Signal ConvertersThe 795x Series of Signal Converters are designedas easy-to-use units which will process signalsfrom <strong>Solartron</strong> <strong>density</strong> or viscosity <strong>transducers</strong>along with live inputs of temperature and pressure.Calculations within the converter includetransducer correction and calculation of line orreffered <strong>density</strong> and viscosity, ºAPI, ºBaume,calorific value, Wobbe Index etc.Model 7950 7951 OptionMounting: Wall PanelInputs Density: 1 1Temperature (PRT 4-wire): 4 4Analogue (0/4-20mA): 4 4 +4/+6Digital/status: 8 8 or 18Outputs Analogue (0/4-20mA): 4 4 +4Digital/status: 8 8 or 16Comms. RS232/RS485: 3 3 +2 HARTCalculations Line and Base <strong>density</strong> (API or Matrix referral)Derived parameters (%volume, %mass, ºBrix, ºAPI, S.G., S.S.U.)Full details of all these products are contained in the brochures listed below:Product7835 Adanced Densitometer7845/46/47 Advanced DensitometerEntrained Gas Densitometer7826 DensitometerGas Density and Gas Specific Products795x Series Flow Computers for Gas Applications795x Series Flow Computers for Oil Applications795x Signal ConvertersBrochure No:B1026B1024B1018B1019B1253B1248B1249B1251

<strong>Solartron</strong> Mobrey has a worldwide network of distributors in 66 countries:Abu DhabiArgentinaAustraliaAustriaBahrainBelgiumBoliviaBrazilCanadaChileChinaColombiaCroatiaCyprusCzechDenmarkDubaiEgyptFinlandFranceGermanyGhanaGreeceHollandHong KongHungaryIcelandIndiaIndonesiaIranIrelandItalyJapanJordanKenyaKoreaKuwaitMalawiMalaysiaMauritiusMexicoMoroccoMyanmarNew ZealandNigeriaNorwayOmanPakistanPeruPhilippinesPolandPortugalQatarRussiaSaudi ArabiaSingaporeSouth AfricaSpainSwedenSwitzerlandTaiwanThailandTurkeyUAEUSAVenezuelaWest IndiesZimbabwe1234<strong>Solartron</strong> Mobrey Limited158 Edinburgh Avenue Slough Berks UK SL1 4UETel: 01753 756600 Fax: 01753 823589e-mail: sales@solartron.com www.solartronmobrey.coma Roxboro Group CompanyBestobell Mobrey GmbH Deutschland tel: 0211/99 808-0<strong>Solartron</strong> Mobrey Ltd China tel: 021 6353 5652Mobrey sp z o o Polska tel: 022 871 7865<strong>Solartron</strong> Mobrey AB Sverige tel: 08-725 01 00Mobrey SA France tel: 01.34.30.28.30Mobrey SA-NV Belgium tel: 02/465 3879<strong>Solartron</strong> Mobrey USA tel: (281) 398 7890The right is reserved to amend detailsgiven in this publication without noticeIP7003Jan 2002